Parker offers needle valves for positive leak-tight shut-off and regulation of liquids and gases, in a variety of stem types, in both in-line and angle patterns. Several designs are provided for oil and gas processing facilities, along with a PFA product for use in aggressive chemical and gas applications.

4-port switching valve 4FN series for foot operation that is extremely durable with a robust structure. A wide variety of connection port sizes are available, from Rc1/4 to Rc3/4. (BSPT)

4-port switching valve 4PN series for hand operation that is extremely durable with a robust structure. A wide variety of connection port sizes are available, from Rc1/4 to Rc3/4. (BSPT)

4-port switching valve 4F series for foot operation that is extremely durable with a robust structure. A wide variety of connection port sizes are available, from Rc1/4 to Rc3/4.

Lubrication-free 5-port hand lever valve RB54-H series. It has a unique design and uses a special sealing with excellent durability and sealing properties. The connection port size is BSPT type.

Lubrication-free 5-port Master valve RB54-A series. It has a unique design and uses a special sealing with excellent durability and sealing properties. The connection port size is BSPT type.

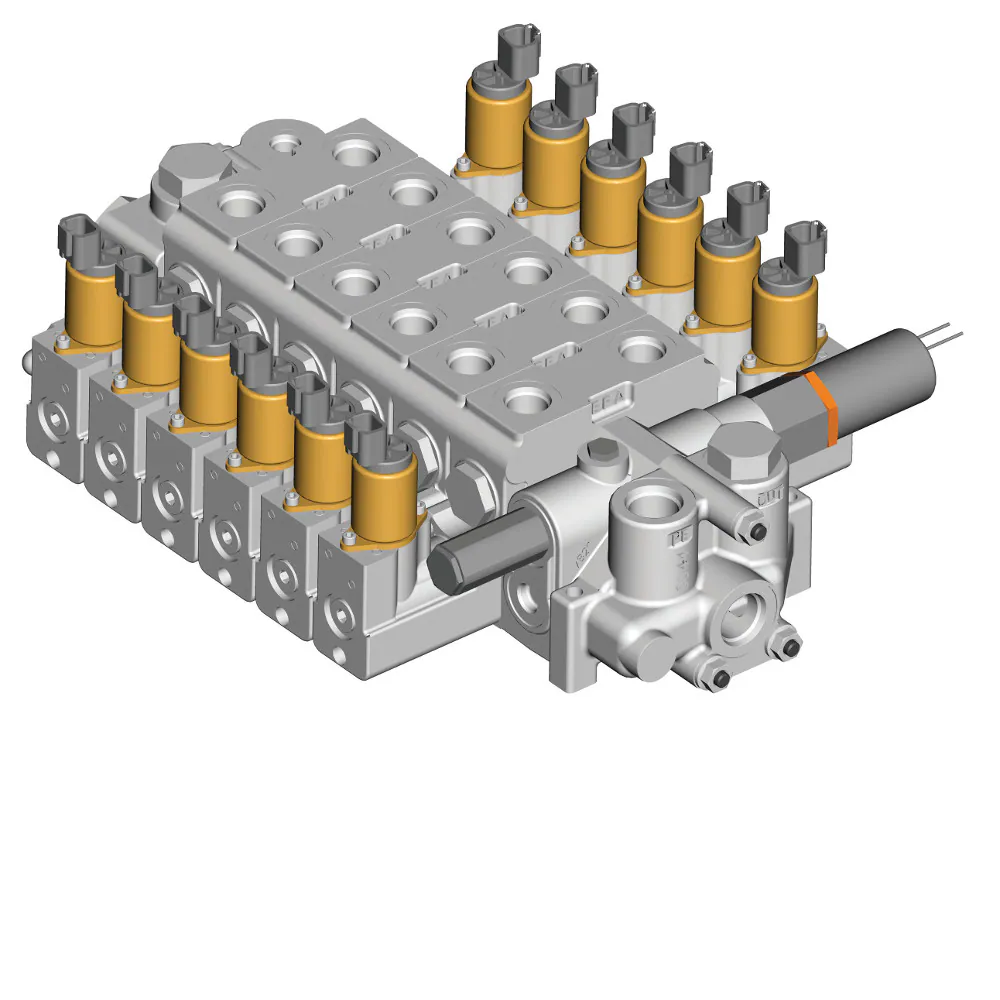

PM series solenoid operated air valves feature internal-pilot-type metal seal and spool valve. Options include 3-way/4-way, single/double solenoid, and 3-position models. Configurations can be customized to meet customer needs.

