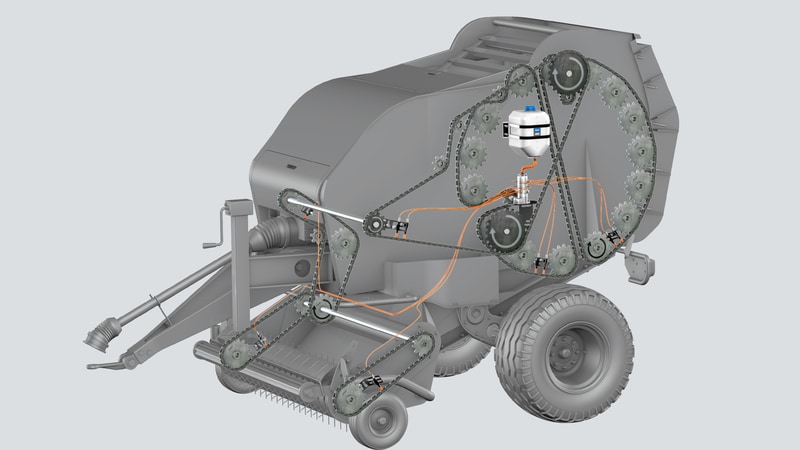

The chain lubrication system OCL-M gives farmers confidence that machinery will run with maximum reliability.

This new grease is offering excellent lubrication properties for a vast majority of conditions found in, among others, the food & beverage industry. LGFG 2 is registered as an NSF ISO 21469 food grade...

Extension of our existing universal and bipolar piston detector range. The inductive sensors can be connected directly to the metering device and have a high resistance to magnetic fields. A strong external...

SKF Flowline is an oil supply unit for oil circulation systems. The unit’s unique design of its space-saving cylindrical stainless-steel reservoir facilitates a far lower oil retention time in the...

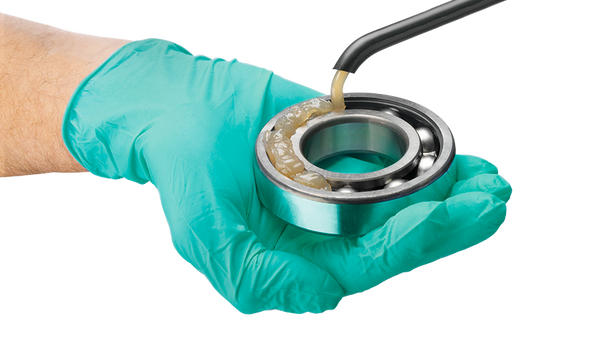

Poor lubrication accounts for over 36% of premature bearing failures. SKF lubricants are designed for your needs and tested for performance in real applications.

Automatically supply a small quantity of clean grease or oil to a lubrication point on a regular basis, thus improving bearing performance.

The SKF manual lubrication tools are specifically designed and selected to support lubricant storage, handling, dosing, labeling, analyzing and applying lubricants.

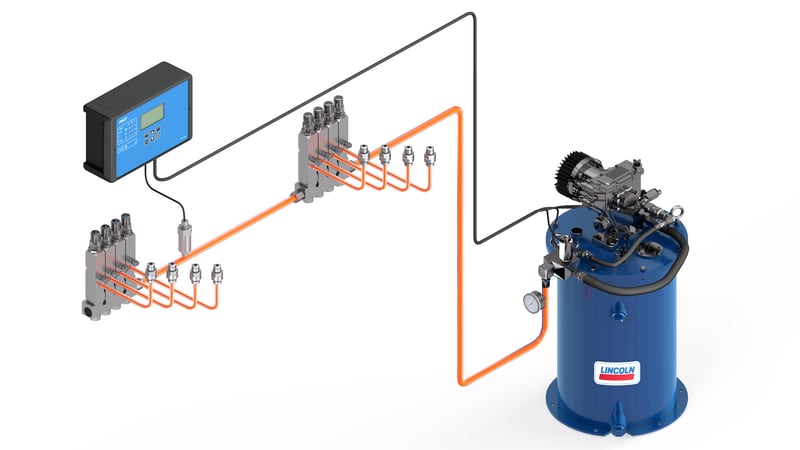

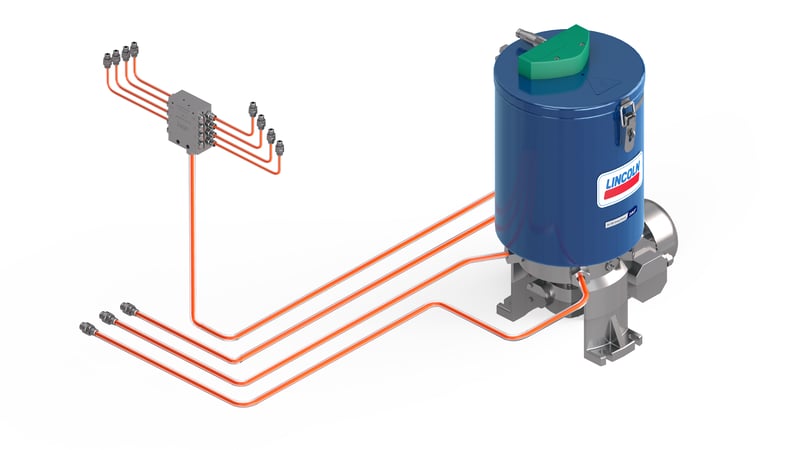

For oil, fluid grease and grease up to NLGI 3. For applications in machine tool, textile or printing (oil and fluid grease) and for heavy applications like mining, food and beverage, construction (grease).

