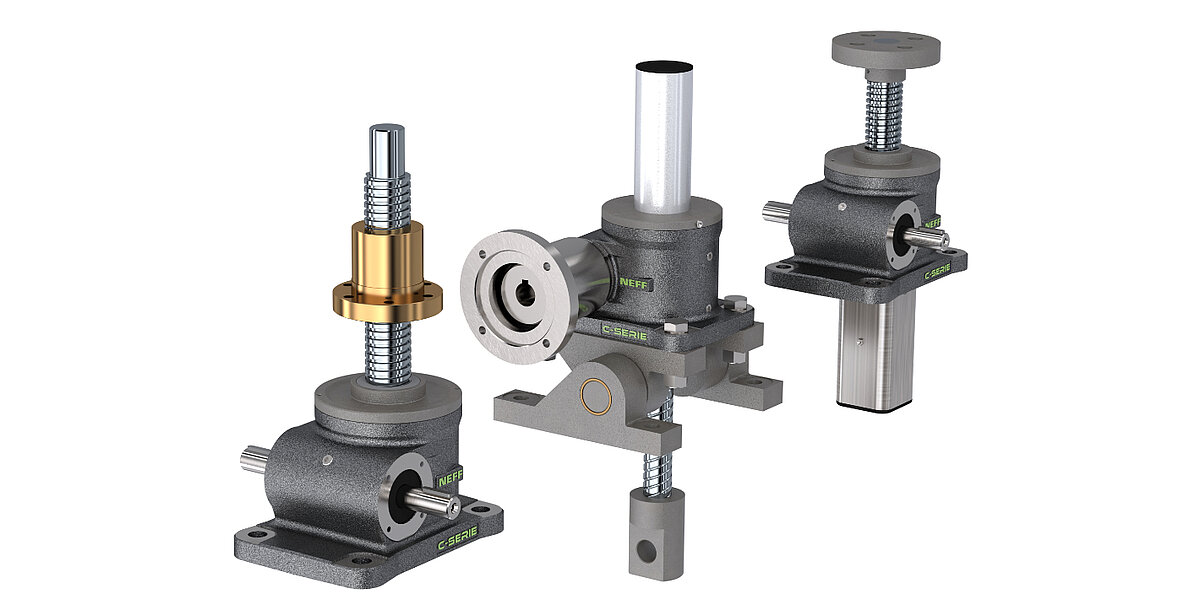

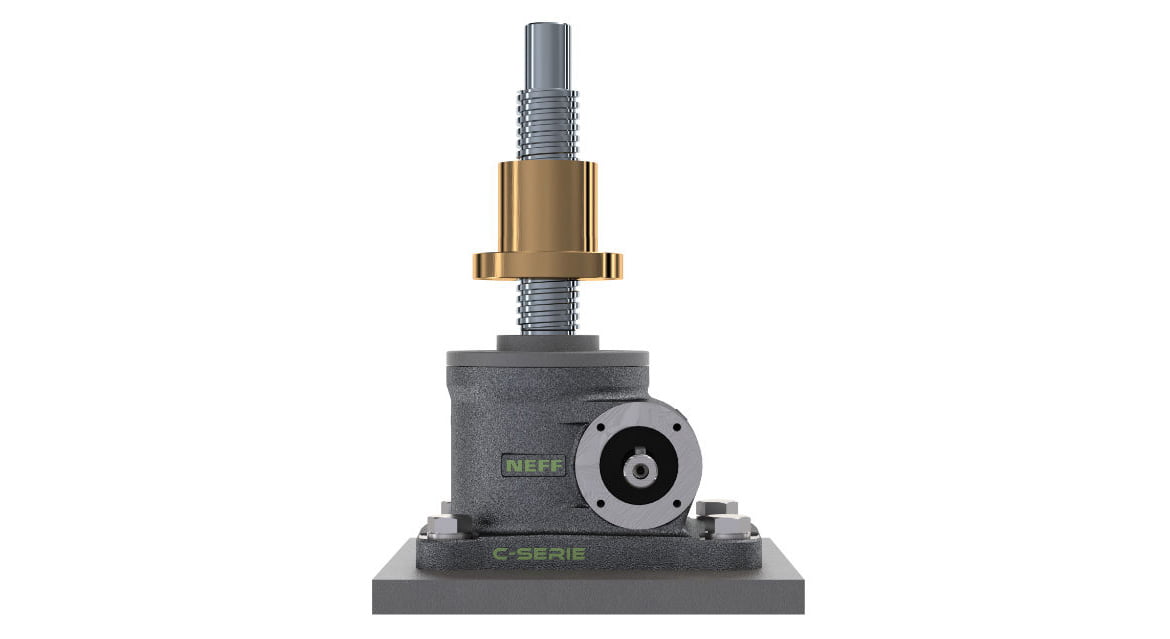

The C-Series Screw Jacks in R-Version is characterized by a rotation screw drive with lead nut. Through the rotating screw and the lead nut fixed with the technical environment a lift drive is affected. The Screw drive is axial fixed and moves not through the gear housing. In case of this the C-Series Screw Jacks can be assembled direct on the bases without take consideration for any installation space for the protective tube. The R-Version covers the advantage that there is lower heat development in the gear housing. That leads to higher duty cycle time at the same conditions. The C-Series Screw Jacks are available with trapezoidal and ball screw drives with different pitches and several lead nuts.

The Screw Jacks of the C-Series in Version N are characterized by a heaving screw. These screws are available with trapezoidal and ball screw drives as well. In both cases the nut of the Screw drive will be integrated in the gear housing. Through the fix assembly of the screw end with the environmental construction the lifting drive is affected. The advantage of the N-Version is that minimal construction space is needed. On the opposite side of the gear housing a protection tube for the incoming screw is assembled. A further advantage of the N-version is that in applications with long strokes the nonrotating screw leads to no oscillation.

The C-Series Screw Jacks of in VK-Version are caracterised by a anti twist device assembled in the square type protection tube. These VK-Version is used when the screw end cannot be assembled with the technical environment and secured against rotation.