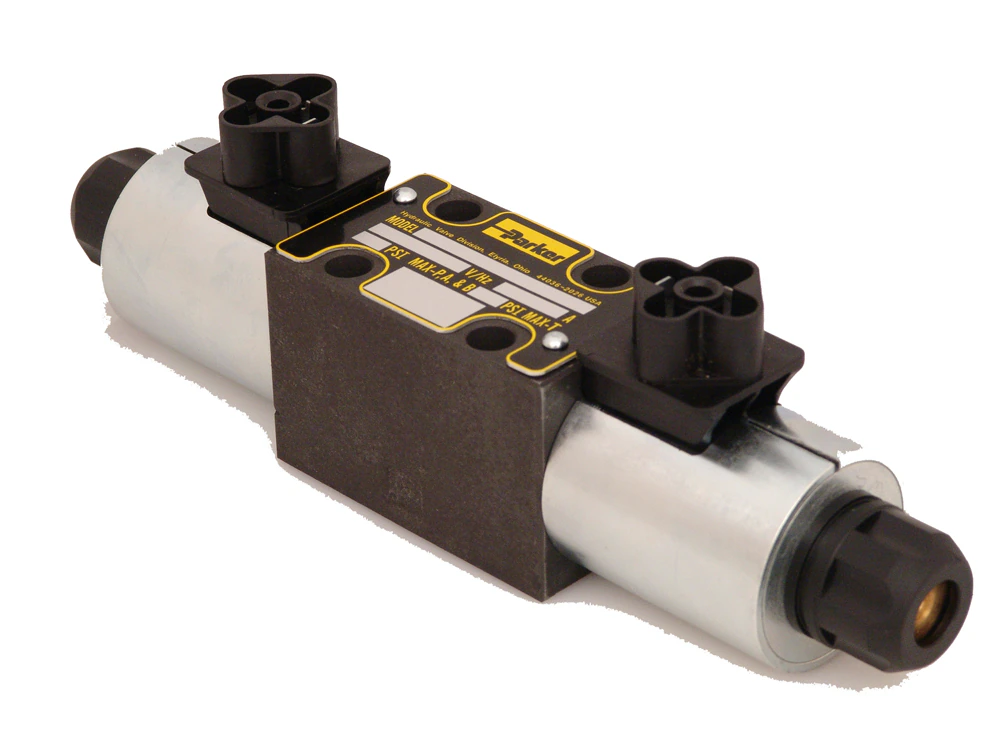

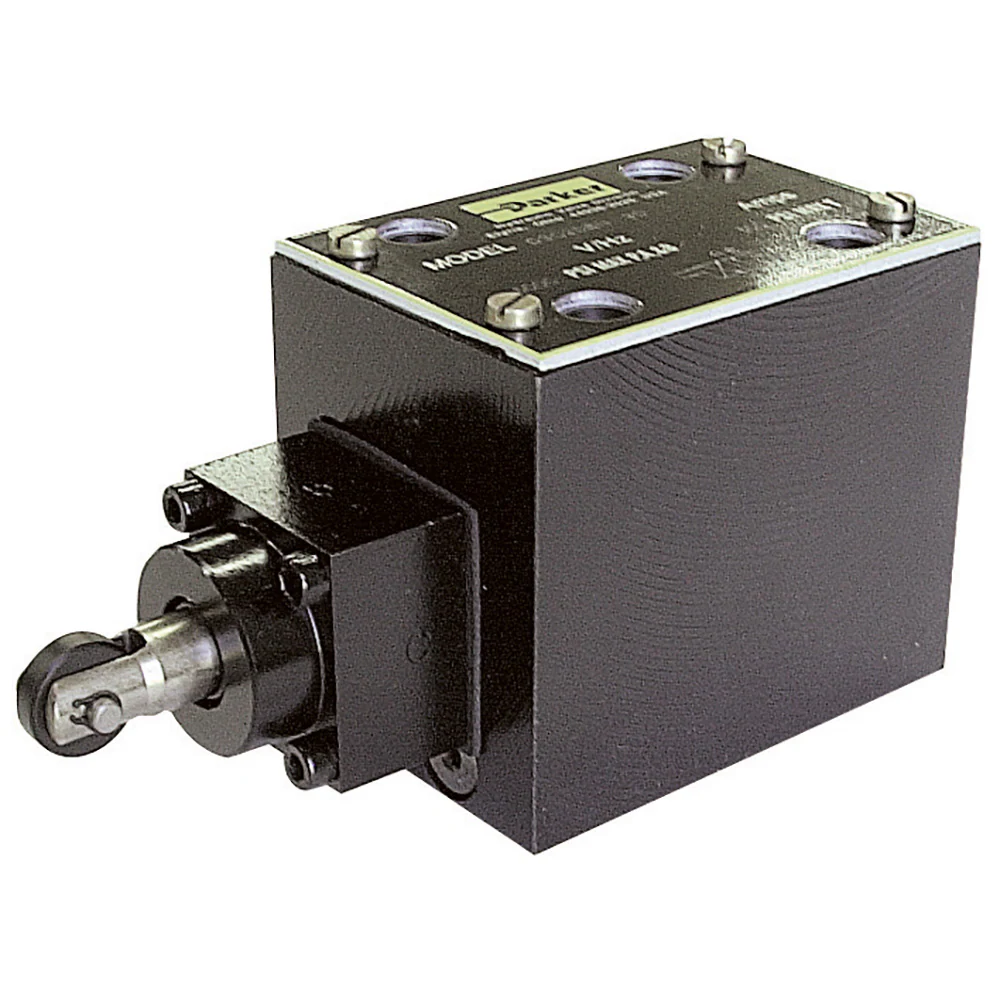

Parker’s D1VW directional control valves are high performance direct operated hydraulic valves. These are wet armature design solenoid valves in either 2 position or 3 position configurations. The D1VW valve conforms to D03 (NG6) mounting pattern.

Parker’s VP120 series is a sectional, pressure compensated load sensing directional control valve for mobile machines.

Parker’s VPL Series is a stackable, multi-section, load-sensing, pressure-compensated directional valve for mobile equipment. Work Port flows rated to 30 GPM at 5000 PSI.

Parker’s VP/VPO series valve is a stackable, multi-section, load-sensing, pressure-compensated directional valve for mobile equipment.

Parker’s VP170 series is a sectional, pressure compensated load sensing directional control valve for mobile machines.

Parker’s pilot operated relief valves are designed for continuous duty applications featuring great stability with low pressure drop; working with pressures up to 420 bar (6000 psi) and flows up to 400 lpm (106 gpm).