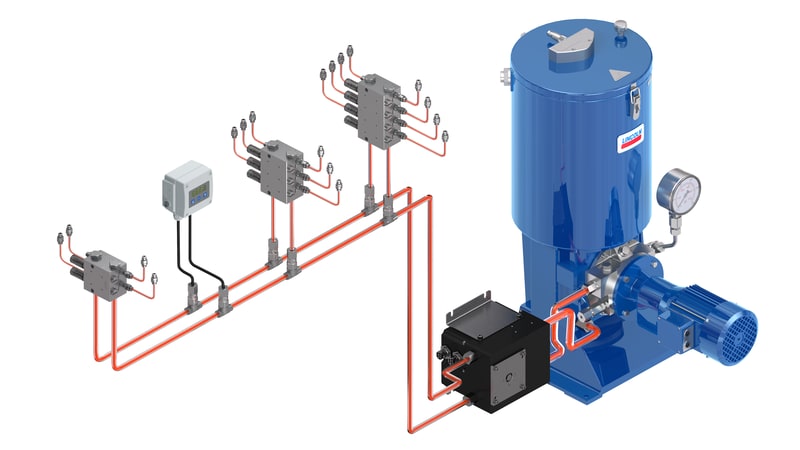

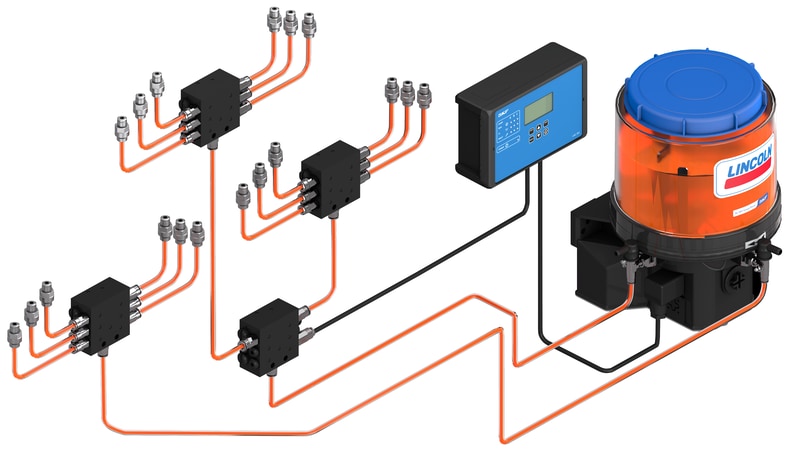

For oil, semi-fluid grease and grease up to NLGI 2. For heavy applications like pulp and paper, mining and metals. Up to 2000 lubrication points over long distances up to 120 m.

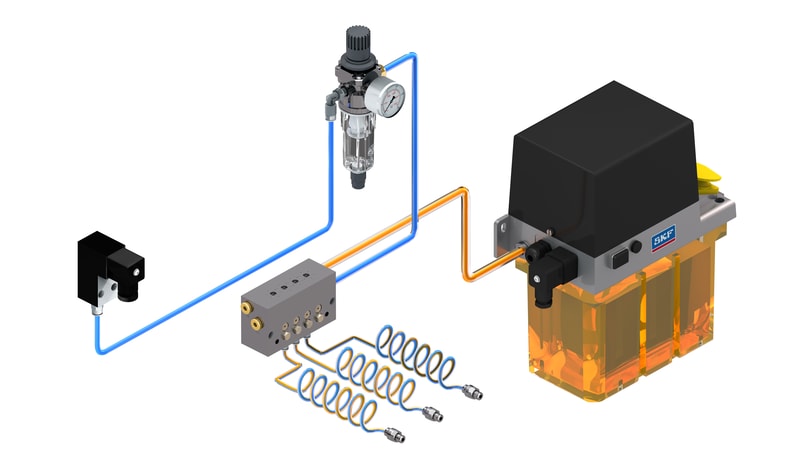

For oil or grease. Simple, accurate and reliable. Meet ATEX and API standards in the oil and gas industry. 1 to 30 outlets.

