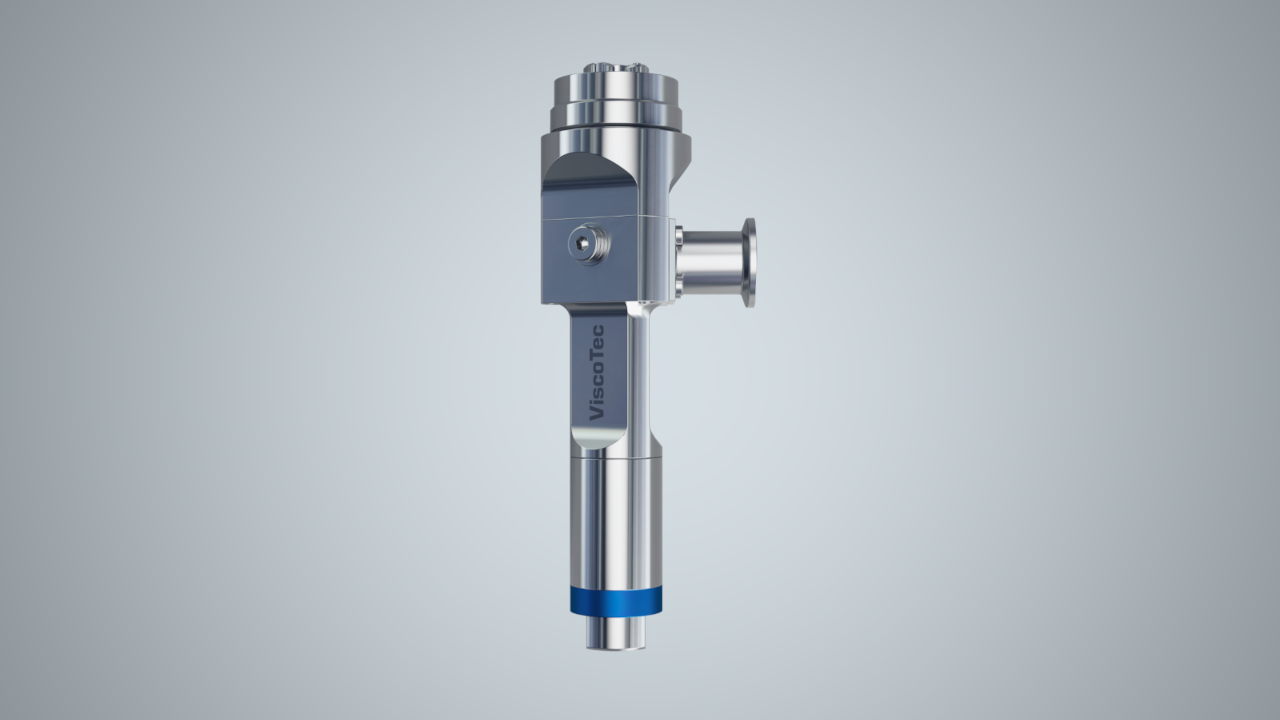

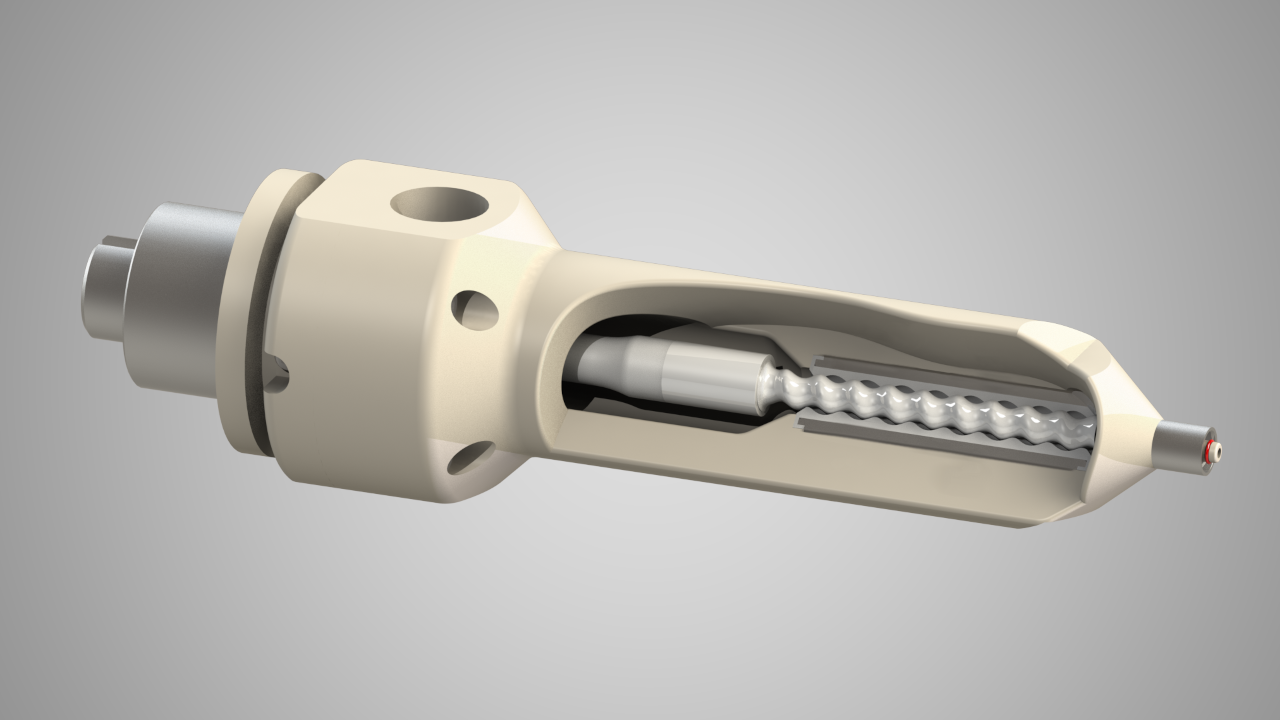

Optional: With hard chrome plated standard rotor or optional with ceramic rotor for highly abrasive materials.

watch an application example on YouTube.

Optional: With hard chrome plated standard rotor or optional with ceramic rotor for highly abrasive materials

watch an application example on YouTube.

watch the video on YouTube.

Optional: With hard chrome plated standard rotor or optional with ceramic rotor for highly abrasive materials

watch the video on YouTube.

watch the video on YouTube.

watch the video on YouTube

.