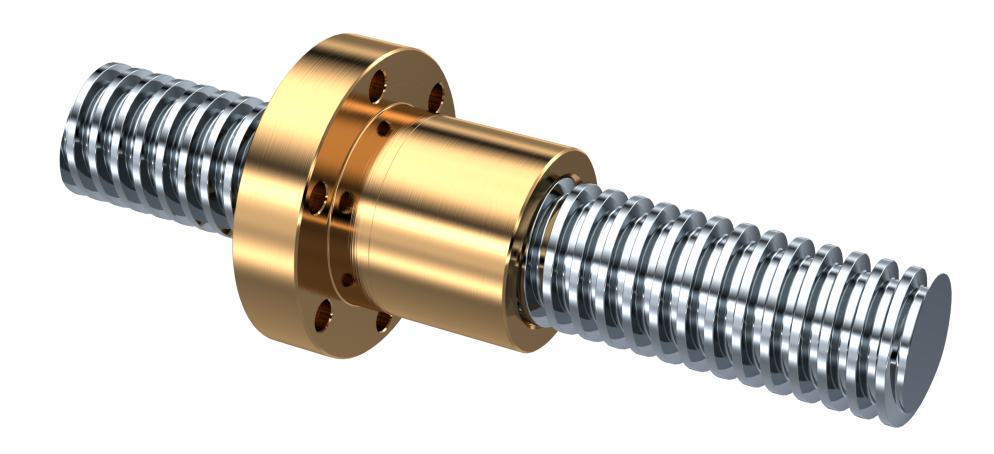

![[Translate to EN:] Trapezgewindespindel TGS [Translate to EN:] gerollte Trapezgewindelspindel TGS](https://www.neff-ballscrews.com/fileadmin/_processed_/5/a/csm_Trapezgewindespindel-TGS-32x6_400x400_da64442f3d.png)

NEFF´s rolled trapezoidal threads are available from stock in over 70 different sizes. We manufacture our spindles in various materials, also in stainless steel. Continuous process control guarantees consistently high quality. Please contact us for individual spindle specifications.

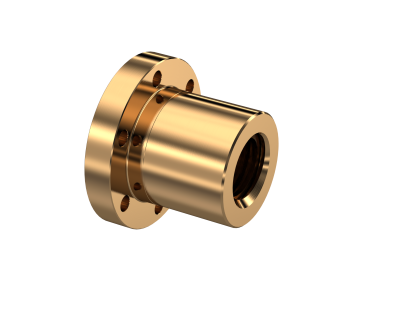

For movement drives with particularly favourable wear characteristics. EFMs can be mounted using the joints KON, KKA, MAFN and KAR. material: 2.1090 (CuSn7Zn4Pb7; RG7)

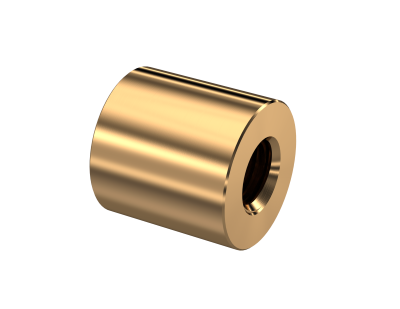

Thanks to the material used, the long red bronze nut TGM-LRM is characterised by particularly low wear. The major diameters are generously dimensioned for individual further processing. material: 2.1090 (CuSn7Zn4Pb7; RG7)

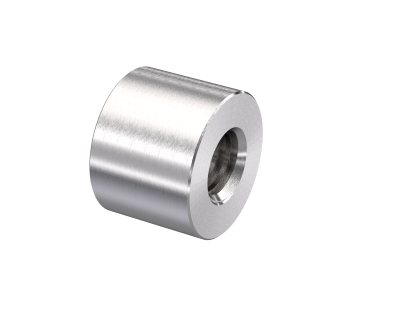

Steel nuts are mainly suitable for clamping operations, adjusting movements in manual operation and as fastening nuts. The short steel nut has a large major diameter, which provides space for individual adjustments. material: 1.0718 (11SMnPb30)

Steel nuts are suitable for clamping procedures, adjusting movements in manual operations and as fixing nuts. Material: 1.0718 (11SMnPb30)

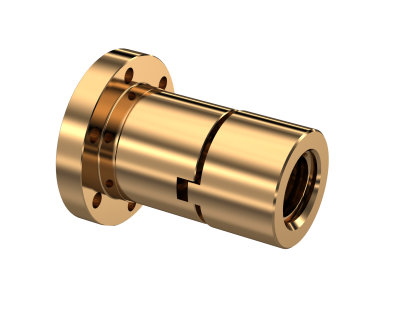

Safety nuts are used to protect people and to prevent costly machine damage. It is about a second, load-free nut which is permanently coupled with the actual support nut and a distance X. With increasing wear of the support nut, the distance X to the safety nut decreases accordingly. In the case of direct danger to people, e.g. on lifting platforms, certain regulations must be observed in accordance with EN 280, EN 1493, EN 1570, EN 1756 (formerly VBG 14), among others. This is when the long safety nuts are used. When using long safety nuts, wear monitoring can be carried out by means of an electrical limit switch. material: 2.1090 (CuSn7Zn4Pb7; RG7)

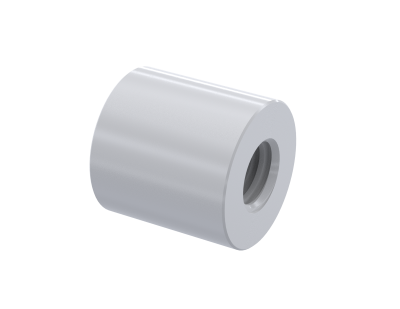

In combination with the rolled trapezoidal screws of high surface quality, the ready-to-install plastic nuts are often an alternative to conventional materials. Particularly low-noise and in many cases lubrication-free, plastic opens up completely new areas of application. The long plastic nuts TGM-LRM have a large major diameter and can be adapted to existing designs by further processing. material: ZEDEX 100 (ZX-100K)