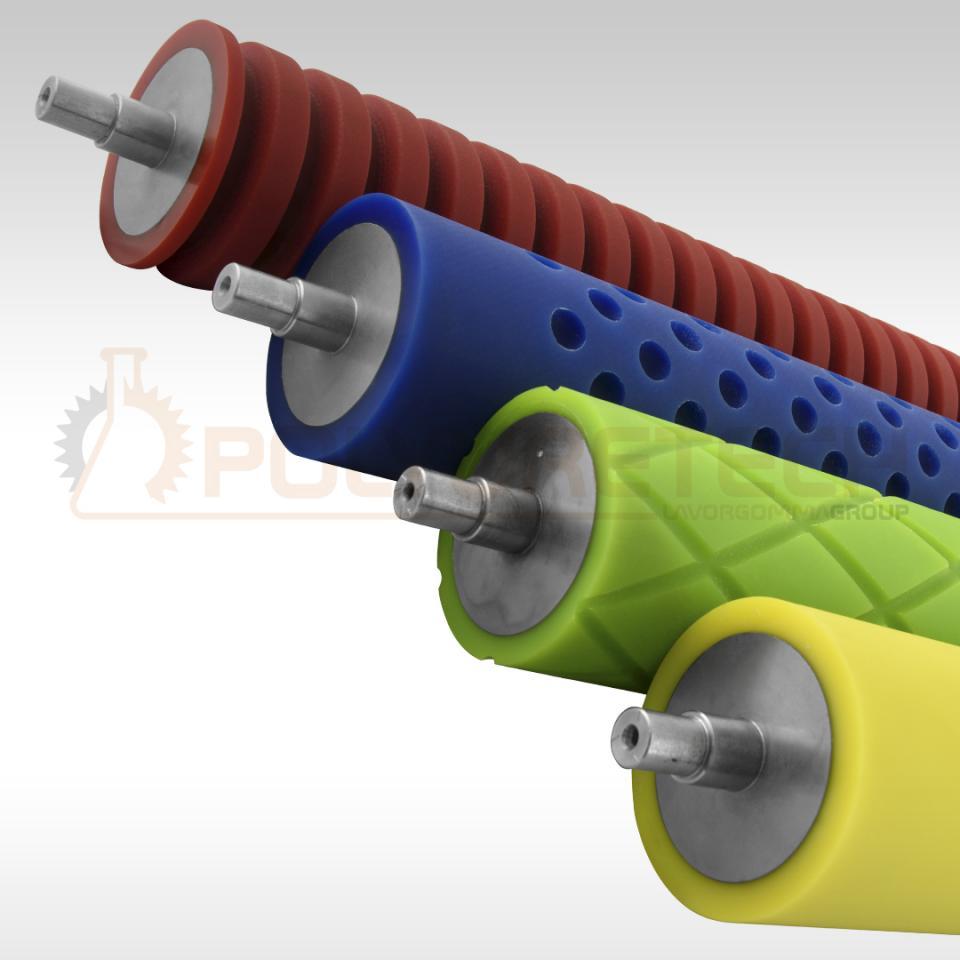

Polyurethane coating of rollers is the most common application for this and other kind of elastomers. The company owns special machining systems to provide various kind of surface finishing and adapt each roll to customer needs.

