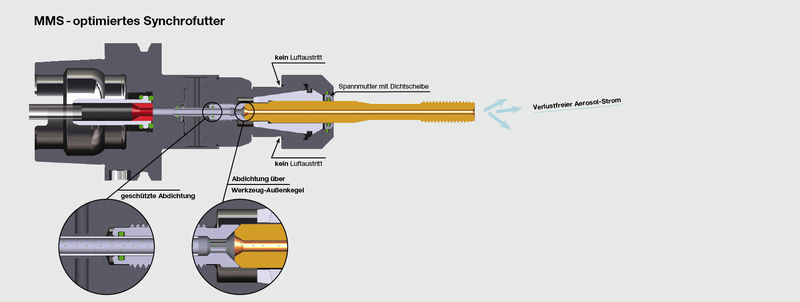

Only the smallest amounts of lubrication are used in connection with MQL clamping tools – the application revolves around correct delivery of coolant to the cutting edge without any drop in pressure. The MQL compliant clamping tool plays a decisive role as part of the MQL delivery system.

a) Optimised leak-proofing for a leak-free aerosol stream with no fine mist of aerosol droplets, no build up of moisture in the clamping chuck

b) Lubrication delivery from the very first moment for a flawless aerosol flow without any drop in pressure to the cutting edge

The new MQL generation from Bilz fully meets these requirements.

Optimised leak-proofing of our synchro chucks is unique on the market so far and a patent was applied for in January 2010.

Combined solution MQL, IC + without coolant – one chuck is sufficient

Combined solution MQL, IC + without coolant – one chuck is sufficient Independent of cooling and lubricant type, the newSCK is suitable for:

• MQL 1-channel/ – 2-channel (optionally)

• IC up to 50 bar coolant pressure

• dry processing

• machines with manual and automatic tool changing

Combined solution two-way length compensation – literally one move

Independently of the collet, the length compensation can now be effected either from the collet side or from the holder side – one move instead of time consuming readjustment

Compact deisgn – even more security

Tool life increases up to 100% because of constantly high quality cutting performance, process security and an easy handling:

• high idle running speed up to 15.000 min-1

• compact construction

• dimensionally stable and very resistant elastomere

• minimal length compensation (pressure/retraction +/- 0,15 mm)

Download

Download