Parker is the world’s largest supplier of hydraulic cylinders and parts for industrial applications. Parker manufactures a diverse range of standard and special tie rod, roundline and ‘mill’ type cylinders to suit all types of industrial cylinder applications. Our cylinders meet every major industry standard, with other certifications available upon request. All Parker hydraulic cylinders and parts are designed to deliver long, efficient service with low maintenance requirements, guaranteeing high productivity throughout the life of the product.

This is a hydraulic cylinder PQC series that works with a cylinder that integrates a load sensor and a position sensor and a controller that incorporates a comprehensive monitoring system.

Cylinder for hole-punching

The 70 / 140P-8 series is a 7 / 14MPa hydraulic cylinder with position sensor. Tie rod style sets the standard for superior performance, durability and trouble-free operation Design and quality that guarantees long cylinder life.

The PSR-1A series is a 16MPa position sensing compact hydraulic cylinder. A cylinder with a position sensor that does not impair the compactness of the compact cylinder.

The PTN/PTH-1B series is a 7 / 14MPa hydraulic cylinder with position sensor. Tie rod style sets the standard for superior performance, durability and trouble-free operation Design and quality that guarantees long cylinder life.

Series HQS2 is an aluminum compact cylinder that can be used pressure up to 16 MPa depending on the frequency of use. The stroke length can be set in 1 mm increments. ISO 16656 standard.

10MPa specification single-acting constant-speed two-stage telescopic cylinder TTC-1 series that contributes to space-saving and compact design. 9 types of output variations are also available.

The 140H-8 series is a 14MPa specification general-purpose hydraulic cylinder. JIS Tie rod style sets the standard for superior performance, durability and trouble-free operation Design and quality that guarantees long cylinder life.

