Parker hydraulic rotary actuators are compact units which can generate very high torque in small spaces using hydraulic pressure. These high efficiency actuators and parts can be controlled precisely and easily. Our hydraulic rotary actuators and parts are proven successful, with a well-sealed housing that can withstand high operating pressures even under the harshest conditions.

It is a swing type hydraulic actuator 35RP2 series that rotates by a rack and pinion. There are 5 types of cylinder bore size from φ32 to φ80, and 3 types of mounting styles.

Vane type rotary actuator 70RV series with a rated pressure of 7MPa. High efficiency and high output can be obtained. Furthermore, a tapered roller bearing is used for the vane shaft and bearing with sufficient rigidity.

The Helac L10 Series is the smallest and most compact helical rotary actuator. Ideal for applications where space is a premium, the ultra-compact L10 Series features extremely high thrust capacity and high shock resistance with 180° or 360° rotation.

The Helac T Series Helical Hydraulic Rotary Actuator is ideal for applications where torque generation and higher cycle rates are the primary requirements, featuring splined output shafts with 200-220 degrees of rotation.

The Helac L20 Series is a cost-effective helical hydraulic rotary actuator, easily designed into a wide range of applications. Helac’s hydraulic rotary actuators feature extremely high thrust capacity and high shock resistance with 180° rotation.

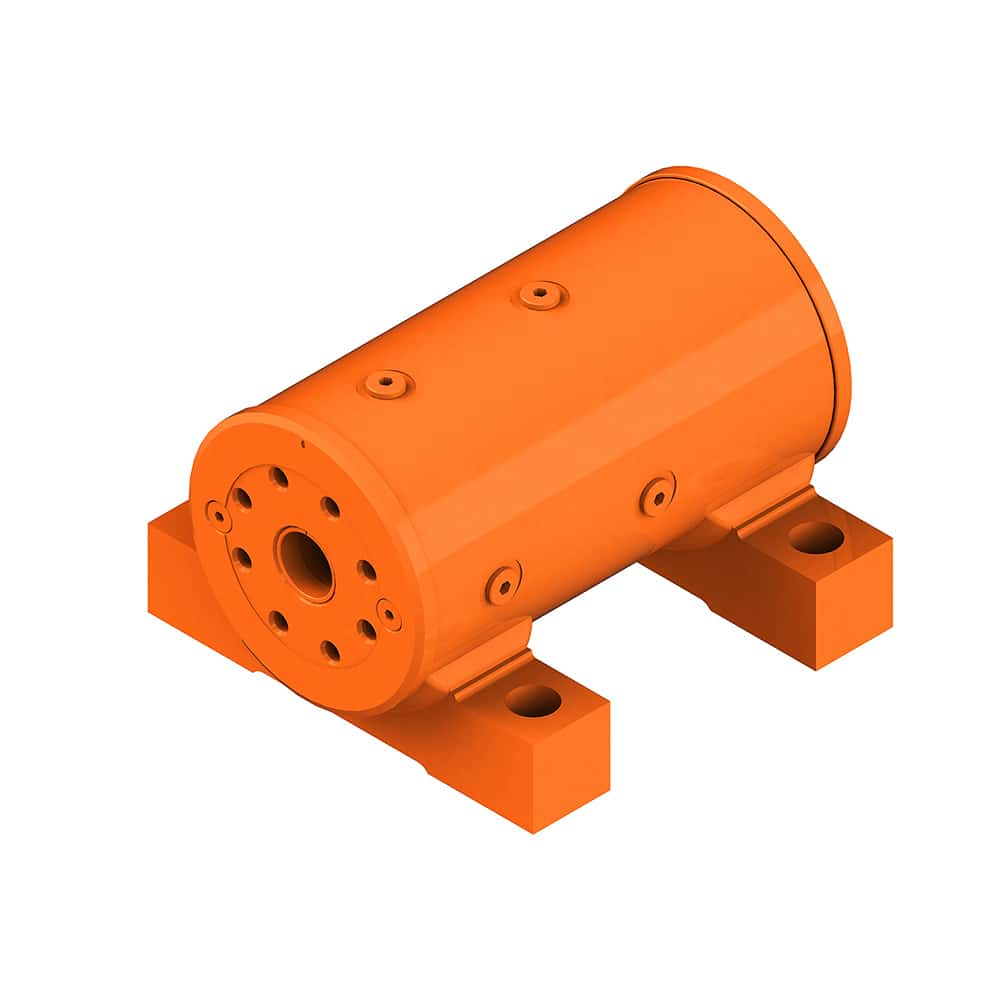

The Helac L30 Series is a heavy duty helical hydraulic rotary actuator that is suitable for harsh environments. Designed for applications that require high bearing capacity, the L30 Series features foot or flange output with 180° or 360° rotation.

