Parker's park brake valves are designed for long, reliable service life while holding the aircraft stationary in the closed (locked) position. Valve models range from fairly simple devices to more complex models with additional features.

Parker’s reservoir type master cylinders are designed for long, reliable service life and feature a reservoir integrated into the housing. This eliminates the need for a separate, remotely mounted reservoir.

The Parker Aerospace automatic bleed valve provides automatic detection and bleeding of air in a closed-hydraulic system without input from maintenance personnel. The device may be controlled directly through the aircraft's computing system.

Highly engineered valve installed within fluid conveyance systems to prevent the loss of reservoir fluid in the event of loss of system pressure.

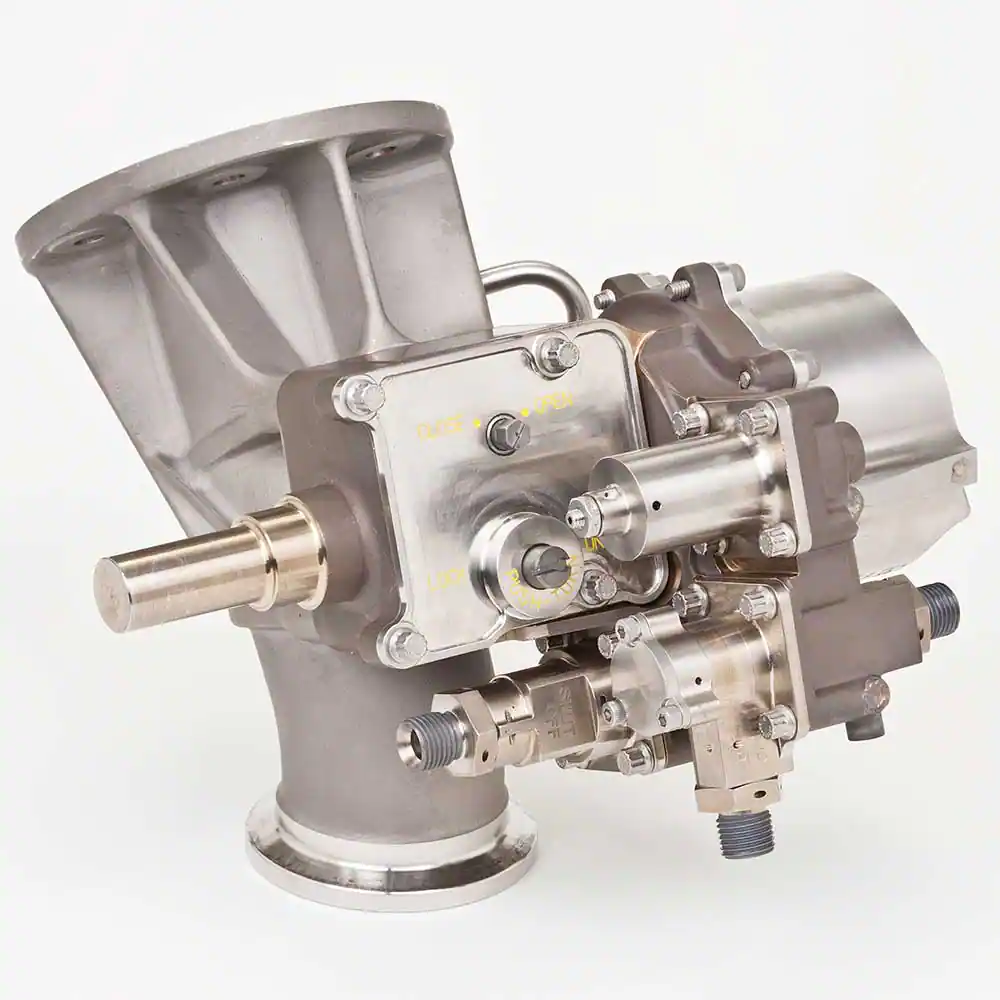

Parker's dual flow shutoff valve (DFSOV) is used on the inert gas generation system of an aircraft to control the nitrogen enriched air (NEA) flow to the fuel tanks.

Proven lifesavers, Stratoflex’s breakaway valves separate under high loads on fluid lines exceeding a

predetermined value. Upon separation, the valves automatically seal the fluids in the lines to effectively

prevent spills.

