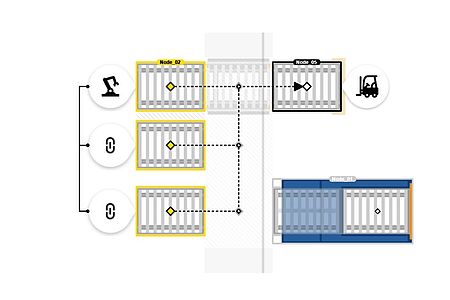

The innovative solution, based on disruptive concept, enables automation of pallet organization in the areas of production machines and order picking. It significantly increases productivity and safety in production environments; waiting times and downtimes make way for just-in-time delivery and intelligent buffering.

Try our easy-to-use online configuration tool! It allows system programming and interfacing with manufacturing machines. Concentrate on your application flow while the software handles the rest.

“With the SPM, Interroll enables automation where it has rarely been used before: upstream of production logistics. Waiting times and downtimes make way for just-in-time delivery and intelligent buffering. The Interroll Smart Pallet Mover significantly increases productivity and safety in production environments by automating in a completely new way.”

A battery-operated motorized unit is mounted on tracks underneath the conveyor rollers. It drives a robust chain belt that uses friction to move rollers and pallets on them weighing up to 800 kg. Safe operation is supported by 60 embedded cells installed in the mover.

The transfer, which runs on a floor-anchored guide rail—moves pallets between parallel conveyors. It has embeded cells to increase safety and runs with max. speed of 0.25 m/s.

Solutions include simple, modular, non-driven conveyor modules for standard pallet types like EUR/EPAL, skid plates, crates or containers. Easy-to-install modules are adjustable horizontally to balance existing floor conditions.

An easy-to-use online configuration tool allows system programming and interfacing with manufacturing machines. Concentrate on your application flow while the software handles the rest.