Seals have a crucial impact on system performance. By choosing SKF Seals, you can make a difference to the capability, durability and performance of your equipment – reduce friction, extend maintenance intervals and achieve greater value while increasing sustainability. With a seal by its side, there’s nothing our bearings can’t do.

Backed by more than 100 years of industrial application experience, SKF sees every sealing challenge as an opportunity to boost performance. Our customers benefit from our unmatched understanding of both the interaction between bearings, seals and lubrication, as well as the dynamics of reciprocating systems.

For example CR Seals has been setting performance and service life standards for industrial and automotive shaft seals. CR Seals has also been part of SKF since 1990, a span during which we’ve developed new materials, manufacturing processes and designs to create some of the most robust seals on the market.

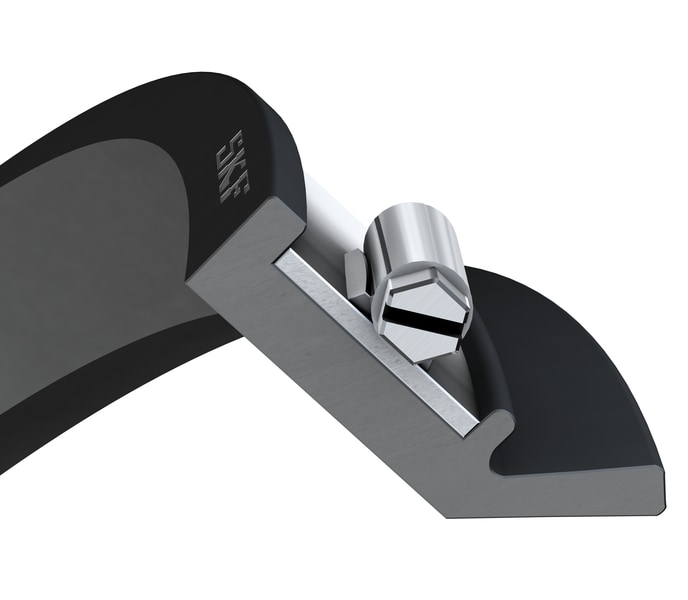

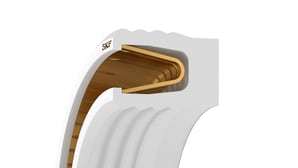

Radial shaft seals sit between rotating and stationary components, or two components in relative motion.

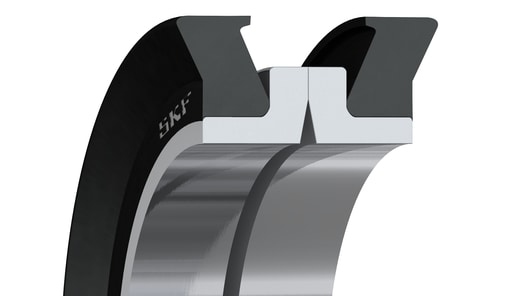

The design of SKF Mudblock cassette seals has been optimized to provide excellent retention of either grease or oil and maximum protection against liquid or solid contaminants.

This thin-walled sleeve developed by SKF, is simply pushed in position over the worn area, providing a counterface surface that is optimized for radial shaft seals.

Track pin seals are designed for oil-lubricated track chains in off-highway applications.

Metal face seals comprise two identical sealing rings to withstand severe service conditions at low circumferential speeds.

V-ring seals are axial shaft seals, available in two types: all-rubber varieties and those with a metal casing (MVR seals).

Axial clamp seals are designed for large and very large shaft diameters. They seal axially against a rotating counterface.

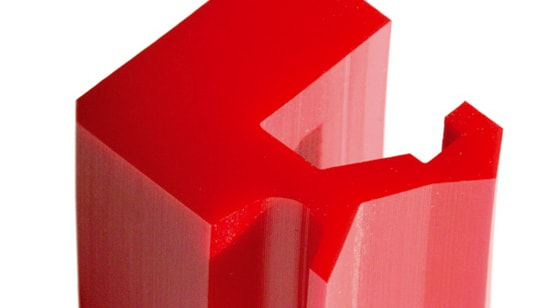

A The flexible concept of machined seals allows quick and customized sealing solutions.

