Parker offers a wide range of hydraulic valves for a variety of mobile and industrial applications. We manufacture all types of hydraulic valves: from directional control valves to pressure control, flow control, shuttle, sequence, high pressure non-return and ball valves, from monoblock and sectional to manifold mounted, in-line and slip-in cartridge valves, from standard on/off valves to high-dynamic proportional valves. Common to all is the combination of outstanding reliability and cost efficiency which makes them the appropriate solution for almost any operational purpose.

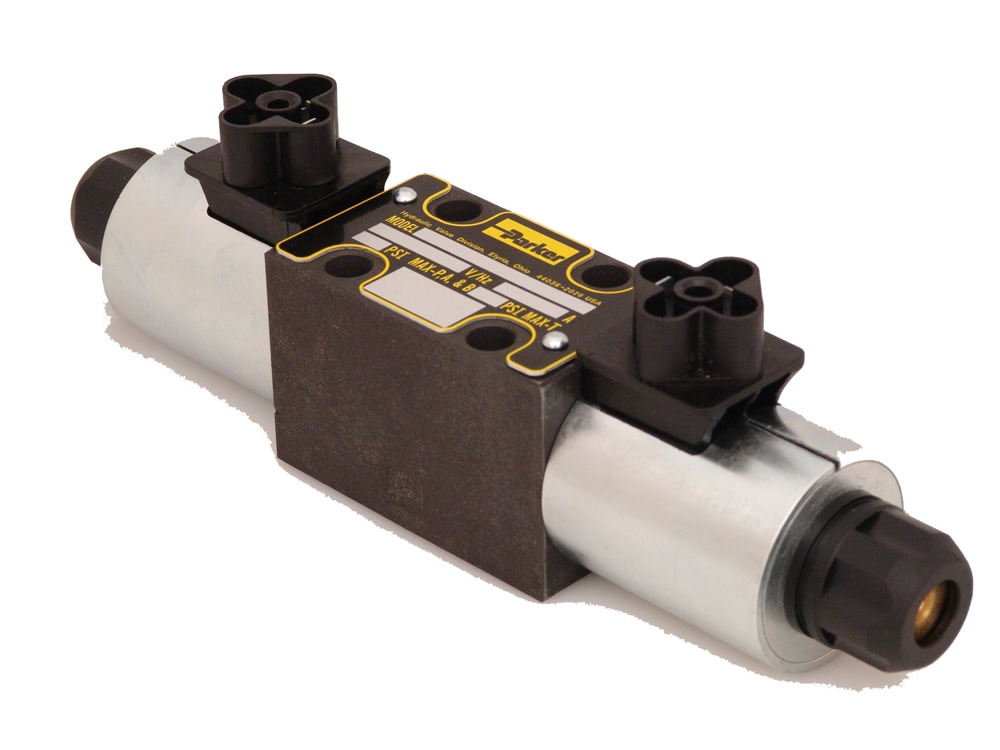

Parker’s D1VW directional control valves are high performance direct operated hydraulic valves. These are wet armature design solenoid valves in either 2 position or 3 position configurations. The D1VW valve conforms to D03 (NG6) mounting pattern

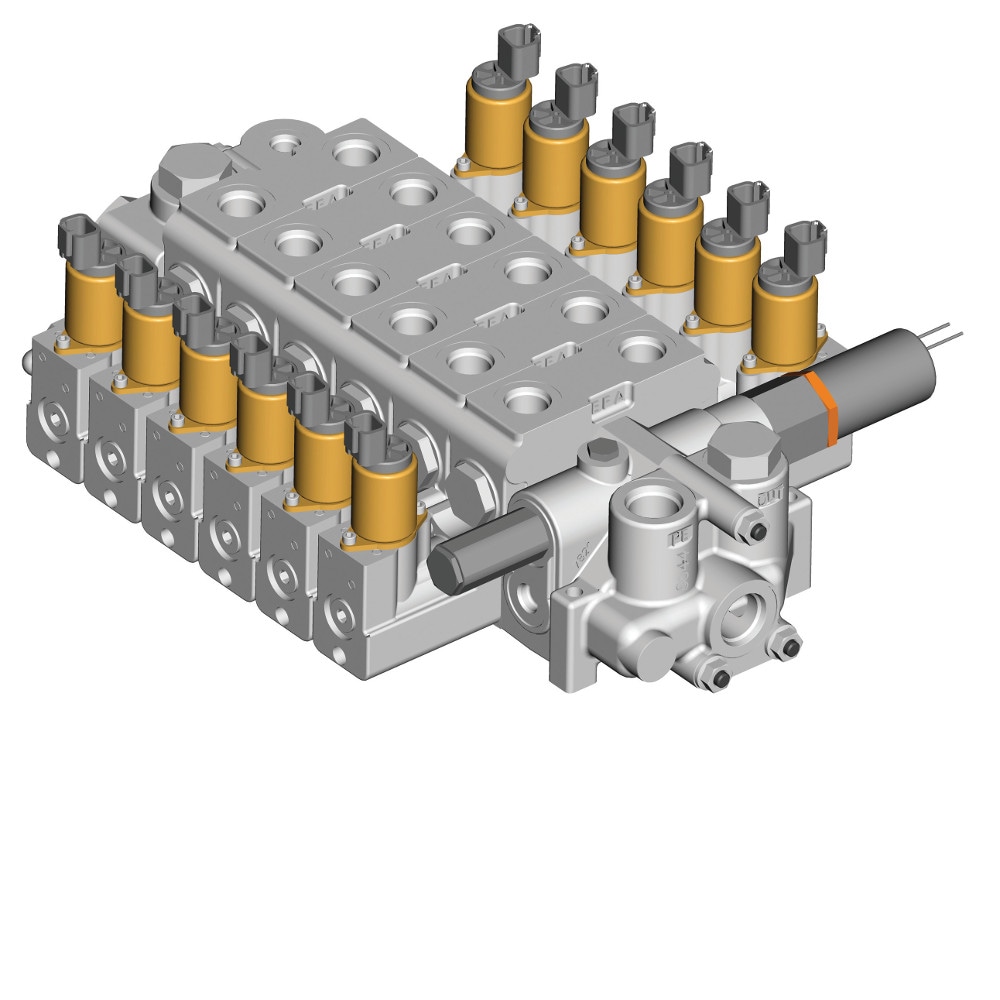

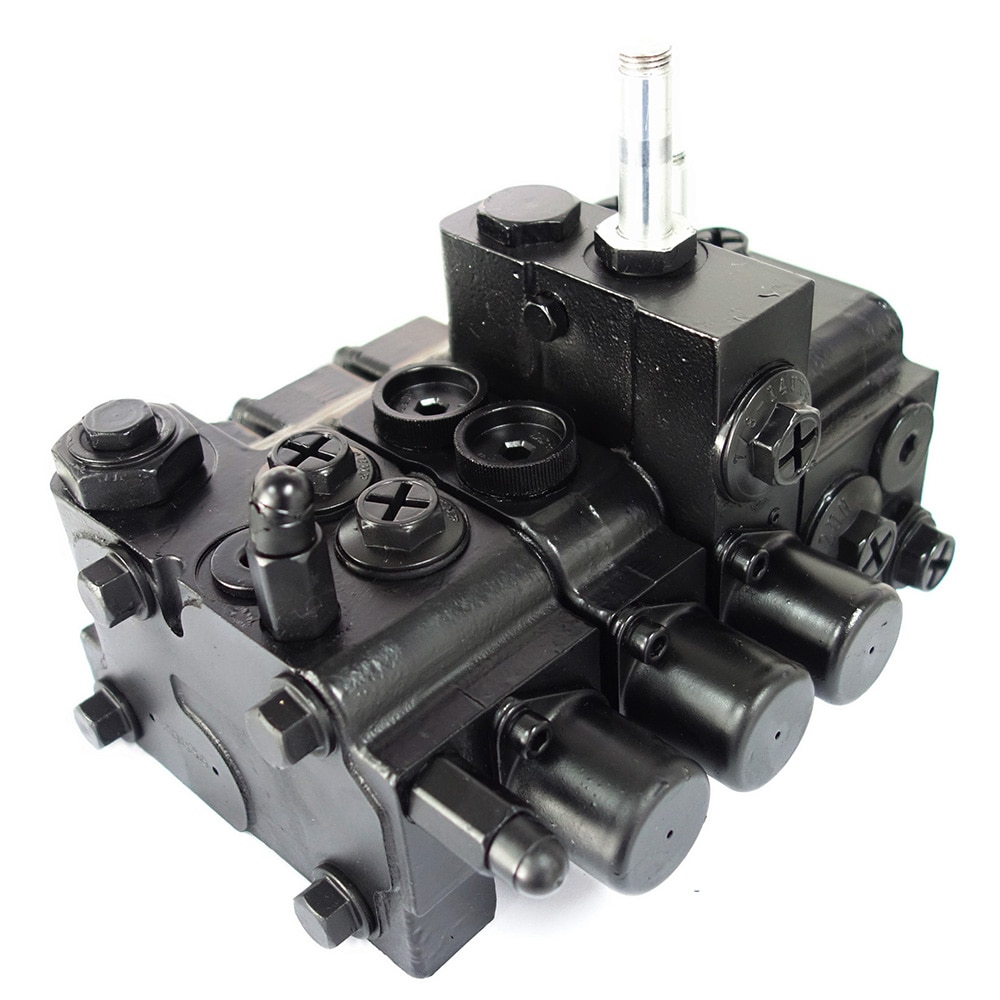

Parker’s VP120 series is a sectional, pressure compensated load sensing directional control valve for mobile machines.

Parker's 2-way poppet solenoid valves check flow in one direction with very low leakage and free flow opposite; normally-open or normally-closed configurations available. Capable of pressures up to 350 bar (5000 psi) and flows up to 260 lpm (70 gpm).

Representing cutting-edge technology, Parker’s new compact D1FC (NG06) / D3FC (NG10) provide optimized process speed with high dynamics and flow for various applications. Optionally with EtherCAT® interface for high data speed and short cycle times.

The Colorflow F series of hydraulic flow control valves permits free flow in one direction and metered flow in the reverse direction. This flow control valve is used in air and oil applications.

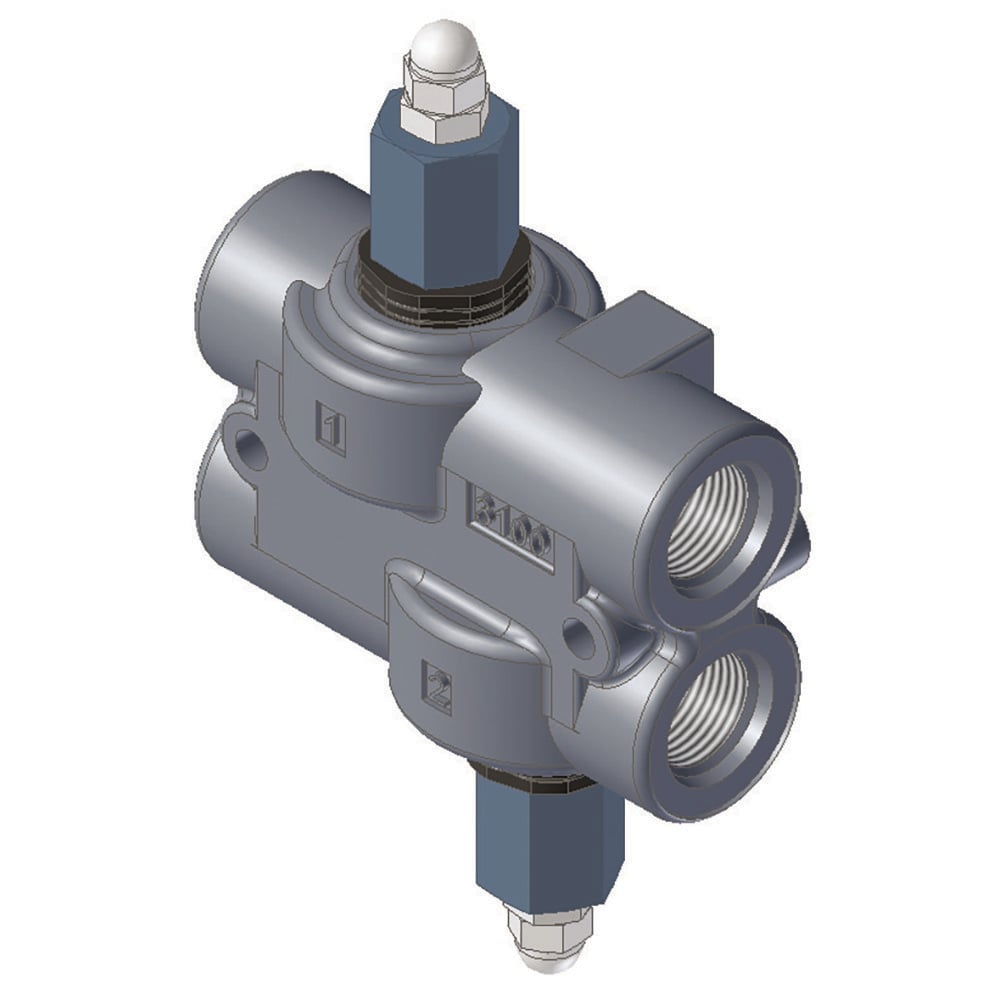

Parker’s piloted load control valves are designed to operate independent of downstream pressure to prevent runaway loads under dynamic conditions using a pilot signal, handling pressures up to 420 bar (6000 psi) and flows up to 350 lpm (90 gpm).