For oil, semi-fluid grease and grease up to NLGI 2. For use on small- to medium sized machines with dispersed lubrication points that require varying lubrication quantities. Delivers frequent and measured…

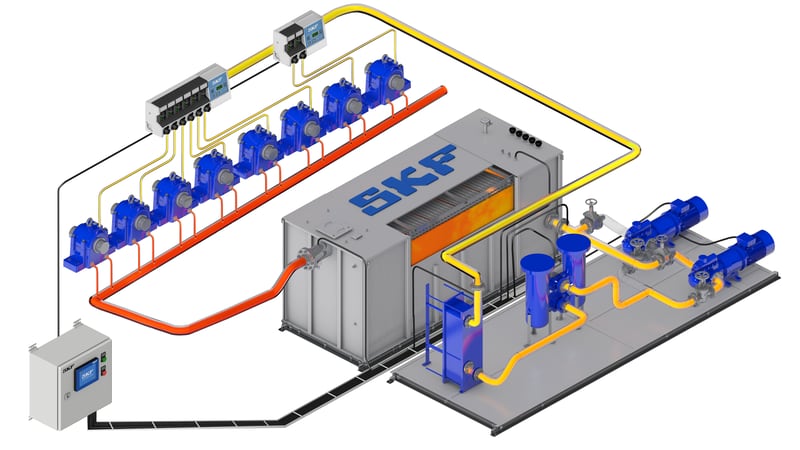

Designed primarily for oil circulation lubrication to lubricate as well as cool highly stressed bearings in nearly every size of machine. Additionally, the returning oil removes and filters out wear…

For high-speed spindle bearings, chains and special applications in the steel industry.

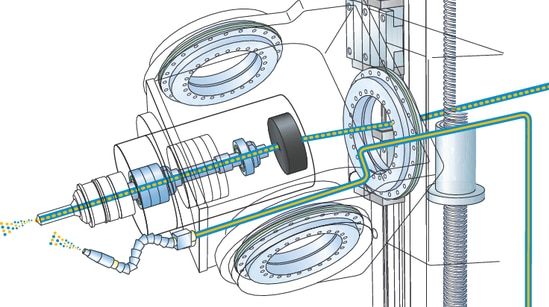

For high-speed cutting processes. Improves ecological and economic efficiency. The principle is simple – lubricant is applied to the tool’s cutting edge as an aerosol in the exact amount required. Using MQL,…

Effective lubrication is key to maximize chain life in order to keep your chain and conveyor processes moving. Air-assisted and airless oil projection system. Oil applicators. Grease injection. Agriculture…

For all types of lubrication systems. For oil, fluid grease and grease. Different drive options. With or without reservoir.

Deliver preset lubricant dosages to lubrication points. For all types of lubrication systems. For oil, fluid grease and grease.

Various devices that generate a visual or electrical signal. For all types of lubrication systems. Switches. Sensors. Transmitters. Valves.

For all types of lubrication systems. To monitor the well function of a lubrication system.

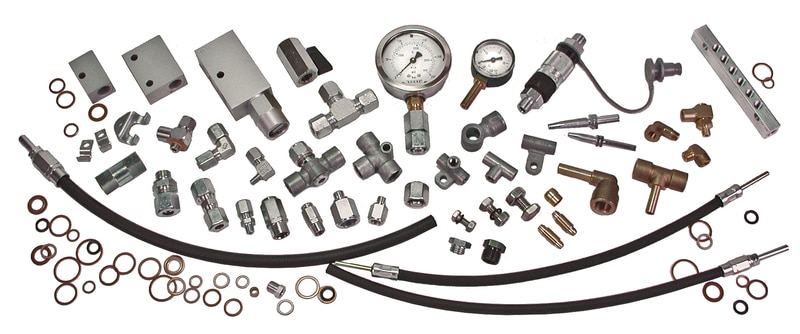

Applicators, filters, fittings, pipes. For all types of lubrication systems.

Components used in the machinery industry are increasingly designed for continuous loads at the limits of materials and technology. This places extreme demands on lubrication. Challenges can include ingress…

With an automatic lubrication system installed on your construction machines, you know that bearings are receiving the right amount of lubricant at the right time. There is also no need to stop the machine…

Efficient lubrication is critical for each rotating machine component, and chains and conveyors need special treatment. Independent from your final product, SKF lubrication solutions support all moving parts…

Fleet maintenance can be performed more efficiently and safely with automatic lubrication systems. Providing lubrication solutions for all types of vessels, SKF helps to optimize your marine operations.

Upstream, midstream or downstream, SKF supports you in every phase by providing automatic lubrication systems that are tailored to the specific characteristics of the job. Class-approved and ATEX- or…

By delivering precise amounts of lubricant directly to the rail/wheel interface, automatic lubrication systems provide significant benefits in terms of wear, energy and noise reduction.

Automatic lubrication systems provide lubricant supply more reliably and precisely to moving components in the nacelle. The result is optimized bearing service life over the long term, more turbine uptime…