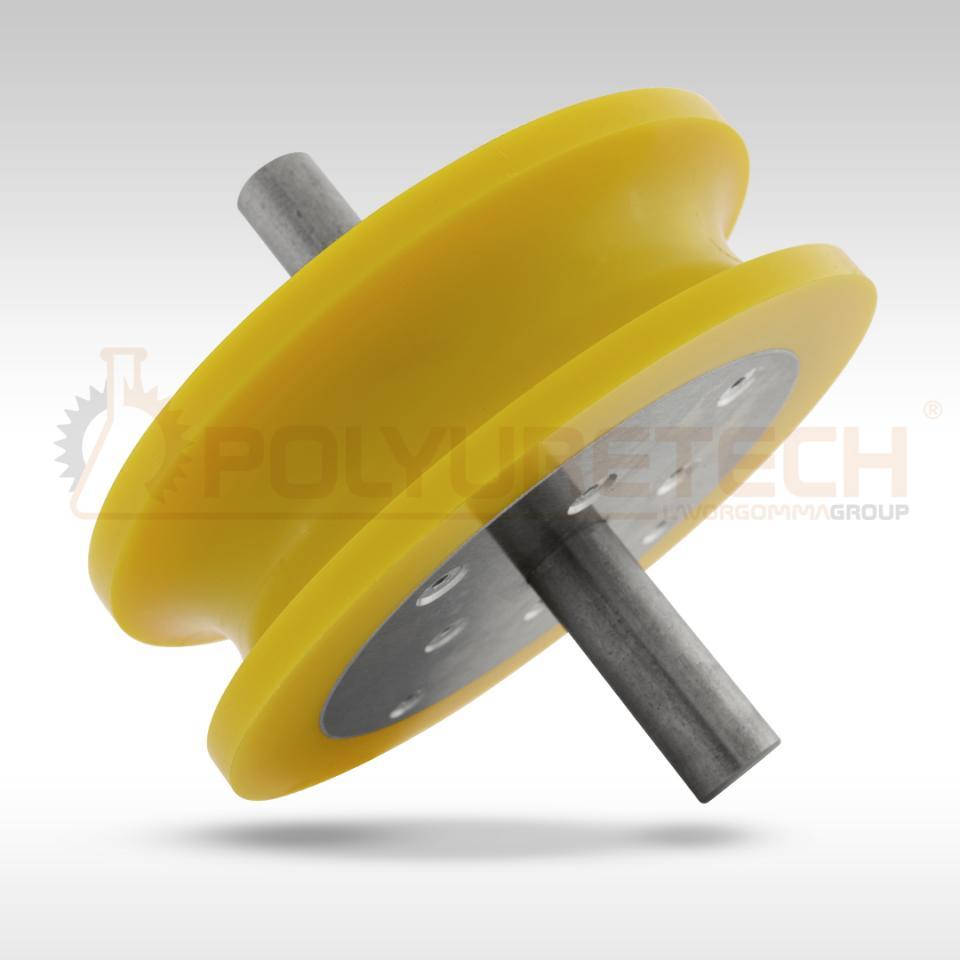

Polyurethane coating of wheels, pulleys and bearings is commonly used to improve wear resistance together with other specific features. Surface finishing procedure is the same of coated rolls.