The D1VW in NG06 (CETOP 03) is an on/off valve which provides high functional limits in combination with a very low, energy-saving pressure drop. It is optionally available with soft shift option or as explosion proof version according to ATEX and IECEx.

Parker non-return valves with nominal pressure ratings up to PN 420 bar offer a wide range of types, making them very flexible.

The D1VW in NG06 (CETOP 03) is an on/off valve which provides high functional limits in combination with a very low, energy-saving pressure drop. It is optionally available with soft shift option

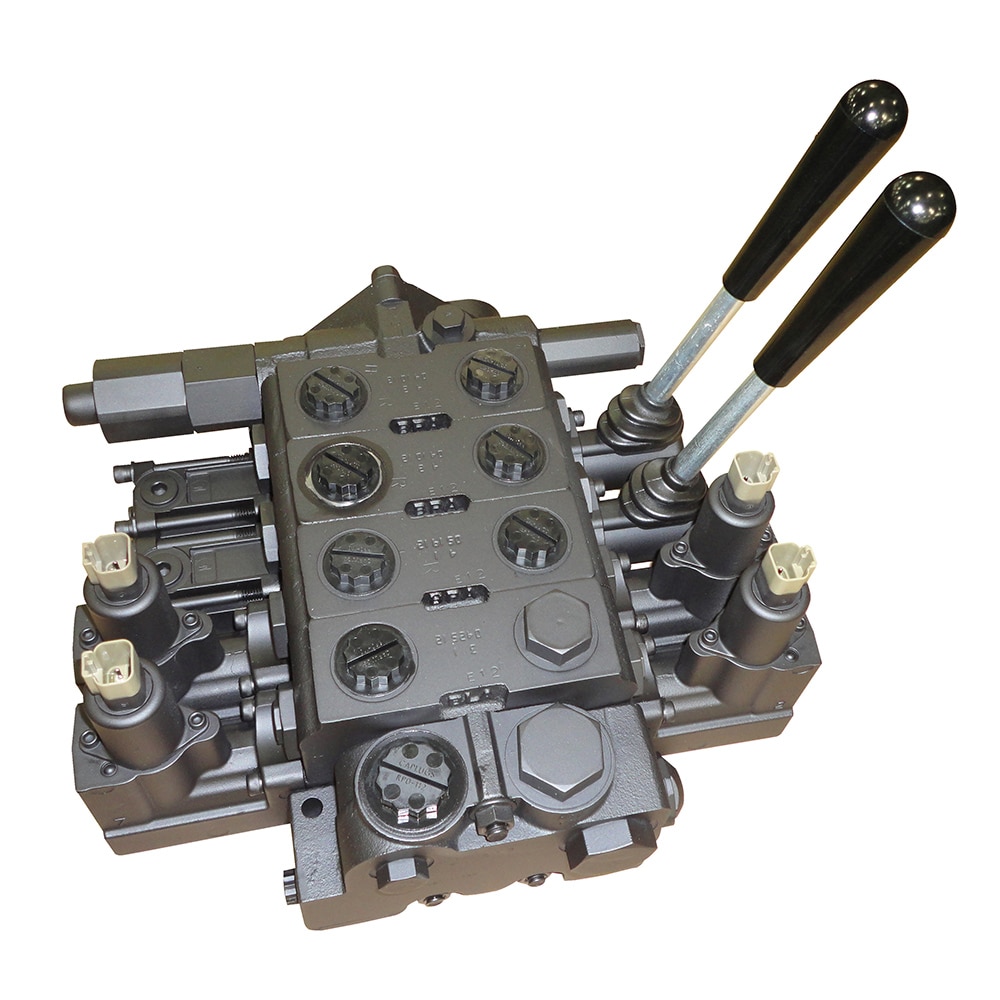

Parker’s VPL Series is a stackable, multi-section, load-sensing, pressure-compensated directional valve for mobile equipment. Work Port flows rated to 30 GPM at 5000 PSI.

Parker’s VP/VPO series valve is a stackable, multi-section, load-sensing, pressure-compensated directional valve for mobile equipment.

The NG10 direct operated directional control valve series D3W provides high functional limits up to 150 l/min in combination with a low, energy saving pressure drop.

Parker’s VP170 series is a sectional, pressure compensated load sensing directional control valve for mobile machines.

Parker’s pilot operated relief valves are designed for continuous duty applications featuring great stability with low pressure drop; working with pressures up to 420 bar (6000 psi) and flows up to 400 lpm (106 gpm).

Direct operated DFplus control valves D1FP in NG06 (CETOP 03) and D3FP in NG10 (CETOP 05) meet highest requirements in terms of dynamics combined with high flow, optionally with EtherCAT interface. The preferred choice for demanding hydraulic controls!

The NG10 direct operated directional control valve series D3W provides high functional limits up to 150 l/min in combination with a low, energy saving pressure drop.

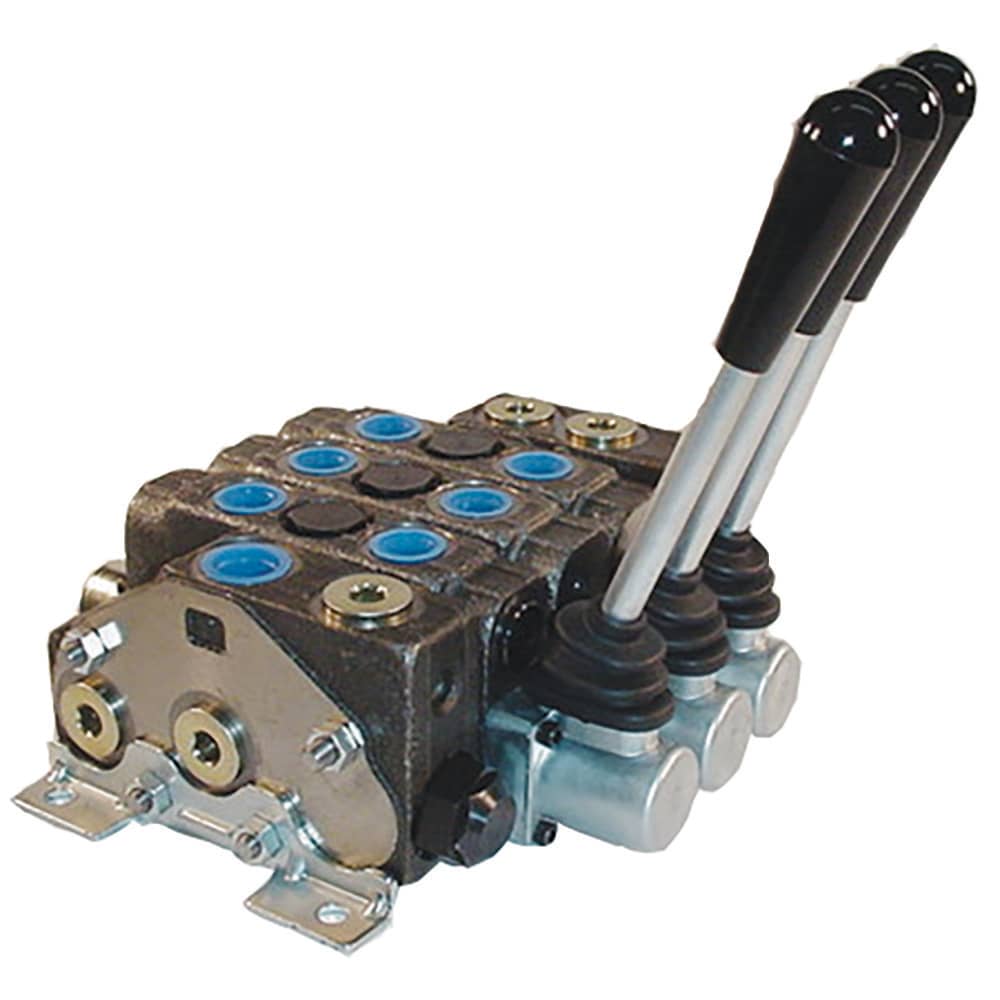

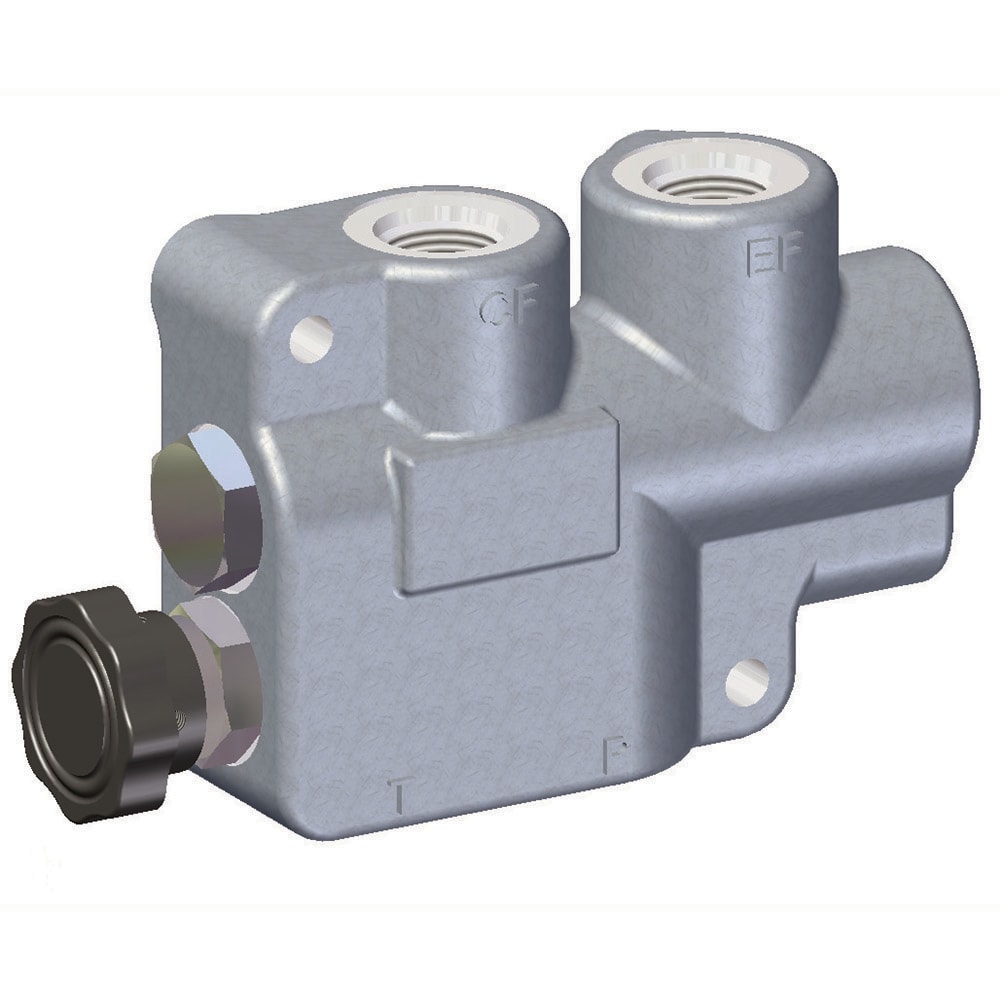

Parker’s V20 Series valve is a sectional, open center, CF (constant flow), or closed center load sensing (variable flow) directional control valve for mobile equipment. It is typically applied between 15 and 25 GPM pump flow at 3500 psi.

