At Flexco, we've developed a wide range of mechanical conveyor belt connector systems over decades that keep your conveyor belts running, ensure high speeds, and maintain long-term uptime by maximizing uptime.

Safety in the workplace is our top priority. With this in mind, we produce a wide range of high-quality conveyor belt maintenance tools with built-in protection mechanisms to protect your crew and make every single step of conveyor belt maintenance easier, faster and safer.

Thanks to state-of-the-art technologies available on the market, the Novitool series of continuous connection tools allow you to quickly prepare your conveyor belt for light duty and produce strong, long-lasting connections in as little as 8 to 12 minutes.

Transporting a product safely and efficiently through the conveyor system is often one of the biggest challenges in material transfer. With our range of segmented transition plates, coupling guards and conveyor belt carrier lugs, you can ensure that your goods reach their destination safely.

Flexco can help you reduce material overflow, as well as prevent uneven belt wear and potential equipment damage when you choose one of our high-performance belt guide systems that can quickly correct belt runout errors, even in the most challenging conditions.

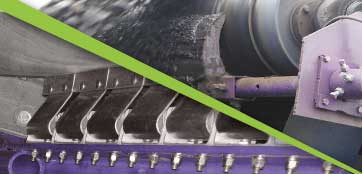

Flexco has developed innovative scraper systems to help our customers meet their specific needs from food processing to extreme mining applications.

Our drum lining products for conveyors are some of the most innovative in the industry, so you shouldn't have a hard time finding the right solution to prevent belt slippage, extend drum life, improve water repellency and increase productivity.

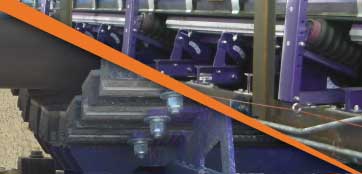

In the area of the loading zone, you need solutions that effectively retain the material and protect the conveyor belt safely. Our products for the loading point have been specially designed with regard to the interception of impact energy, an extension of the belt service life and the control of dust generation.