The primary reason for using a compressed air filter is to remove contamination and improve air quality. Parker’s design philosophy of air quality, energy efficiency has led to products that provide highest air quality, lowest power consumption, lowest operational differential pressure, lowest CO2 emissions and lowest total cost of ownership. Since the introduction of the first Parker OIL-X range, Parker has continued to develop both the compressed air filter and the standards governing compressed air quality.

High efficiency coalescing and dry particulate filters with very low pressure drop providing excellent energy savings.

Compact, modular construction oil vapour removal filters designed to reduce oil vapour when industrial applications require compressed air to meet ISO8573-1 Class 0 or Class 1.

Activated carbon filters for the reduction of oil vapour and hydrocarbon odours, providing a maximum remaining oil content of <0.003mg/m³ (<0.003ppm) @ 21°C (70°F).

High pressure filters for compressed air applications up to 350 bar g with optimized flow rates and improved housing design for high energy efficiency, maximum reliability and safe operation.

High pressure filters for compressed air applications up to 100 bar g with optimized flow rates and improved housing design for high energy efficiency, maximum reliability and safe operation.

Parker’s Finite J-Series filters are designed to filter contaminants such as rust, pipe scale, compressor lube oil, and water from compressed gases. These filters are often used in high pressure Compressed Natural Gas (CNG) systems.

Parker’s special UNI-CAST formed elements and our deep bed pleated elements provide lower pressure drop and less frequent changeouts, saving time and money.

High efficiency compressed air filters for industrial applications requiring pressures of up to 50 barg.

High efficiency compressed air filters for applications requiring large flow rates up to 31248 m³/hr @ 7 bar g with a maximum operating pressure of 16 bar g.

Parker Balston 2000 series compressed air and gas filters remove contaminants at an efficiency of up to 99.99% for 0.01 micron particles and droplets.

Parker Balston 6000 series stainless steel compressed air filters remove 99.99% of 0.01 micron particles and droplets

Parker Balston sterile air filters for the food industry remove all viable organisms from compressed air and other gases at an efficiency of 99.9999+% for 0.01 micron sized particles.

Balston high pressure compressed air filters offer exceptionally high efficiency coalescing filtration of compressed air at high flow rates. The housings are ASME Code stamped to 665 psig. 15 Parts

Natural Gas Filters 6 IN to 10 IN Line Size Parker Balston High Flow Rate Natural Gas Filters offer high efficiency coalescing filtration and are specifically designed to remove suspended liquids and dirt from pipeline natural gas.

Parker Balston higher flow rate ASME code stamped compressed air filters offer high efficiency coalescing filtration at very high flow rates.

Parker Balston SA filters are rated at 99.9999+% efficiency for 0.01 micron particles.

Parker Balston disposable filter units offer all the advantages of microfiber filter cartridges for high efficiency liquid and gas filtration combined with the economics and convenience of complete disposability.

Activated carbon adsorbers for the removal of oil vapour in industrial compressed applications. Available for volume flows up to 86 m³/h @ 7 barg (50.62 cfm @ 102 psig).

Activated carbon adsorbers for the removal of oil vapour in industrial compressed air applications. Available for volume flows up to 940 m³/h @ 7 barg (553 cfm @ 102 psig).

