shorter process time, higher rotating speed, flexible material characteristics and a huge range of operating conditions. Simultaneously, new energy-saving solutions and maintenance-free characteristics are increasing economic efficiency of modern machine systems.

Based on decades of experience, GMN has specialized in producing extremely high quality machine tool components.

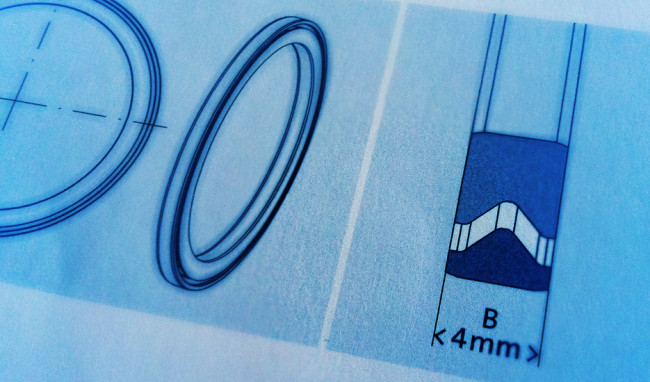

Through this strategy, GMN manufactures a wide range of standard non-contact seals and customized solutions.

The frictionless, no-wear characteristics of GMN non-contact seals offer effective, economical and ecological solutions for modern applications in and outside of the machine tool industry.

The machine tool industry and its end users are continuously demanding the utmost in quality in every aspect of their machine.

Highly specialized components are resulting in

Benefits for our customers:

GMN seals fulfill all key requirements and seal even in extreme spray exposure. Take a look at an application example from the field of rail vehicle technology.

We would like to inform you, that data will be transmitted to YouTube after activating the video.