Robotics solutions from Schmalz are used for loading and unloading machines, for order picking, palletizing and depalletizing, or for bin-picking processes. The program includes standardized and configurable end effectors, gripper kits, vision & handling sets, and electrical and pneumatic vacuum generators.

Our gripper solutions are compatible with all common lightweight robots and cobots and are provided as ready-to-connect sets. Equipped with communication interfaces for bidirectional data exchange, with diagnostic functions for the handling process, with vision systems for gripper point detection or ecosystems for automated gripper change, the gripper takes a central wheel in the overall system.

Robotics solutions from Schmalz are characterized by maximum precision, safety and process control in the gripping process.

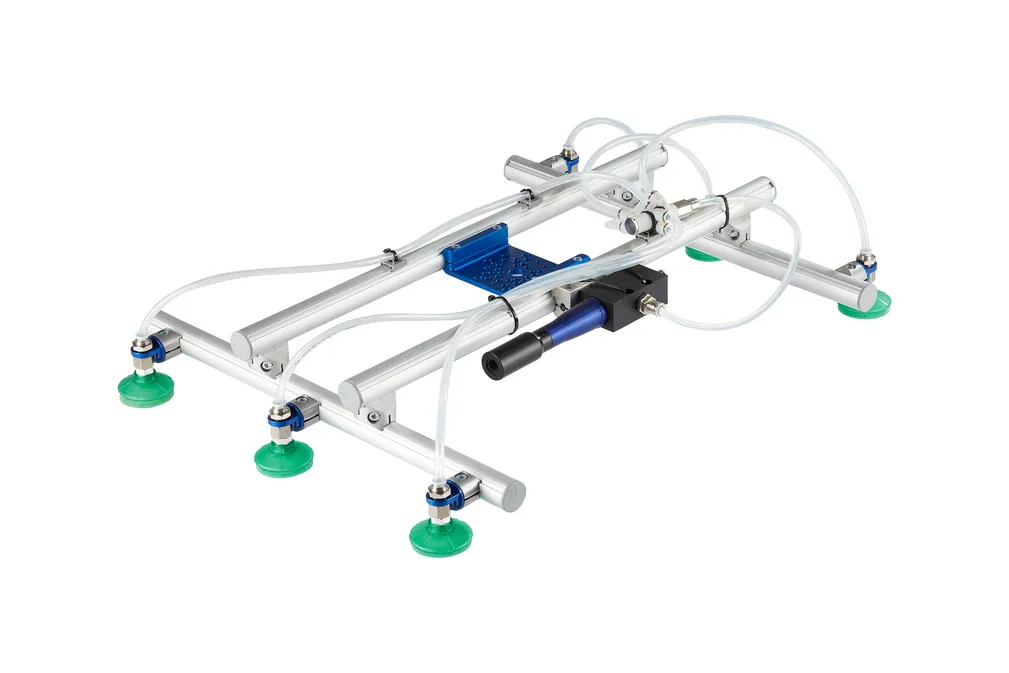

Solution for bin picking

Plug & work

Collision free gripping

Complete application solution

Lift capacity up to 25 kg

Compatible with all common lightweight robots

Modular system

For common lightweight robots

Flexibly expandable

Vacuum generators provide the required vacuum. The vacuum is generated either pneumatically (ejectors) or electrically (pumps, blowers). Ejectors offer intelligent functions for energy and process control.