Parker controllers provide up to sixteen axes of coordinated motion control for complete electromechanical, hydraulic and pneumatic motion systems. Products include stand alone multi-axis motion controllers, integrated control and drive packages and integrated motion and machine controllers.

Parker's Accelerometer and Inclinometer Sensors are MEMs devices with an output voltage dependent on the amount of inertial force applied . The accelerometers and inclinometers have an inertial range up to ±1.5G.

Parker's IQAN-SP pressure transducers belong to the family of IQAN accessories developed to complement IQAN control systems. The SP is a range of pressure transducers for mobile hydraulic applications.

Parker's IQAN-ST temperature transducers belong to the family of IQAN accessories developed to complement IQAN control systems. The ST is a range of temperature transducers for mobile hydraulic applications.

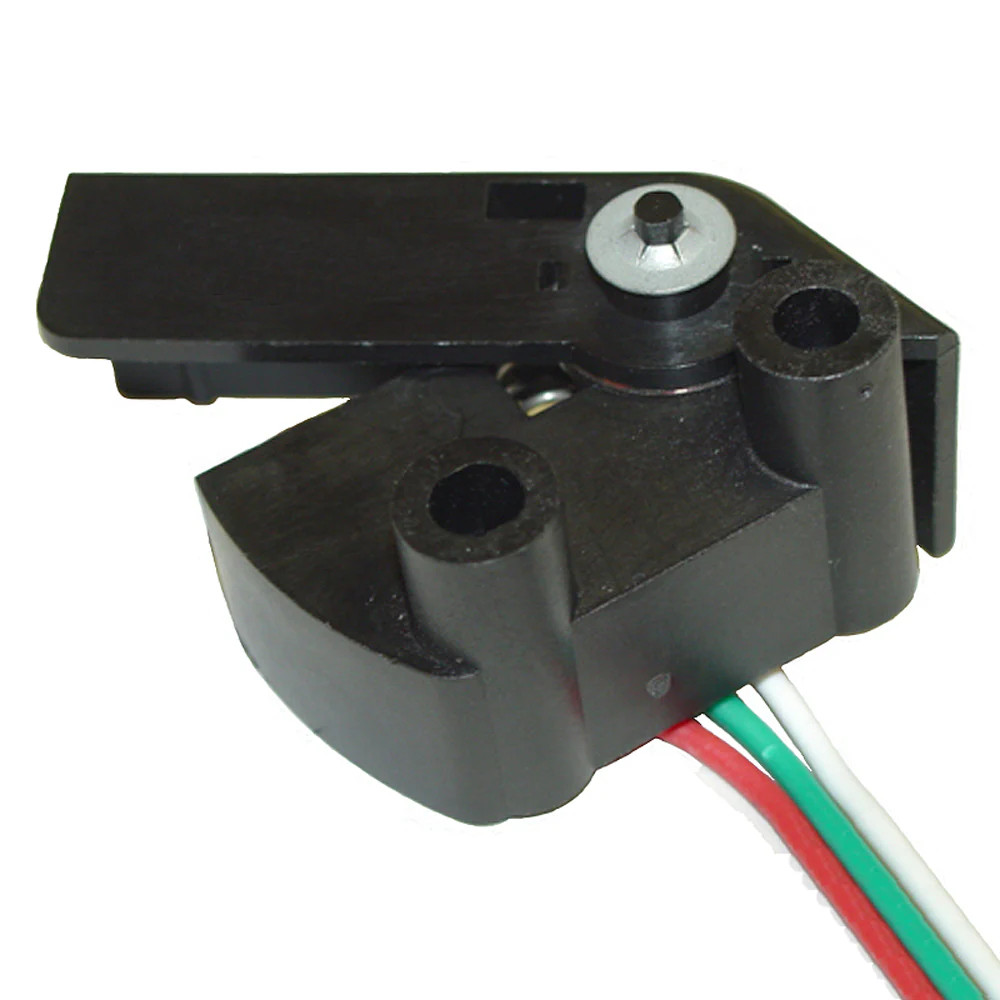

Parker's Analog Lever Distance Sensors are Hall Effect devices with an output voltage dependent upon the angular position of a lever arm. They utilize non-contacting technology and provide linear output over one inch (35 degrees) of travel.

Parker's True Ground Speed Sensor (TGSS) belongs to the family of accessories provided to complement electronic control systems. The TGSS determines true ground speed using Doppler beam technology and reports the information using a frequency signal.

