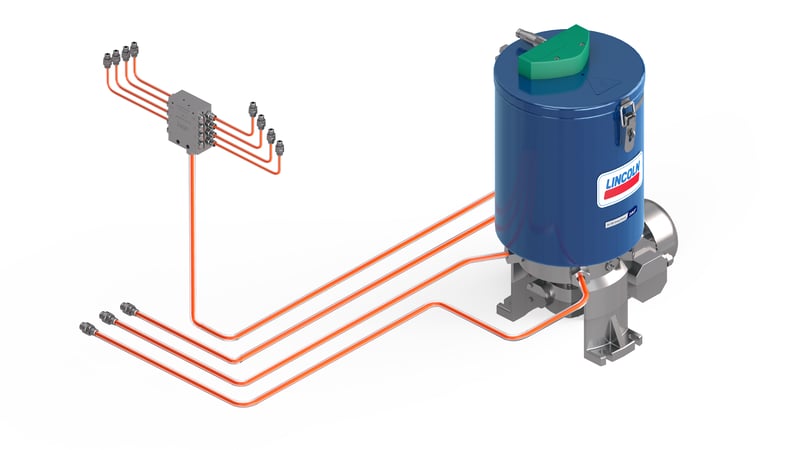

Centralized automatic lubrication systems are an effective way to increase machine availability while reducing reliance on scarce talent. With an automatic lubrication system installed on your construction machines, you know that bearings are receiving the right amount of lubricant at the right time. There is also no need to stop the machine for relubrication – you simply need to keep the lubrication system filled and maintained.

For manual lubrication, training is required to make maintenance staff aware of the importance of properly storing, handling, and applying grease. A lubrication program should be followed to encourage regular relubrication and keep components functioning as they should. Manual lubrication systems, such as multipoint grease guns, can help by using distributors to group lubrication points. This increases the consistency of maintenance as the system avoids the possibility of points being overlooked, and saves time as maintenance staff do not have to search for each point.

Nevertheless, manual lubrication requires the machine to be stopped. Depending on the machine, it usually takes over an hour to complete the task. With manual lubrication methods, bearings are often overgreased initially. They eventually become undergreased as too much time passes until relubrication. Optimal lubrication is only achieved for a short period of time.

Lubrication is a critical aspect in machine reliability. Yet for many operators, manual lubrication is becoming too much of a challenge. By finding a simpler, smarter way to lubricate your machinery, you could maintain reliability without the costs and effort of manual lubrication.

An automatic lubrication system (ALS) lubricates continuously while the machine is working. This increases efficiency as there is no need to stop machinery for lubrication. Lubricating while the bearings are rotating also improves the distribution of lubricant. A small amount of grease remains flowing, keeping out contamination even when the machine is operating in a harsh environment.

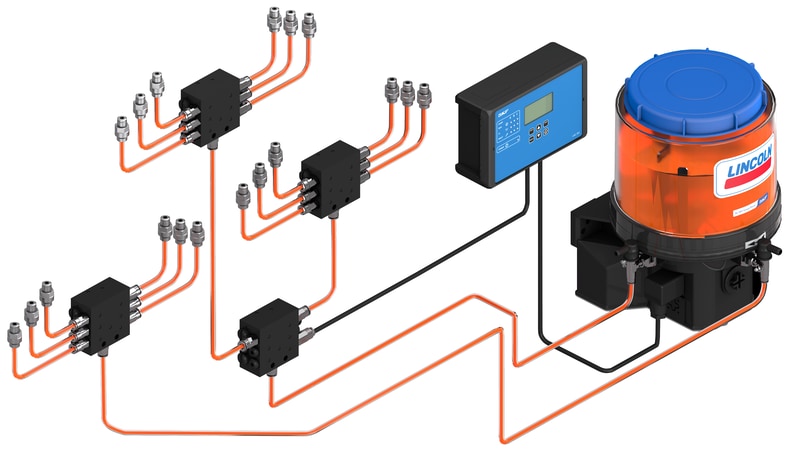

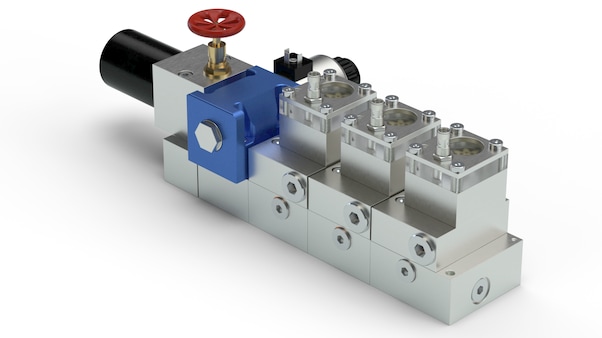

For oil, semi-fluid grease and grease up to NLGI 2. For use on small- to medium sized machines with dispersed lubrication points that require varying lubrication quantities. Delivers frequent and measured…