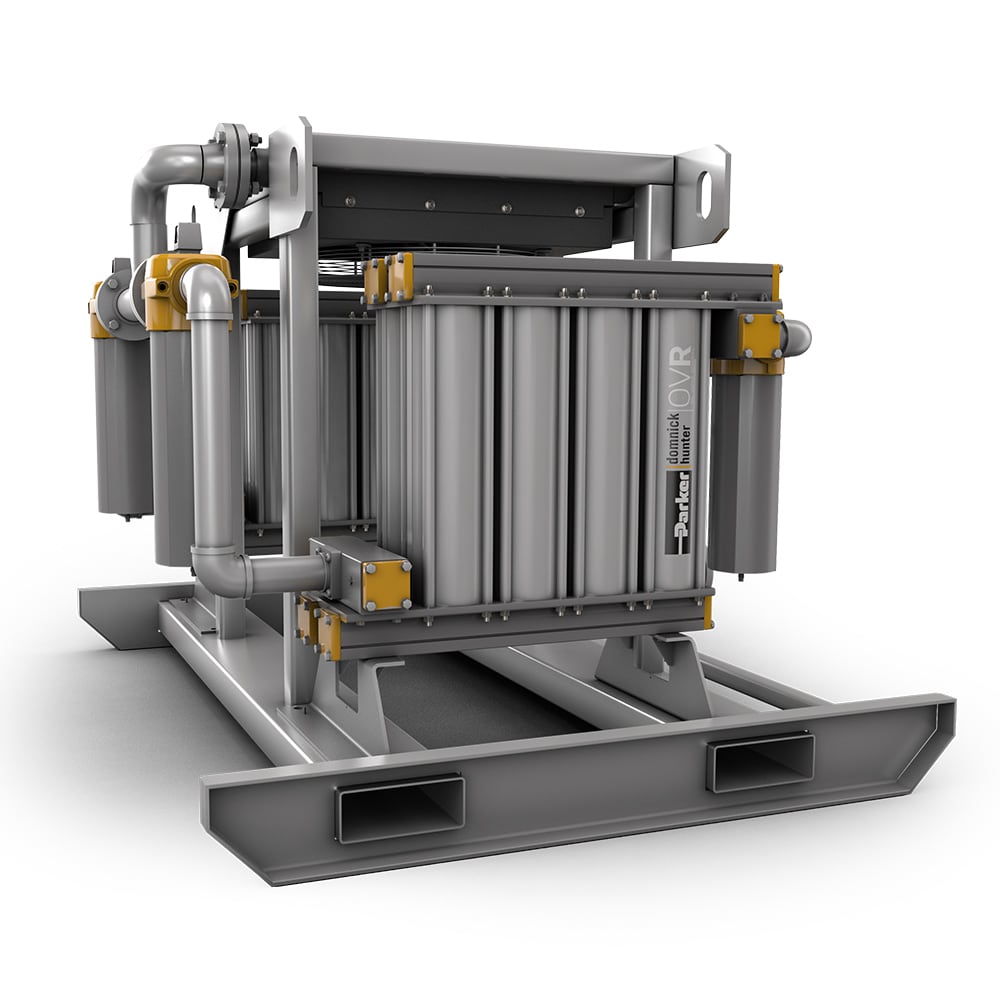

Activated carbon adsorbers for volume flows up to 6100 m³/h for industrial compressed air treatment applications

Parker's 02F miniature coalescing, disposable, inline filter is designed to remove liquid aerosols, water, oil and submicron particulate matter from your pneumatic system. These filters will provide oil free air for several demanding applications.

Parker's 10F is a miniature coalescing filter that is designed to remove liquid aerosols, water, oil and submicron particulate matter from your pneumatic system. These filters will provide oil free air for several demanding applications.

Prep-Air II Particulate/Coalescing Filters are designed to remove water, oil aerosols and particulate matter from your pneumatic system. These filters are generally used in industrial applications where water, oil, and harmful dirt must be removed.

Parker's 35F/43F heavy duty high flow coalescing filters are designed to remove liquid aerosols, water, oil and submicron particulate matter from your pneumatic system. These filters will provide oil free air for several demanding applications.

Parker's F701 is a high flow coalescing filter that is designed to remove liquid aerosols, water, oil and submicron particulate matter from your pneumatic system. These filters will provide oil free air for several demanding applications.

Parker's P3NF is a high flow coalescing filter that is designed to remove liquid aerosols, water, oil and submicron particulate matter from your pneumatic system. These filters will provide oil free air for several demanding applications.

The P3Y filters are specially designed to efficiently filter out rust, dirt, moisture and other impurities from compressed air lines. P3Y filters are available globally and designed to fit port sizes ¾” & 1”.

Parker's PF11 is a stainless steel coalescing filter that is designed to remove liquid aerosols, water, oil and submicron particulate matter from your pneumatic system. These filters will provide oil free air for several demanding applications.

Parker’s Finite filter vessels eliminate oil, water, and particulate contamination from large flows of compressed air and gas.

Parker’s Finite filter vessels eliminate oil, water, and particulate contamination from large flows of compressed air and gas.

The P3NF is used for the removal of solid particle contaminants down to 40 micron and the separation of bulk liquids. This type of filter is generally used in industrial applications where liquid water, oil, and harmful dirt particles must be removed.

The PF10 is used for the removal of solid particle contaminants down to 5 micron and the separation of bulk liquids. This type of filter is generally used in industrial applications where liquid water, oil, and harmful dirt particles must be removed.

The PF504 is used for the removal of solid particle contaminants down to 5 micron and the separation of bulk liquids. This type of filter is generally used in industrial applications where liquid water, oil, and harmful dirt particles must be removed.

The 35F/43F is used for the removal of solid particle contaminants down to 5 micron and the separation of bulk liquids. This type of filter is generally used in industrial applications where liquid water, oil, and harmful dirt particles must be removed.

The F602 is used for the removal of solid particle contaminants down to 5 micron and the separation of bulk liquids. This type of filter is generally used in industrial applications where liquid water, oil, and harmful dirt particles must be removed.

