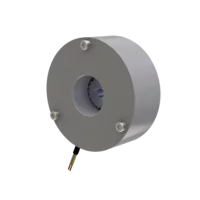

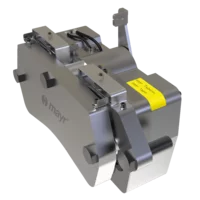

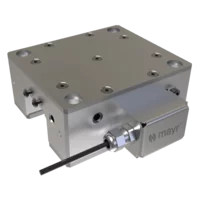

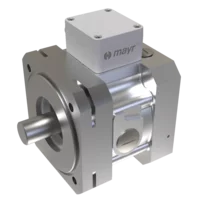

Brakes from mayr® power transmission are used in many applications. We distinguish between two product families:

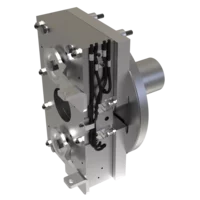

- Spring-applied safety brakes. They operate according to the fail-safe principle and are closed (brake on) in the de-energised state. Spring-applied brakes are primarily designed as holding brakes but are also suitable for emergency stops and, depending on the design, can also be used for dynamic braking.

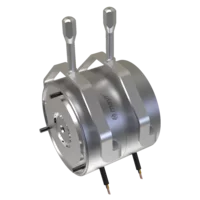

- Energise to Engage brakes. These apply torque when the brake is powered and are open (brake off) when the current is switched off. They are not classed as safety brakes. The electromagnetic brakes are particularly suitable for precise positioning and reliable stopping up to their wear limit.