Parker’s V10 Series valve is a sectional, open center, CF (constant flow), directional control valve for mobile equipment. It is typically applied between 5 and 15 GPM pump flow at 3500 psi.

Parker has a large selection of direct acting 4-way, 3-position spool-type solenoid valves to cover a wide range of flow requirements up to 57 lpm (15 gpm) and pressures as high as 350 bar (5000 psi); closed, open, float, and tandem centers available.

Parker's proven standard performance pilot operated proportional DC valves series D*1FB with onboard electronics are universally applicable and feature progressive flow characteristics for sensitive flow rate adjustment.

Parker’s VA35/VG35 is a sectional, open center, CF (constant flow), directional control valve for mobile machines. It is typically applied between 20 and 45 GPM pump flow.

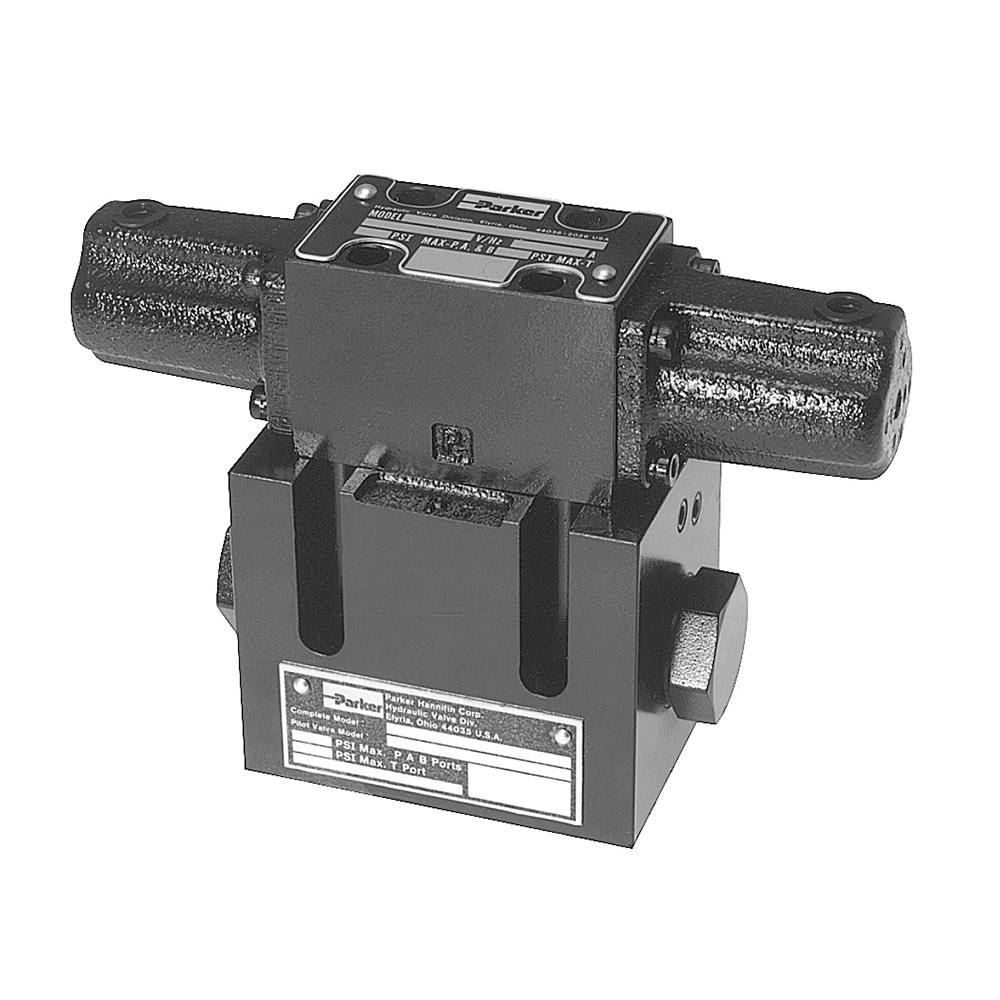

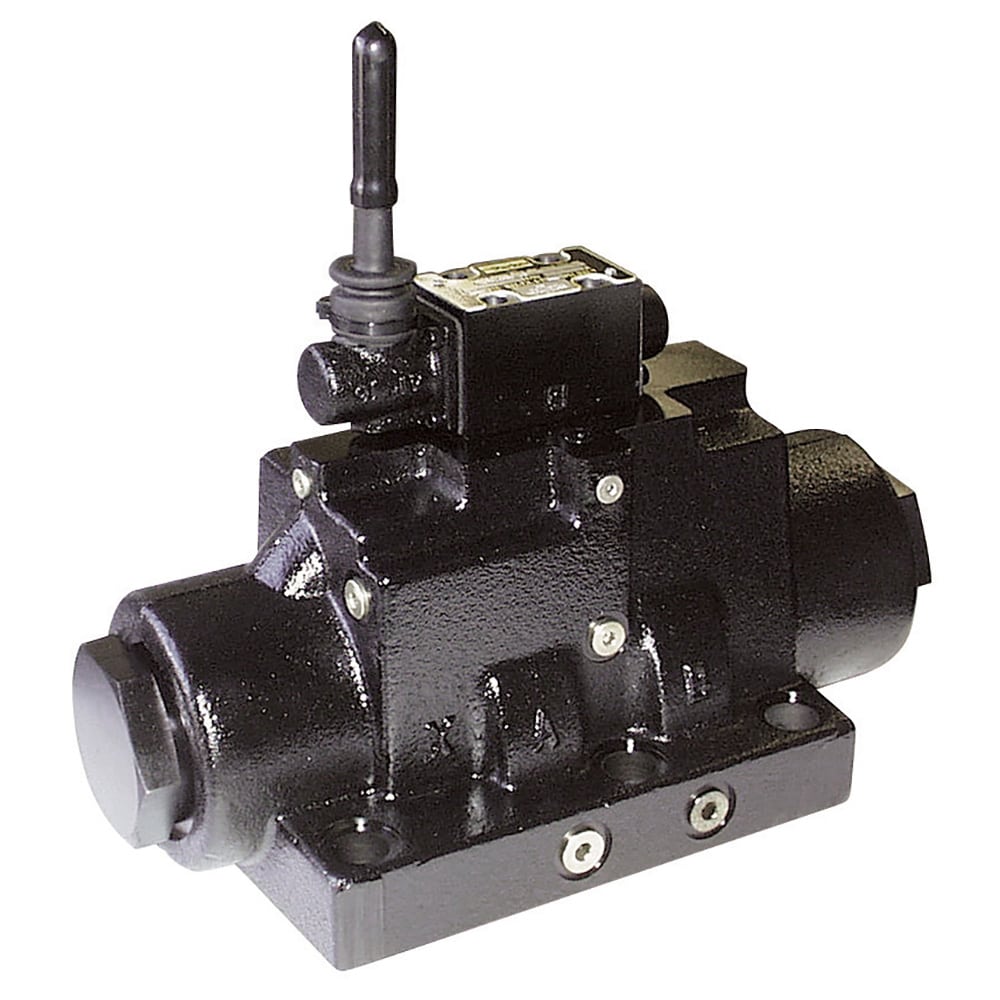

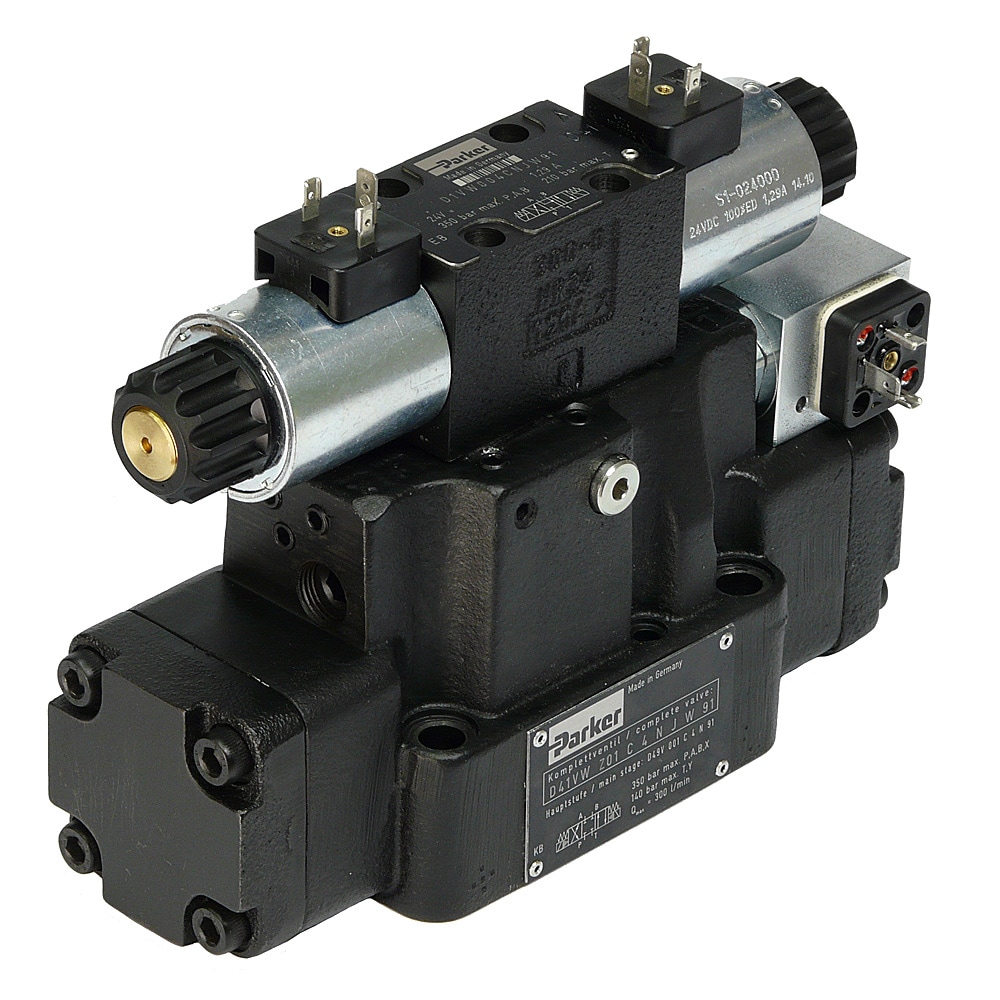

Setting standards for pilot operated on-/off valves in terms of functional limits and pressure drop, Parker's series D31DW, D31NW, D*1VW are suitable for practically any industrial application. Optionally available as ex-proof version.

Parker double-throttle check valves series FM in sandwich design offer an easy configuration of stack systems and provide a very good price-performance ratio. They are optionally available with a cylindrical needle for fine adjustment in NG06 and NG10.

Parker’s V20EH is a sectional, open center, CF (constant flow), directional control valve for mobile machines. It is Electro-Hydraulic actuated and can be applied up to 25 GPM

Parker's VG35EH valve is a sectional, open center, CF (constant flow), directional control valve for mobile machines. It is Electro-Hydraulic actuated and typically applied between 30 and 65 GPM pump flow.

With a high-definition position feedback system and an excellent price-performance ratio, Parker's pilot operated proportional directional control valves series D*1FC offer numerous competitive advantages for users - optionally with EtherCAT® interface.

Parker’s PC55 series valve is a sectional, pressure compensated load sensing directional control valve for mobile machines.

Capable of flows from 3.5 to 303 lpm (0.9 to 80 gpm) and pressure as high as 420 bar (6,000 psi), Parker’s poppet and ball style check valves have a simple and robust design which are used to block flow in one direction, and allow flow in the opposite.

The pilot operated 2-way high response valves series TDP provide a precise control of high flows at maximum dynamics. Typical applications for these slip-in cartridge proportional throttle valves are die cast, injection molding and hydraulic presses.

FLV95 mobile valve is integrated in a multi-function configuration. Better control and lower power consumption. FLV95 is a sectional valve designed for forklift used in fixed displacement pump systems.

Parker's pilot operated check valves series CPOM in sandwich design ensure an easy configuration of stack systems and provide a very good price-performance ratio.