Parker's Global FRL Filters are designed to remove particulates, liquid aerosols, water, oil, submicron particulate matter or taste and odors from your pneumatic system. These filters are used in industrial applications where particles must be removed.

Parker's 02F is a miniature aluminum inline filter used to remove solid particle contaminants down to 5 micron and for the separation of bulk liquids.

Parker's Global FRL Filters are designed to remove particulates, liquid aerosols, water, oil, submicron particulate matter or taste and odors from your pneumatic system. These filters are used in industrial applications where particles must be removed.

P3XF is a 62mm lightweight coalescing/adsorber filter, 1/2" & 3/4" BSPP (NPT 1/2" only), 0.01µ with DPI, 1µ, activated carbon element, high tech polymer bowl with combi manual/semi-auto or auto drain. Max P1 pressure of 16 bar. Temp from -40° to 60°C

P3XF is a 62mm lightweight particulate filter, 1/2" & 3/4" BSPP (NPT 1/2" only), 5µ & 40µ element, high tech polymer bowl with combi manual/semi-auto or auto drain. Max P1 pressure of 16 bar. Temp from (combined drain) -40°C to 60°C.

The P3Y filters are specially designed to efficiently filter out rust, dirt, moisture and other impurities from compressed air lines. P3Y filters are available globally and designed to fit port sizes ¾” & 1”.

Parker's 14F is a miniature particulate filter that delivers high moisture removal in a compact package. This type of filter is generally used in industrial applications where liquid water, oil, and harmful dirt particles must be removed.

PF504 is a 40mm S/Steel (316) particulate filter, 1/4" ported BSPP/NPT, 5µ & 20µ element, metal bowl without sight gauge and manual/auto drain. Max P1 pressure 20.7 bar (manual drain). Temp from -18°C to 82°C.

PF10 is a 60mm S/Steel (316) particulate filter, 1/2" ported BSPP/NPT, 5µ & 40µ element, metal bowl without sight gauge and manual/auto drain. Max P1 pressure 20.7 bar (manual drain). Temp from -18°C to 82°C. 2 Parts

PF501 is a 40mm S/Steel (316) coalescing filter, 1/4" ported BSPP/NPT, 0.3µ element, metal bowl without sight gauge and manual/auto drain. Max P1 pressure 20.7 bar (manual drain). Temp from -18°C to 82°C.

PF11 is a 60mm S/Steel (316) coalescing filter, 1/2" ported BSPP/NPT, 0.01µ element, metal bowl without sight gauge and manual/auto drain. Max P1 pressure 20.7 bar (manual drain). Temp from -18°C to 82°C.

Parker’s Finite filters make it possible to improve process efficiency and provide optimal process protection.

Finite's High Pressure Stainless Steel SJ Series Compressed Air and Gas Coalescing Filters are designed for the extremely demanding environments including off shore applications, food processing, chemical plants, refineries, and general industrial uses.

Parker domnick hunter developed the SCE-HB Series with an absolute retention rate of 0.01 micron in gas and compressed air. With the help of pleated depth media, the flow rate may be increased several times while maintaining a low differential pressure.

High Pressure activated carbon adsorbers for volume flows up to 1180 m³/h and 50 bar for industrial compressed air treatment applications

Compressed air filters providing guaranteed silicone-free compressed air for paint applications in the automotive industry.

High efficiency compressed air filters for applications requiring very low flow rates, up to 11 m³/hr @ 7 bar g, with a maximum operating pressure of 10.5 bar g.

Accessories including incident monitors, fixing clamps, mounting bracket kits, tie rod kits, replacement drains and O ring kits.

Assorted accessories and service spares for OIL-Xplus Series filters, ported and flanged.

Die cast aluminium coalescing, dry particulate and oil vapour removal compressed air filters.

Compressed air filter for general industrial standard. Available in a range of sizes to match the most commonly encountered compressor free air deliveries.

Finite HX 3-Stage Filters for Food Contact Applications. Finite 3 Stage Aluminum Filters deliver up to 99.9999+% efficiency at 0.01 microns. Finished with a durable powder coating that will hold up to the most demanding non-washdown applications.

Finite SN 3-Stage Filters for Food Contact Applications. Finite 3 Stage Stainless Steel Filters deliver up to 99.9999+% efficiency at 0.01 microns. These filters will hold up to the most demanding washdown applications.

12 month service kits for AK, AKM and AKN activated carbon adsorbers.

Highly engineered portable oil vapor removal systems, ideal for rental applications, that deliver "technically oil free" compressed air when installed downstream of proper compressed air filtration and dehumidification equipment.

Parker Balston gas and liquid sample filters protect sensitive analyzers from sample impurities.

The QUBE system unit offers flexible and extensive configurability by enabling the combination of various components and attachments, making it easy to create tailored tuning and pressure control units.