Parker Aerospace’s inerting solutions comprise fuel-tank inerting controllers that support nitrogen enriched air (NEA) distribution to fuel tank ullages; single- and multi- air separation modules (ASM) that supply inert gas to fuel tanks; heat exchangers that condition engine and compressor output for delivery to ASMs; and dual-flow shutoff valves to control NEA flow to fuel tanks.

Engine bleed air temperature or output from a compressor is conditioned prior to delivery to the air separation module. The pressurized air flow is cooled by means of ram air or by an electric cooling fan using a prescribed thermal control algorithm.

Parker’s air separation module (ASM) uses fiber membranes to remove oxygen from the supplied pressurized air stream and generate nitrogen-enriched air that is distributed to the fuel tanks.

The single air separation module (ASM) pallet is part of a fuel tank inerting system (FTIS) and provides inert gas to aircraft fuel tanks by removing oxygen from the conditioned bleed airstream to supply the tanks with inert gas.

Parker's dual flow shutoff valve (DFSOV) is used on the inert gas generation system of an aircraft to control the nitrogen enriched air (NEA) flow to the fuel tanks.

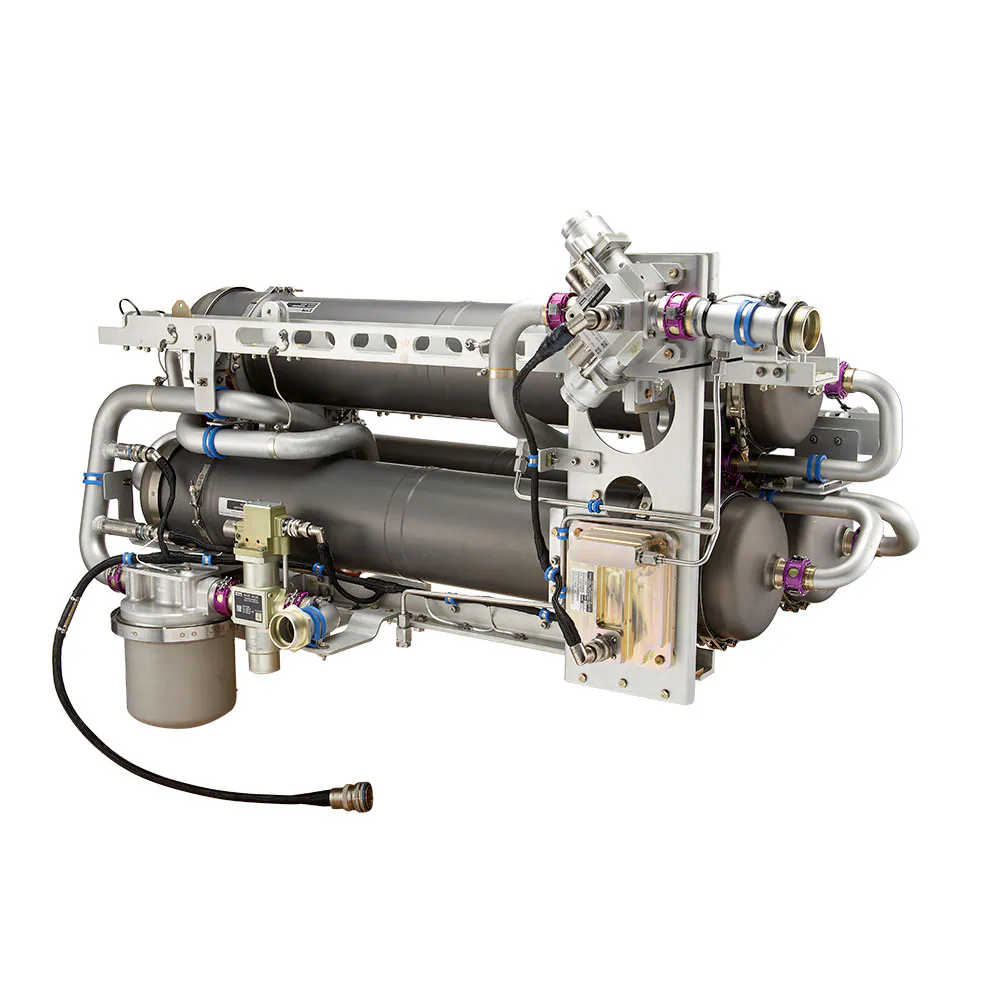

Parker's multi ASM pallet is part of a fuel tank inerting system providing inert gas to aircraft fuel tanks. The nitrogen enriched air generation subsystem removes oxygen from the conditioned bleed airstream to supply the tanks with inert gas.

The fuel tank inerting controller monitors and controls the fuel tank inerting system (FTIS). Pressure, oxygen, and temperature data are used by the controller to support the distribution of nitrogen enriched air (NEA) into the fuel tank ullage.