Parker’s push-type master cylinders utilize hardened steel rods, aluminum housings, and pistons that have low seal friction, which means they are designed for long, reliable service life.

Master cylinders are located in the cockpit on each of the pilot’s rudder pedals, using pressure to actuate the brakes on an aircraft. Parker’s pull-type master cylinders have been designed for long, reliable service life.

The wing tank is divided into a number of semi-sealed compartments that allow easy fuel migration inboard while minimizing fuel migration outboard. The compartments contain check valves that are the boundaries between compartments.

The fuel swing check valve is an inline, swing flapper check valve that has many uses; one of which is to prevent reverse fuel flow from the ejector pumps to the engine feed subsystem.

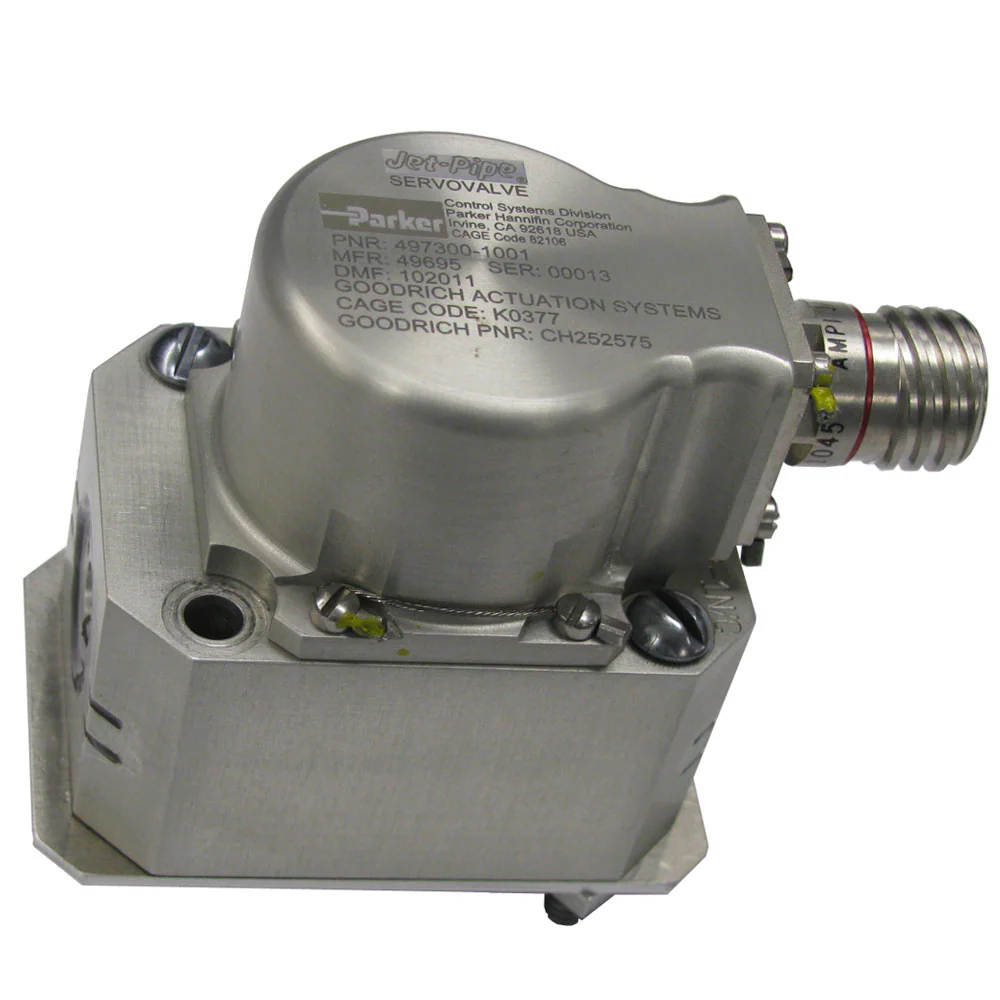

A series of three- or four-way electrohydraulic servovalves (EHSVs) that drive actuators or motors in closed-loop servosystems used to control position, velocity, and force in hydraulic systems, fuel systems, and engine control applications.

