Parker venturis provides directional air movement for cutting machines in mining and construction applications where dust suppression and ventilation is required. The easy to use, corrosion resistant venturi is designed to bolt on to a chute or conveyor belt with low maintenance required. The product range includes three series, double, single and mini and all feature interchangeable nozzles across the range to keep customers’ stock levels to a minimum.

MCA is lightweight single stage vacuum generator. Female vacuum ports allow a vacuum cup to be installed directly at the cup which reduces space and response time of the system. Available port sizes are either 1/8" or 1/4" NPT.

Parker Pneumatic offers a range of vacuum ejectors including basic ejectors, basic ejectors with an electro-mechanical switch,inline ejectors, ejectors including blow-off, plus both small and large integrated ejectors.

CV is a basic single stage vacuum generator with an aluminum basic body. Vacuum port sizes range from 1/4" to 3/4." CV vacuum generators include exhaust mufflers.

Moduflex Vacuum Generators can be mounted inline or directly onto a valve island. They feature an integrated blow-off flow controller, optional plug-in vacuum feedback sensor and use proven Venturi technology, reaching up to 90% vacuum.

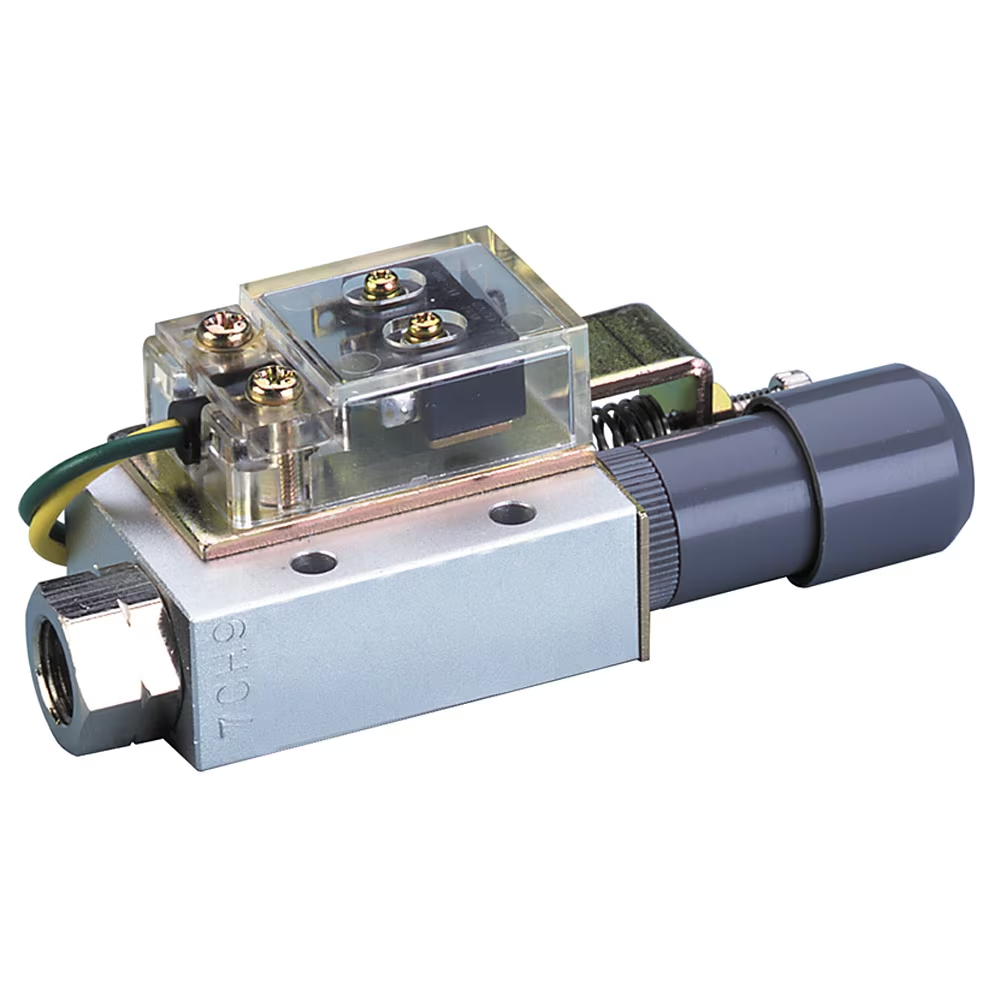

CV-CK is a single stage vacuum generator with an adjustable open contact mechanical switch for vacuum confirmation. Switch output is normally open and can be connected to AC or DC power.

