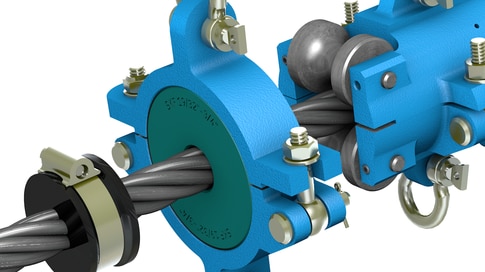

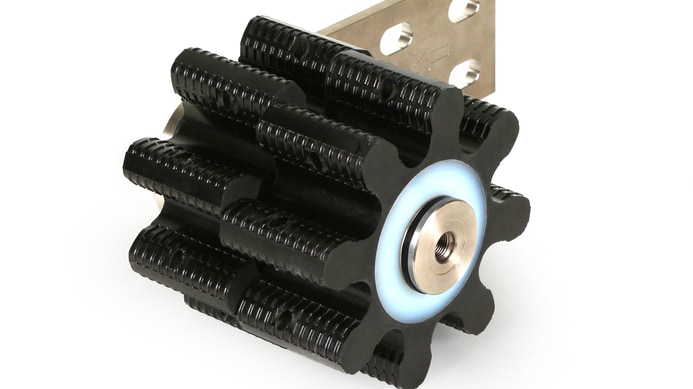

Vibration, high mechanical loads, contamination and moisture are all threats to bearing service life. Like any mechanical system, slewing rings and bearings in deck cranes and pulleys on cantilever arms require proper lubrication to function optimally.

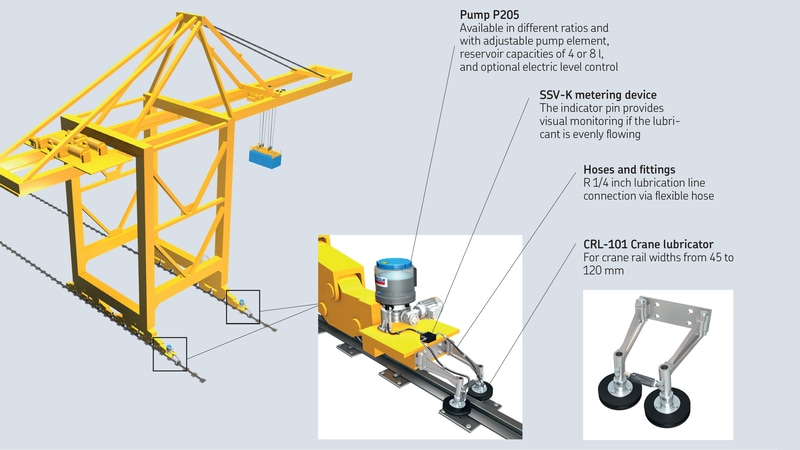

SKF and Lincoln automatic lubrication systems deliver the exact quantity of the appropriate lubricant to the right place at the right time while the equipment is running – without downtime. Automatic lubrication systems are able to pump long distances within a wide temperature range and can reliably service difficult-to-access points.

Benefits

applications