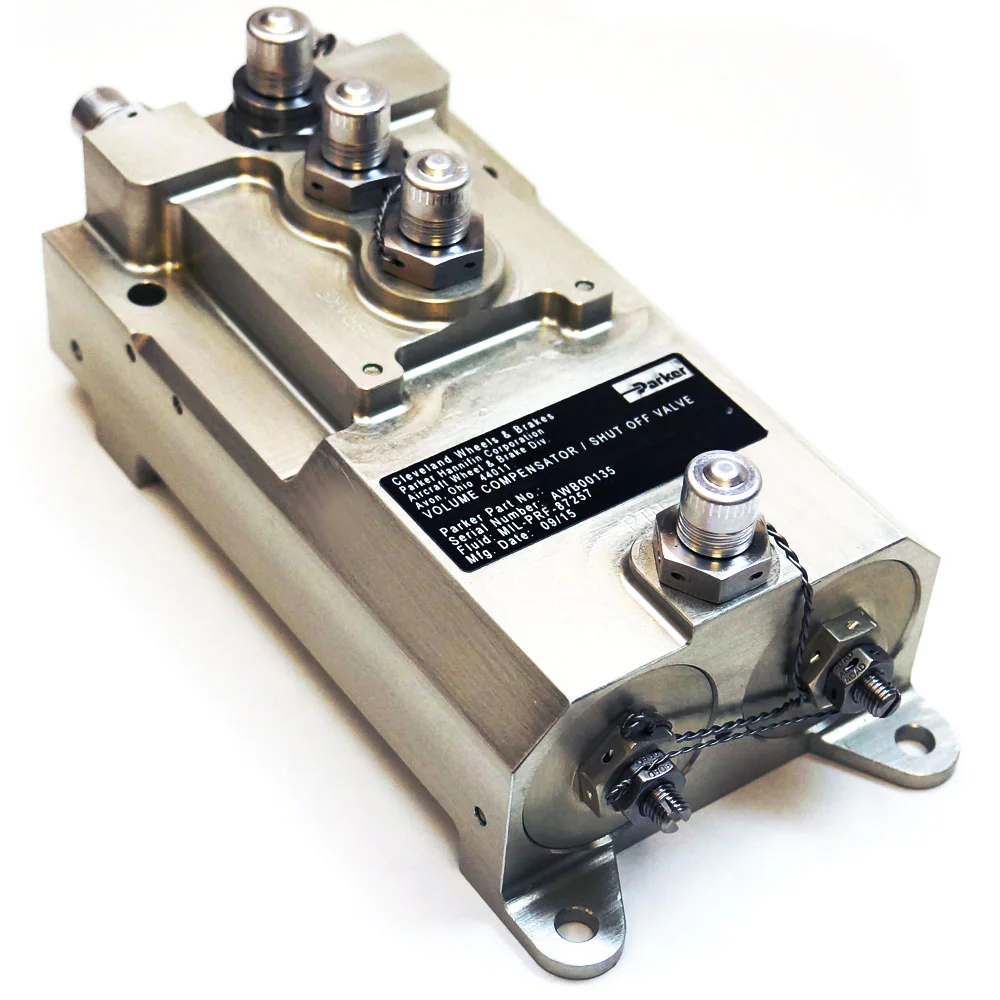

Parker Aerospace's shutoff valve/volume compensator is a multi-function hydraulic valve. Its main purpose is to increase aircraft efficiency and provide pedal feedback to the pilot.

The motor-operated fuel shutoff valve is spar-mounted and is driven by a 28 VDC brush-type motor actuator to open and close when electrically commanded.

When the aircraft is connected to a ground refueling source, the fuel management system commands the refuel shutoff valve to close when the selected fuel quantity is reached in conjunction with the refuel control solenoid or pilot-operated float valve.

Parker Aerospace anti-ice pressure regulating shut-off valve controls the application of HP3 air to the downstream anti-ice pressure relief valve to maintain the engine intake (nacelle) free from ice under fault-free operation.

Incorporates a number of solenoid valves (two to six) that are used to control pneumatic valves. The solenoid bank is designed to be located in zone two of the engine. The solenoid valves are connected, via servo pipes, to individual pneumatic valves.

