Ordering information

Specifications

Reversed power supply polarity protection, output short-circuit protection, Reversed output polarity protection, and mutual interference prevention | |||

Features

One mounting

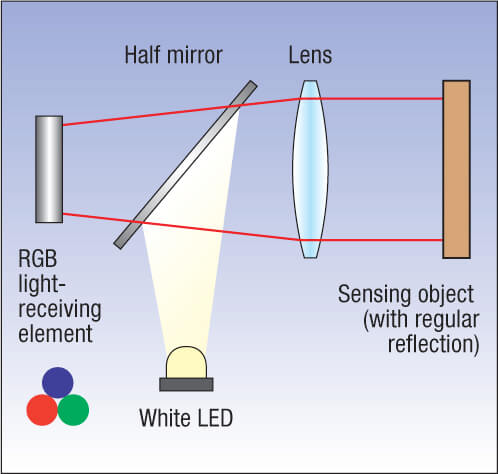

Optics

Coaxial optical system with white LED

Remote teaching

Remote teaching

Detergent resistance

Performance comparison

Registration mark detection

The packaging material used in many packaging machines is very often delivered in rolls and has to be cut and positioned accurately. In order to avoid waste and errors and to compensate for environmental influences, a registration mark (usually black or in a colour that provides maximum contrast to the background) is added to the packaging material.

The goal of any mark sensor development is to reliably detect these registration marks even in changing environmental conditions. A particular challenge is the frequent exchange of packaging materials and the continuously changing packaging designs.

At Omron we closely work together with leading packaging machine makers to evaluate the requirements for sensors from commonly used packaging material as well as most critical designs or materials. In addition the performance requirements vary according to the overall machine value concept.

Solution portfolio

Complex shape and position detection and synchronized quality inspection.

For positioning and machine synchronisation tasks e.g. requiring the recognition of words or symbols, the shape, position detection functionalities of the vision sensors and systems can be set up to provide solutions for the most complex and challenging tasks. The vision systems can also detect the registration mark and perform position and quality inspections at the same time.

- FQ2 – Simply guided and crystal clear

- Xpectia-Lite – Performance in touch with simplicity

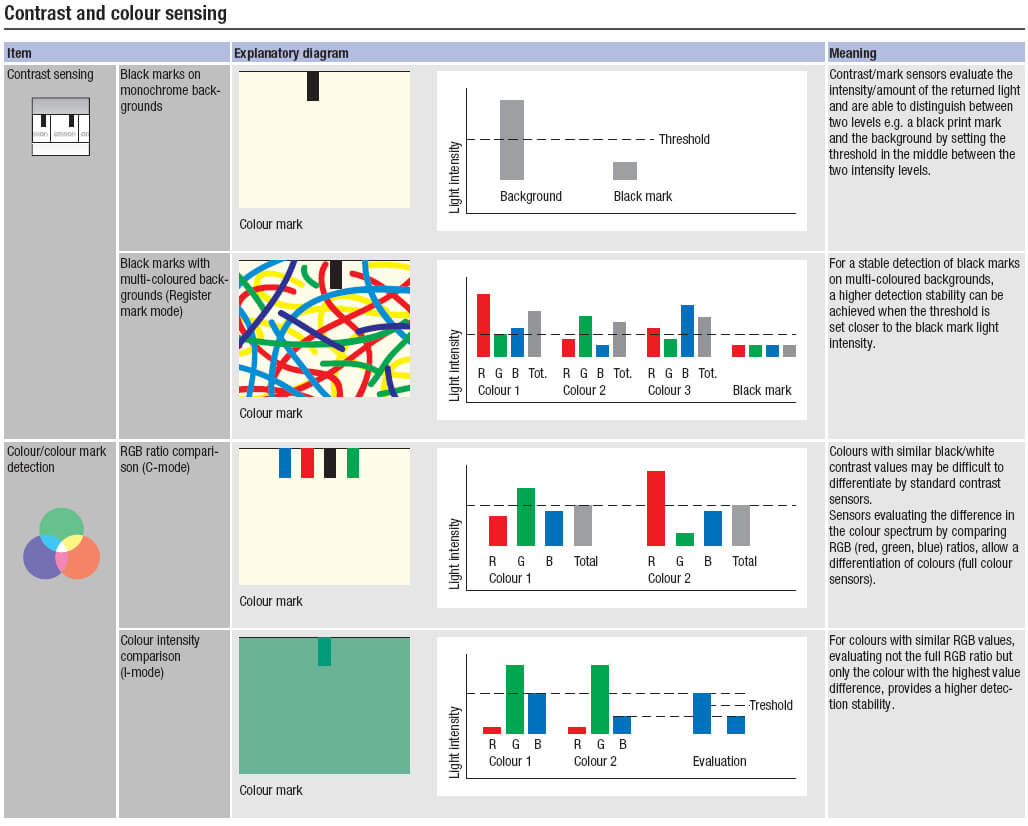

Challenging designs or colour marks

Objects with complex designs or where the contrast between print mark and background is low, require sensors that allow an easy adaption to the specific requirements of the particular task.

- Amplifiers with digital value displays and advanced signal evaluation functions for application optimised settings

- Wide range of sensing heads fitting the application and distance requirements

- White LED, RGB ratio comparison and extended functionality

Standard print mark detection

For print marks most commonly used in the packaging and printing industry, the contrast sensors with white LED have an optimised light intensity and RGB ratio evaluation algorithm ensuring a stable and fast detection.

- Compact housing concept for high flexibility in machine design

- Fast response time of 50 μs

E3ZM-V

- Autoteach and white LED

For more information go to E3ZM-V

Technical information