Thousands of trains around the world operate more reliably and efficiently because of SKF and Lincoln automatic lubrication systems. By delivering precise amounts of lubricant directly to the wheel/rail interface, automatic lubrication systems provide significant benefits in terms of wear, energy and noise reduction.

Rail wear has been a challenge for many years in areas of tight curves or heavy loaded tracks. Additionally, in dry weather, the so-called curve screeching or squealing can occur.

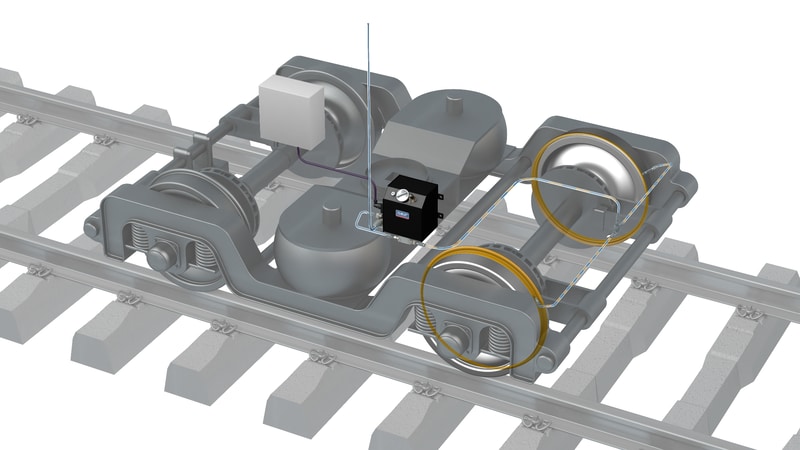

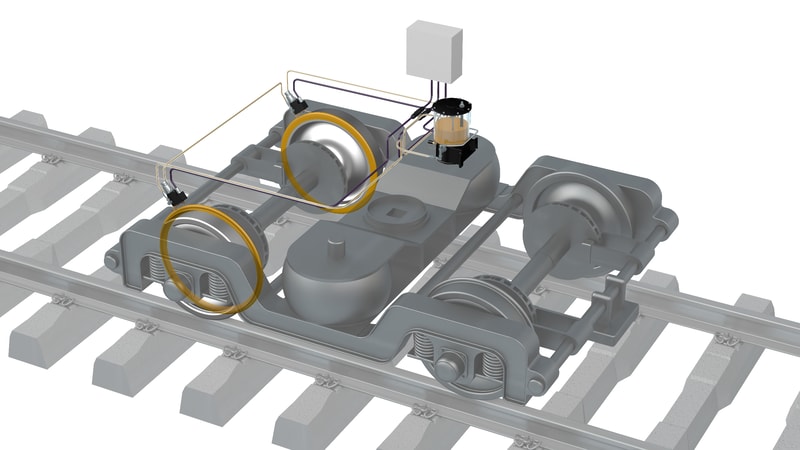

SKF EasyRail on-board systems for wheel flange lubrication and top-of-rail conditioning usually are mounted on the first leading vehicle axle. On-board lubrication systems have proven to be very flexible and effective for railway operators due to their variable setting options.

