Application: general mechanical Engineering, Medical- and Dental Technology, Mold and Die, Renewable Energy

M stands for Constant Maximum Clamping Forces.

Due to the consistant maximum overlap of tool and chuck, the design ensures constant hight clamping forces. The sleeve is also available with pullout protection (Weldon).

M stands for added value.

For the first time, TMG clamps tool shanks of almost any diameter with one and the same shrink chuck. In this way, the entire production requirement can be covered cost-effectively. The flexibility of basic holders can be used to cover the entire production requirement.For the first time, TMG clamps tool shanks of almost any diameter with one and the same shrink chuck. In this way, the entire production requirement can be covered cost-effectively. The flexibility of basic holders can be used to cover the entire production requirement.

The new Bilz TMG clamping system combines the strengths of shrink clamping technology

with the flexibility of collet solutions. The system consists of basic holders and specially coated collets.

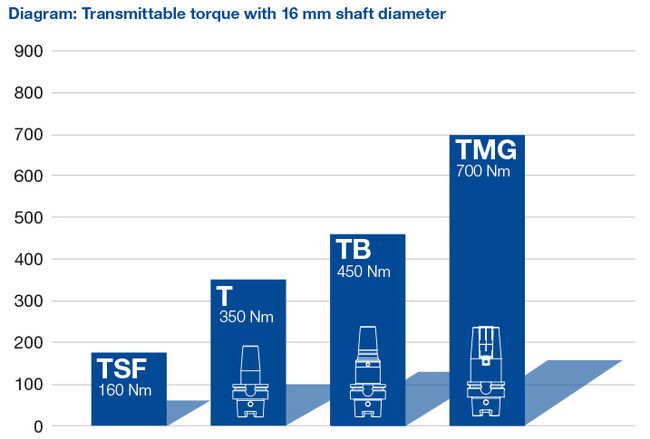

Shank tools from 2 to 32 mm can be clamped with previously unattained clamping forces. For example,

more than 850 Nm for a 20 mm tool shank. This is done in a fully automatic or manual patent-pending

process on induction shrink fit machines.

Download

Download