Control cabinet controllers

The controllers can be used both for challenging motion control tasks under any market-standard control system or as independent higher-level controllers for automation or even cyber-physical control.

The control technology is based on a common platform for control cabinet and decentralized controllers with the same functionalities and identical interface diversity.

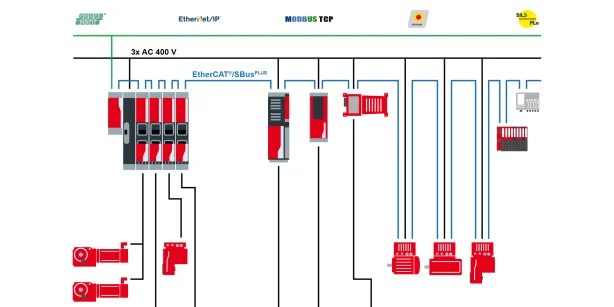

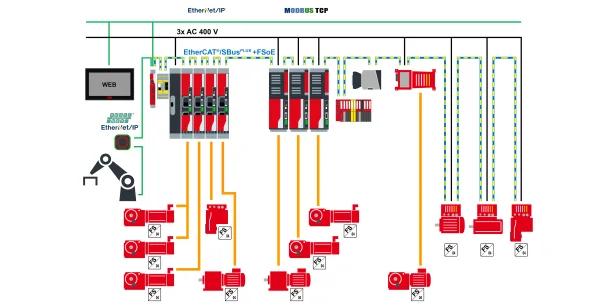

Whether they are used for motion control, automation control or cyber-physical control tasks, MOVI-C® CONTROLLER units can be linked to the higher-level controller of a machine cell or system using classic fieldbus slave interfaces for the PROFINET, PROFIBUS, EtherNet/IPTM or Modbus TCP fieldbus systems.

Alternatively, they can be used as independent controllers for machines or systems, in which case they take care of smooth communication via EtherCAT®/SBusPLUS with the subordinate devices – e.g. MOVIDRIVE® application inverters – and their synchronous connection to the movement/application.

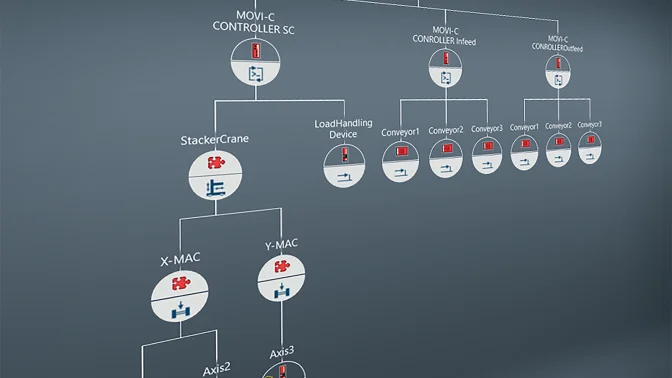

The performance class of a MOVI-C® CONTROLLER depends on the number of inverters and the number of synchronous axes and auxiliary axes required and to be configured for the movement. Four performance classes for up to 32/32, 16/16, 8/8 or 2/6 axes are available. All versions have a compact design, meaning they can fit into even small machine control cabinets.

The decisive added value for reducing complexity is provided by the integrated software of the central and decentralized controllers: parameterizing instead of programming. For you as a user, this software means more scope for parameterization and less programming effort.

Our control technology and software also give you the option of writing your own programs. Would you prefer to create your own bespoke programs for your application, such as PLC functions or specific rules, so you can stand out from your competitors? If so, then our software platform has exactly what you need.

