ViscoTec filling pumps fulfill the demanding and strict requirements of the pharmaceutical, food and cosmetics industries. Solid-containing and sensitive materials are filled absolutely shear-sensitive and industrial processes are optimized. Even abrasive materials can be filled highly precise. Our filling pumps can be easily integrated into already excisting processes and systems.

With our technology you achieve a reliable, exact and automatic filling from a few microlitres to around 1 litre per second, depending on the material. Our portfolio can handle viscous flavorings, high-viscosity semi-solids in the pharmaceutical sector, chunky jam and many other fluids & pastes.

Accurate, clean, automatic and repeatable: For precise material handling and exact compliance with the filling amount.

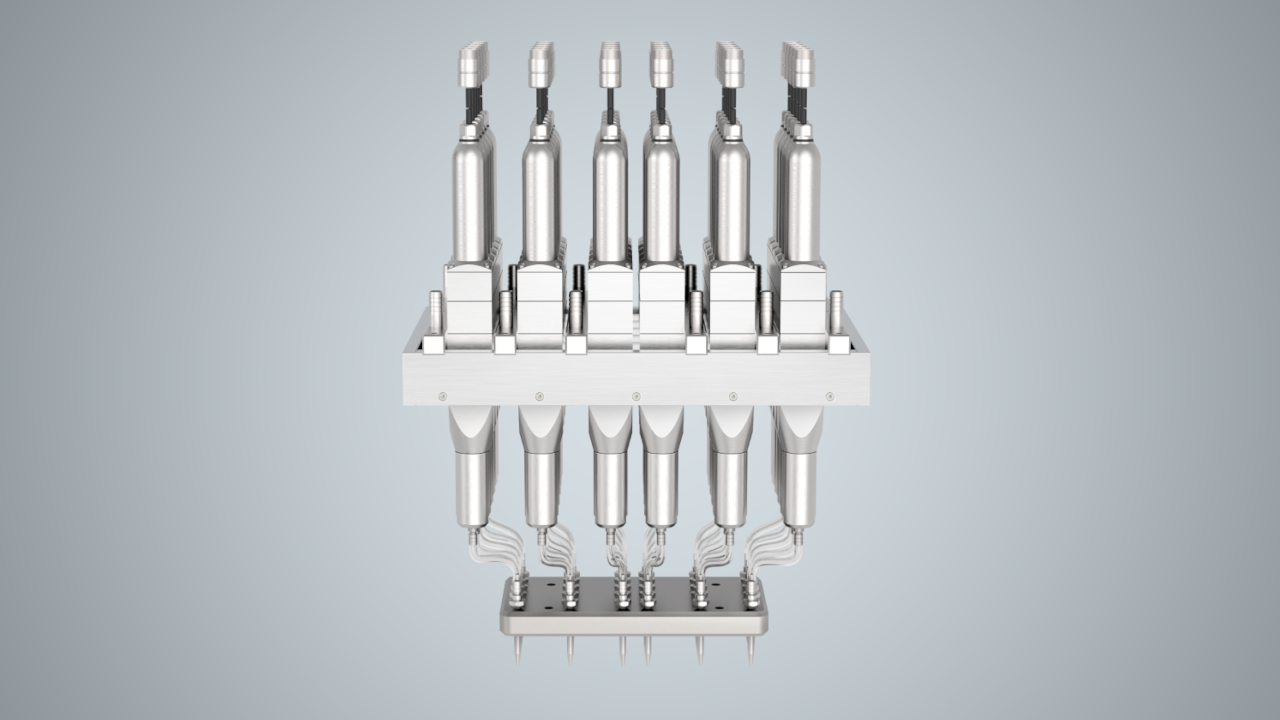

The vipura-PUMP 10T is suitable for dosing and filling of food and pharmaceuticals, as well as household products and cosmetics.

Find everything else in our product news.

Or in the YouTube video.