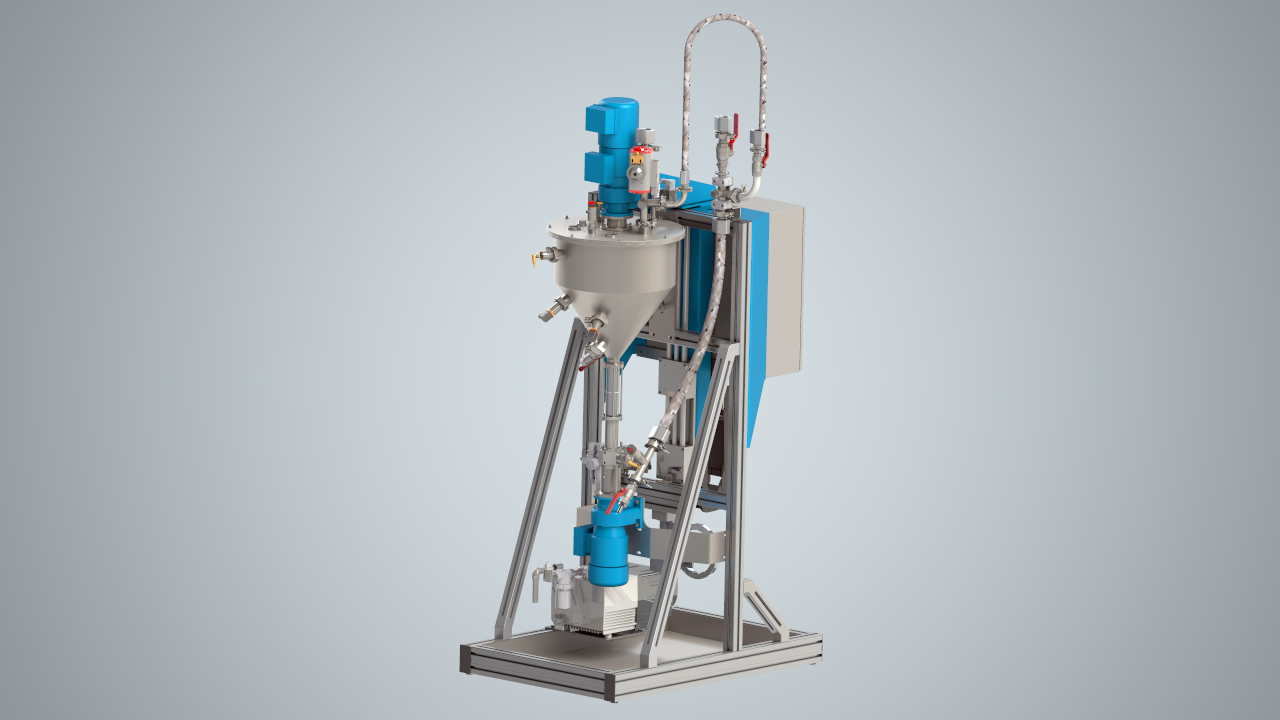

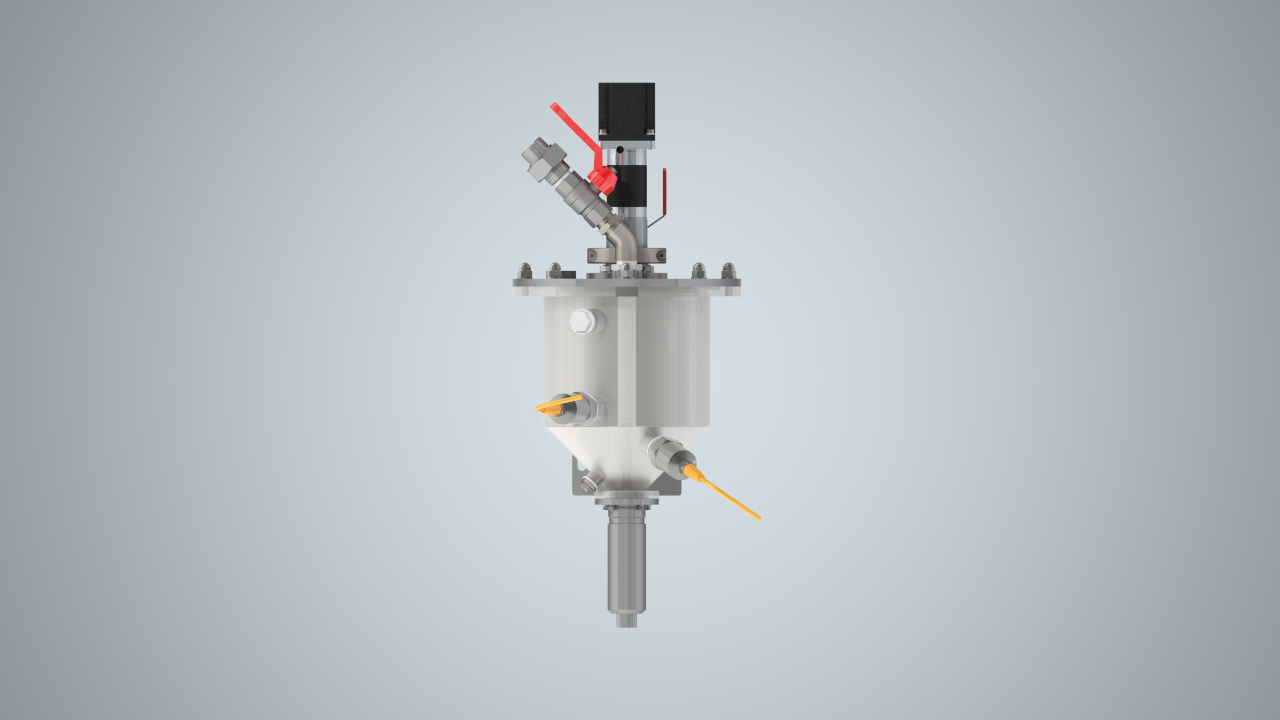

Our supplying systems enable consistent and reliable product supply ─ they ensure you seamless production without interruption thanks to various functions. Thanks to optional vacuum suction, they ensure absolutely air-bubble-free supply to the 1-component and 2-component dispensers. The operator has no contact with the material.

All components of our supplying systems & dispensing systems are assembled to fit your process and optimized for your application. For efficient product handling from removal to supplying and dispensing (e.g. by compensating for pressure fluctuations). Our endless piston principle scores with continuous, pulsation-free and repeatable handling of low to high viscosity materials. With the systems of our ViscoTreat series you get the optimal solution for batchwise as well as continuous material treatment. They are installed as a preceding measure to dosing applications for low to high viscosity materials. We will be happy to find out for you which supplying system fits best into your production process.

Continuous and constant product supply for seamless production without interruption.