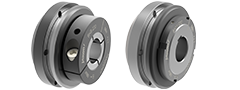

Safety couplings for indirect drives PDF General

Properties: parallel drive via toothed wheel or toothed belt

For overload limitation or collision protection for indirect drives, JAKOB offers a comprehensive standard range of series with integrated ball bearings or plain bearings.

Toothed belt sheaths, gear wheels, flanges or other attachments can be attached to the respective coupling flange rings with a concentricity or plane accuracy of a few hundredths of a millimeter.

Safety couplings for direct drives PDF General

Properties: coaxial drive » shaft — shaft

The safety couplings for direct drives are a combination of the JAKOB release mechanism, which has been tried and tested and optimized for decades, with a coupling element to compensate for misalignments between the input and output shaft.

Various versions with metal bellows or elastomer couplings can be selected from an extensive range.

JAKOB offers other series with the following properties.

• with release mechanism

• with tandem bearing for greater bearing width

• rustproof or stainless steel variant

• special locking or release functions (e.g. backstop)

• hub design and dimensions according to customer specifications

• on request!

or torque limiters from JAKOB Antriebstechnik effectively protect your drive from costly overload damage in the event of a collision. They are the result of decades of experience with countless applications that are covered by the proven JAKOB modular system. Our safety couplings are mainly used in demanding drives in mechanical engineering, from protecting highly dynamic servo axes in machine tools to overload protection for conveyor systems.

Safety couplings from JAKOB Antriebstechnik are available both for indirect drives (connection, for example, via belt pulley or gears) and for direct drives (connection using a combination of safety part and tried-and-tested JAKOB servo coupling). Torque limiters for direct drives combine the reliable release behavior of the safety part with the specific advantages of metal bellows (torsional rigidity, all-metal design, high operating temperatures) or elastomer couplings (vibration-damping, pluggable, isolating, up to 120°C)

At the same time, they ensure backlash-free, precise torque transmission with minimal moments of inertia. Depending on the application, different series are possible. Potential users of our couplings should therefore not hesitate to take advantage of our technical advice.

The user can freely set the torque at which the torque limiter disengages and thus interrupts the drive train without delay in the setting range of the respective size and series. The safety clutch slips with low residual torque until the cause of the collision or overload has been eliminated and then engages again automatically. The status query can be implemented using a proximity switch.

Depending on the application, you can also choose between different working safety parts. In applications with high operating speeds (e.g. test benches) or long run-on times (immediate stop not possible), it may be necessary to replace the re-engagement mechanism with a release mechanism. In this case, the clutch does not re-engage automatically, but must be re-engaged manually. JAKOB offers different solutions for this.

In working environments in which heavy soiling plays a role, the SKB, SKY, SKX-L or SKW series should be used, since the locking mechanism is protected by a labyrinth seal against the ingress of dirt particles and the washing out of the lubricants. For high speeds, on the other hand, couplings from the SKY series are best suited.