Machine operators can reduce production costs significantly by using SKF minimal quantity lubrication systems (MQL). These systems provide longer tool life and improved production quality due to more precise surface machining. Because MQL systems do not require cooling lubricant, the cost of that lubricant, its associated lubricant filters, preparation systems and disposal is eliminated. Also workpieces and chippings do not need to be cleaned.

Benefits

applications

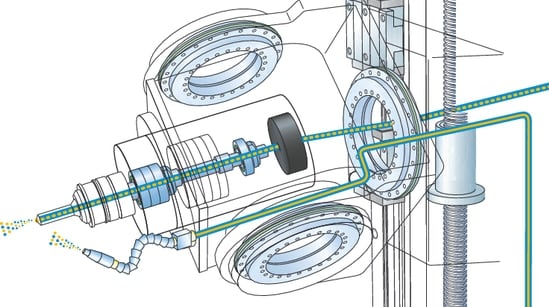

With the internal lubrication method, compressed air or the aerosol is applied through the spindle, the tool holder and the tool directly at the point between tool and workpiece.