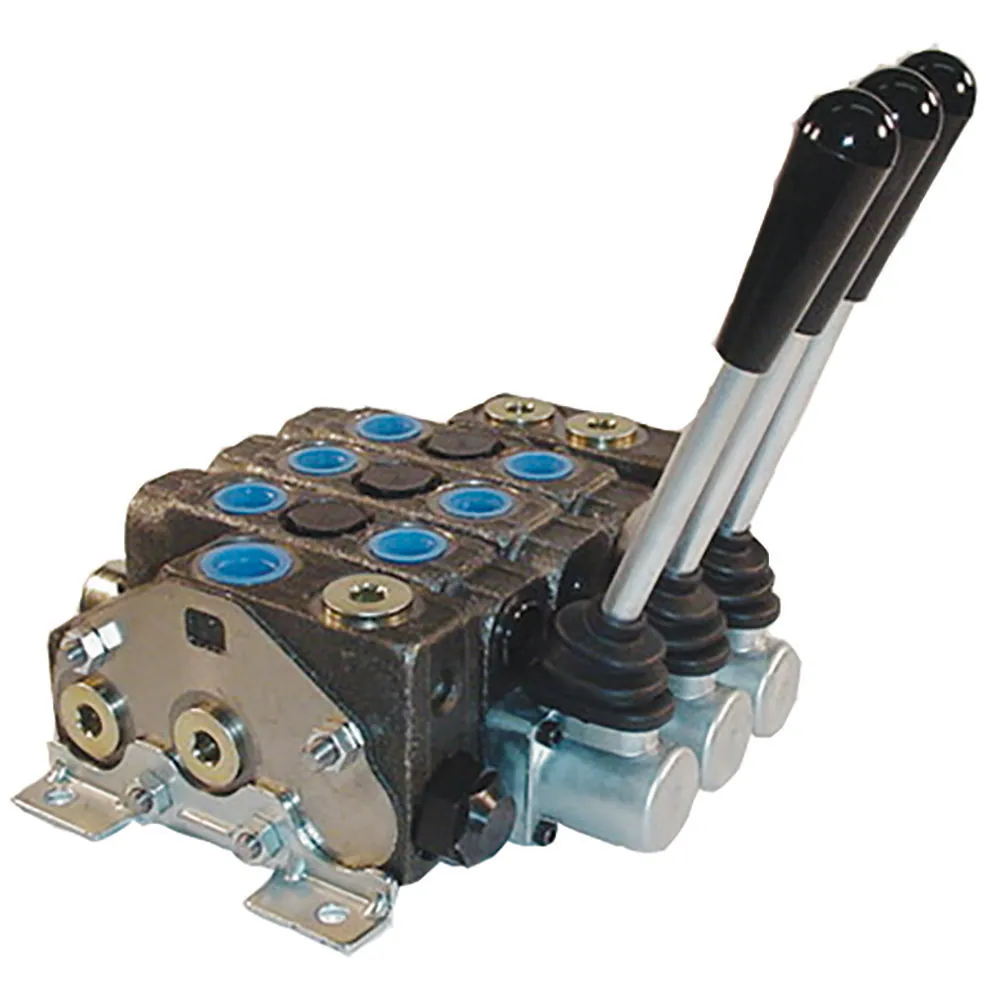

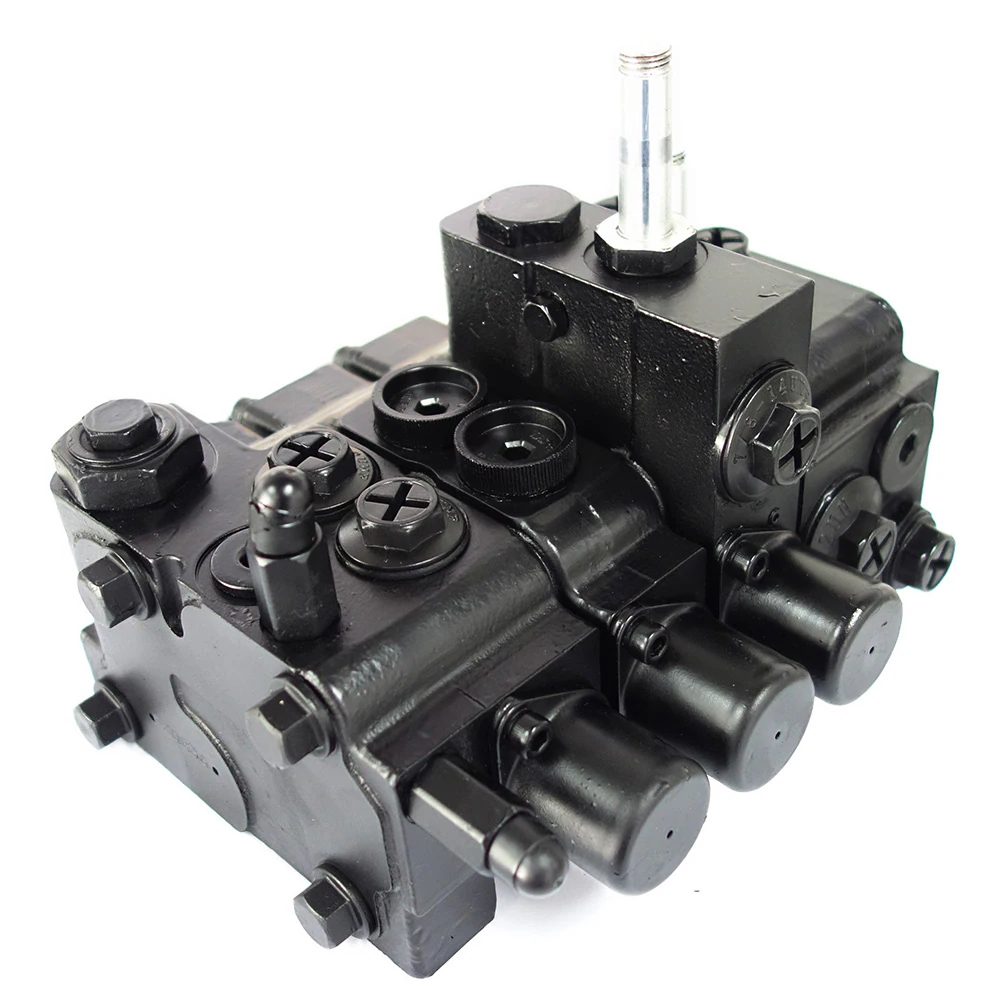

Parker’s V20 Series valve is a sectional, open center, CF (constant flow), or closed center load sensing (variable flow) directional control valve for mobile equipment. It is typically applied between 15 and 25 GPM pump flow at 3500 psi.

Parker’s V10 Series valve is a sectional, open center, CF (constant flow), directional control valve for mobile equipment. It is typically applied between 5 and 15 GPM pump flow at 3500 psi.

Parker has a large selection of direct acting 4-way, 3-position spool-type solenoid valves to cover a wide range of flow requirements up to 57 lpm (15 gpm) and pressures as high as 350 bar (5000 psi); closed, open, float, and tandem centers available.