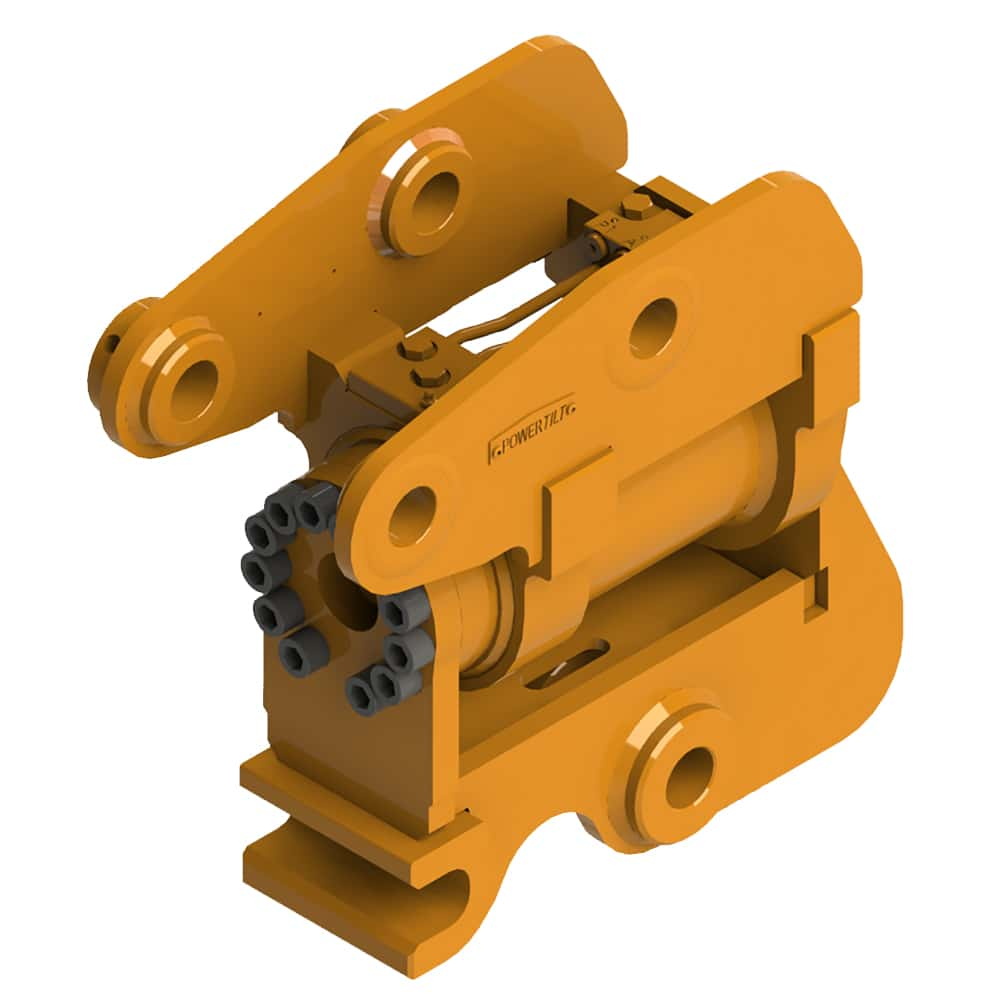

The Helac PowerTilt tilting coupler, construction equipment attachment, is for excavators and backhoes. Tilt your bucket or attachment up to 180°.

The HTR Series has many features ideal for the most demanding high production applications. The HTR Series can be utilized as an integral machine component, where the actuator simultaneously transmits torque and supports the line shaft or the load.

Designed to meet steel mill specs, the M series non-tie rod units provide heavy duty dependable service. Heat treated pinions provide low tooth contact pressures and permit hollow shaft configurations with bore sizes capable of full operating torques.

The LTR series is ideal for low pressure hydraulic applications. The LTR combines an alloy steel gear set with a high strength aluminum housing and Parker 3L or 2A Series cylinder components into an actuator suitable for years of trouble free service.

The Tork-Mor Series is available in 8 sizes with 145K lb-in of torque. Capable of providing full torque instantly in either direction, it is available with 100° or 280° rotation. The Tork-Mor can be mounted in any axis with numerous mounting options.

The HUB Series is designed to perform in the harshest environments with hard coat anodized and hardened alloy steel components. Add-on valve modules, feedback, & visual indication are available for lower integration costs & increased product performance