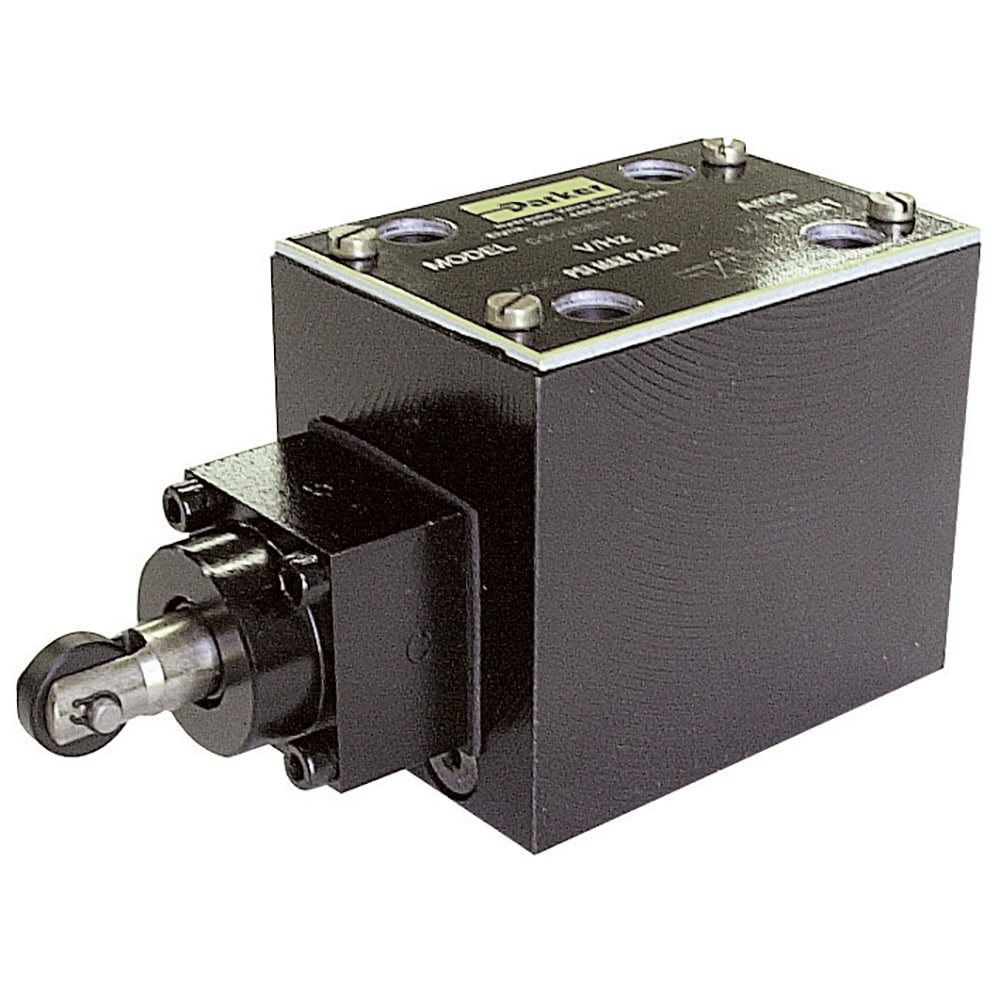

Parker’s D1VC, D1VD and D1VG directional control valves are high performance, 4-chamber, direct operated, cam controlled, 4-way valves.

Parker’s D3DW directional control valves are high performance, 5-chamber, direct operated, wet armature, solenoid controlled, 3 or 4-way valves.

High pressure solenoid valves are direct acting 3-way, 2-position spool-type to cover a wide range of flows up to 57 lpm (15 gpm) and pressures as high as 350 bar (5000 psi). These screw-in cartridge valves are fast to respond to coil voltage.

2-way slip-in cartridge valves series CE and CP are hydraulically controlled seat valves which are universally applicable. The complete modular system covers all sizes.

Parker’s D3L directional control valves are high performance, 5-chamber, direct operated, lever controlled, 4-way valves.

Parker’s 2-way bi-directional poppet solenoid valves block flow both directions with very low leakage and are available in normally-open or normally closed configurations. Capable of pressures up to 350 bar (5000 psi) and flows up to 285 lpm (75 gpm).

Parker's pilot operated check valves series CPOM in sandwich design ensure an easy configuration of stack systems and provide a very good price-performance ratio.

Parker non-return valves with an ISO 8434-2 (Triple-Lok®) or 8434-3 (O-Lok®) connection offer a wide range of sizes, male threads and cracking pressures, making them very flexible.

Setting standards for pilot operated on-/off valves in terms of functional limits and pressure drop, Parker's series D31DW, D31NW, D*1VW are suitable for practically any industrial application.

Parker’s D3A directional control valves are high performance, 4-chamber, direct operated, air pilot controlled, 4-way valves.

Parker’s D3C and D3D directional control valves are high performance, 4-chamber, direct operated, cam controlled, 3 or 4-way valves.

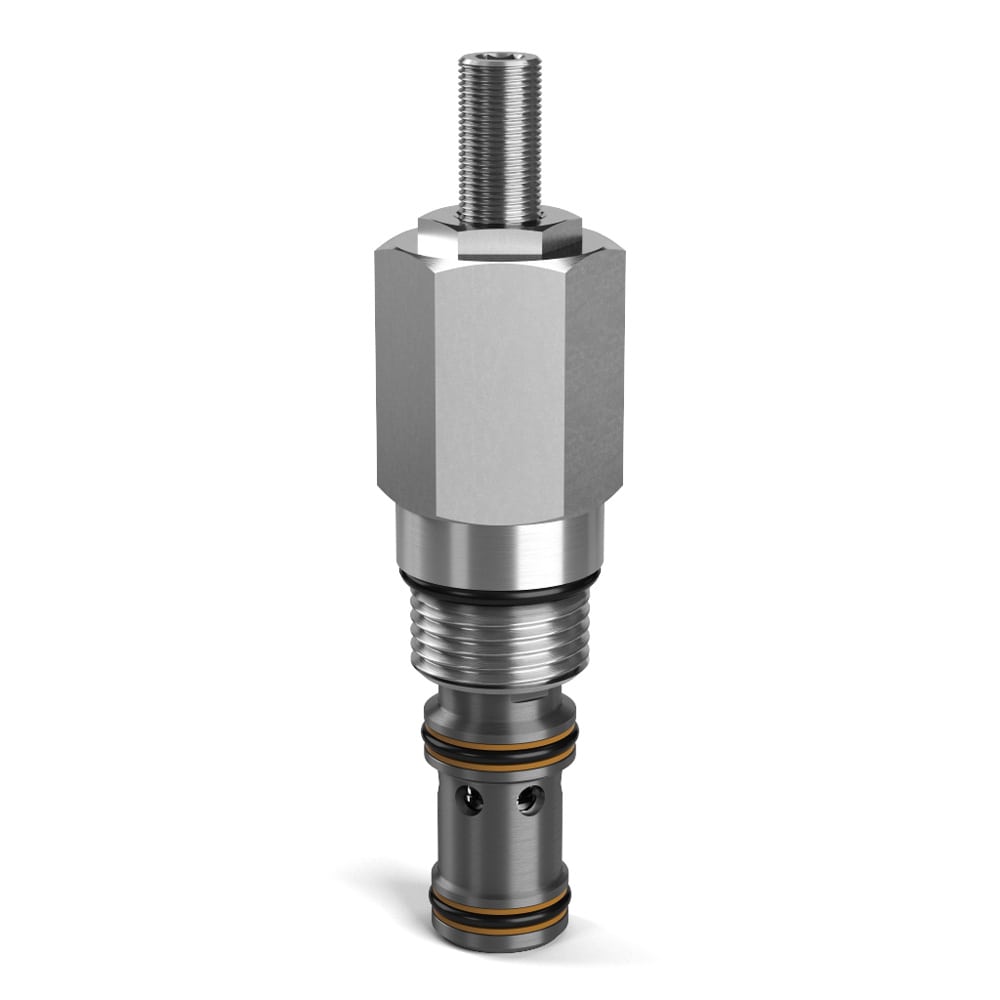

Parker’s direct acting relief valves are available in several cavity sizes and are designed for continuous duty applications with pressures up to 420 bar (6000 psi) and flows up to 200 lpm (53 gpm).

The proven 2-way proportional throttle valves series TDA feature a precise control of large oil flows for an efficient, reliable operation.

KM300 mobile valve equipped with the function of low pressure regeneration, Better control and lower power consumption. KM300 is a monoblock valve designed for wheel loader and other mobile machinery used in open center systems.

Parker's D3*P series directional control valves are 5-chamber, oil pilot operated valves

Parker’s P.O. check valve assemblies allow flow up to 150 lpm (40 gpm) with pressures up to 420 bar (6,000 psi). Return flow can be enable by an external pilot supply, which shifts the internal poppet into an open position

Parker's pilot operated servo proportional directional control valve series D*1FP is the ultimate choice for demanding hydraulic applications. The valves are optionally available with energy-saving regenerative/hybrid function and EtherCAT® interface.

Parker direct operated pressure reducing valves series PRDM in sandwich design ensure a precise pressure regulation in one area of a hydraulic circuit at a predetermined level below normal system pressure.

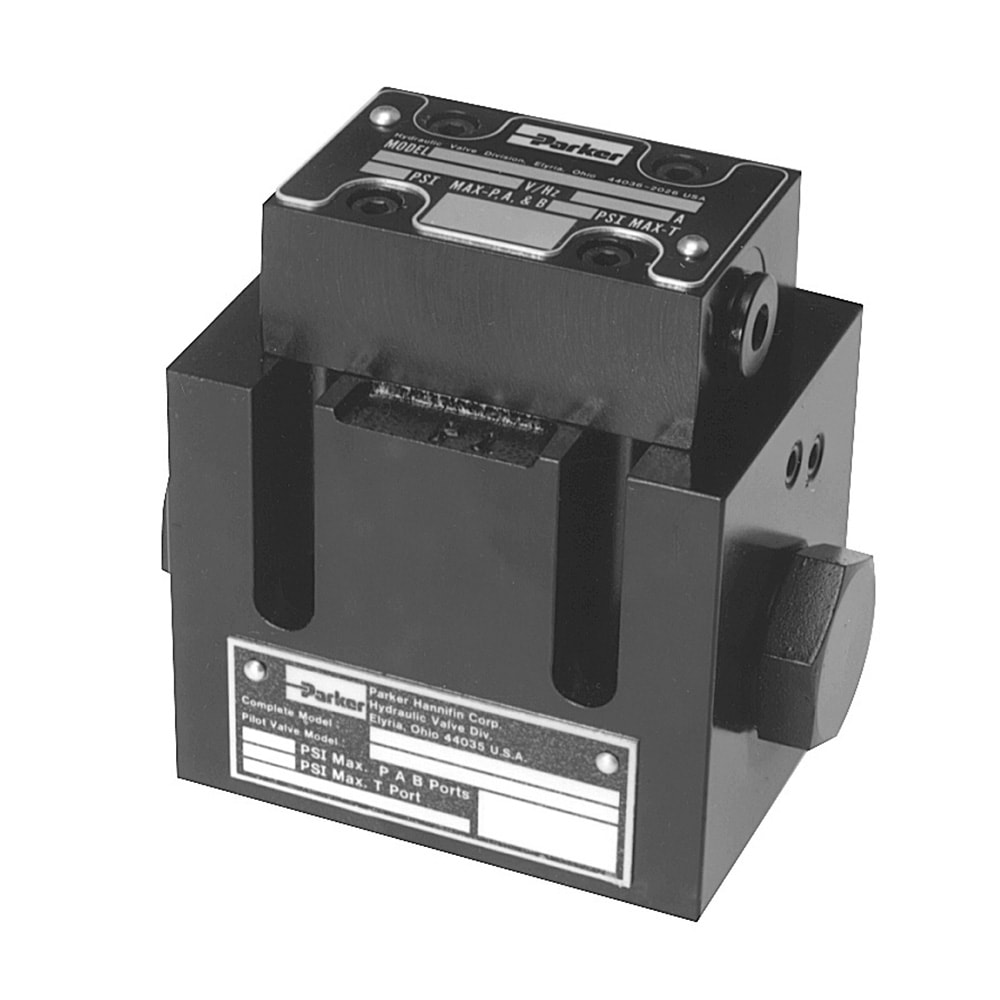

Parker’s D31 directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker’s D31*A directional control valves are 5-chamber, air pilot operated valves

Parker's proven direct operated proportional directional control valves series D1FB OBE (NG06) / D3FB OBE (NG10) are universally applicable. The standard performance valves with onboard electronics provide high repeatability and low hysteresis.