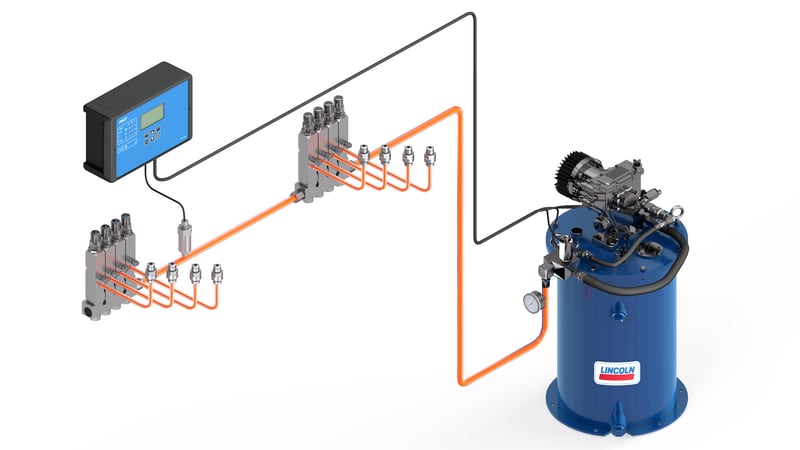

For oil, fluid grease and grease up to NLGI 3. For applications in machine tool, textile or printing (oil and fluid grease) and for heavy applications like mining, food and beverage, construction (grease).

For hammers and breakers. The Lincoln HTL 201 lubrication pump mounts directly to the hydraulic tool and lubricates continuously throughout the working phase the tool.

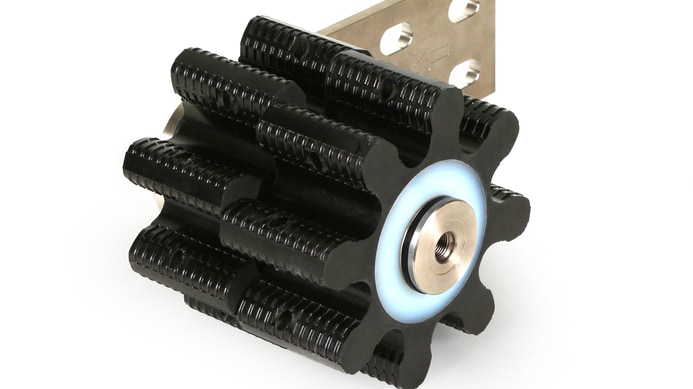

Lubrication pinions provide contact lubrication of pinion gears on open gear wheels and gear racks. A lubrication pinion also lubricates the tooth flanks of open gears, such as large slewing bearings or…

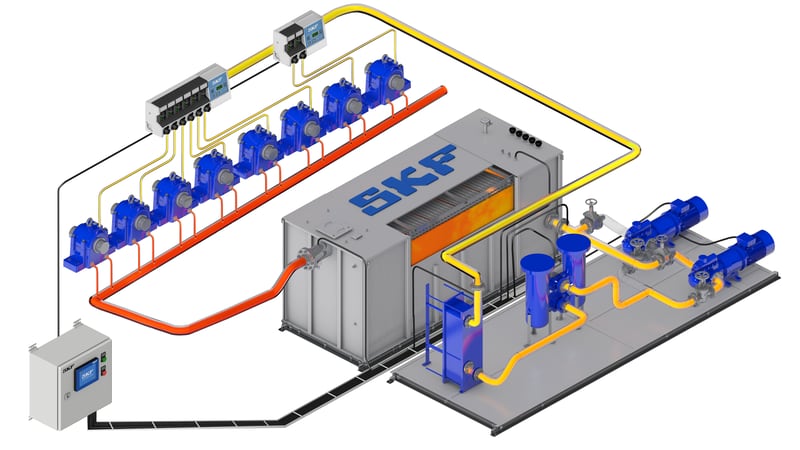

Designed primarily for oil circulation lubrication to lubricate as well as cool highly stressed bearings in nearly every size of machine. Additionally, the returning oil removes and filters out wear…

SMB product series are pressure-compensated flow limiters with optional monitoring, flow rates from 0.08 to 132 l/min

For oil or grease. Simple, accurate and reliable. Meet ATEX and API standards in the oil and gas industry. 1 to 30 outlets.