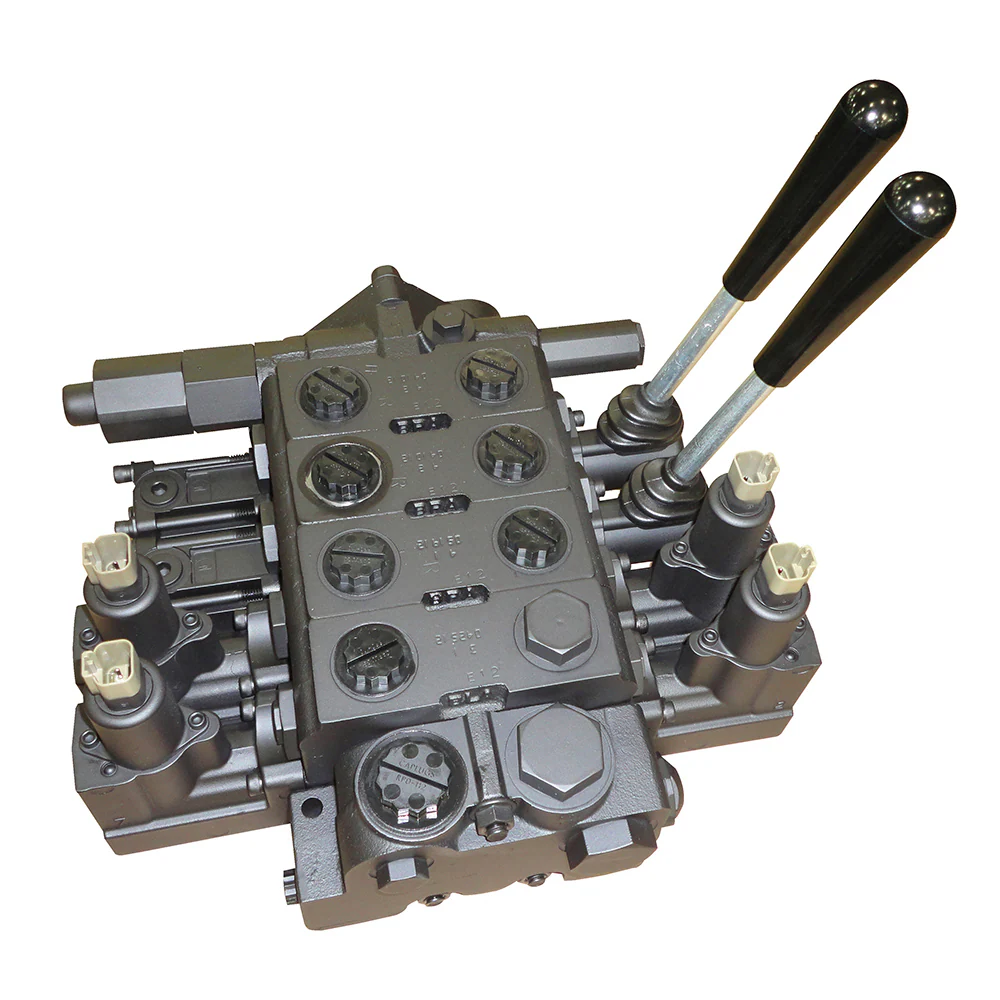

Parker’s VA35/VG35 is a sectional, open center, CF (constant flow), directional control valve for mobile machines. It is typically applied between 20 and 45 GPM pump flow.

Parker’s V20EH is a sectional, open center, CF (constant flow), directional control valve for mobile machines. It is Electro-Hydraulic actuated and can be applied up to 25 GPM

Parker's VG35EH valve is a sectional, open center, CF (constant flow), directional control valve for mobile machines. It is Electro-Hydraulic actuated and typically applied between 30 and 65 GPM pump flow.

Parker’s PC55 series valve is a sectional, pressure compensated load sensing directional control valve for mobile machines.

FLV95 mobile valve is integrated in a multi-function configuration. Better control and lower power consumption. FLV95 is a sectional valve designed for forklift used in fixed displacement pump systems.

Parker’s D1VC, D1VD and D1VG directional control valves are high performance, 4-chamber, direct operated, cam controlled, 4-way valves.

Parker’s D3DW directional control valves are high performance, 5-chamber, direct operated, wet armature, solenoid controlled, 3 or 4-way valves.

High pressure solenoid valves are direct acting 3-way, 2-position spool-type to cover a wide range of flows up to 57 lpm (15 gpm) and pressures as high as 350 bar (5000 psi). These screw-in cartridge valves are fast to respond to coil voltage.