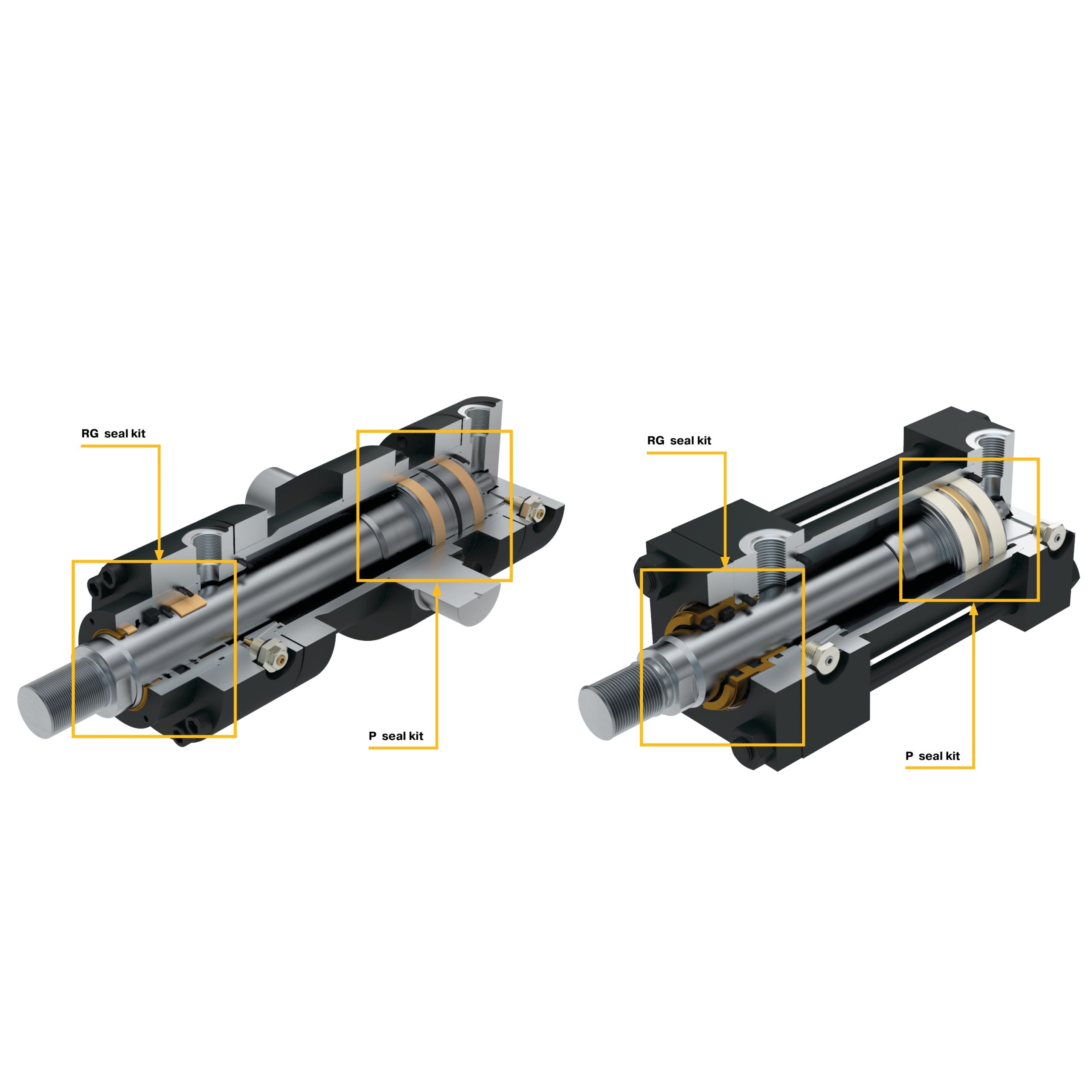

Seal kits for EMEA manufactured cylinders

Heavy Duty Hydraulic Cylinders, tie rod style Series 2H/2HD & Series 3H/3HD, and non-tie rod Series 2HB/3HB set the standard for performance, durability and trouble-free operation with superior design and quality to ensure long cylinder service life.

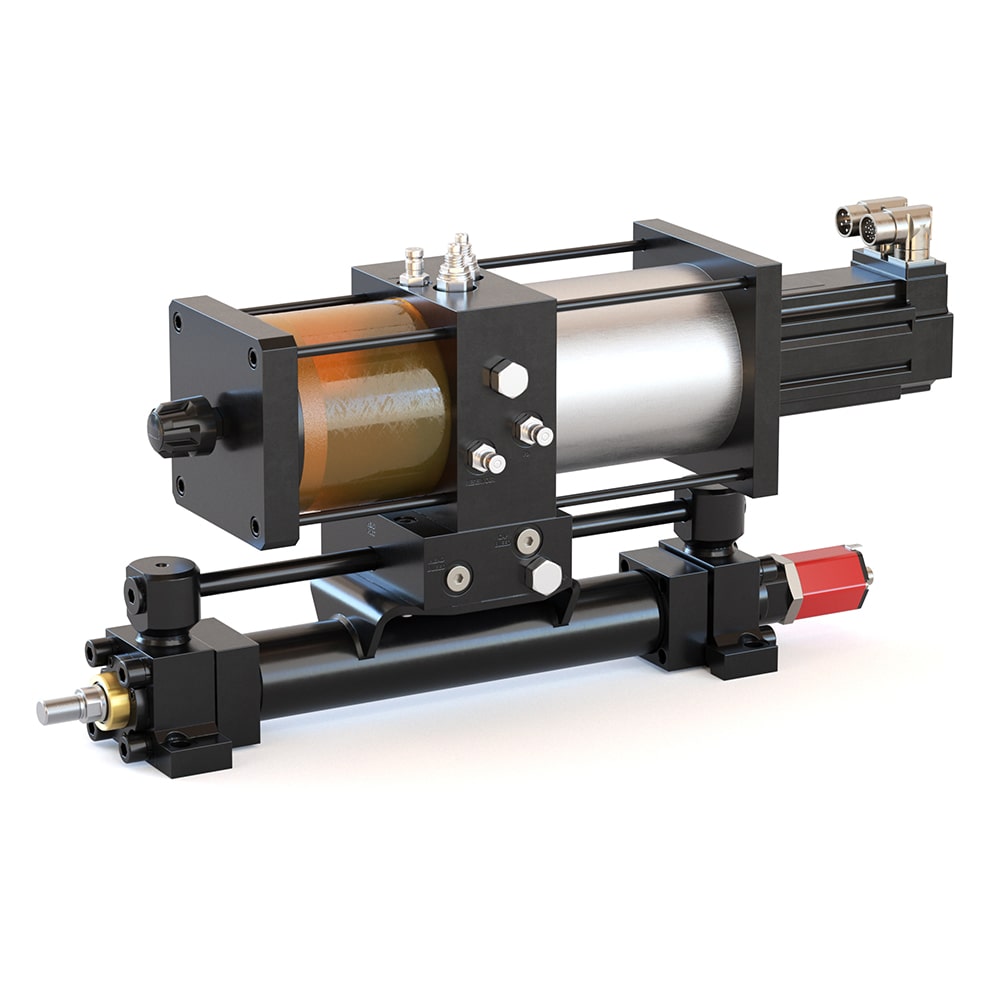

Heavy Duty Electrohydraulic Cylinders – Series 2HX/3HX, 2HDX/3HDX and 2HBX/3HBX – are engineered for your feedback/control systems with transducer, valve manifold and hydraulic plumbing and are electronically tested to verify required output.

210 bar Industrial Hydraulic Cylinders conforming to to ISO 6020/2. The tie rod construction sets the standard for performance, durability and trouble-free operation with superior design and quality to ensure long cylinder service life.