Parker’s D31*L directional control valves are 5-chamber, pilot operated, lever controlled valves

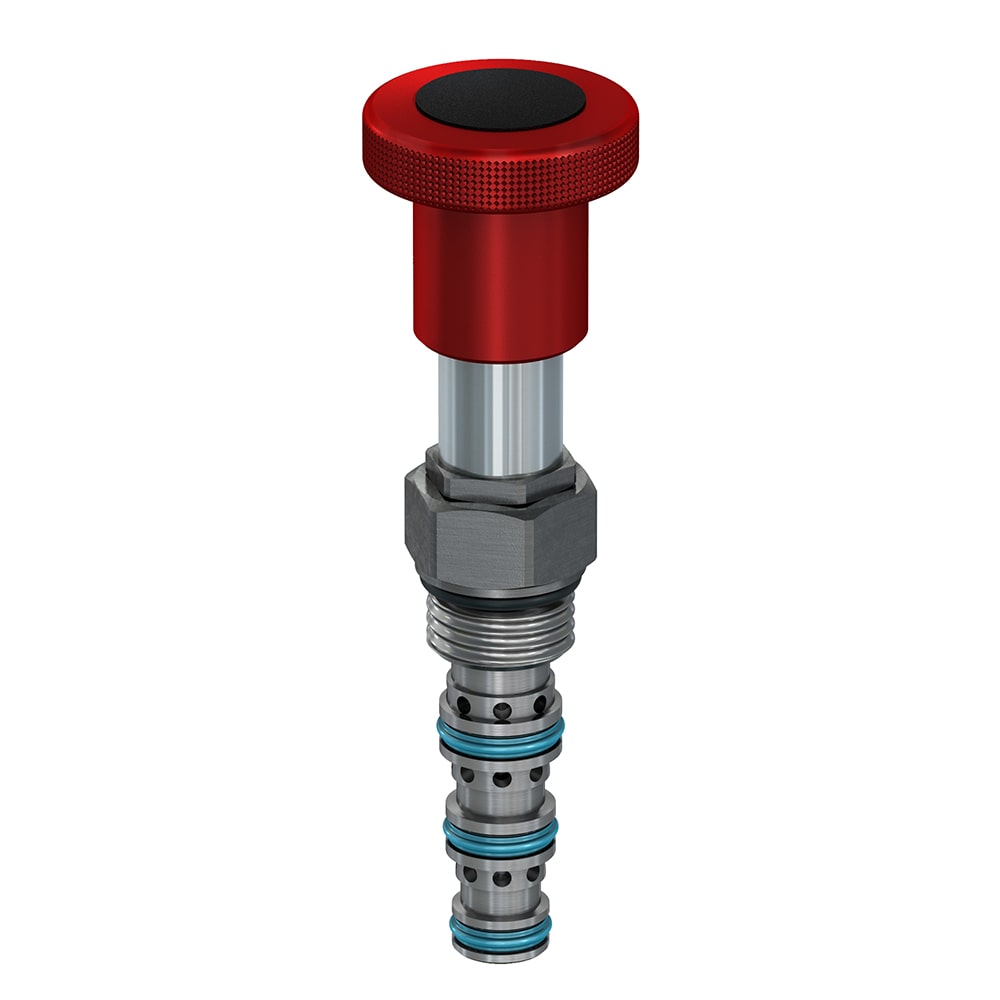

Parker offers standard needle valves and needle valves with a reverse free-flow check. Parker’s needle valves are non-compensated adjustable orifices capable of flows up to 225 lpm (60 gpm) and pressures as high as 420 bar (6000 psi).

With flow rates up to 9500 l/min and fast response times, proportional throttle valves series TEA are predestined for injection molding and die cast applications. The directional valve integrated in the pilot circuit provides the safety function.

Pressure relief valves series RDM are direct operated piston type valves with low hysteresis. They can be used as P-T relief or as T-T controlled counter balance valve. They are available in NG06 and NG10.

Parker’s D61VW directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker’s D61VL directional control valves are 5-chamber, lever operated valves.

Parker’s direct acting 4-way, 2-position spool-type solenoids offer a simple electronic solution for actuation or reversing applications; available with flows up to 113 lpm (30 gpm) and pressures as high as 350 bar (5000 psi).

Parker double-throttle check valves series FM in sandwich design offer an easy configuration of stack systems and provide a very good price-performance ratio. They are optionally available with a cylindrical needle for fine adjustment in NG06 and NG10.

Parker’s D6P directional control valves are 5-chamber, pilot operated valves.

Parker’s selection of direct acting 2-way, 2-position spool-type solenoid valves cover a wide range of flows up to 75 lpm (20 gpm) and pressures as high as 350 bar (5000 psi), with both normally-closed and normally-open options available.

Parker direct operated pressure reducing valves series PRDM in sandwich design ensure a precise pressure regulation in one area of a hydraulic circuit at a predetermined level below normal system pressure.

The pilot operated pressure relief valves series SCRM are in sandwich design for easy configuration of stack systems. They are available in size NG06.

Parker’s D81VW directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker’s D81VL directional control valves are 5-chamber, lever operated valves

Parker’s spool type logic elements can be used for direction and pressure/flow control, and are available normally-open and normally-closed with internal or external pilots for pressures up to 420 bar (6000 psi) and flows up to 500 lpm (132 gpm).

Parker's proven direct operated proportional DC valves series D1FB (NG06) / D3FB (NG10) are universally applicable, provide high repeatability and low hysteresis. The D1FB*EE with explosion proof solenoids allows the usage in hazardous environments.

Parker’s D81VA directional control valves are 5-chamber, air pilot operated valves.

Parker’s pilot operated acting reducing & relieving valves are used in applications where specific functions require reduced and regulated pressure. Capable of flows up to 150 lpm (40 gpm) and pressures up to 380 bar (5500 psi).

Parker's proven standard performance pilot operated proportional DC valves series D*1FB are universally applicable and provide progressive flow characteristics for sensitive flow rate adjustment. Also available as ex-proof version conform to ATEX.

Parker direct operated check valves series CM in sandwich design are predestined for an easy configuration of stack systems. A large number of options offer a multitude of uses for hydraulic switching.

Parker’s D8P directional control valves are 5-chamber, pilot operated valves.

Parker’s D101V directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker’s N5 valves are high flow / high pressure 3-way 2-position spool-type pilot-operated cartridge valves that can be used to control direction, pressure, or flow.

Parker pilot operated pressure relief valves for subplate mounting series R4V/R6V provide an outstanding constant pressure behaviour. Series R4V/R6V Proportional enables a continuous pressure adjustment by the additional proportional unit.

Parker’s D101VL directional control valves are 5-chamber, lever operated valves

Parker offers a wide range of pressure compensated flow controls for applications that demand constant flow with varying loads and pressures; handling pressures as high as 420 bar (6000 psi) and flows to 56 lpm (15 gpm) in a single common cavity.

Parker direct operated check valves series C5V with SAE flange are easy to install and provide high flow rates. They can be mounted either directly on the outlet flange of pumps or on the inlet flange of actuators to achieve a very compact design.

These valves are suitable for applications with pressures up to 300 bar. High performance materials and quality manufacturing allow for a wide range of operating pressures and temperatures.

Parker's proven pilot operated pressure reducing valves series PRM in sandwich design enable an easy configuration of stack systems. They are available in size NG06.

Parker’s D101VA directional control valves are 5-chamber, air pilot operated valves

Parker’s Series D10P directional control valves are 5-chamber, pilot operated valves.

Parker’s selection of proportional pressure reducing valves are for pressure sensitive applications and are capable of flows up to 37 lpm (10 gpm) and pressures as high as 210 bar (3000 psi)

Parker digital amplifier modules series PCD00A-400 combine all necessary functions for the optimal operation of two proportional pressure/flow control valves.

Parker’s BD series servovalves provide high resolution in the control of position, velocity and force in motion control applications.

Parker’s selection of proportional pressure relieving valves are for applications that require dynamic relieving and valves that are capable of flows up to 95 lpm (25 gpm) and pressures as high as 350 bar (5000 psi).

Parker's 3-way high-response cartridge valves series TPQ provide high flow control at maximum dynamics. They are predestined for demanding applications like injection molding and die cast.

The QDS6 sequence valve is designed to open or close a hydraulic pilot signal when it reaches a predetermind pressure level.

Parker’s SE05, SE10, SE15 & SE2N series valves are two stage, 4-way, flapper and nozzle style servovalves.

Parker offers four different flow divider/combiner valves to cover a wide range of flows up to 320 lpm (85 gpm) and pressures as high as 420 bar (6,000 psi). Standard and custom ratios are available, along with optimized flow range options.

The proven seated type directional control valve series D1SE in size NG06 is almost leakage-free and can be used for a wide range of hydraulic applications.

Parker’s SE20 series valve is a two stage, 4-way, flapper and nozzle style servovalve.

Parker’s direct acting differential area relief valves are for fast response intermittent applications and work up to 380 bar (5500 psi) and 151 lpm (40 gpm). These valves have lower leakage rates and pressure rise than standard direct acting reliefs.

The NG06 direct operated directional control valve D1VW with inductive position control provides high functional limits up to 80 l/min in combination with a low, energy saving pressure drop. It is typically used in safety relevant applications.

The VV6 valve consists of a housing, a poppet and two valve seats. It has two inlets and one outlet

Parker’s SE31 series valve is a two stage, 4-way, flapper and nozzle style servovalve and is designed to fit onto DIN NG10 or NFPA D05 port patterns.

Parker’s SE60 series valve is a two stage, 4-way, flapper and nozzle style servovalve.

Parker’s vented load control valves are designed to operate independent of downstream pressure to prevent runaway loads under all dynamic conditions, handling pressures up to 350 bar (5000 psi) and flows up to 113 lpm (30 gpm).

The directional control valve series D1VW 8 Watt is based on the standard D1VW design. The low watt, low current solenoid (< 0.5 A) of this on/off valve allows a direct connection to a PLC.

Parker’s Colorflow MVI series is a cartridge-type metering valve that meters flow in both directions.

Parker’s unloading pressure control valves automatically charge and maintain a specific pressure range within accumulators by loading and unloading pump flow. Usable with fixed or variable pumps and pressure of 420 bar (6000 psi) and flow up to 1 gpm.

Parker's direct operated proportional pressure relief valve series RE06M*W provides a fast response time and low presssure drop due to its powerful solenoid.

The PRS6 is a 3-way pressure reducing valve

Parker's NS series needle valve provides excellent speed control and shutoff for hydraulic applications where a free reverse-flow check is not needed.

Parker’s FS series flow control valve offers superior construction and high versatility due to its variety of materials, sizes and port styles. It can be used in both the mobile and industrial markets.

Parker offers an extensive range of 2-way flow control proportional valves through the use of Current Controlled Pulse Width Modulation (PWM) valve drivers with flow capabilities up to 227 lpm (60 gpm) and pressures as high as 210 bar (3000 psi).

Parker pilot operated pressure relief valves series R5V and R5V*P2 provide an outstanding constant pressure behaviour. The SAE flanges allow to mount the valves directly on the flanges of pumps or actuators to achieve a very compact design.

Parkers Colorflow C series hydraulic check valves offer superior construction and versatility with a variety of materials, sizes and ports. These one-way check valves are used in hydraulic and pneumatic applications in the mobile & industrial markets

Pressure compensated priority flow control valves maintain constant flow regardless of changes to inlet pressure for flows up to 90 lpm (24 gpm) and pressures up to 420 bar (6000 psi); excess flow is diverted once the priority flow requirement is met.

2-way flow control valves series GFG provide pressure compensated flow for a precise movement control. The valve design largely compensates temperature variations.

Parker's Colorflow N series hydraulic flow control, in-line needle valves meters flow in both directions or provides a reliable shut off. This needle valve flow control is used in air and oil applications and has standard and fine metering options.

Parker’s Colorflow MV series valves is a high precision adjust needle valve that meters flow in both directions.