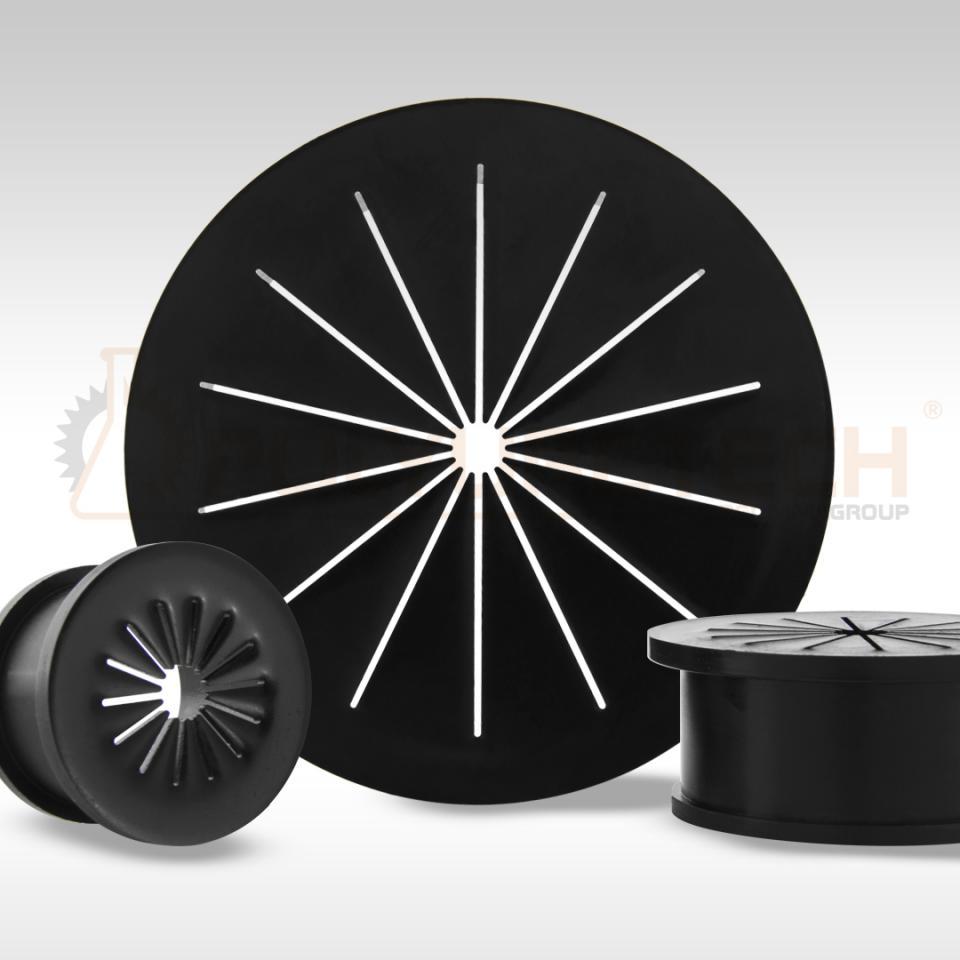

The possibility to obtain different shapes and the variety of physical and mechanical properties of polyurethane, make it a very good material for the manufacturing of seals and rings.

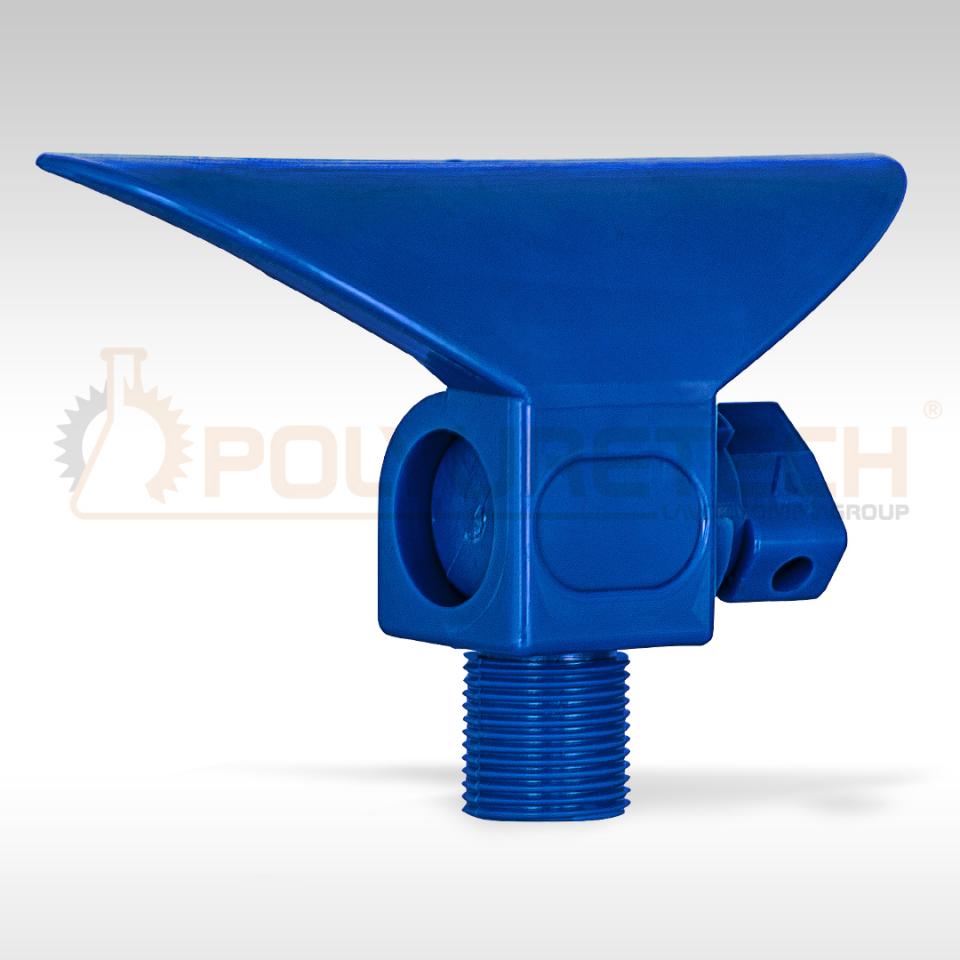

The versatility of polyurethane allows to manufacture the most various kind of applications and adapt them to several industrial fields.

Molds for casting and especially insert to be coated, can be directly manufactured by the company in order to supply the complete component to the customer.

Different available manufacturing processes, allow to manufacture several articles with techno-polymers.

Polyurethane and plastic materials can be processed by injection molding. This manufacturing process is particularly suitable when big quantities, short manufacturing times and low prices are essential big quantities, short manufacturing times and low prices.