Application: Automotive, general Mechanical Engineering, Renewable

Machine type: machining centres, CNC-turning and special purpose machines with synchronized feed

for the tapping operation

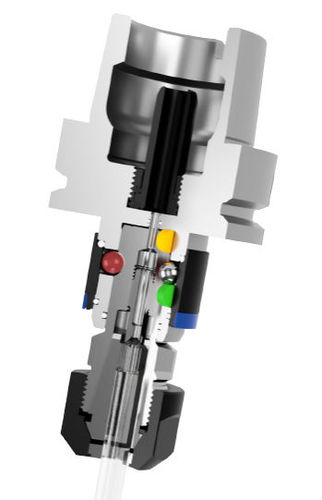

Tool presetting via axial adjustment screw possible from both sides

(screw is not included in the scope of delivery)

You can use our 3D-Synchro chuck as a collet chuck

for driven tool holders as well as for direct clamping

in machine spindles.

The elastomers used are dimensionally stable and resistant to all

coolants/lubricants. Due to the defi ned length compensation,

plastic deformation of the damping elements is excluded.

This results in consistent cutting behavior over the entire life of the tool.

| Print direction Steaming at the gate |

| Direction of rotation Damping during chip breaking |

| Direction of pull Compensatesthe synchronization errors |

The latest generation S3D- Synchro chuck has been adapted to the current market requirements.

Tool presetting is possible from the machine side and the tool side, the lubricant feed-through

has been optimized, thus ensuring a leakage-free transfer to the tap.

The length compensation on compression and tension (e.g. +/- 0.5 mm), as well as the damping

in the direction of rotation compensate for the smallest synchronization errors and position deviations.

This reduces the pressure on the on the thread fl anks of the tool is reduced and the required cutting torque is minimized.

Download

Download