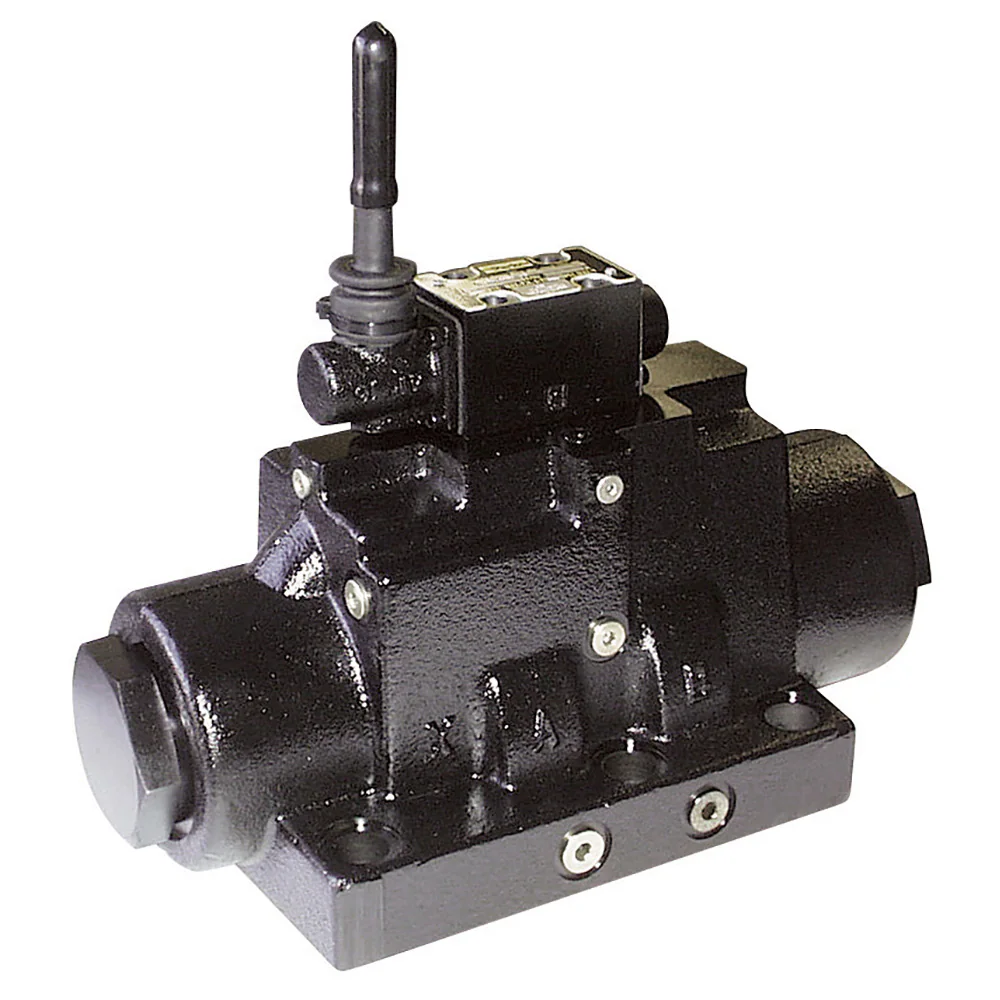

Parker’s D3L directional control valves are high performance, 5-chamber, direct operated, lever controlled, 4-way valves.

Parker’s D3A directional control valves are high performance, 4-chamber, direct operated, air pilot controlled, 4-way valves.

Parker’s D3C and D3D directional control valves are high performance, 4-chamber, direct operated, cam controlled, 3 or 4-way valves.

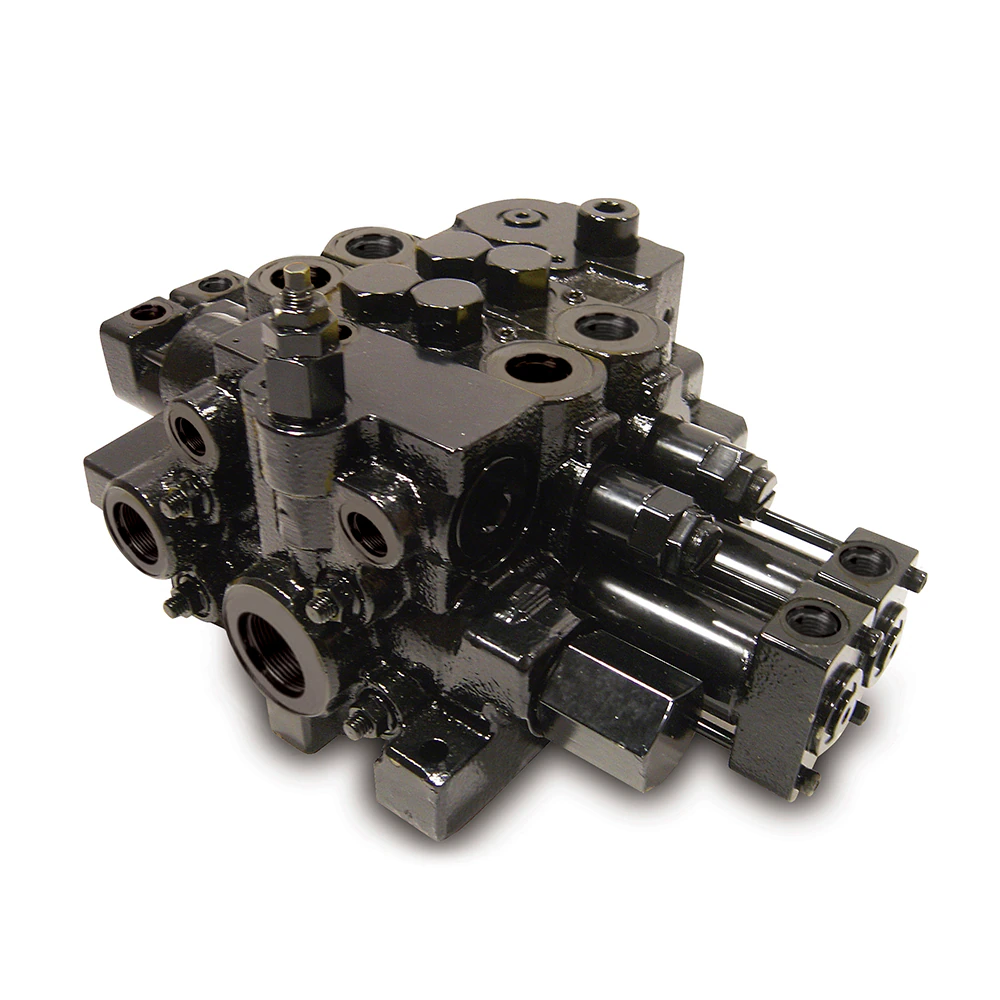

KM300 mobile valve equipped with the function of low pressure regeneration, Better control and lower power consumption. KM300 is a monoblock valve designed for wheel loader and other mobile machinery used in open center systems.

Parker's D3*P series directional control valves are 5-chamber, oil pilot operated valves