Parker's ball type inline shuttle valves are plumbed external from manifolds and line bodies and are available in two flow size options of 11 lpm (3 gpm) or 22 lpm (6 gpm), and pressures up to 207 bar (3000 psi).

Parker digital amplifier modules series PWD00A-400 combine all necessary functions for the optimal operation of proportional directional control valves without position sensor.

Parker’s Colorflow PC*M series in-line pressure compensated valves regulate flow at a selected rate within 5% regardless of fluctuations in inlet and outlet flow. This hydraulic flow control valve can be used within a variety of applications.

Parker’s ball and poppet style check valves are cartridges designed to be inserted inside manifolds and can handle flow up to 500 lpm (132 gpm) and pressures at 420 bar (6,000 psi) for circuit optimization and space savings.

The 2/2 way seat valves series C10 C*E in cartridge design are equipped with an inductive switch to monitor the closed position. They are preferably used for safety-relevant applications.

Parker’s Colorflow PC*K series in-line hydraulic valve is a pressure compensated flow control valve that regulates flow at a selected rate within 5% regardless of fluctuations in inlet and outlet flow.

Parker’s PMCS series valves are designed to regulate flow at a selected rate.

Designed to lock hydraulic circuits or actuators in rest conditions, Parker’s dual pilot operated check valves allow bidirectional flow ranging up to 19 lpm (5 gpm) and pressure up to 207 bar (3,000 psi) after pilot pressure is supplied.

Parker's directional control valves series D1MW (NG06) / D3MW (NG10) are optimally suited for mobile applications due to an excellent surface protection. They provide high flow rates and a wide range of connector versions.

Parker’s GT series valves isolate gages from damage and inaccurate readings caused by line pressure surges and hydraulic hammer.

Cross-Over Relief cartridge valves provide pressure protection to hydraulic motors, cylinders and rotary actuators up to 120 lpm (32 gpm) and 350 bar (5000 psi). Available in single or dual cartridge, in-line, manifold, or motor mount configurations.

Parker's pilot operated pressure relief valves series ZDV in sandwich design offer maximum flow rates up to 140l/min and enable an easy configuration of stack systems.

Parker’s GF series valves isolate gages from damage and inaccurate readings caused by line pressure surges and hydraulic hammer.

Parker’s High Pressure BV Series ball valves offer a variety of porting and thread types. These valves are rated up to 11,600 psi and are zinc coated to extend the live of the valve.

Designed to lock hydraulic circuits or actuators in rest conditions, Parker’s dual pilot operated check valves allow bidirectional flow from 38 lpm (10 gpm) to 226 lpm (60 gpm) and pressures up to 350 bar (5,000 psi) after pilot pressure is supplied.

Parker pressure intensifiers series SD500 are particularly suitable for machine tools. They enable a cost-effective system solution especially in clamping applications

Parker’s pilot operated pressure reducing valves are capable of flows up to 150 lpm (40 gpm) and regulating pressures up to 350 bar (5000 psi) and are commonly used for setting the pressure of a sub-circuit within a hydraulic system.

Parker electronic modules series PWDXXA-40* combine all necessary functions for the optimal operation of proportional directional control valves with position sensor or valves in closed loop systems.

Parker’s CB series counterbalance valve controls the actuator movement with overrunning loads.

Parker’s CP series pilot operated check valves are designed for maximum flow rates.

Parker’s direct acting reducing & relieving valves are used in intermittent duty applications where specific functions require reduced and regulated pressure. Capable of flows up to 56 lpm (13 gpm) and pressures up to 420 bar (6000 psi).

The proportional pressure relief valve series RE06M*T (NG06) with onboard electronics provides a fast response time and low presssure drop. It is based on the functionality of the digital amplifier PCD00.

Parker’s FC, FD series throttle check valves are designed for maximum flow rates.

Parker’s family of 3-position, 4-way proportional directional control valves come standard with closed or float center spools and are capable of flows up to 32 lpm (8.5 gpm) and pressures as high as 350 bar (5000 psi).

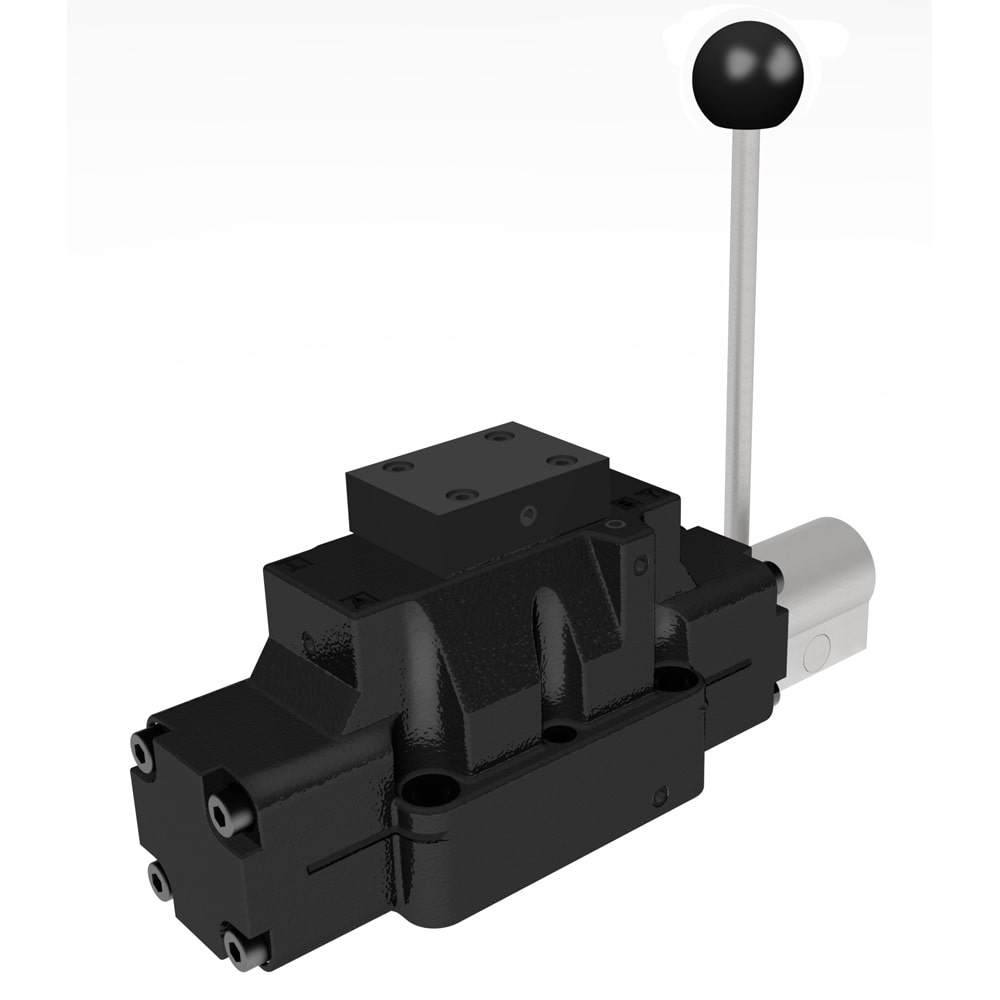

The direct operated directional control valves series D1VL (NG06 / CETOP 03 / NFPA D03) and D3DL (NG10 / CETOP 05 / NFPA D05) with hand lever provide high flow and feature a wide range of spool options.

Parker’s CH series check valves provide free flow in one direction and blocked flow in the reverse direction.

Parker’s RG series valve is a full time regenerative valve assembly.

Parker logic elements are screw-in type cartridge valves that can be used to control flow, pressure, or direction up to 303 lpm and 240 bar, and when applied in the proper arrangements, can perform multi-task control functions.

Parker's pilot operated pressure reducing valves series ZDR in sandwich design provide maximum flow rates up to 120l/min and enable an easy configuration of stack systems.

Parker’s CM series check valves is an integral, full flow check valve.

Parker's 2-position, 3-way ball type shuttle valves are designed to fit an industry common cavities and allow flows up to 50 lpm (13 gpm) and 420 bar (6000 psi).

The NG10 direct operated directional control valve series D3W with inductive position control provides high functional limits up to 150 l/min in combination with a low, energy saving pressure drop. It is typically used in safety relevant applications.

Parkers RV series direct acting, pressure relief valves are designed to limit pressure in various parts of a hydraulic circuit

Parker’s PR series pilot operated pressure reducing/relieving valves are used to regulate pressure in one area of a circuit at a set pressure below the normal system pressure.

Parker's insert type shuttle valves for countersinking inside manifolds are available as either poppet or ball type; capable of flows up to 38 lpm (10 gpm) and pressures up to 420 bar (6000 psi).

Electro-hydraulic pressure switches series PSB are robust, long-life high performance devices that provide an electrical signal when sensed pressure rises above or falls below the selected setting. The maximum operating pressure is 315 bar.

Parker’s RPL In-line Relief Valve rated at 60 GPM is designed for limiting the maximum pressure which can be applied to the portion of the hydraulic circuit where it is installed

Parker’s pilot operated sequence valves can be internally or externally piloted to allow multiple actuators to work in sequence based on pressure settings; working with flows up to 152 lpm (40 gpm) and pressures up to 380 bar (5500 psi).

Parker subplate mounted pilot operated pressure reducing valves series R4R ensure a constant pressure in the secondary part of the hydraulic system. Series R4R*P2 enables a continuous adjustment by the proportional solenoid operated pilot stage.

Parker’s S, H, SM, & HM are two position Selector Valves. The S & SM Models are designed for directing an input flow to two different selectable circuits. The H & HM Models are designed for adding float (or freewheeling) functionality to a circuit.

Parker’s LO & LOA are Pilot Operated Check Valves that are designed to lock a cylinder, or part of a circuit, without leakage while a control valve is in the neutral position.

3-way Pilot Operated, Threaded Cartridge Spool Valves used in normally closed or normally open directional control three way circuits requiring remote pilot actuation.

Multi-station manifolds series MSP are used to save space when connecting several directional control valves to a common pressure and return line.

Parker’s DXV Crossover Relief Valve is a fast, direct acting design that provides pressure overload protection for an actuator where the relieved flow is 10 GPM or less.

A pilot-operated, cartridge style screw-in hydraulic directional valve used in two way circuits with remote pilot actuation. Available in both normally-open and normally-closed orientation.

With high flow capacity and practically no flow limits, Parker's pilot operated proportional DC valve series D30FP in size NG10 (CETOP 05) delivers optimized cycle times and exceptional dynamic performance in a small footprint.

Parker’s WJL In-line Relief Valve rated at 25 GPM is designed for limiting the maximum pressure which can be applied to the portion of the hydraulic circuit where it is installed.

Parker’s CFQ Adjustable Flow Divider Valve is designed for providing a Controlled Flow source through one of three optional flow ranges from 0-30 GPM.

Parker selection of normally-closed 3-way flow control proportional valves used with Current Controlled Pulse Width Modulation (PWM) valve drivers have flow capabilities up to 75 lpm (20 gpm) and pressures as high as 210 bar (3000 psi).

Parker direct operated and hydraulically pilot operated check valves series C4V are robust and almost universally applicable. They are equipped with a leak-free seat cartridge

Parker’s DS, Two Position, Double Selector valve is designed for directing an A & B input to two different selectable circuits.

Parker’s direct acting sequence valves can be piloted and vented allowing multiple actuators to work in sequence based on pressure settings; working with flows up to 56 lpm (15 gpm) and pressures up to 420 bar (6000 psi).

Parker offers a wide range of accessories for liquid and gas, electronic, manual and thermal mass flow controllers (MFCs) for flow rate applications. Parker's line of MFCs includes models for vapor delivery systems, liquid MFC, gas MFCs and variable constant differential flow controllers.

Parker’s DWV Crossover Relief Valve is a fast-acting differential area design that provides pressure overload protection for an actuator where the relieved flow is 30 GPM or less. They are installed between the control valve and actuator.

Parker’s PD and PDC accessory valves are pressure compensated flow dividers that are designed for applications where two separate hydraulic circuits are to be served from a single pump.

Parker's 3-position, 3-way spool type closed center shuttle valves are available in two cavity sizes and provide high performance pilot control; capable of flows up to 175 lpm (46 gpm) and 350 bar (5000 psi).

Parker direct operated check valves series CM in sandwich design are predestined for an easy configuration of stack systems. A large number of options offer a multitude of uses for hydraulic switching.

