Our High Performance Worm Gear Screw Jacks of the MH- and JH-Series are convincing of an optimized worm gear associated with a higher efficiency and longer duty cycles.

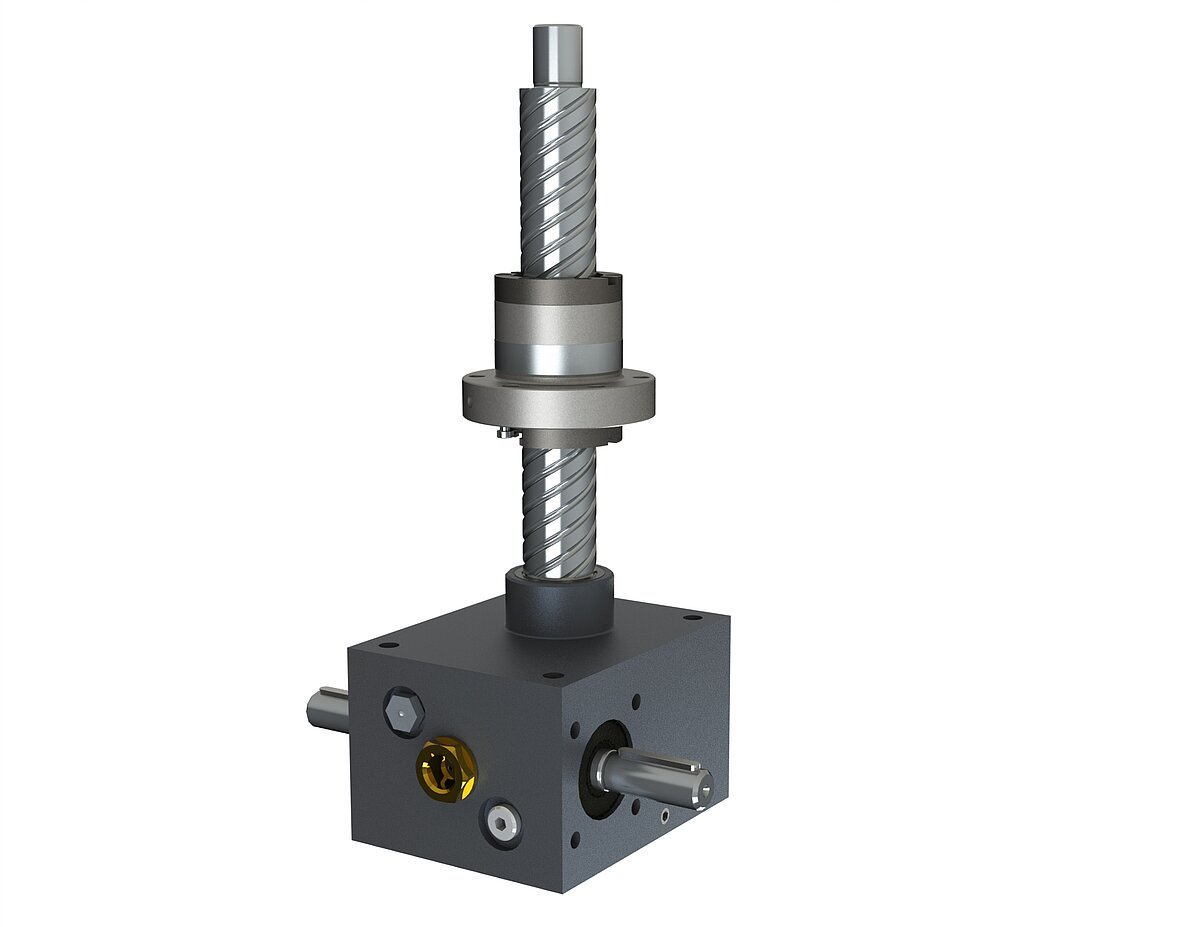

By separating the gear lubrication from the spindle lubrication the MH- and JH-Serie can be run with an input-speed up to 3000 1/ min. The case-hardened and grounded worm gear guarantees maximum drive torques and fatigue fracture strength.

Type R is characterized by a rotating spindle with travelling nut. This means: the lifting motion is performed by the travelling nut, the lifting spindle remains fixed in its axial position. Thereby worm gear screw jacks type R can be mounted right on the base, without extra implementing space needed. It´s also an advantage that the screw jack is always located outside the gearbox housing. Therefore, less heat development in the housing allows longer duties in the same conditions. Worm gear screw jacks type R are available with either trapezoidal screw drives or ball screw drives with various nut-applications.