Parker's SCP sensor family is a range of compact pressure sensors for mobile hydraulic applications. The sensors feature compact construction, high linearity and excellent electromagnetic interference resistance.

Parker's Rotary Controls are panel mount Hall Effect devices with an output voltage dependent upon the angular position of it's driver. They have non-contacting electronics and are offered in multiple angular ranges to fit most every application need.

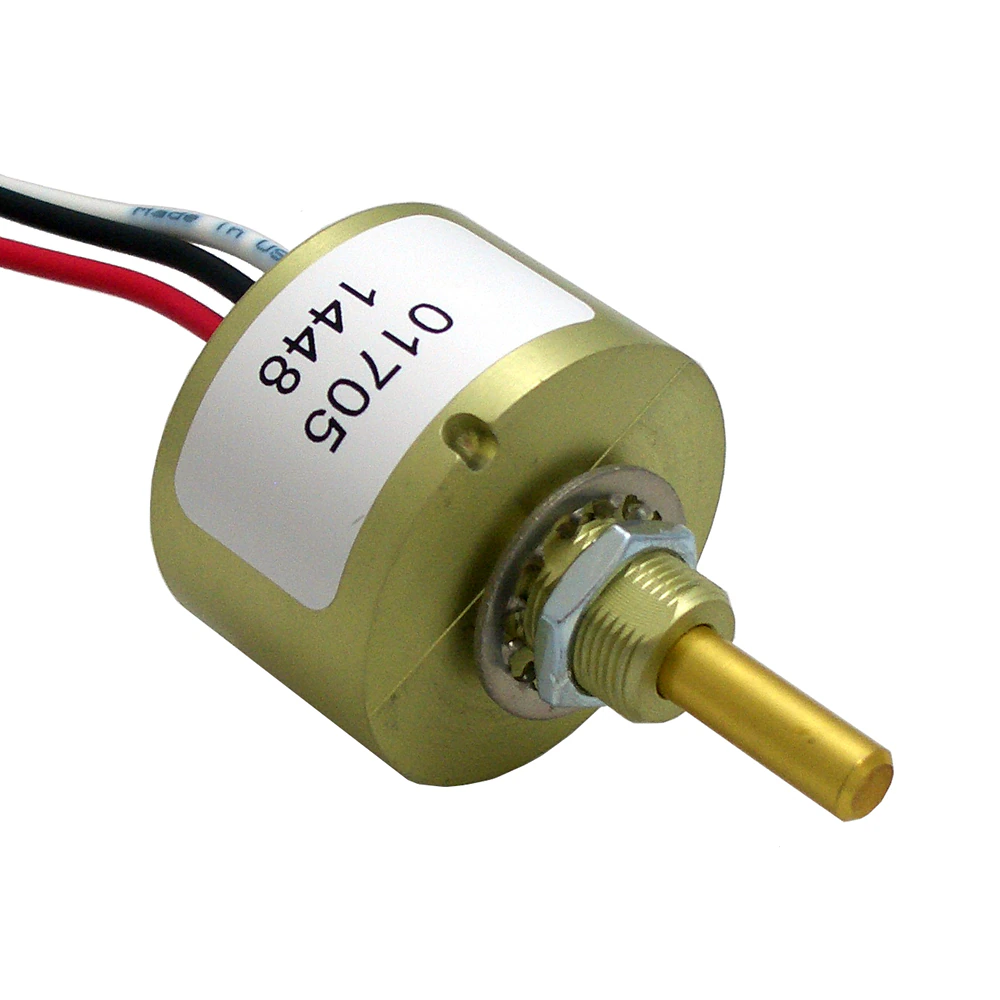

Parker's Rotary Position Sensors are Hall Effect devices with an output voltage dependent upon the angular position of the sensor. They utilize non-contacting technology and are offered in several linear ranges up to 360 degrees of rotation.

Parker's ATS Angle/Tilt Sensors are Hall Effect devices with an output dependent upon the angular movement in one or two horizontal planes. Offered in single or dual axis configurations, they are non-contacting and fit most every level application need.

