With the EASYMill, all common milling operations can be perfectly covered, such as roughing, finishing, slotting, ramping or helical plunging. The EASYMill can efficiently be used in steel and stainless steel materials. At the same time, the EASYMill optimizes the price/performance ratio in your production processes.

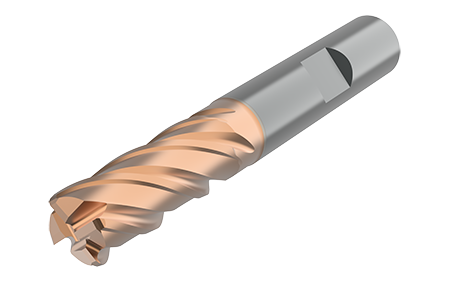

With our solid carbide end mills from the new HPC family (High Perfomance Cutter), we offer multifunctional high-performance milling cutters for a myriad of roughing and finishing applications. Thus, the HPC H is especially suitable for hardened steels ≤ 45 to 55 HRC, the HPC P for high-alloy steels and cast iron, and the HPC M for austenitic steels, non-ferrous metals and titanium. As a full flute cutter with a large chip removal space, the HPC U is universally applicable.