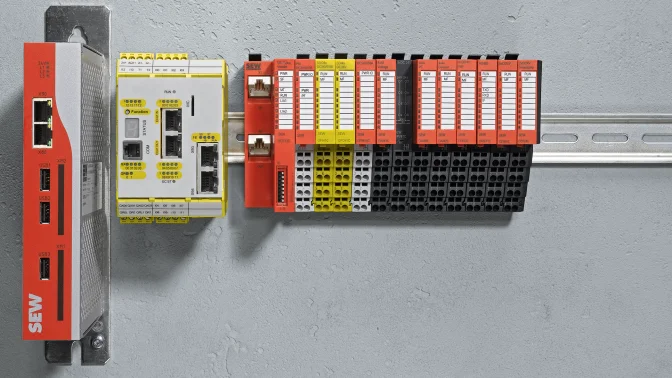

SEW-EURODRIVE is continuously expanding the control technology in the MOVI-C® modular automation system with new hardware. The new components, perfectly matched to the existing MOVI-C® family, offer new, exciting options for implementing simple to complex systems.

The controllers can be used both for challenging motion control tasks under any market-standard control system or as independent higher-level controllers for automation or even cyber-physical control.

In addition to drives with the MOVI‑C® FIELD CONTROLLER, we also offer motion controllers for customized applications. The high degree of protection allows flexible use in the field.

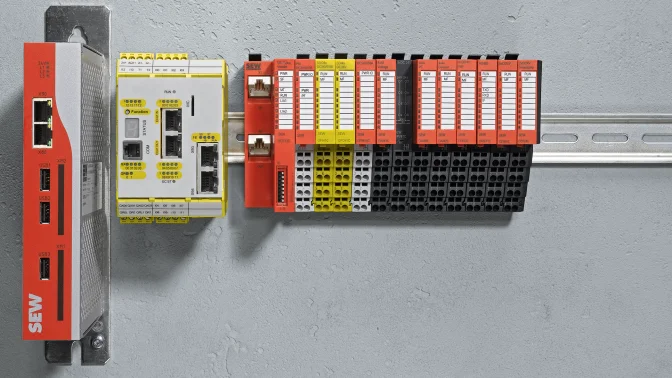

MOVI-PLC® I/O modules offer a high bus transfer rate and, in combination with the MOVI-C® CONTROLLER portfolio, allow ideal interaction with external sensors and other peripheral devices.

MOVI-C® means motion control without headaches. The MOVI-C® controllers with software modules MOVIKIT® ensure the movement of the various handling units or production machines. For engineering and startup of your application, the MOVI-C® modular automation system also offers the right software solution with MOVISUITE®. Always with the aim of reducing your time and programming efforts.

MOVISUITE® enables you to start up and diagnose the drive train easily and quickly – from the inverter to the controller.

The MOVIRUN® software platform on the MOVI-C® CONTROLLER or MOVI-C® FIELD CONTROLLER handles the coordination of the axes and the execution of the software modules MOVIKIT®.

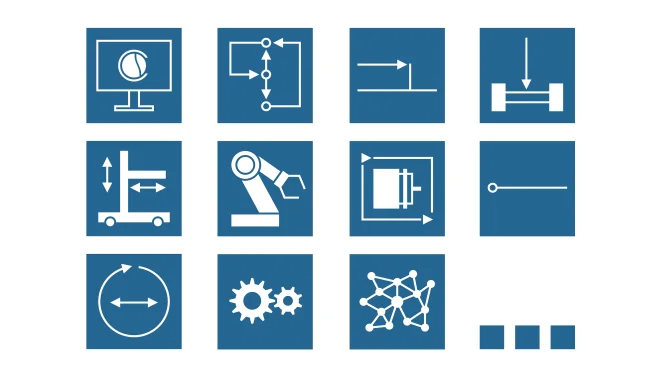

The range of ready-made MOVIKIT® software modules extends from simple drive functions to sophisticated motion control and robotics functions. Simply parameterize and off you go.

The CONTROLLERs from the MOVI-C® modular automation system can solve a range of tasks with ease. A variety of options are available for integrating them into the system topology, depending on requirements or application.

Find out more.

To help you maintain an overview of sophisticated drive tasks with a large number of axes, we offer you a three-part modular visualization system that covers every conceivable requirement.

MOVI-PLC® I/O modules offer a high bus transfer rate and, in combination with the MOVI-C® CONTROLLER portfolio, allow ideal interaction with external sensors and other peripheral devices.