Parker’s HP50 Pilot Generation Valve is designed to provide an in-line solution for generating a 300-500 PSI pilot pressure source that is typically required for hydraulic joysticks or solenoid operated main control valves.

Parker offers a wide range of accessories for liquid and gas, electronic, manual and thermal mass flow controllers (MFCs) for flow rate applications. Parker's line of MFCs includes models for vapor delivery systems, liquid MFC, gas MFCs and variable constant differential flow controllers.

Universally applicable for compact manifold block installation, Parker's cover without auxiliary functions series C*A and cover for pilot system mounting series C*C are available in many different sizes.

Parker’s DC25A Adjustable Flow Divider is designed for providing a 1-26 GPM controlled flow source. It is typically applied for applications where frequent adjustments to the controlled flow rate are required.

Parker’s RPJL In-line Relief valve rated at 25 GPM is designed for limiting the maximum pressure which can be applied to the portion of the hydraulic circuit where it is installed.

Parker’s poppet style check valve with thermal relief allow flows up to 130 lpm (40 gpm) and pressure to 420 bar (6,000 psi), with thermal relieving in the reverse direction to protect the circuit from high hydraulic fluid thermal expansion pressures.

Parker's cover with stroke limiter series C*B and C*H are universally applicable for compact manifold block installation and available in many different sizes.

Parker’s CFDA Adjustable Flow Divider is designed for providing a 0-15 GPM controlled flow source. It is typically applied for applications where frequent adjustments to the controlled flow rate are required.

Parker’s 2-position, 2-way normally-closed manual poppet valves are available with stem, knob, or lever actuators and are capable of flows up to 49 lpm (13 gpm) and pressures as high as 210 bar (3000 psi).

Parker's proven pilot operated pressure reducing valves series PRM in sandwich design enable an easy configuration of stack systems. They are available in size NG16 and NG25.

Parker’s CFD Controlled Flow/Priority Type Flow Divider is designed for providing a fixed 1-5 GPM controlled flow source for power steering systems and other applications where two separate hydraulic power circuits are to be served from a single pump

Parker’s P.O. check valve’s allow flows up to 226 lpm (60 gpm) and pressure up to 350 bar (5,000 psi). Return flow can be enable by an external pilot supply, which shifts the internal poppet into an open position.

Pressure relief valves series RDM are direct operated piston type valves with low hysteresis. They can be used as P-T relief or as T-T controlled counter balance valve.

Parker’s manually operated 4-way, 2 or 3-position directional control spool valve is capable of flows up to 7.5 lpm (2 gpm) and pressures as high as 240 bar (3500 psi). Knob and lever actuators are available with detents.

Proportional pressure reducing valves series VMY in size NG10 and NG16 allow the variable adjustment of the reduced pressure from 0 bar up to the nominal pressure.

Manifold Mounted Motor Control Valve capable of pressures up to 210 bar (3000 psi) and flows up to 56 lpm (15 gpm). Designed to direct mount on TB, TE, TF, and TG series Parker Low Speed, High Torque motors.

The hydraulically pilot operated check valve for subplate mounting series SVLA in size NG06 is proven part of the wide Parker pilot control range for DIN cartridge valves.

Parker’s manually operated 3-way, 2 or 3-position directional control spool valve is capable of flows up to 23 lpm (6 gpm) and pressures as high as 240 bar (3500 psi). Knob and lever actuators are available with detents.

2-way high-response valves series TEP in cartridge design base on the TDP range and provide a precise control of high flows at maximum dynamics. Additionally, TEP valves are equipped with a direction control valve for shutting off the pilot system.

Parker's pilot operated sequence valve with a built-in reverse check combines two functions into a single cartridge reducing space, components, and manifold complexity. Capable of flows up to 70 lpm (32 gpm) and pressures up to 420 bar (6000 psi).

Proportional pressure reducing valves series PRPM are particularly suitable for machine tools. They provide optimum performance in combination with a digital amplifier module PCD00A.

Parker’s priority pressure compensators provide constant flow regardless pressure changes via a fixed or adjustable orifice with priority to one outlet port. These valves can handle flows up to 95 lpm (25 gpm) and pressures up to 380 bar (5500 psi).

Parker's throttle check valves series ZRD in sandwich design feature maximum flow rates up to 160l/min and enable an easy configuration of stack systems.

Parker’s family of 2-way proportional poppet valves are available in normally-open or normally-closed configurations and are capable of flows up to 117 lpm (31 gpm) and pressures as high as 210 bar (3000 psi).

Parker check valves series SPZBE in size NG16, NG25 and NG32 are proven slip-in cartridge valves. Key advantage of this robust valve: the little space which is required for installation.

Parker check valves designed for “reverse” flow from the side port (port 2) to the end port (port 1) from 19 to 500 lpm (5 to 132 gpm) and pressures up to 420 bar (6,000 psi), allowing manifold space optimization while achieving superior performance.

The durable proportional pressure reducing valve D1FV OBE in NG06 (CETOP 03) features a very good pressure control behaviour. The digital onboard electronics is situated in a robust metal housing and provides a wide range of available commands.

Parker’s family of 2-way proportional poppet valves are available normally-open or normally-closed with a standard integrated pressure compensator; capable of flows up to 83 lpm (22 gpm) and pressures as high as 210 bar (3000 psi).

Parker pilot operated pressure relief valves for in-line mounting series R4V provide an outstanding constant pressure behaviour. Series R4V*P2 enables a continuous pressure adjustment by the additional proportional unit.

Parker’s 3-position, 4-way manual spool valves are spring centered shift by pushing and pulling with available detents and are capable of flows up to 19 lpm (5 gpm) and pressures as high as 350 bar (5000 psi).

Pilot operated pressure relief valves series R4V (TUEV) and R6V (TUEV) provide an outstanding constant pressure behaviour. They include a certification according to directive 97/23/EG for the usage in safety-related applications.

Parker’s pilot operated relief valves are designed for continuous duty applications and features a spool type pilot operated valve with an integrated reverse flow check; working with pressures up to 420 bar (6000 psi) and flows up to 350 lpm (92 gpm).

The proven counterbalance valve series ZNS in size NG06 (CETOP 03) and NG10 (CETOP 05) enables a reliable operation by controlling the actuator movement at overrunning loads.

Parker's 3-position, 3-way spool type open center shuttle valves are available in two cavity sizes and are pilot controlled. These shuttle valves are capable of flows up to 100 lpm (26 gpm) and 420 bar (6000 psi).

The screwable check valves series RK and RB are designed to go into simple, threaded cavities. They block the flow in one direction and open in the opposite direction.

The pilot operated pressure relief valves series R and RS*E are particularly suitable for the protection of the pump. These valves in slip-in cartridge design are offered as complete units and available in numerous variations.

Parker’s solenoid operated unloading relief valves are a combination of a solenoid unloader and system relief in a single valve and cavity; capable of flows up to 60 lpm (16 gpm) and pressures to 280 bar (4000 psi).

The hydraulically operated directional control valves series D1VP (NG06 / CETOP 03 / NFPA D03) and D3DP (NG10 / CETOP 05 / NFPA D05) ensure safe shifting and provide a wide range of spool options.

Hydraulically pilot operated check valves series RH for in-line mounting allow free flow in one direction (B to A). The counter flow (A to B) is blocked leak-free.

Pilot-to-close check valves operate as standard check valves, but block flow completely when a pilot signal is supplied; capable of flows up to 38 lpm (10 gpm) and pressures up to 240 bar (3,500 psi).

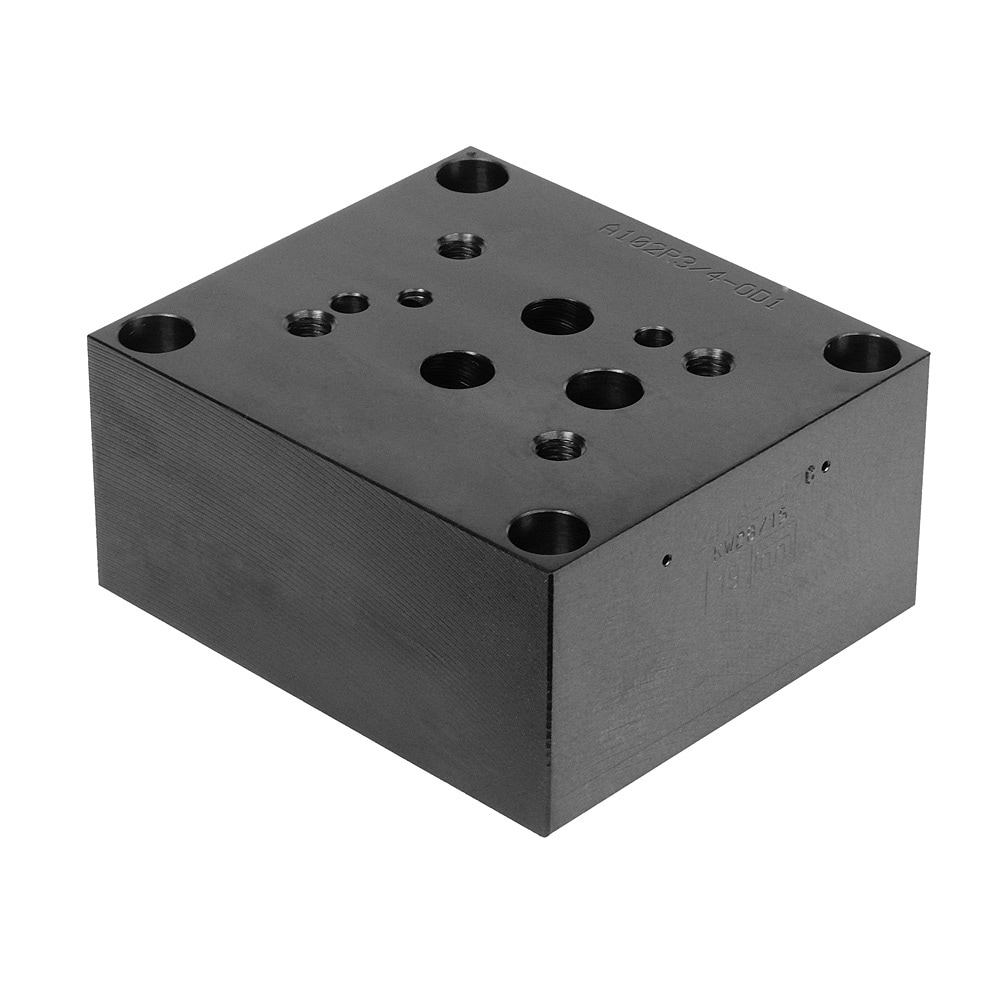

Subplates series SPD are used for directional control valves with BSPP threads. They are available in different versions from size NG06/CETOP 03 to NG25/CETOP 08.

Parker’s kick-down pilot operated spool type sequence valve is a hydraulic fuse used to unload flow once the pressure setting is reached, resetting when less than 45 psi. Capable of flows up to 160 lpm (42 gpm) and pressures up to 420 bar (6000 psi).

The flow compensated direct operated pressure relief valve series EVSA is a reliable seated type valve for screw-in mounting. It is predestined for pressure relieving of entire hydraulic systems.

Parker's 3-position, 3-way open center spool type inverse shuttle valves are available in two cavity sizes and are pilot controlled with integrated reverse checks. These shuttle valves are capable of flows up to 100 lpm (26 gpm) and 420 bar (6000 psi).

2-way flow control valves series 2F1C in size NG 10 and NG16 provide a pressure and viscosity compensated flow. Additionally they avoid unintended initial actuator motion.

Parker’s pressure compensator valves provide constant flow regardless of upstream or downstream pressure changes via a fixed or adjustable orifice. These valves can handle flows up to 150 lpm (40 gpm) and pressures up to 245 bar (3500 psi).

The shuttle valves for sandwich plate mounting series ZSRA and ZSRB in size NG06 are part of the wide Parker pilot control range for DIN cartridge valves.

Parker's 2-position, 3-way spool type shuttle valve with spring offset are purposefully spring biased into its normal position and are designed to fit an industry common cavity and are capable of flows up to 90 lpm (24 gpm) and 420 bar (6000 psi).

The series of active pilot operated 2/2 way throttle valves TDW enables fast and safe switching operations. The valves in cartridge design are supplied as one unit to ensure easy installation.

