Metal bellows couplings

Metal bellows couplings are highly flexible all-metal couplings with high torsional rigidity and minimal mass moments of inertia.

Cone and clamp connections are available, as well as various metal bellows shapes for a wide variety of applications.

Properties of the metal bellows couplings:

• Torques up to 50,000 Nm

• High torsional rigidity

• Temperatures up to 350°C

• High speeds

• Optional stainless steel version

Elastomer couplings – claw couplings

Elastomer couplings are pluggable, backlash-free, flexible shaft couplings for small to medium torques.

A plastic star with a high Shore hardness serves as a connecting and compensating element. The elastic star

of the elastomer coupling can compensate for minor shaft misalignments, is electrically isolating and exhibits

good vibration-damping properties.

Properties of the elastomer couplings:

• Torques up to 2,000 Nm

• Vibration-damping

• Pluggable (blind assembly possible)

• Temperatures up to 120° C

• Economical

Miniature Couplings

Miniature couplings are servo-flexible couplings designed for misalignment or axial displacement of two shafts

. Miniature couplings are available as bellows, elastomer or cross slide and

universal joint couplings in the torque range up to around 20 Nm. Miniature couplings

are used in particular for tachometers, NC axes, stepper motors, potentiometers, robot drives,

linear units, handling equipment, angle encoders or servo drives.

Properties of the miniature couplings:

• vibration-damping (with elastomer star)

• high temperatures (with metal bellows)

• large shaft misalignment possible (cross-slide coupling)

• blind assembly (with elastomer star)

• low cost version

PDF General

PDF Installation and assembly

Spacer couplings – cardan

shafts Spacer couplings, also known as intermediate axles or cardan shafts, are servo couplings for large

center distances without complex intermediate storage. The common design feature of the

spacer couplings, intermediate axles or cardan shafts is an intermediate tube that is variable in length, which

can be optimally adapted to the customer-specific application.

Properties of the spacer couplings:

• variable overall length up to 6m

• high torsional rigidity

• low moments of inertia

• high speeds

• temperatures up to 300° C

• low cost version

Stainless steel couplings

JAKOB Antriebstechnik offers some series in stainless steel versions. One of the strengths of the material is its resistance to chemicals, such as those used for cleaning in the food industry.

JAKOB Antriebstechnik has been offering solutions for everything to do with drives in machine tool construction for over 40 years.

Servo couplings (or shaft couplings) are a part of our range that also marks the origin of JAKOB Antriebstechnik. Couplings of this type of product transmit torque backlash-free and at the correct angle from the input to the output shaft and, depending on the design, also function as compensating couplings that can compensate for significant shaft misalignment. In addition, our servo couplings are characterized by the highest possible torsional rigidity and minimal mass moments of inertia. The high balancing quality makes excellent operating behavior possible even at high speeds.

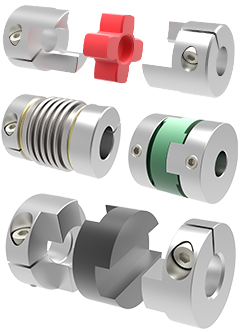

The servo coupling product area consists of four core areas: metal bellows couplings, elastomer couplings (claw couplings), miniature couplings and spacer couplings.

JAKOB Antriebstechnik was originally able to make a name for itself with metal bellows couplings and can be considered the original. More than forty years ago, Ludwig Jakob developed the flanged press-in process for connecting metal bellows and hub, which is now the industry standard. Metal bellows couplings offer maximum torsional rigidity and at the same time are wear-free in applications up to 350°C. The ability to compensate for shaft misalignments depends on the design and shape of the metal bellows that acts as a compensation element. Various force-locking clamp and conical hub connections are available for connection to the input and output shaft, but a customer-specific flange connection can also be implemented in many cases.

Elastomer couplings or claw couplings offer particularly convenient and easy handling during assembly thanks to their pluggability. At the same time, the elastomer stars used have a vibration-damping and electrically insulating effect, although their material properties only allow use up to a maximum of 120°C, sometimes with reduced operating parameters. They are therefore a cost-effective alternative for applications with low to medium torques and are still able to compensate for minor shaft misalignments.

JAKOB Antriebstechnik offers miniature couplings in a wide variety of designs for the smallest drives, which, however, largely correspond to their larger relatives, the metal bellows and elastomer couplings. In addition to the two well-known variants, JAKOB Antriebstechnik also offers miniature couplings with cross slide parts as compensating elements, which can compensate for particularly large radial shaft misalignments.

The range of servo couplings is rounded off by spacer couplings or cardan shafts, which can transmit torque over distances of up to six meters without having to resort to intermediate supports. Couplings from this range are available both as elastomer and as metal bellows couplings. For particularly demanding applications with high speeds, we offer the variable-length intermediate tube made of CFRP. Manufactured in a half-shell design, spacer couplings from JAKOB Antriebstechnik can usually be installed by a single person.