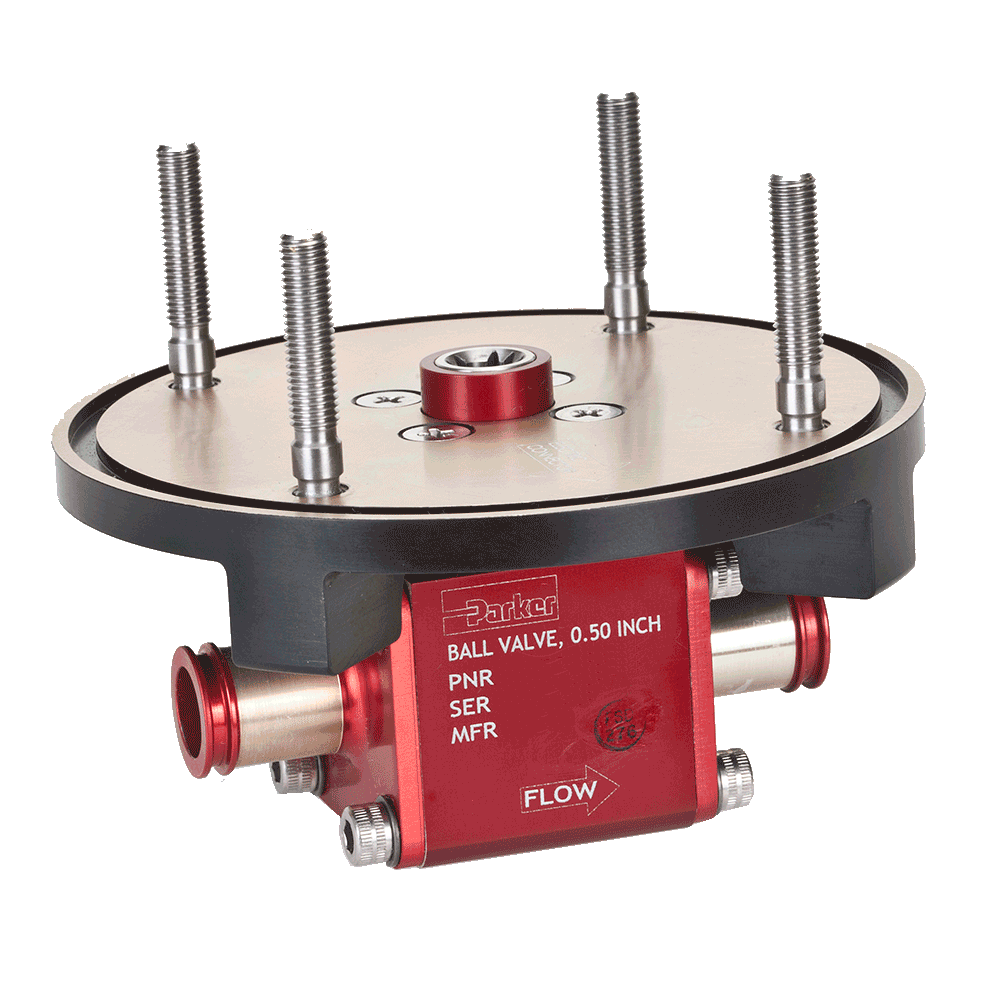

Engine feed shutoff valves are ball valves operated by 28 vdc motor actuators. Each valve is installed in an engine feed fuel line to prevent fuel from flowing into wing fire zones during an engine shutdown.

Precision check and relief valves are designed by Parker Stratoflex to provide high reliability, small envelope size and low pressure drop performance while meeting challenging application requirements in aerospace engine and hydraulic fluid systems.

The potable water fill valves and lavatory rinse/fill valves provide a durable and reliable interface for connecting to ground service carts. Each interface is sized to only connect to the correct service hose.

The shimmy damper is a hydraulic fluid-filled cylinder that prevents rapid movement of the nose or main landing gear without interfering with slower operations.

Vent valves are often installed to close the vent lines when fuel is present. As fuel rises in the tank, the float swings up due to buoyancy forces until the poppet mates against the housing.

A transient bleed valve (TBV) is used to expand the stall margin of a turbine engine’s compressor by controlling the outlet of bleed air from the engine’s compressor.

The Parker heater valve provides a small heating circuit flow to remote areas of a hydraulic system when the system temperature in that area drops below the desired temperature, while ensuring devices in the system receive flow priority.