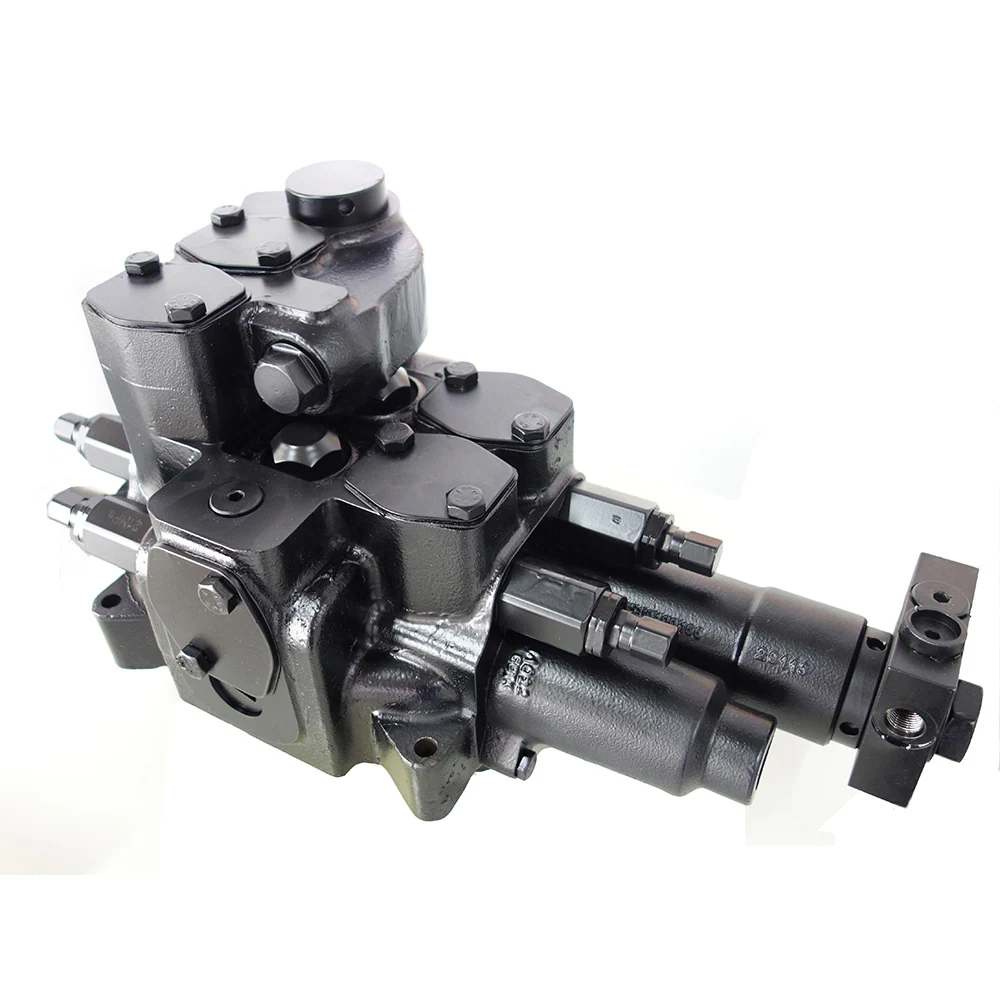

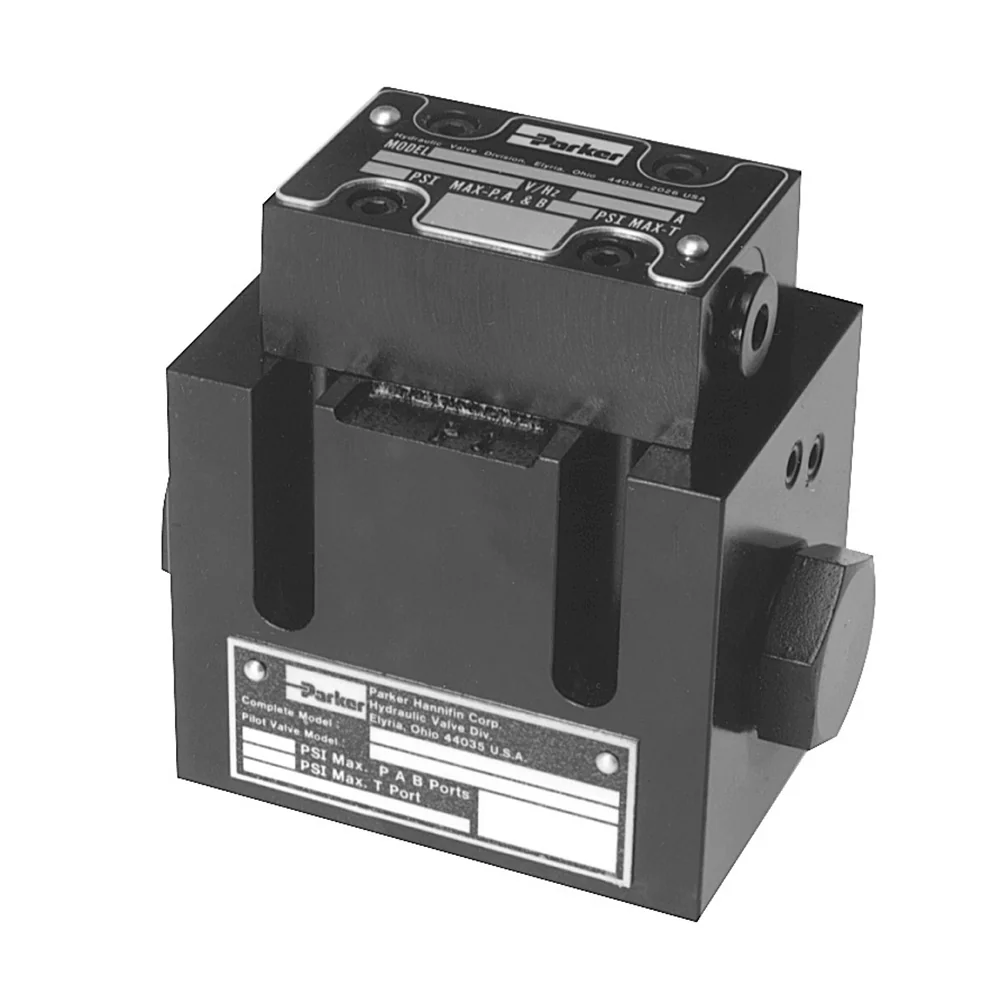

Parker’s D31 directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker's D31*A directional control valves are 5-chamber, air pilot operated valves.

Parker’s D31*L directional control valves are 5-chamber, pilot operated, lever controlled valves.

