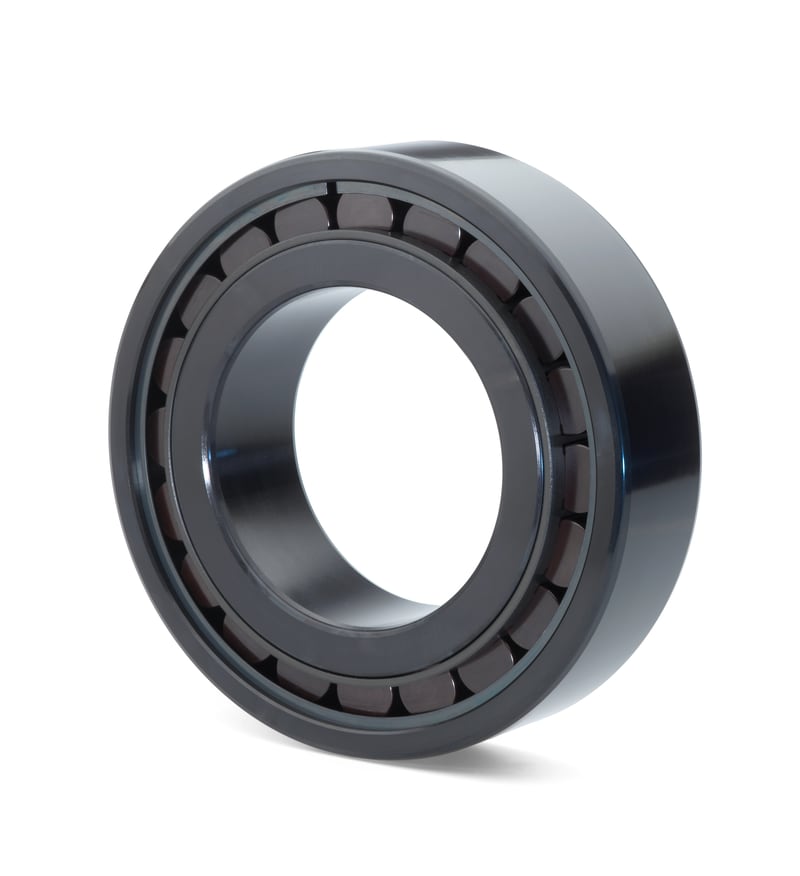

Available in many designs, series and sizes, with a higher axial load carrying capacity and a high speed capability, the major differences between these bearings is cage design and material, and configuration of inner and outer ring flanges.

As they are not equipped with a cage, these bearings incorporate a maximum number of rollers and are therefore suitable for very heavy radial loads and have an increased radial stiffness.

With the high load carrying capacity of full complement bearings and high speed capability of bearings with a cage, these bearings are designed for applications such as industrial and wind turbine gearboxes, and mining equipment.

Also without a cage, the second row of rollers means the design of these bearings can incorporate the maximum number of rollers, making them suitable for very heavy radial loads and increased radial stiffness.

Because of their second row of rollers, these bearings are suitable for heavy radial loads, along with a higher axial load carrying capacity and a high speed capability.

Primarily intended for difficult-to-access bearing arrangements or for cranked shafts, use split bearings where maintenance or replacement of non-split bearings will be time-consuming and cause long and expensive machine downtime.

With a cylindrical or tapered bore, and open or sealed design, these bearings can accommodate very heavy radial loads because of the high number of rollers and are well suited for rolling mill applications with high rolling speeds.