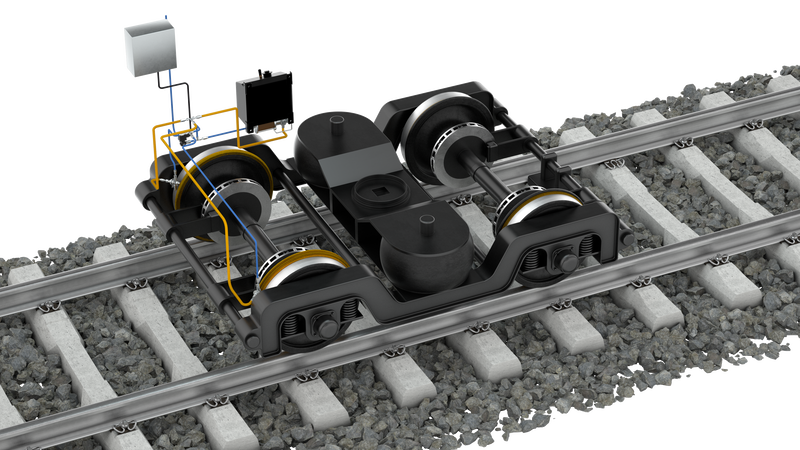

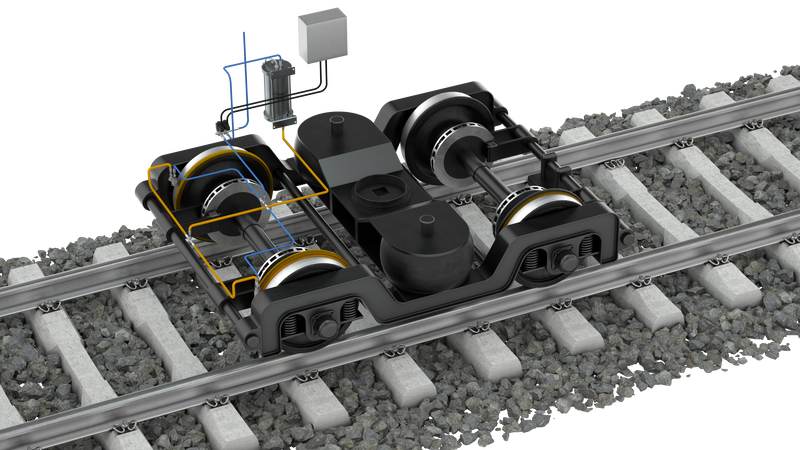

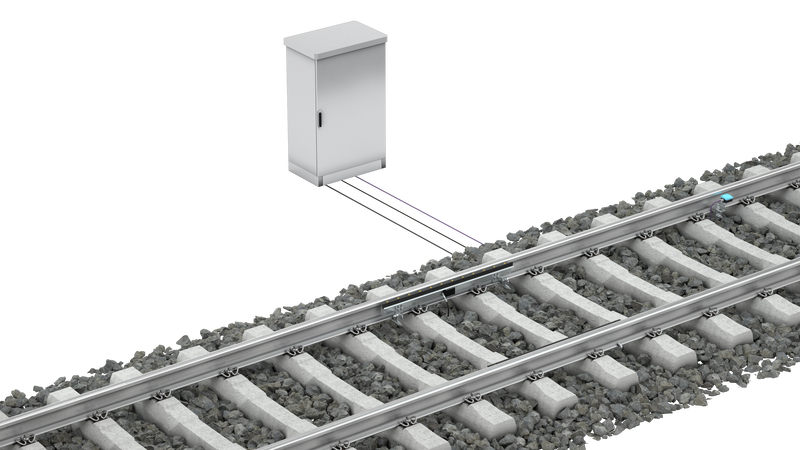

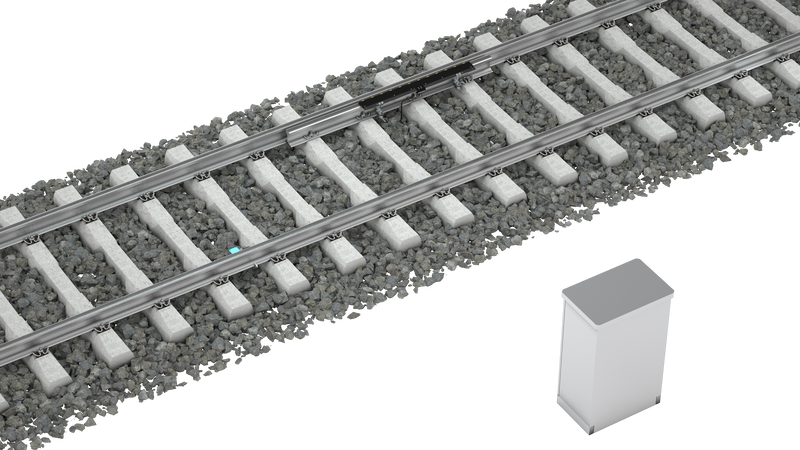

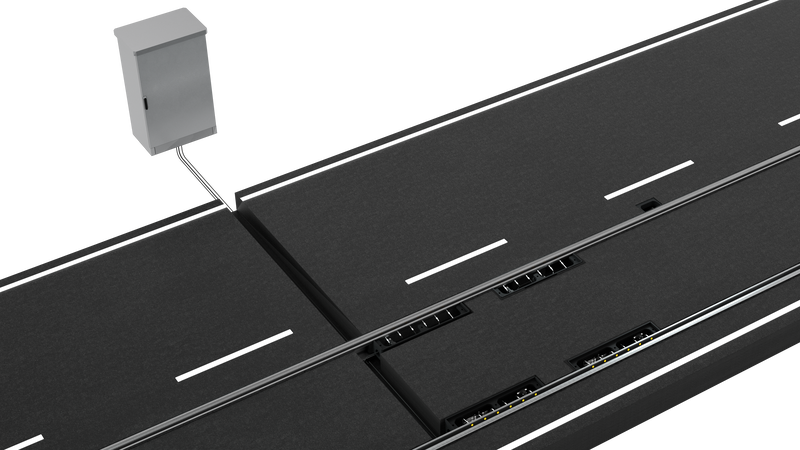

Wayside lubrication systems effectively apply a consistent and controlled volume of lubricant to the rail. The systems hold that grease or friction modifier in place, allowing the wheels to grab and carry it around the track curve. The product range includes solutions for gauge face, top-of-rail and restraining rail.

High-viscous lubricants and friction modifiers that are applied automatically and independently from each other help achieve the desired reduction of noise and wear.

SKF EasyRail wheel flange lubrication and top-of-rail conditioning systems are mounted on-board on the first leading vehicle axle. When activated, air and lubricant are fed from the grease tank to the spray nozzle. The lubricant is sprayed to the wheel flange in a thin layer and transferred to the gauge face of the rail by direct contact. SKF EasyRail systems can be configured for single- and dual-line lubrication system applications, for high and low pressure. SKF EasyRail Airless is available for vehicles without on-board air supply. All SKF EasyRail systems also are available as top-of-rail conditioning systems in which the nozzles apply the friction modifier directly to the top of the rail. They require low maintenance and operate reliably even under extreme climatic conditions.

Advantages:

Single-line lubrication systems for railway vehicles. For less demanding applications.

For challenging applications in terms of temperatures, vehicle speeds and if special lubricants are required.

For applications where reliability and low maintenance cost are important.

For applications where air pressure is not available or difficult to get.

In Lincoln’s wayside systems for gauge face lubrication and top-of-rail conditioning, passing trains are detected by track-mounted wheel sensors. The applied lubricant is picked up by passing wheels.

High-pressure, low-volume pumps effectively cover the rail with just enough lubricant, minimizing waste. A wiper bar with an integrated progressive metering device applies the lubricant or friction modifier directly to the gauge face or top-of-rail. The progressive pump-to-port technology (PTP) enables exact metering of grease, helping to ensure each lube port receives the same small amount of grease every time, automatically.

The systems are capable of pumping long distances, as well as high-viscosity lubricants. Dual track systems and customized solutions are available

Advantages:

For mainline trains. Systems apply grease to the gauge corner and face.

For mainline trains. Reduces wear and noise emission.

For mainline trains. Systems apply friction modifier to the top of rail or grease to the gauge corner.

For tram and metros. Lubricants or friction modifiers are brought to the lubrication point via high-pressure hoses.