Parker’s D61VW directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

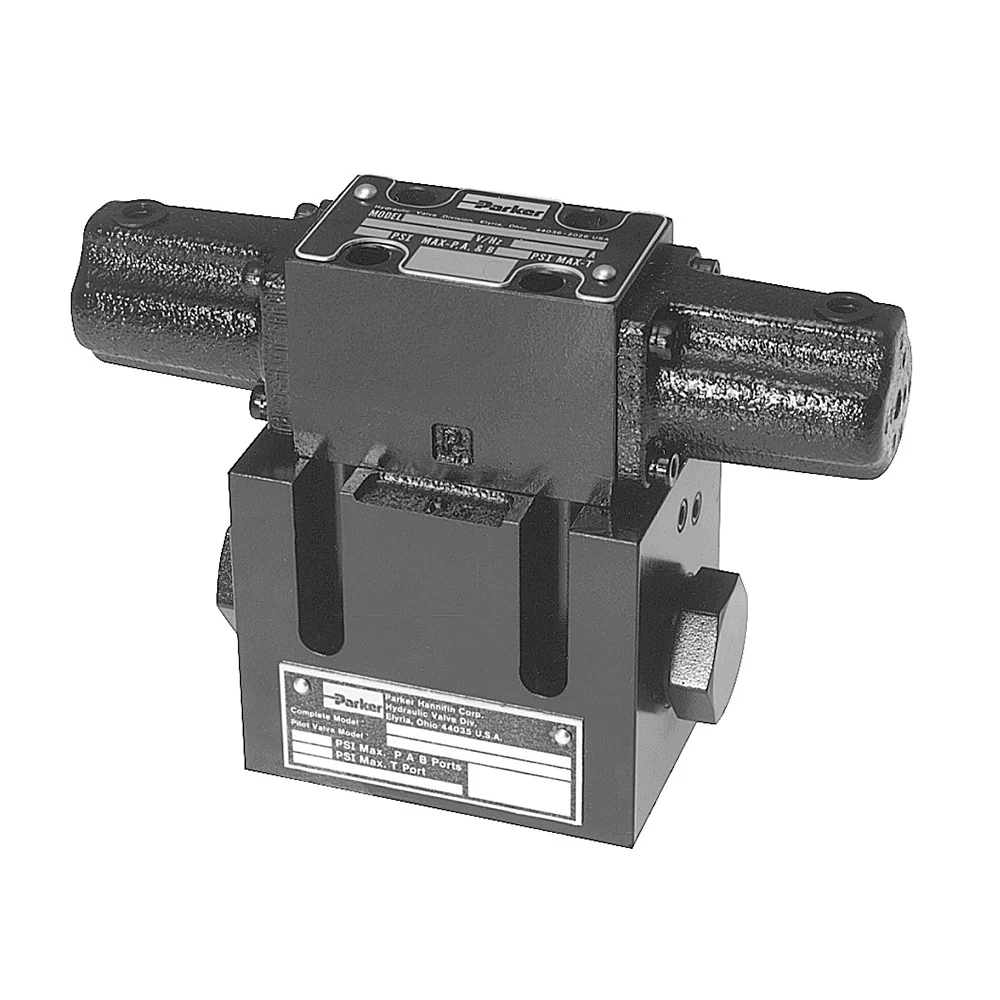

Parker’s D61VL directional control valves are 5-chamber, lever operated valves.

Parker’s direct acting 4-way, 2-position spool-type solenoids offer a simple electronic solution for actuation or reversing applications; available with flows up to 113 lpm (30 gpm) and pressures as high as 350 bar (5000 psi).

Parker’s D6P directional control valves are 5-chamber, pilot operated valves.

Parker’s selection of direct acting 2-way, 2-position spool-type solenoid valves cover a wide range of flows up to 75 lpm (20 gpm) and pressures as high as 350 bar (5000 psi), with both normally-closed and normally-open options available.

Parker’s D81VW directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker’s D81VL directional control valves are 5-chamber, lever operated valves

Parker’s spool type logic elements can be used for direction and pressure/flow control, and are available normally-open and normally-closed with internal or external pilots for pressures up to 420 bar (6000 psi) and flows up to 500 lpm (132 gpm).

Parker’s D81VA directional control valves are 5-chamber, air pilot operated valves.

Parker’s pilot operated acting reducing & relieving valves are used in applications where specific functions require reduced and regulated pressure. Capable of flows up to 150 lpm (40 gpm) and pressures up to 380 bar (5500 psi).

Parker’s D8P directional control valves are 5-chamber, pilot operated valves.

Parker’s D101V directional control valves are 5-chamber, pilot operated, solenoid controlled valves.

Parker’s N5 valves are high flow / high pressure 3-way 2-position spool-type pilot-operated cartridge valves that can be used to control direction, pressure, or flow.

Parker’s D101VL directional control valves are 5-chamber, lever operated valves.

Parker offers a wide range of pressure compensated flow controls for applications that demand constant flow with varying loads and pressures; handling pressures as high as 420 bar (6000 psi) and flows to 56 lpm (15 gpm) in a single common cavity.

Parker’s D101VA directional control valves are 5-chamber, air pilot operated valves

Parker’s Series D10P directional control valves are 5-chamber, pilot operated valves.

Parker’s selection of proportional pressure reducing valves are for pressure sensitive applications and are capable of flows up to 37 lpm (10 gpm) and pressures as high as 210 bar (3000 psi).

Parker’s selection of proportional pressure relieving valves are for applications that require dynamic relieving and valves that are capable of flows up to 95 lpm (25 gpm) and pressures as high as 350 bar (5000 psi).

Parker offers four different flow divider/combiner valves to cover a wide range of flows up to 320 lpm (85 gpm) and pressures as high as 420 bar (6,000 psi). Standard and custom ratios are available, along with optimized flow range options.

Parker’s unloading pressure control valves automatically charge and maintain a specific pressure range within accumulators by loading and unloading pump flow. Usable with fixed or variable pumps and pressure of 420 bar (6000 psi) and flow up to 1 gpm.

Parker offers an extensive range of 2-way flow control proportional valves through the use of Current Controlled Pulse Width Modulation (PWM) valve drivers with flow capabilities up to 227 lpm (60 gpm) and pressures as high as 210 bar (3000 psi).

Pressure compensated priority flow control valves maintain constant flow regardless of changes to inlet pressure for flows up to 90 lpm (24 gpm) and pressures up to 420 bar (6000 psi); excess flow is diverted once the priority flow requirement is met.

Parker’s pilot operated pressure reducing valves are capable of flows up to 150 lpm (40 gpm) and regulating pressures up to 350 bar (5000 psi) and are commonly used for setting the pressure of a sub-circuit within a hydraulic system.

Parker’s direct acting reducing & relieving valves are used in intermittent duty applications where specific functions require reduced and regulated pressure. Capable of flows up to 56 lpm (13 gpm) and pressures up to 420 bar (6000 psi).

