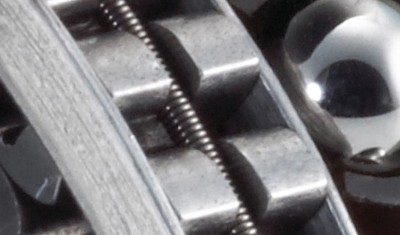

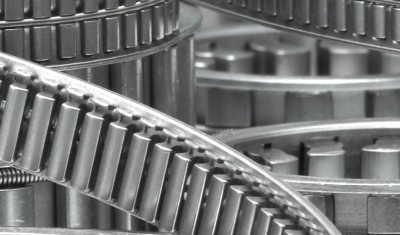

components, GMN has chosen to specialize in the production of efficient, long-life sprag type freewheel clutches.

components, GMN has chosen to specialize in the production of efficient, long-life sprag type freewheel clutches.

We emphasize on maximum precision in the development and production of GMN sprag type freewheel clutches. This ensures their certification to international standards and produces consistent, outstanding quality characteristics with respect to torque handling, indexing reliability and long service life.

The standardized model series offer a large selection of feature options to furnish effective freewheel clutch solutions for almost any field of application.

Based on its many years of experience in the development and production of high-quality machine

Benefits for our customers:

Our compact freewheel clutch solutions are not only extremely powerful, but also highly robust. These properties are particularly useful where the material is regularly subjected to high levels of stress. Take the motor shaft of a helicopter, shown here as an example.

We would like to inform you, that data will be transmitted to YouTube after activating the video.