The retract cylinders can be either on the nose or main gear of the aircraft. They are used to retract the landing gear of the aircraft during flight to reduce parasitic drag losses, which increases aircraft efficiency.

The climb and dive valve controls tank-to-ambient and ambient-to-tank pressure differentials during ground and flight operations. When an aircraft climbs, ambient air pressure decreases; during aircraft descent, ambient pressure increases.

Handling bleed valves (HBVs) control the outlet of bleed air from the engine and into other aircraft systems. They are primarily used for engine starting, transient bleed, and surge control.

The turbine clearance control valve (TCCV) modulates the flow of cooling air into turbine tip clearance control systems in gas turbine engines.

The auxiliary power unit (APU) feed shutoff valve is a ball valve operated by a 28 VDC motor actuator. The valve is installed in the APU feed fuel line to prevent fuel from flowing into the APU compartment during an APU shutdown.

Refuel control solenoid valves are installed in the pilot lines between the refuel-shutoff valves and the fuel tanks. When powered open, they enable the refuel-shutoff valves to open for fueling. When closed, their refuel valves close also.

Parker Aerospace filter bypass valve provides emergency flow of lubricating oil to turbine engines when the filter is clogged or missing.

Pressure-regulating valve is a control valve that reduces the input pressure of a fluid to a required value at its output. Alternatively, it is a valve that works in a way that at a certain pressure, it automatically stops the flow of a liquid.

A pressurization valve is a control valve used to limit or control pressure of a fluid in a system to a required output value.

Multifunction valves for oil service allow for gravity fill, remote fill, and even remote automatic overfill.