Parker Conflow's double flat Venturi provides high directional air movement for cutting machines in mining for larger dust suppression and ventilation requirements.

CHF High Flow Series is a multistage vacuum generator. The CHF unit is intended for higher flow vacuum applications that, due to system porosity issues, have a low application degree of vacuum and include flow through exhaust mufflers.

Parker Conflow's single flat Venturi is designed to provide directional air movement with a large spray area for dust suppression on cutting machines, conveyor belts and chutes in mines.

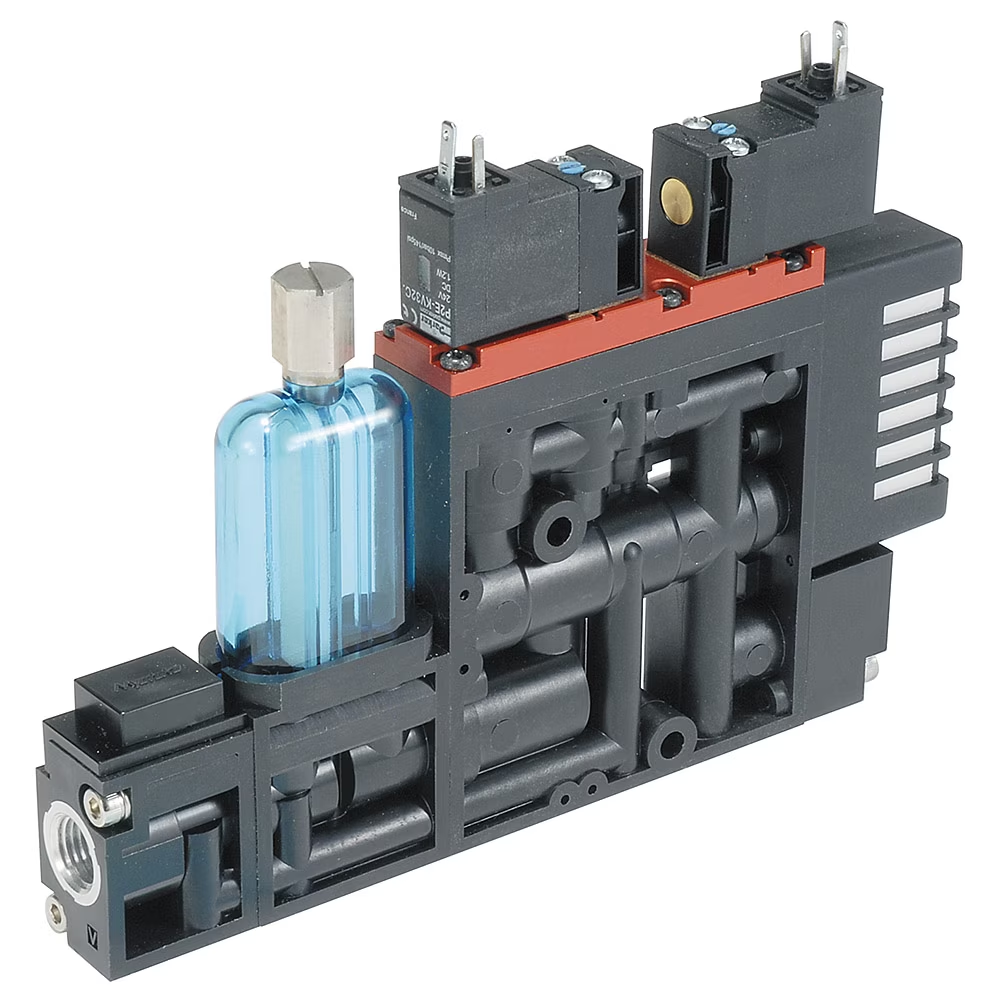

The MC22 is a light weight vacuum package for factory automation. The MC22 includes vacuum and blow-off solenoids, a regulating blow-off needle, vacuum filters, exhaust mufflers, pressure sensors and an optional vacuum check valve.

Parker Conflow’s Code 5102 is a single flat Venturi, which provides directional air movement with a compact spray head for improved ventilation for cutting machines in mining, conveyor belts or chutes in dust suppression applications.