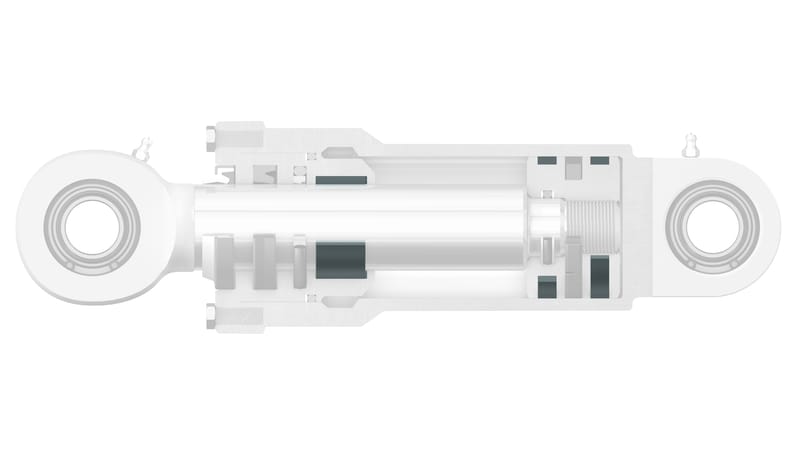

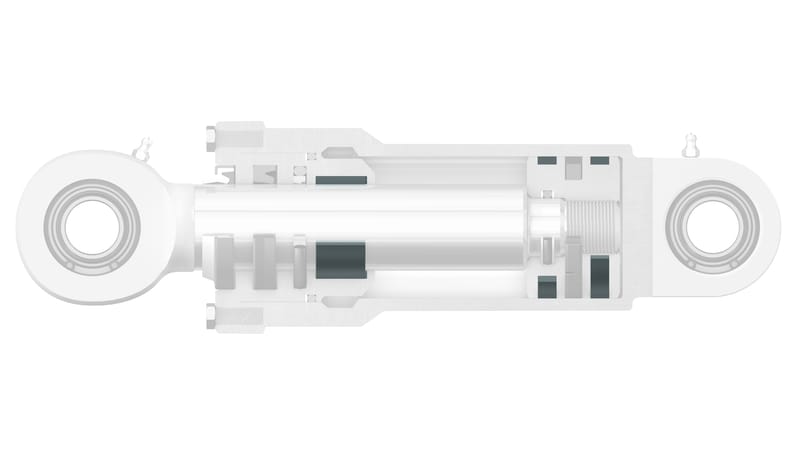

Piston seals maintain sealing contact between a piston and cylinder bore.

Rod and buffer seals maintain sealing between a cylinder head and moving piston rod.

Wiper seals maintain sealing contact to the piston rod, whether the equipment is stationary or in use.

The most commonly used guides in hydraulic cylinders are guide rings (and guide strips).

O-rings, one of the most common sealing solutions, are available in many sizes and materials.

SKF Spectraseals are predominately used for extreme and demanding application requirements.

Wellhead seals are designed to maintain smooth operation of wellheads in the oil and gas sector.

The flexible concept of machined seals allows quick and customized sealing solutions.

Fluid power seals transmit power via fluid pressure.

Machined seals for power transmission provide a sealing function between a rotating and stationary component, or between two components in relative motion.

Seals are manufactured on a special-purpose CNC lathe, in diameters up to 14 000 mm and even larger can be produced using a special welding technique.

CNC technology to custom-machine seals on a just-in-time basis.

Thermoplastic elastomers which demonstrate the characteristics of elastomers over a wide temperature range and in addition have the processing behaviour of thermoplastics.

Elastomers, respectively rubber materials are polymers, which are chemically cross-linked by the vulcanization process.

Include standard and special hard grade materials with outstanding wear resistance for mechanical applications and top performance PTFE compounds with highest chemical and temperature resistance.

All standard materials can be modified to meet your specific needs.