Parker’s kick-down pilot operated sequence valve is a hydraulic fuse used to unload flow once the pressure setting is reached, resetting when all flow is removed. Capable of flows up to 160 lpm (42 gpm) and pressures up to 420 bar (6000 psi).

As a part of Parker's comprehensive modular DIN cartridge system, the sandwich valve with pressure relief function series ZUDB provides maximum flexibility in building pressure functions.

The pilot operated proportional pressure relief valves R4V/R6V OBE form a compact unit with the integrated electronics. They provide an excellent balanced pressure behaviour.

Parker's 2-position, 3-way spool type shuttle valves will fit industry common cavities while providing superior performance; capable of flows up to 90 lpm (24 gpm) and 420 bar (6000 psi).

Being extremely versatile for directional control functions, Parker's leak-free subplate-mounted seat valves series D4S enable individual hydraulic solutions based on various function options.

The proven directional control valves series D4L (NG16 / CETOP 07 / NFPA D07) and D9L (NG25 / CETOP 08 / NFPA D08) with hand lever are robust units suited to a wide range of industrial applications where high flow rates are required.

The new Parker 2-way high performance proportional throttle valves series TDC are characterized by a precise control of high flows at high dynamics. Typical applications for TDC slip-in cartridge valves are injection molding and hydraulic presses.

Subplate mounted unloading valves series R4U are used to unload a circuit at low pressure.

Parker's proportional pressure relief cartridge valve series RE*E*W consists of a proportional pilot stage and a slip-in cartridge main stage. It is universally suitable for applications with high flow.

The robust and durable proportional pressure reducing valve series D1FV in NG06 (CETOP 03) provides a very good pressure control behaviour. It is optionally available as explosion proof version according to ATEX and IECEx.

The hydraulically pilot operated check valve series SVLB is based on Parker's comprehensive modular DIN cartridge system. It is mainly used to shut-off the cylinder.

Universally applicable for compact manifold block installation, Parker's cover with shuttle valve series C*V and cover with shuttle valve and pilot system mounting series C*W are available in many different sizes.

Universally applicable for compact manifold block installation, Parker's cover with pressure relief valve series C*F and cover with pressure relief valve and pilot system mounting series C*G are available in many different variations.

Parker electronic modules PZD00A-40* for command signal processing may be connected in series to proportional valves with onboard electronics as well as to Parker amplifier modules.

The unloading valves series UR*E and US*E consist of a mechanical pilot stage and a slip-in cartridge main stage. In addition the series US*E is vented by electrical operation. These valves are used to unload a circuit at low pressure.

Working extremely stable and precise, the proportional version series VBY*K in size NG06 is particularly suitable for use in machine tools and other applications.

The hydraulically operated directional control valves series D4P (NG16 / CETOP 07), D9P (NG25 / CETOP 08) and D11P (NG32 / CETOP 10) ensure safe shifting and provide a wide range of spool options.

The pilot operated pressure relief valves series DSDU in cartridge design are mostly used for accumulator pressure relief.

Parker electronic modules series PID00A-40* for closed loop control meet the demands of position, pressure and velocity control applications for valves with integrated electronics and spool position feedback capability.

Direct operated pressure reducing valves series VM for subplate mounting regulate pressure in one area of a hydraulic circuit at a predetermined level below normal system pressure

Direct operated spool-type sandwich DC valves series Z1DW size NG06 are used for shutting off the flow in stack systems.

Parker pilot operated pressure unloading valves series R5U are particularly suitable for unloading a circuit at low pressure. The SAE flanges allow to mount the valve directly on the outlet flanges of pumps to achieve a very compact design.

The regenerative and hybrid pilot operated directional control valves series D31NWR, D*1VWR, D*1VWZ allow energy saving circuits with differential cylinders.

Direct operated pressure relief valves with manual adjustment series VS in size NG06 and VB in size NG06 respond very quickly and work extremely stable and precise. The perfect choice for use in machine tools as well as other applications.

Subplates series SPP are used for pressure valves with BSPP threads. They are available in different versions from size NG10 to NG32.

Direct operated pressure relief valves series R1E02 are seated type valves typically used for remote control of pilot operated pressure valves or compensators of variable pumps.

The pilot valve with proportional relief function series RPDM for sandwich mounting is a part of the wide Parker pilot control range for DIN cartridge valves. It provides a fast response time and low pressure drop due to its powerful solenoid.

The pneumatically controlled directional control valve series D1VA in size NG06 is based on the standard D1VW design. These valves are useful to control hydraulic systems in hazardous areas.

The shuttle valve series SSR is designed as a threaded cartridge valve. All parts are assembled in one unit and easy to mount.

Being extremely versatile for directional control functions, Parker's leak-free seat valves series D5S with SAE61 flange enable individual hydraulic solutions based on various function options.

The pilot valves with unloading function series UR06M for subplate mounting and US06M for sandwich plate mounting in NG06 are part of the wide Parker pilot control range for DIN cartridge valves.

The pilot operated pressure relief valves from the Parker Manapak series RM are in sandwich design for easy configuration of stack systems. They are available in size NG16 and NG25.

The cover plates series D51 in 3 different variants for NG06 / CETOP 03 and NG10 / CETOP 05 are part of Parker's comprehensive modular system for vertical stackings.

Pressure gauge selector valves series WM allow to connect up to 5 or 10 measuring points to one pressure gauge. When measuring is completed, the gauge is pressure-relieved to prevent it from being damaged by pressure surges.

The sandwich plates series H06 in 8 different variants for NG06 / CETOP 03 are part of Parker's comprehensive modular system for vertical stackings.

Parker in-line mounted pilot operated pressure reducing valves series R4R ensure a constant pressure in the secondary part of the hydraulic system. Series R4R*P2 enables a continuous adjustment by the proportional solenoid operated pilot stage.

Adaptor plates series PADA for NG10 to NG06 are used to combine cartridge components like covers and pilot valves in different sizes. They are available in two versions: connection A-B / B-A or connection A-A / B-B.

Parker's direct operated check valves series ZRV in size NG06 (CETOP 03) and NG10 (CETOP 05) are equipped with a cartridge type insert to ensure zero leakage and high lifetime.

The proportional pressure relief valve series RE*E*T with onboard electronics consists of a proportional pilot stage and a slip-in cartridge main stage. It is electronically based on the functionality of the digital amplifier PCD00.

Being extremely versatile for directional control functions, Parker's leak-free 2/2-way seat valves series D4S for in-line mounting enable individual hydraulic solutions based on various function options.

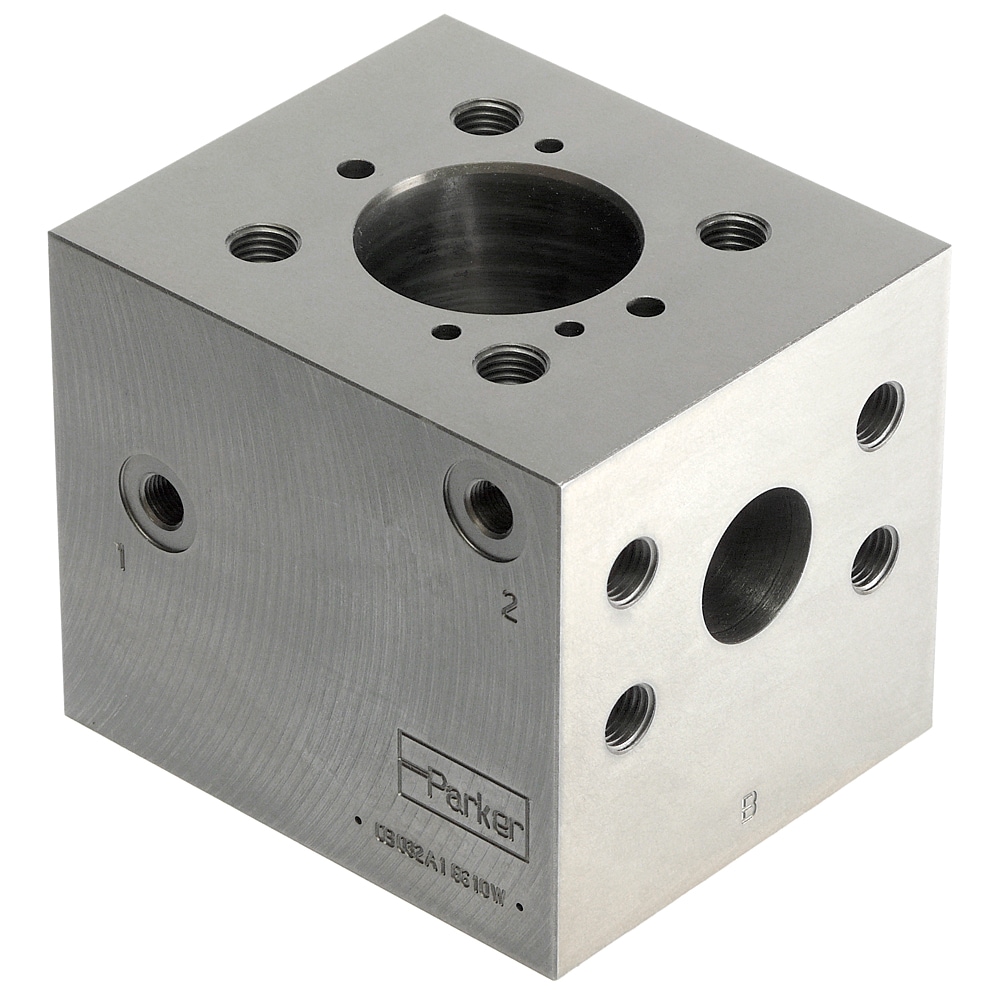

Parker cartridge manifold blocks series CB are bodies for 2/2-way slip-in cartridge valves. They are used in systems with only one cartridge valve without the need to design a specific manifold block.

The check valve series C1DB is a ready-for-use cartridge valve using proven components of Parker's modular DIN cartridge system. It provides a wide range of options and is particularly suitable for a compact manifold block installation.

Subplate mounted sequence valves series R4S enable a hydraulic system to operate in a pressure sequence.

The pilot valves with pressure relief function series R06M for subplate mounting and RS06M for sandwich plate mounting in size NG06 are part of the wide Parker pilot control range for DIN cartridge valves.

Sandwich plates series CS06 for NG06 / CETOP 03 offer a wide variety of applications, e.g. for vertical stackings. Cover plates series CS06 for NG06 / CETOP 03 may be used to connect porting patterns.

The pilot valves with preload function series DSBA100 in NG06 are part of the wide Parker pilot control range for DIN cartridge valves. They are available in two versions for subplate mounting or sandwich plate mounting.

Direct operated 3-way pressure compensators series R5P with SAE flange can be combined with fixed or adjustable flow resistors (throttles) to provide a load compensated flow.

The test unit EX-M05 ValveMaster® is particularly suitable for testing and commissioning of Parker proportional and servo proportional valves with onboard electronics.

Parker sandwich plates series H10 allow energy saving circuits for differential cylinders in combination with various directional control and proportional DC valves in size NG10 / CETOP 05.

The solid subplate series A102 in size NG10 is used for mounting the proven Parker pressure valves series VB and VM.

Subplates series A are used for directional control valves with metric threads. They are available in size NG06/CETOP 03 and NG10/CETOP 05.

Parker pilot operated sequence valves series R5S enable a hydraulic system to operate in a pressure sequence. The SAE flanges allow to mount the valves directly on the outlet flanges of pumps to achieve a very compact design.

The pilot valve for pressure sequence function series S06M in size NG06 is a proven component of the wide Parker pilot control range for DIN cartridge valves.

Parker adaptor plates series A10 allow energy saving circuits for differential cylinders in combination with various directional control and proportional DC valves in size NG10 / CETOP 05.

The regenerative and hybrid direct operated directional control valves series D3DWR in NG10 allow energy saving circuits with differential cylinders.

The new proportional cartridge throttle valves series TFP provide outstanding flow rates and minimized pressure losses. They control highest flows precise and with maximum dynamics in applications like die cast, hydraulic presses and injection molding.

Parker’s Explosion Proof D1VW ER is a tri-rated , directional control valve for NFPA D03 (NG06 / CETOP 03) up to 20 GPM and to 5,000 PSI.

Proportional throttle valves series F5C with SAE61 flange allow to adjust the flow in proportion to the input signal.