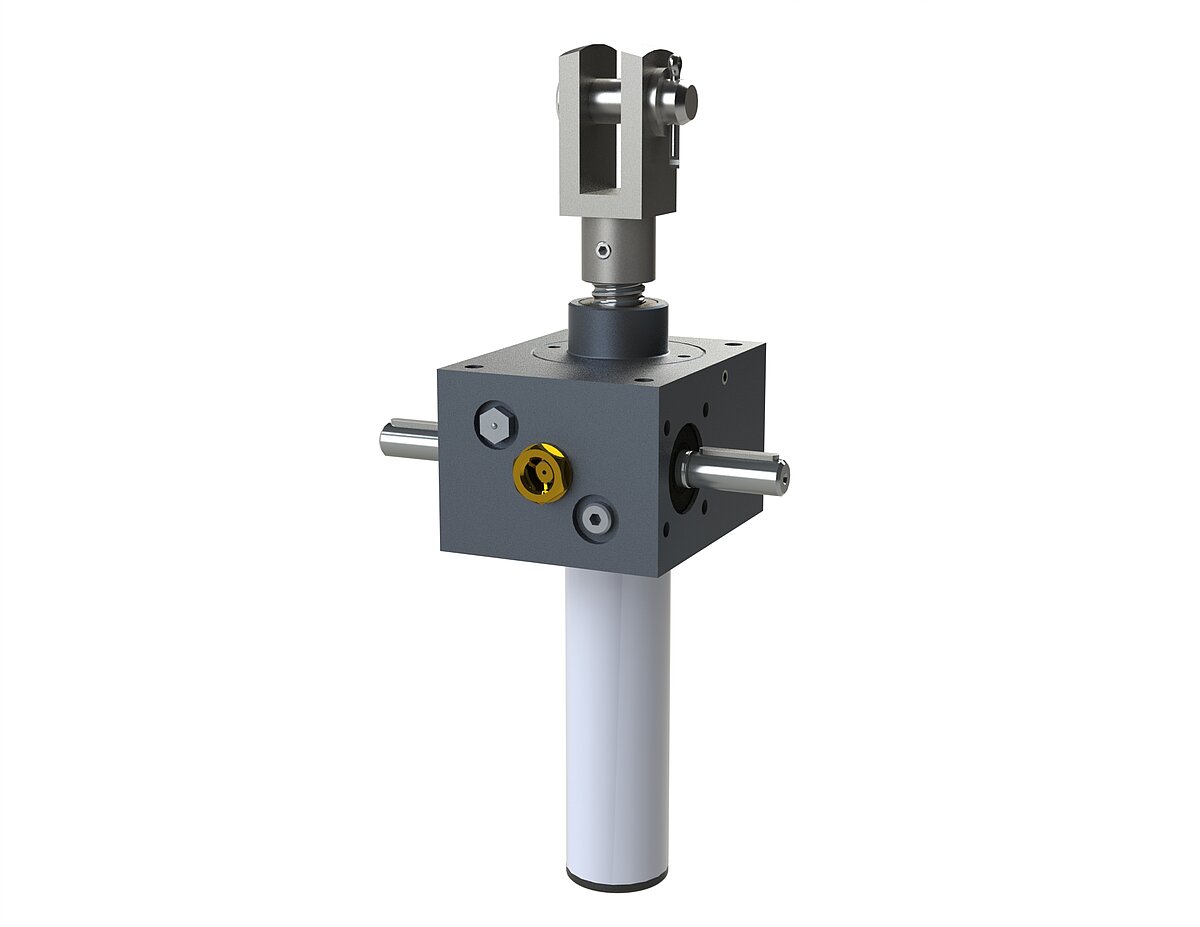

The N-Type worm gear screw jacks are characterized by the lifting spindle. Like all other NEFF-ball screws, Type N of the M-J series is available with trapezoidal ball screws as well as with ball screw drives. That is, the nut thread of the ball screw is in the center of the worm gear. Protected against twisting, the spindle is executing the lifting movement: the not rotating spindle moves right through the gearbox housing. On the side of the load, worm gear screw jacks type N can be mounted with little required space. On the opposite side, installation space is required for the threaded spindle entering a protective tube. One advantage of this type: vibrations, which might be triggered by the rotation spindle and long lifts, are impossible.

Corresponding to Type N, the ball screw with the nut thread implemented in the worm gear is lead through the gearbox housing. Protection against twisting is achieved by linear bearing in a square protective tube on the gear side. Application for example, if due to the situation, the ball screw cannot be fixed against rotation.