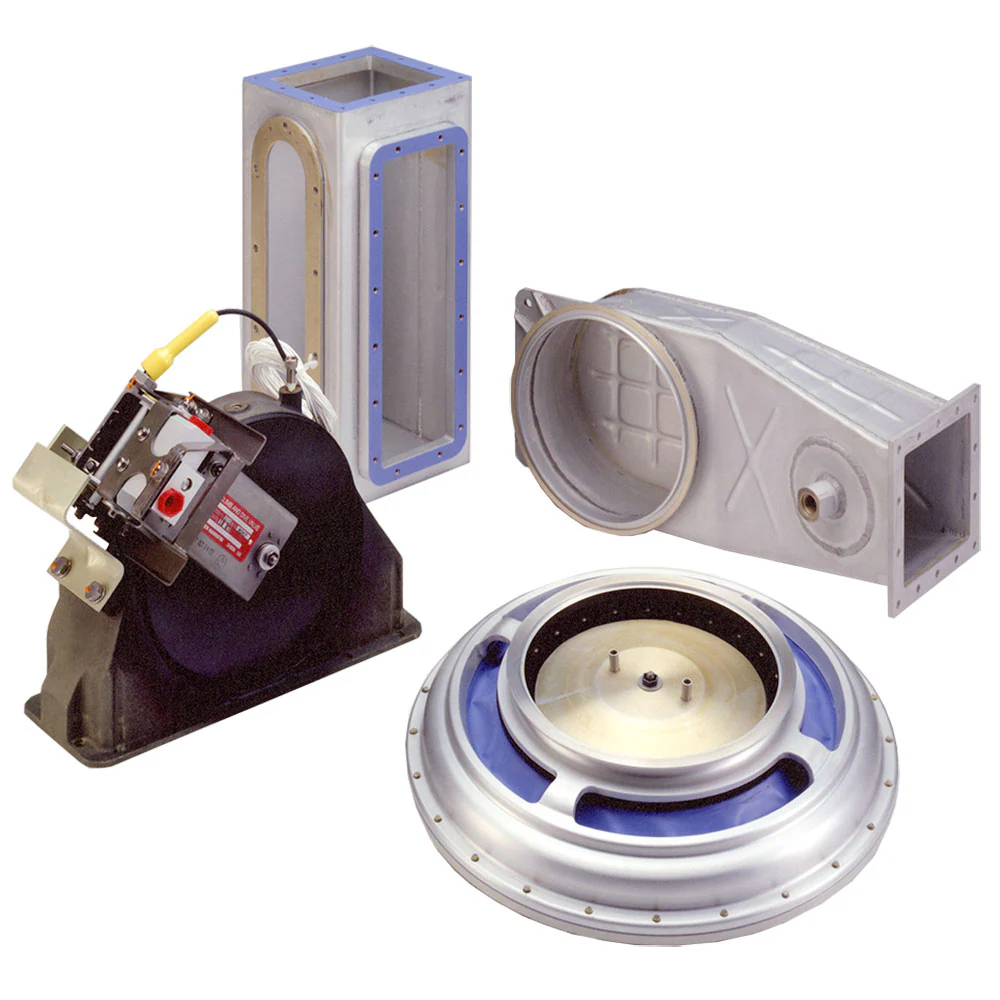

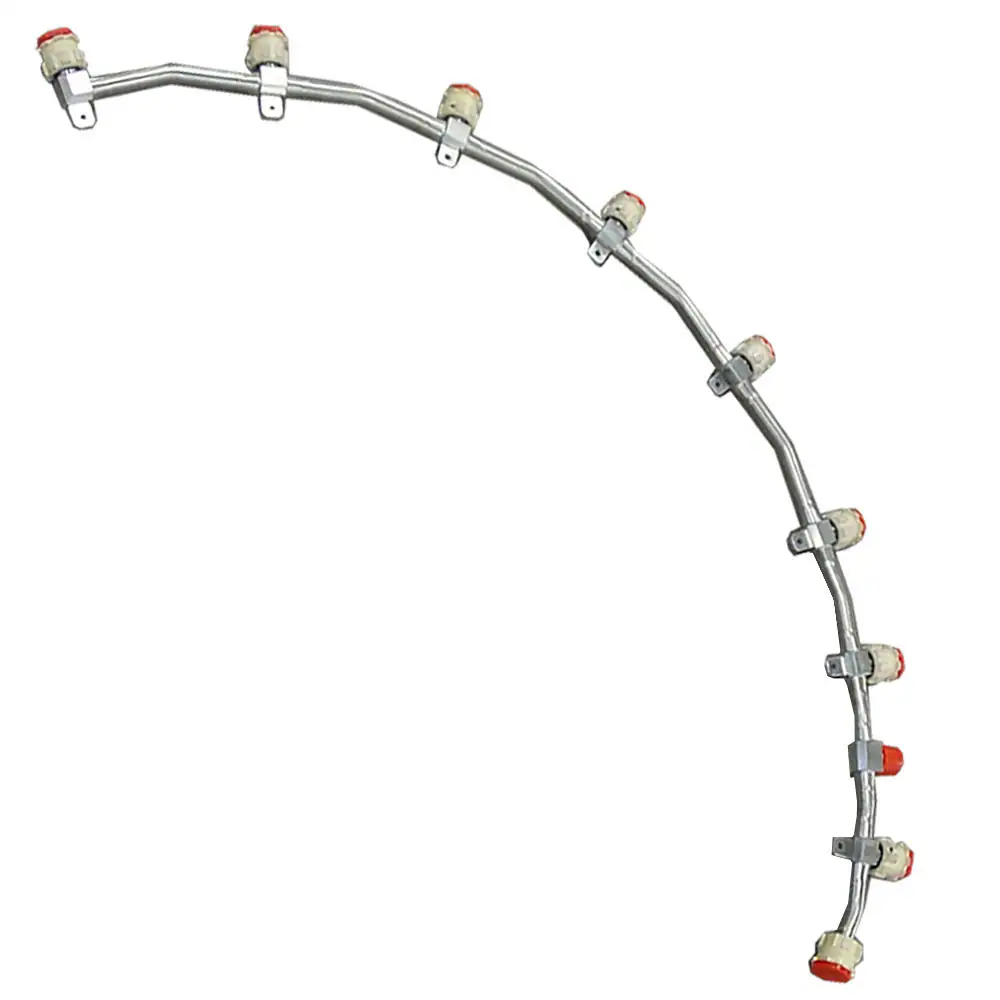

Parker Aerospace fuel manifolds provide fuel distribution to multiple injectors (nozzles) on gas turbine engines and can offer single or multiple circuits for staged flows.

Parker Aerospace anti-draindown valves prevent the draining of lubricating oil from the tank or reservoir through lubrication system components (like pumps) into the gearbox.