210 bar Industrial Hydraulic Cylinders conforming to to ISO 6020/2. The HMIF is available to you at fast despatch. With lots of options to choose from, the new e-configurator will assist you in the configuration of your individual cylinder

210 bar Industrial Hydraulic Integral Feedback Cylinders conforming to ISO6020/2 and DIN24554. The tie rod construction sets the standard for performance, durability & trouble-free operation with superior design and quality for long cylinder service life

Rated to 250 bar and conforming to ISO 6022, the heavy duty MA3 series cylinders are fatigue-free at their full rated pressure and have been designed for use in steel mills and other arduous applications where a rugged, dependable cylinder is required.

160 bar Heavy Duty Roundline Cylinders conforming to ISO 6020/1 and CETOP RP58H. MMB Series cylinders are fatigue-free at their full rated pressure and designed for use in steel mills and similar demanding applications.

Parker Single Acting Telescopic Hydraulic Cylinders provide extremely long cycle life and are field-repairable. Parker telescopic cylinders are 2,000 PSI rated and support application specific requirements (stroke lengths, closed lengths, and mountings).

Series RDH industrial grade heavy duty roundline hydraulic cylinders provide extremely long cycle life and are field-repairable. 3,000 psi rated Series RDH is configurable in 9 standard mounts, strokes to suit your needs and many standard options.

Series 3L medium duty hydraulic cylinders offer advanced features like the “Jewel” rod gland assembly, adjustable floating cushions, case hardened piston rods and high strength tie rods with rolled threads - compare and choose the Parker advantage.

70 bar Industrial Tie Rod Hydraulic Cylinders conforming to ANSI and NFPA. The tie rod construction sets the standard for performance, durability and trouble-free operation with superior design and quality to ensure long cylinder service life.

The Compact Electro-Hydraulic Actuator (EHA) is a self-contained, bi-directional DC motor-driven system that delivers reliability and power. Its integral hydraulic cylinder achieves up to 4,800 lbf of force with speeds up to 84 mm (3.3 in) per second.

HAS 500 Series’ hybrid design combines the controllability of electromechanical actuators with the durability of a traditional hydraulic system in an all-in-one actuation system that eliminates the need for a hydraulic power unit, hoses and valving.

Series CHD Metric Compact Hydraulic Cylinders – best choice when mounting space is at a premium and the application demands a high force cylinder at operating pressures up to 207 bar with optional end-of-stroke position sensing.

Series CHE Metric Compact Hydraulic Cylinders – best choice when end-of-stroke, mid-stroke or continuous stroke position sensing is required; limited mounting space and operating pressures up to 140 bar (bore size dependent).

Parker Custom Cylinders are purpose-built cylinders with unique features and no common standard or size. Cylinder assemblies and systems are our specialty - from the basic to the most complex.

210 Bar Heavy Duty Tie Rod Hydraulic Cylinders conforming to ANSI and NFPA. The tie rod construction sets the standard for performance, durability and trouble-free operation with superior design and quality to ensure long cylinder service life.

210 bar Industrial Hydraulic Cylinders conforming to DIN 24554. The tie rod construction sets the standard for performance, durability and trouble-free operation with superior design and quality to ensure long cylinder service life.

Series VH Very Heavy Duty Hydraulic Cylinders are built for high speed service with ports two sizes larger than NFPA standards, and extra-long tapered cushions to maximize end-of-stroke energy absorption.

Series CHGH Metric Compact Hydraulic Cylinders – best choice when mounting space is at a premium and the application demands a high force cylinder at operating pressures up to 160 bar.

Series CHE Metric Compact Hydraulic Cylinders – best choice when end-of-stroke, mid-stroke or continuous stroke position sensing is required; limited mounting space and operating pressures up to 140 bar (bore size dependent).

Series CHD Metric Compact Hydraulic Cylinders – best choice when mounting space is at a premium and the application demands a high force cylinder at operating pressures up to 207 bar with optional end-of-stroke position sensing.

Series 160S-1 Compact Hydraulic Cylinders – best choice when mounting space is at a premium and the application demands a high force cylinder at operating pressures up to 16 MPa.

The 35H-3 series is a 3.5MPa specification general-purpose hydraulic cylinder. Tie rod style sets the standard for superior performance, durability and trouble-free operation Design and quality that guarantees long cylinder life.

The 70H-8 series is a 7MPa specification general-purpose hydraulic cylinder. JIS Tie rod style sets the standard for superior performance, durability and trouble-free operation Design and quality that guarantees long cylinder life.

The HTR Series has many features ideal for the most demanding high production applications. The HTR Series can be utilized as an integral machine component, where the actuator simultaneously transmits torque and supports the line shaft or the load.