Parker’s family of 3-position, 4-way proportional directional control valves come standard with closed or float center spools and are capable of flows up to 32 lpm (8.5 gpm) and pressures as high as 350 bar (5000 psi).

Parker’s pilot operated sequence valves can be internally or externally piloted to allow multiple actuators to work in sequence based on pressure settings; working with flows up to 152 lpm (40 gpm) and pressures up to 380 bar (5500 psi).

3-way Pilot Operated, Threaded Cartridge Spool Valves used in normally closed or normally open directional control three way circuits requiring remote pilot actuation.

A pilot-operated, cartridge style screw-in hydraulic directional valve used in two way circuits with remote pilot actuation. Available in both normally-open and normally-closed orientation.

Parker selection of normally-closed 3-way flow control proportional valves used with Current Controlled Pulse Width Modulation (PWM) valve drivers have flow capabilities up to 75 lpm (20 gpm) and pressures as high as 210 bar (3000 psi).

Parker’s direct acting sequence valves can be piloted and vented allowing multiple actuators to work in sequence based on pressure settings; working with flows up to 56 lpm (15 gpm) and pressures up to 420 bar (6000 psi).

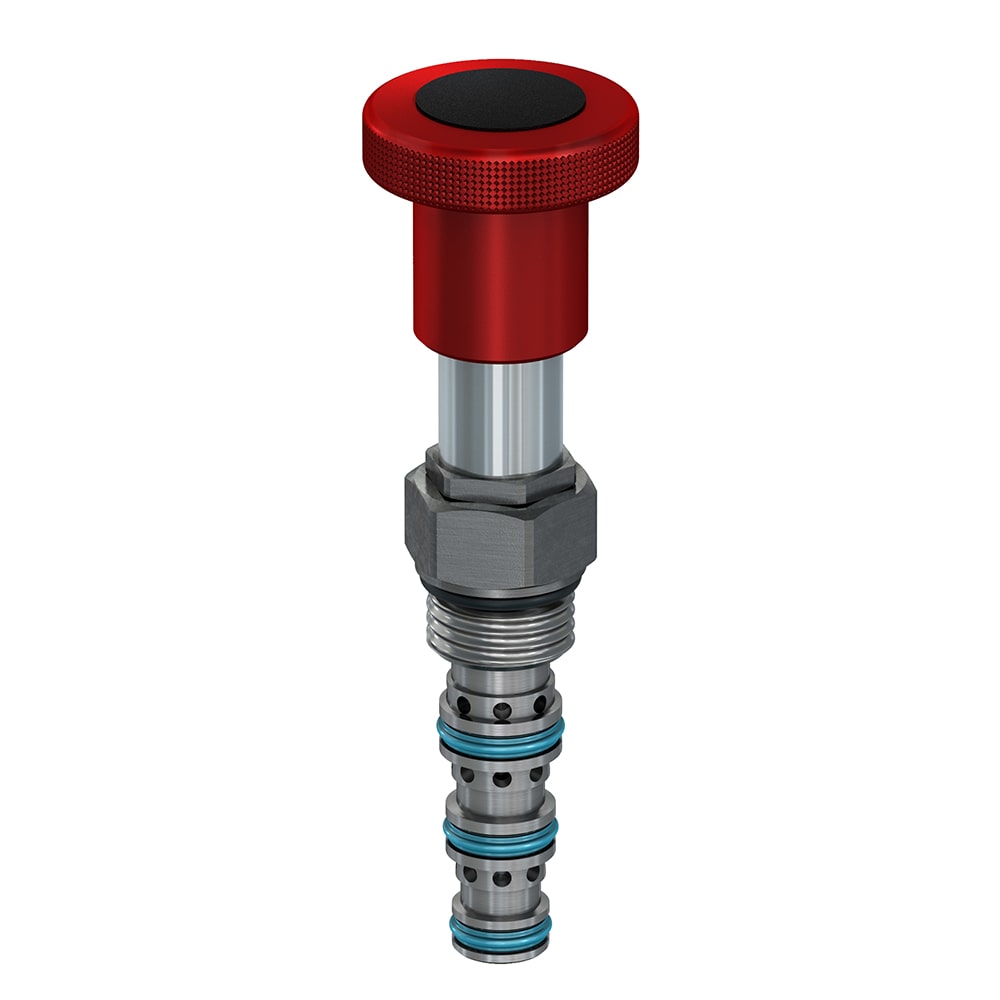

Parker’s manually operated 4-way, 2 or 3-position directional control spool valve is capable of flows up to 7.5 lpm (2 gpm) and pressures as high as 240 bar (3500 psi). Knob and lever actuators are available with detents.

Parker’s manually operated 3-way, 2 or 3-position directional control spool valve is capable of flows up to 23 lpm (6 gpm) and pressures as high as 240 bar (3500 psi). Knob and lever actuators are available with detents.

Parker's pilot operated sequence valve with a built-in reverse check combines two functions into a single cartridge reducing space, components, and manifold complexity. Capable of flows up to 70 lpm (32 gpm) and pressures up to 420 bar (6000 psi).

Parker’s priority pressure compensators provide constant flow regardless pressure changes via a fixed or adjustable orifice with priority to one outlet port. These valves can handle flows up to 95 lpm (25 gpm) and pressures up to 380 bar (5500 psi).

Parker’s family of 2-way proportional poppet valves are available normally-open or normally-closed with a standard integrated pressure compensator; capable of flows up to 83 lpm (22 gpm) and pressures as high as 210 bar (3000 psi).

Parker’s 3-position, 4-way manual spool valves are spring centered shift by pushing and pulling with available detents and are capable of flows up to 19 lpm (5 gpm) and pressures as high as 350 bar (5000 psi).

Parker’s pressure compensator valves provide constant flow regardless of upstream or downstream pressure changes via a fixed or adjustable orifice. These valves can handle flows up to 150 lpm (40 gpm) and pressures up to 245 bar (3500 psi).

Parker’s kick-down pilot operated sequence valve is a hydraulic fuse used to unload flow once the pressure setting is reached, resetting when all flow is removed. Capable of flows up to 160 lpm (42 gpm) and pressures up to 420 bar (6000 psi).

Parker's range of flushing rings are available in number of different styles and configurations. The flushing Ring is held in place by the through bolting, this allows for ease of installation and to positively locate in process control applications