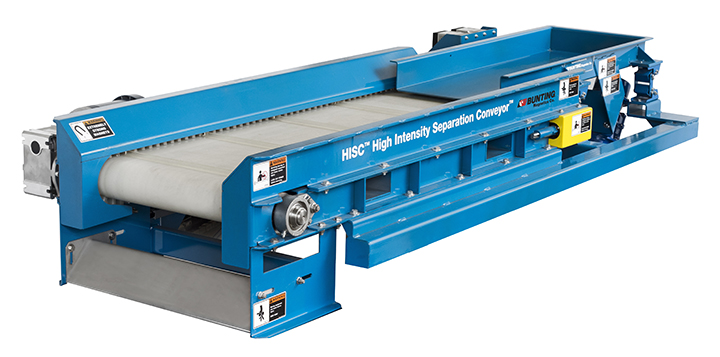

Bunting® provides a large lineup of material handling equipment for the Recycling, Metal Stamping, Plastics and Food industries. Bunting combines our material handling conveyors with magnetic separation and metal detection equipment to separate and purify materials. We add magnetic rails to conveyors to stabilize, transport and hold ferrous parts through manufacturing operations.

Bunting® magnetic separation includes units designed to remove metal contamination from dry particulates, liquids, and slurries in gravity, mechanical, or pneumatic conveying systems. Widely used in the food, dairy, grain, chemical, plastics, oil, textile, recycling, and other industries.

Bunting® metal detection products are designed to monitor free-flowing gravity-fed products, pneumatically conveyed materials on conveyor belts as well as liquids, pastes, and slurries in pipes. For use in the Food, Grain & Milling, Powder & Bulk, Recycling and Plastics Industries.

Bunting® magnetic printing cylinders can be custom built for any type of printing press. This includes presses for flexographic, two-piece can, corrugated box or plastic up printing, drum-feed laser imagers or drum-feed plate developers and more.

Bunting® Permanent Magnets and Holding Assemblies in hundreds of shapes and sizes are available for immediate shipment from our warehouse inventory in Elk Grove Village.

There’s no substitute for being prepared. Keep Bunting spare parts on-hand to prevent costly stoppages.