NEFF high-speed gearboxes supplement the range of screw jacks for extended applications with greater dynamics. Its application range is in the middle load range (12.3 kN – 117 kN). High-speed gearboxes have hardened and ground, spiral-toothed bevel gear ratios. You achieve high lifting speeds while improving efficiency.

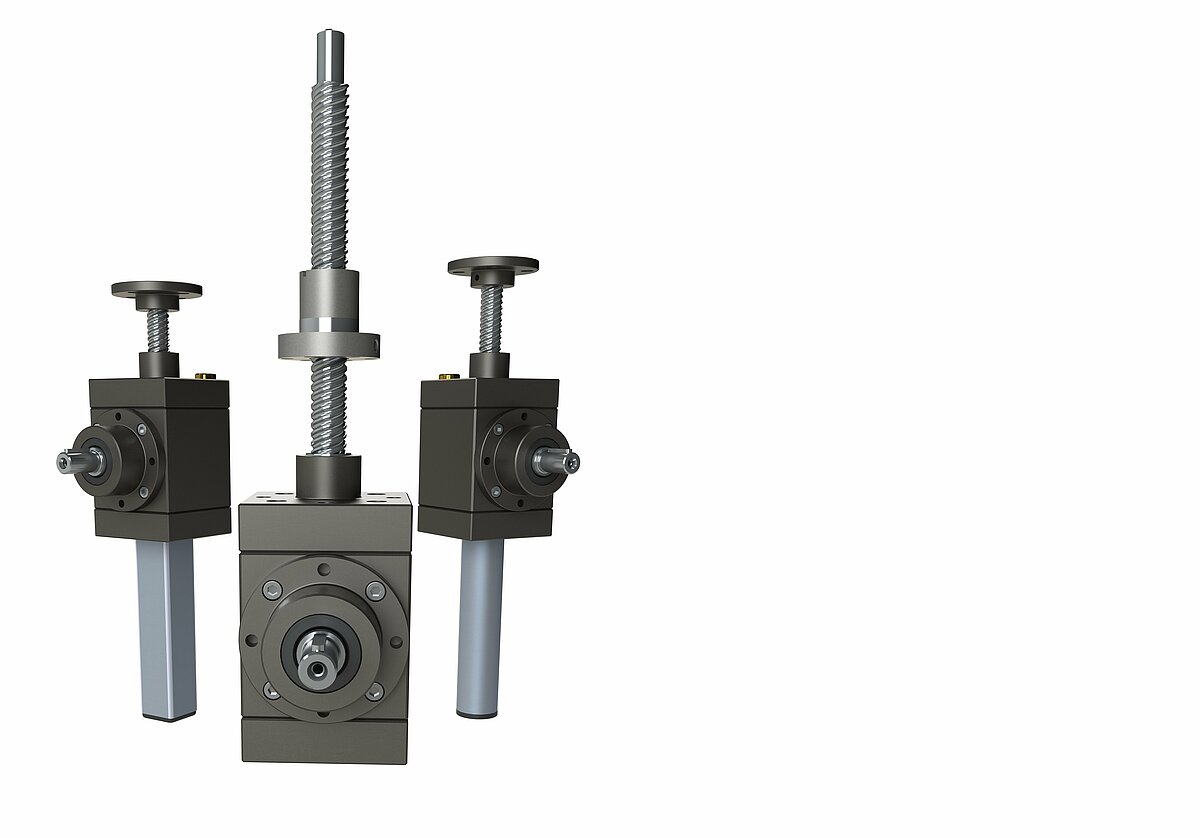

The three sizes G1, G2 and G3 are available both as N-version with stationary, continuous spindle, as V-version protected against twisting and as R-version with rotating spindle. The 2: 1 and 3: 1 gear ratios in conjunction with high pitch ball screw spindles enable high dynamic drive solutions.

With ball screw spindles, high speed screw jacks achieve even better performance. All high speed screw jacks are functional in any position and can be mounted on all sides thanks to the cubic design. Depending on the application, the gear units are supplied with up to four drive shafts, so that additional bevel gear drives may be omitted. All high speed screw jacks are filled with oil at the factory.

Type R is characterised by the rotating threaded spindle with travelling nut. This means that the stroke movement is carried out with the travelling nut, the jack screw remains fixed in its axial position. This means that type R worm gear screw jacks can be mounted directly on the base without requiring any installation space opposite the spindle side. The advantage of this is that the screw drive is always located outside the gear housing. The resulting lower heat generation in the housing allows a higher duty cycle under the same operating conditions. R-type quick-lift gearboxes are available with trapezoidal or ball screw drive and various nut applications.

N type quick-lift gearboxes are characterised by the lifting spindle. Like all NEFF high speed screw jacks, the type N of the M/J series is available with both trapezoidal screw and ball screw. This means that the nut thread of the screw drive is located in the centre of the caliper wheel. Provided that the nut is fixed in such a way that it cannot rotate, the threaded spindle performs a stroke movement. Simplified description: The non-rotating threaded spindle moves through the gear housing. On the load side, type N quick-lift gearboxes can be adapted with a small space requirement. On the opposite side, installation space is required for the threaded spindle retracting into a protective tube. One of the advantages of this design is that vibrations which could occur due to rotating spindles during long strokes are excluded.

In accordance with type N, the threaded spindle of type VK is guided through the gear housing with a threaded nut implemented in the hollow shaft. However, the anti-rotation feature is provided by the integration of a linear guide in the square protection tube.This type is used, for example, when the threaded spindle cannot be fixed against twisting due to the situation.