Buffer seals are primary seals in tandem sealing configurations. Designed to withstand pressure peaks from the system, Parker hydraulic buffer seals employ an unsymmetrical cross-section design and are often combined with anti-extrusion rings to prevent gap extrusion. State-of-the-art designs include a pressure-relief functionality from the low pressure side, addressing concerns related to drag-oil pressure trapped between the tandem elements. Our comprehensive selection of premium buffer seals are designed for use with hydraulic cylinders, providing excellent wear resistance, and high pressure capabilities. Parker buffer seals combine advanced polymer materials, such as PTFE or TPU with sophisticated product design.

Rod sealing set for hydraulic cylinders, single-acting, PTFE slipper seal design. Low friction. For high-pressure applications. ISO 7425.

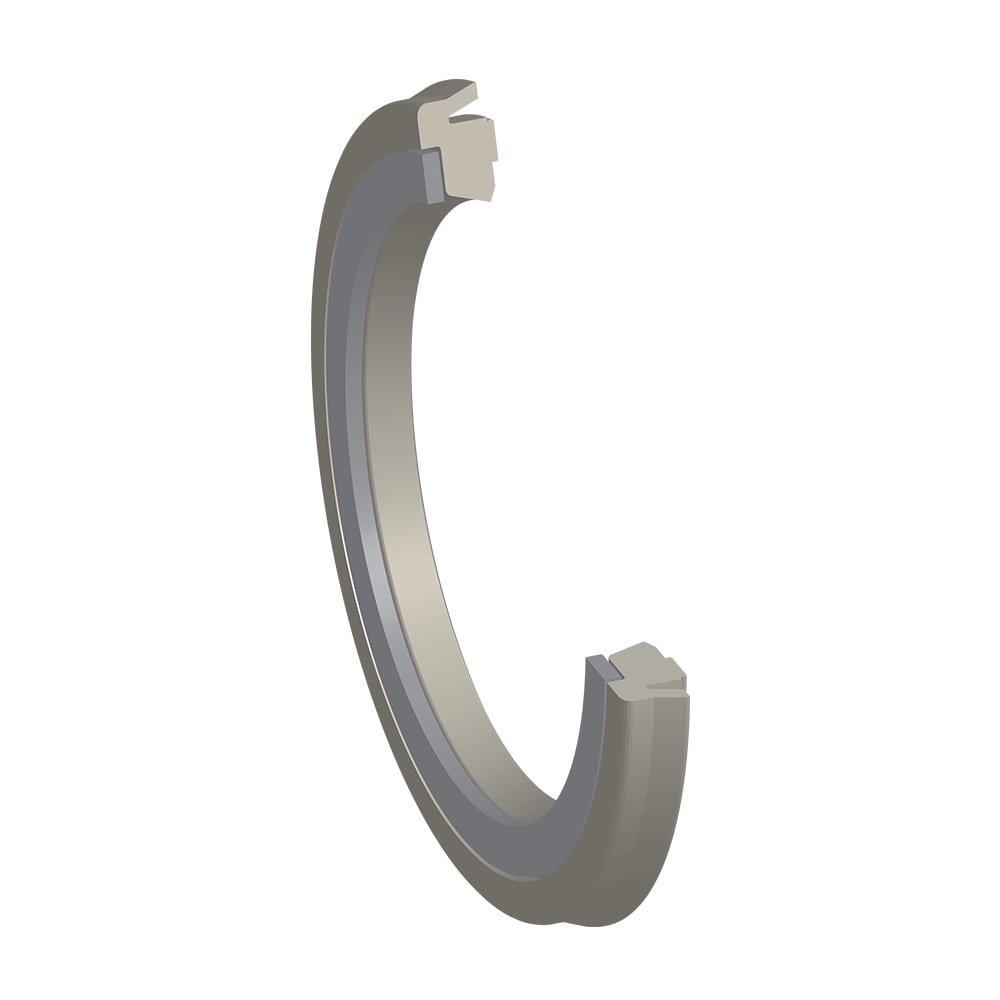

Rod and buffer seal for hydraulic cylinders, single-acting. Compact seal design with anti-extrusion ring. Primary seal in tandem systems. For high pressures and extreme pressure peaks. Robust design with extreme wear resistance. ISO 5597 and ISO 7425.

BR Profile rod buffer seal used in conjunction with primary rod seals for optimal performance to withstand high pressure and system pressure spikes in hydraulic cylinder and actuator applications. Robust Resilon® polyurethane for extreme wear resistance

Rod sealing set for hydraulic cylinders, single-acting, PTFE slipper seal design. Low friction. For high-pressure applications. ISO 7425.

Rod buffer seal,polyurethane,housing meet ISO7425/II