A drop of oil is pulled apart in streaks by a current of air in a narrow tube. It is then transported in the direction of the lube point. The bearing is continuously supplied with fine droplets of oil from the outlet nozzle. The carrier air leaves the bearing nearly free of oil.

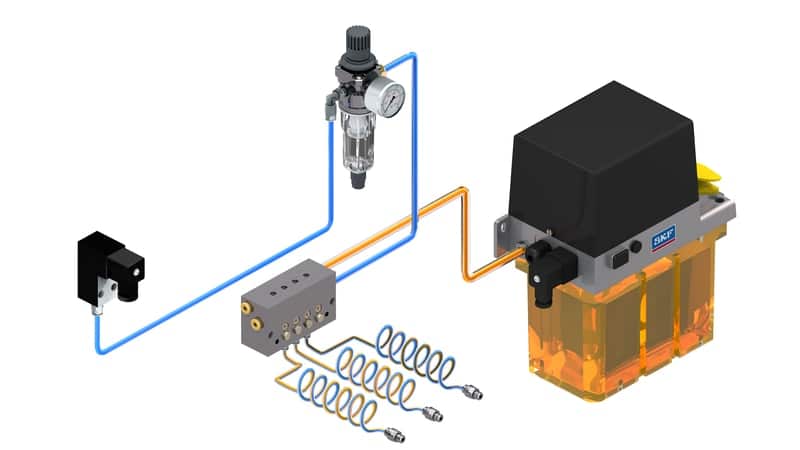

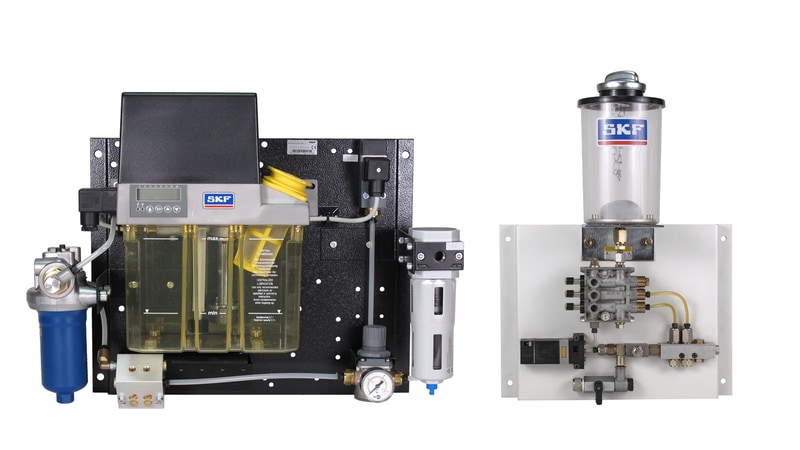

Oil and air lubrication systems can be tailor-made and apply leading oil-streak sensor technology.

Benefits

applications

In oil and air lubrication systems, a volumetrically metered quantity of oil is pulled apart by a continuous air flow in a tube. It is carried along the tube wall in the direction of compressed-air flow. The quantity of oil is fed into the air flow in pulses at a mixing point (mixing valve). A nearly continuous flow of oil is produced that leaves the outlet nozzle as fine drops and is fed to the rolling bearing without contact. This means that the bearing housing is under a slight overpressure, which keeps dirt away from the sensitive bearings.

The carrier air leaves the bearing nearly free of oil. This concept creates no oil mist or oil fog, making it environmentally friendly as well.

Can be supplied as a complete unit (model OLA) or individually. Mixing valves with or without metering.

Oil+Air mixing valves with or without metering and flow dividers

Oil, fluid grease and grease. ISO VG viscosity classes from 2 to 3 200. NLGI grades 000 to 6. For use in lubrication systems.

For planning a lubrication system, conditions the system will be used in need to be determined first.