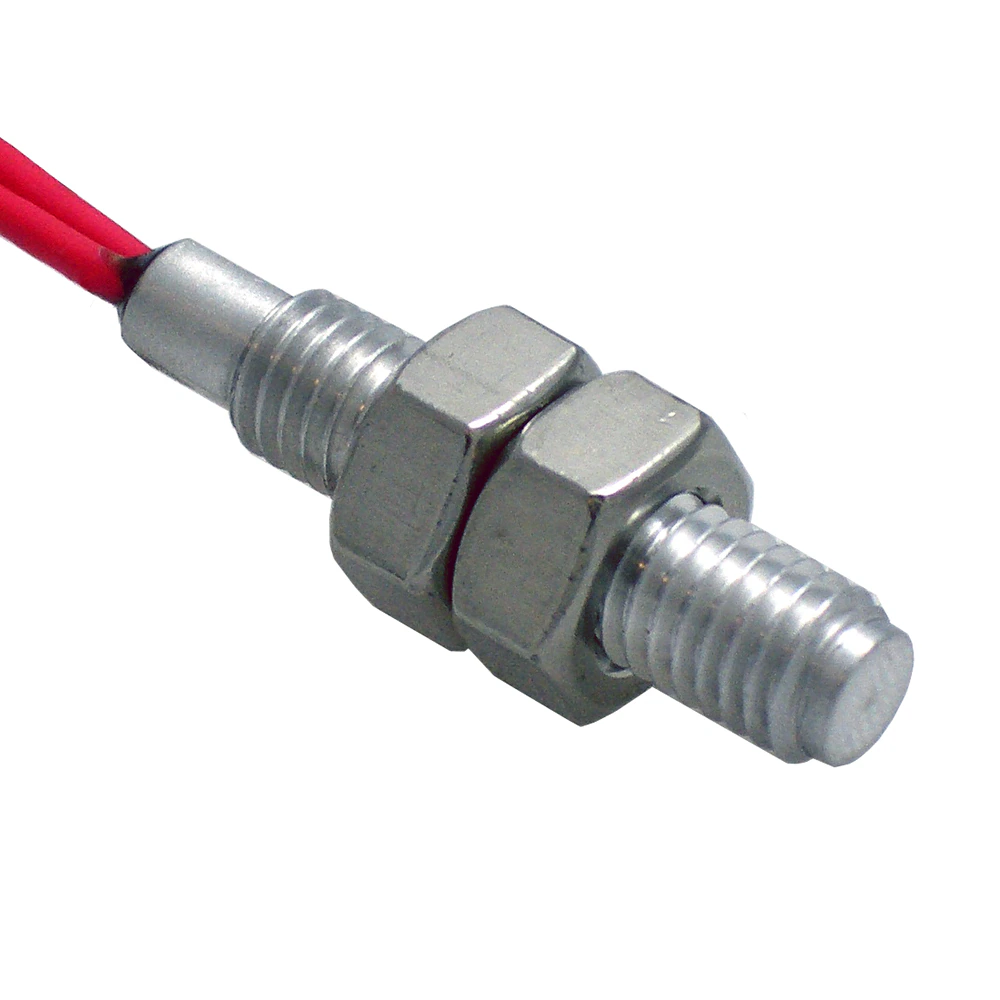

Parker's Proximity Sensors use non-contacting technology to detect the presence of a magnet target. Designed using reed switch technology and potted electronics, they are very robust and well suited for applications where large air gaps are required.

Parker's Ferrous Proximity Sensors use back-biased reed switch technology non-contacting technology to detect the presence of ferrous targets. Because they are non-contacting with no moving external components they are well suited for many applications.

Parker's GS Gear Speed Sensors provide a sinking output when detecting a ferrous target. They use back-biased, Hall Effect technology for zero speed sensing capability. Offered in multiple mounting configurations, they are immune to alignment issues.

Parker's RM50 tilt switches detect angular movement in a single axis. They are designed using reed switch technology and no moving external components making them very robust and well suited for applications where mercury (Hg) cannot be used.

Parker's LS60 is a solid state, dual axis, level sensor designed to limit the amount of tilt during normal operation. Custom X and Y trip angles can be created quickly with minimal expense to meet your applications specific needs.

Parker's UTS-ID Universal Tilt Sensor for Impact Detection communicates impact events and acceleration signals of impact magnitude and acceleration orientation information using SAE J1939 CAN bus protocol.

Parker’s UTS Universal Tilt Sensors with Gyroscope communicate angle of tilt, pitch, and roll information using SAE J1939 CAN bus protocol. They are engineered with MEMs devices for reliability and built to withstand rugged applications.

Parker’s UTS Universal Tilt Sensors communicate angle of tilt, pitch, and roll information using SAE J1939 CAN bus protocol. They are engineered with MEMs devices for reliability and built to withstand rugged applications.

Parker’s CDS-125 is a compact force sensor for ground-engaging machinery, sweeping and clamping applications engineered to withstand the most challenging work environments.