The 300 series is compact and powerful. Their planetary drive train makes them the ideal choice for all severe duty applications where shock loads and impacts are more the rule than the exception. The product configuration is highly versatile, due to several options for mounting, gear layout, output shaft and motor interface. All the features are available for each of the 20 finely spaced frame sizes, with a torque range of 1,000 to 1,100,000 Nm.

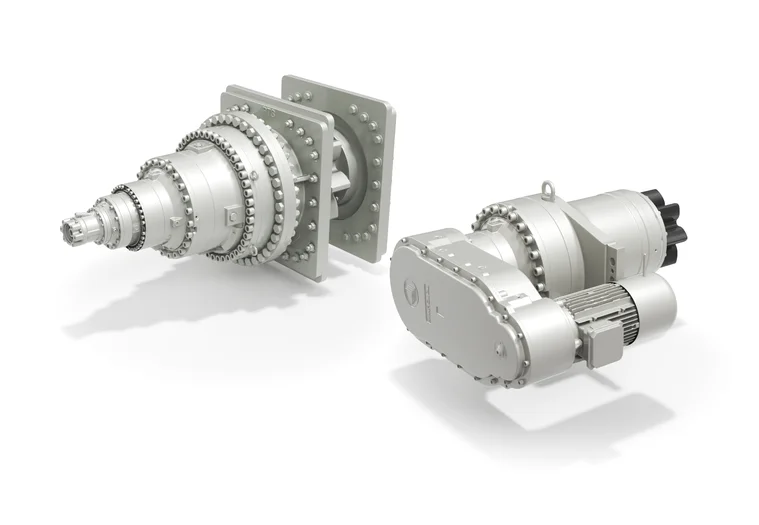

Dual stage planetary drive units with integrated pulley support, designed for cold planers, milling machines and surface mining machines with engine power from 80 to 1200kW and different rotor widths. The offset input option ensures higher machine productivity due to the increased cutting depth. The shiftable 2 speed solution allows two possible cutting speeds with huge benefits in terms of machine performance.

Dual-stage planetary drive units with integrated pulley support designed for cold planers and milling machines with engine power from 200 to 550 kW and rotor width from 1.0 to 2.5 m. The offset input option ensures higher machine productivity due to increased cutting depth. The unique integrated cooling system allows greater performance, easier system maintenance and optimal level of reliability.

With these planetary gearboxes, Bonfiglioli offers the opportunity for operating the rack to raise and lower the entire hull. The units can be in-line or with a bevel gearbox to facilitate installation of the motor. They can be operated electrically or hydraulically, with or without a negative parking brake. They can be complete with output, with integrated torque arm for easy installation on the machine and with integrated pinion shaft with 50 or 100 toothing module, and large capacity bearing.

The specific design of the O&K Jack-up Series has been assessed by ABS to work in lifting and lowering legs and hulls of drilling and service jack up rigs, lift boats and windmill installation vessels. Units can be in-line or have a drop box for offsetting the motor installation. They can be electrically or hydraulically driven, with or without a negative parking brake. These jack-up drives can deliver integrated pinions from m50 to m100 and lantern pieces with integrated torque arm for easy installation. Units have class approval from ABS and DNV GL, and full 3.2 certification of the load-bearing parts of the gear transmission with full traceability from raw material to final machined component.

With a reliable optimized design, the Bonfiglioli 700T Series for auger applications meets all feed mixer requirements. The different interfaces make this series very flexible. Two shafts for the in-line and multi-auger models are also two fundamental features.

The VF/W-EP Series is designed to meet the requirements of the food & beverage and pharma & chemical industries and, more generally, to ensure risk-free operation in harsh environments. This version of the gearmotor is manufactured with improved sealing, enhanced corrosion protection and paint suitable for accidental food contact as the standard option. All these features work together to meet the highest hygienic requirements and to greatly increase gearmotor cleanability and operating lifetime in harsh and humid environments.

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers' needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers’ needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers’ needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

Some industrial environments are characterized by the presence of explosive atmospheres and thus require additional safety measures. Industrial equipment operating in such conditions must be specifically designed to prevent ignition of the flammable substances present in the atmosphere. To meet our customers’ needs, Bonfiglioli has developed an entire line of gearboxes that can be safely used in explosive environments in accordance with ATEX Directive 201/34/EU. If the ATEX version is selected, gearboxes of VF/W, ACF, HD and 300M Series will be manufactured for the utilization in zones 2G/2D and 3G/3D.

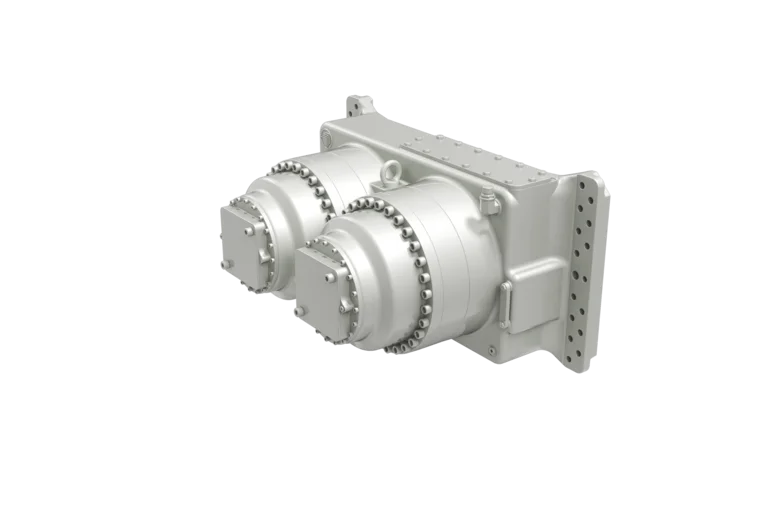

The FTU Series are perfectly suited to tunnel boring machines and large mining equipment. Robust, powerful and durable these drives are matching all the requirements of this specific application.

This product is dedicated to the extruder market and provides high customization of output and gear ratio combinations to fulfill our customers' needs. This gear unit provides a robust nodular cast iron gear case suitable for high loads and specific heavy duty thrust bearing sourced exclusively from primary brands. This solution also allows easy machine integration thanks to a universal mounting gearbox case (customized screw interface can be provided too) and can come with an auxiliary thermal aid device (cooling coil, oil to water heat exchanger), and oil temperature and level sensors to easily monitor its functioning.

The R3 Series is compact and powerful. Their planetary gear train makes them the ideal choice for all heavy-duty applications where shock loads and impacts are more the rule than the exception. The product configuration is highly flexible, thanks to several mounting, synchro gear layout, output shaft and motor interface options. According to the torque need and customer machine layout, the R3 Series can be equipped with 1, 2 or 4 hydraulic motor adapters; an electric motor adapter is also available upon request.