The MC72 is perfect for non-porous material handling with air economizing options. The MC72 includes vacuum and blow-off solenoids, a regulating blow-off needle, vacuum filters, exhaust mufflers, pressure sensors and an optional vacuum check valve.

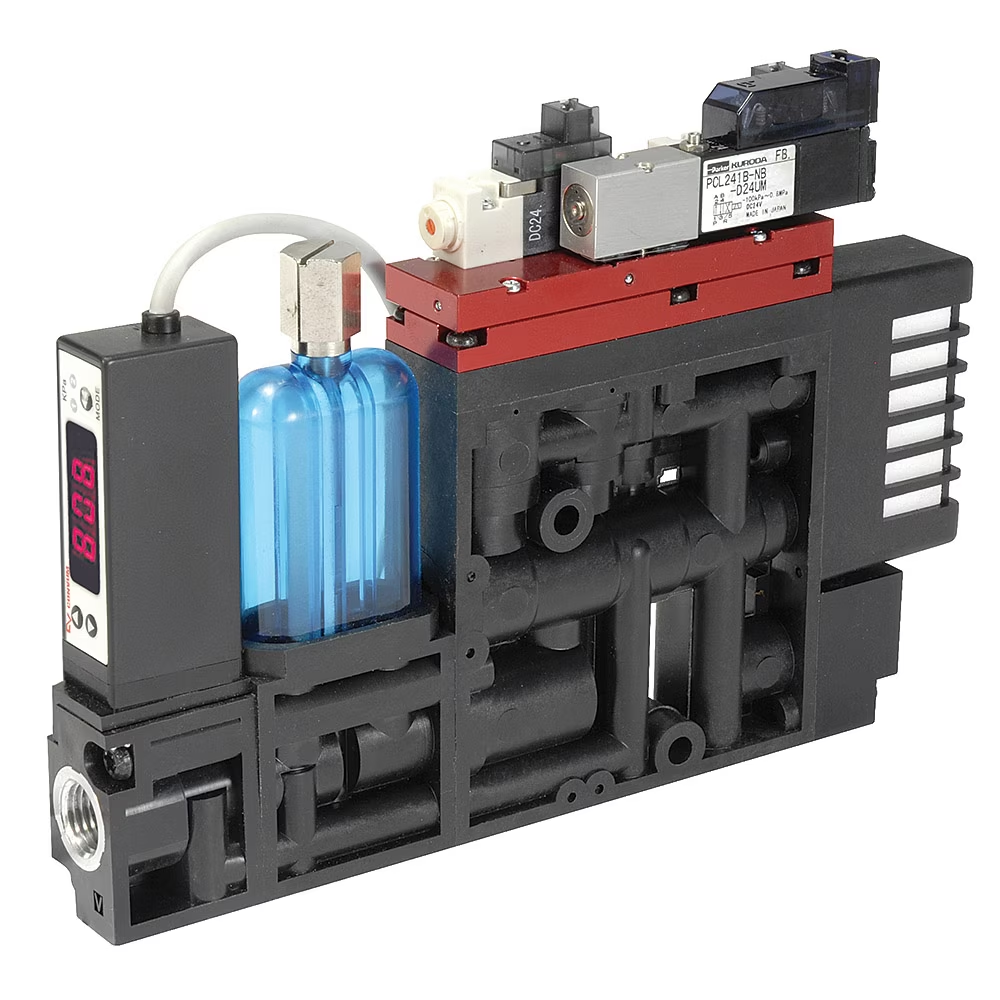

The CEK is perfect for non-porous material handling with air economizing and emergency stop features. CEK includes vacuum and blow-off solenoids, a regulating blow-off needle, vacuum filters, exhaust mufflers, pressure sensors and a vacuum check valve.

Parker Conflow’s Code 1912 is a Venturi spray nozzle for the purpose of dust suppression on a cutting drum in mining that maximises efficiency, whilst minimising the amount of water it uses.

The CVXCEK is perfect for non-porous material handling with air economizing and emergency stop features. It includes vacuum and blow-off solenoids, a regulating blow-off needle, vacuum filters, exhaust mufflers, pressure sensors and a vacuum check valve.

The CVX026B is perfect for non-porous material handling with air economizing & emergency stop features. It includes vacuum and blow-off solenoids, a regulating blow-off needle, vacuum filters, exhaust mufflers, pressure sensors, & a vacuum check valve.