Pneumatic positioning device for flexible control of pneumatic grippers..

Customized gripper fingers – configurable in a very short time via a license-free and browser-based web tool.

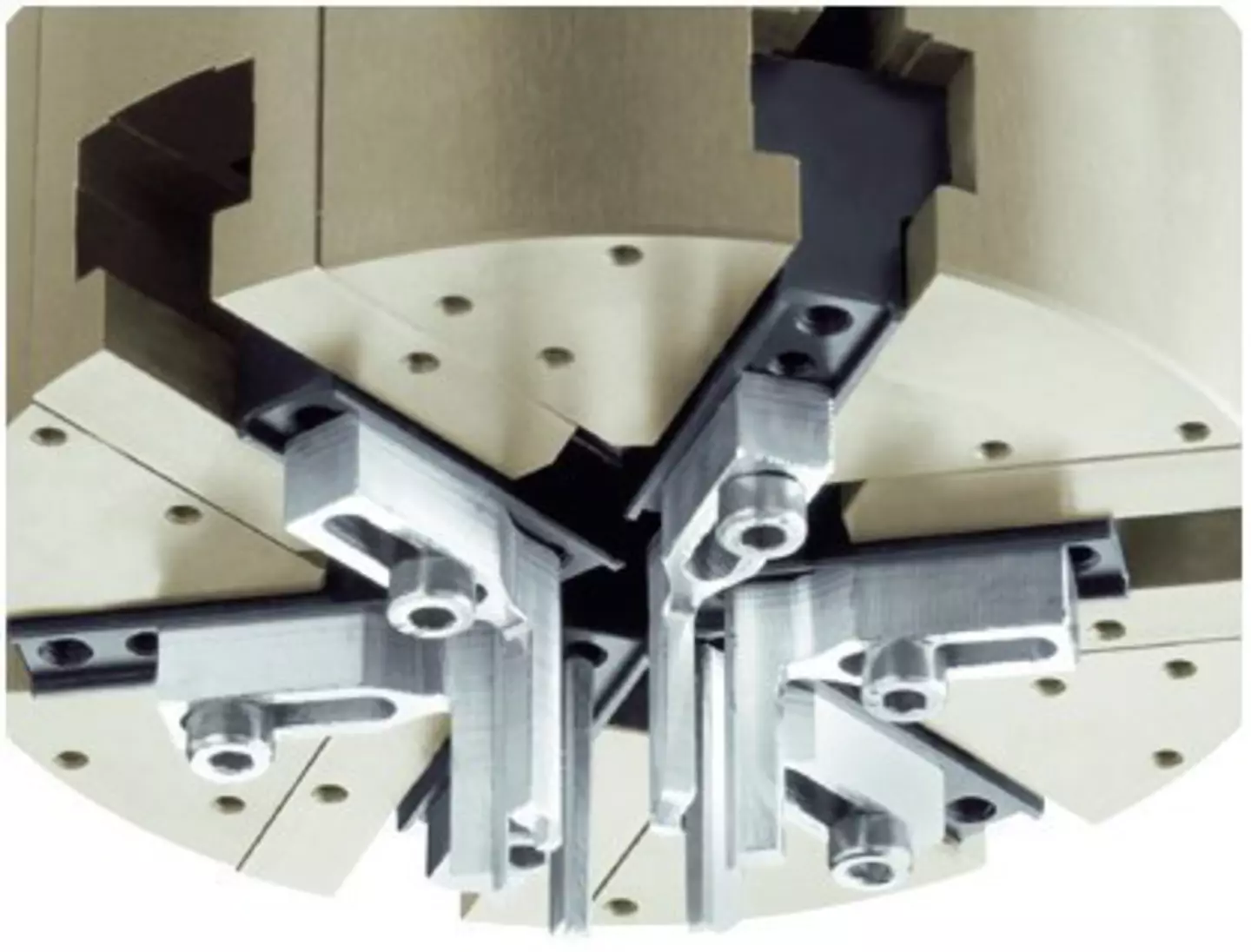

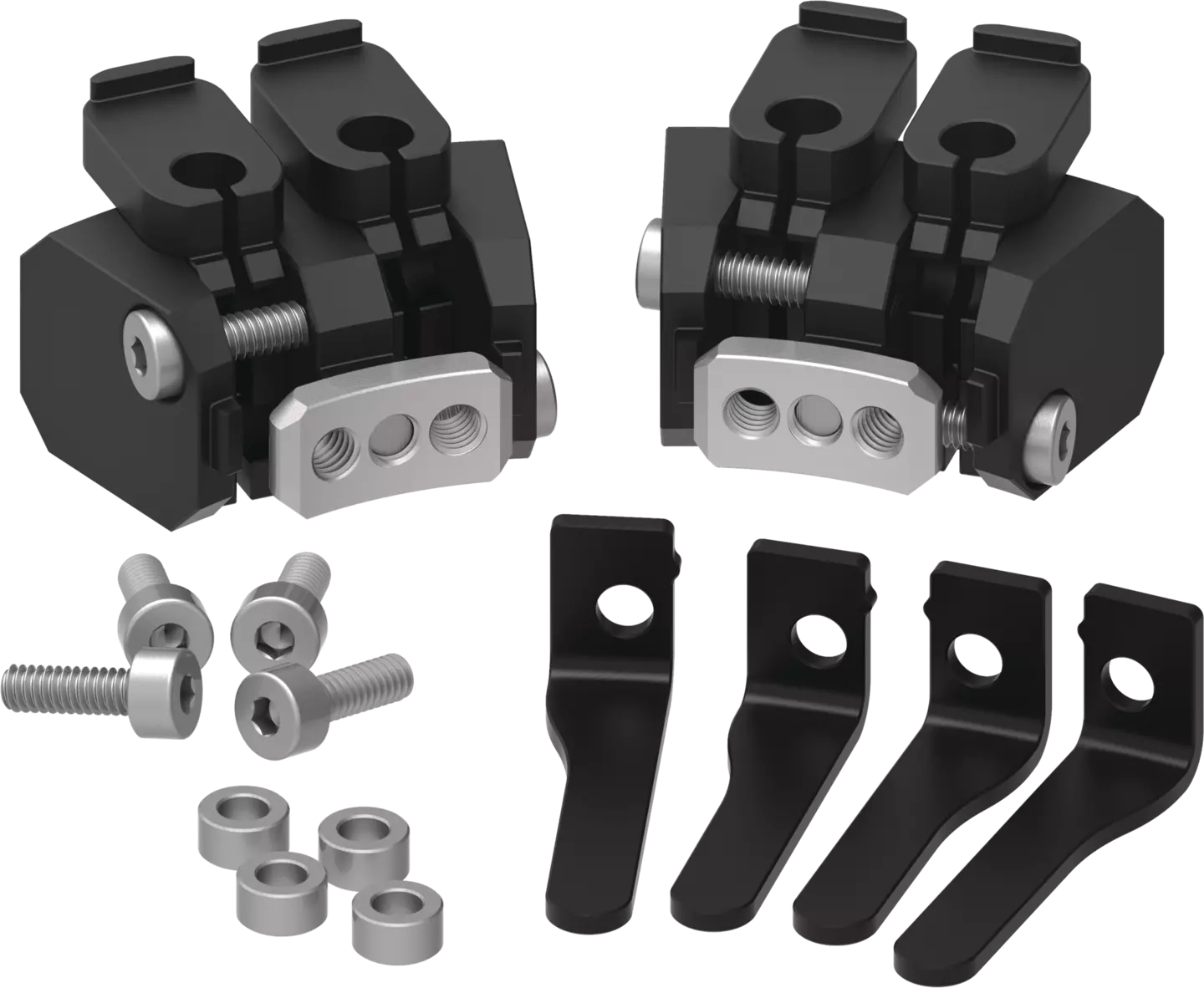

The tool-free BSWS-M jaw quick-change system allows top jaws to be exchanged on the gripper manually and rapidly. Two adapter pins (= one BSWS-A set) and a base (BSWS-BM) are required for each gripper jaw. In case of reverse assembly and provided that no addional height is created, two adapter pins (= one BSWS-AR set) and an assembly kit (BSWS-URM) per gripper jaw are required. Another effect of the BSWS-URM is that there are no more problematic mounting holes in the finger contours.

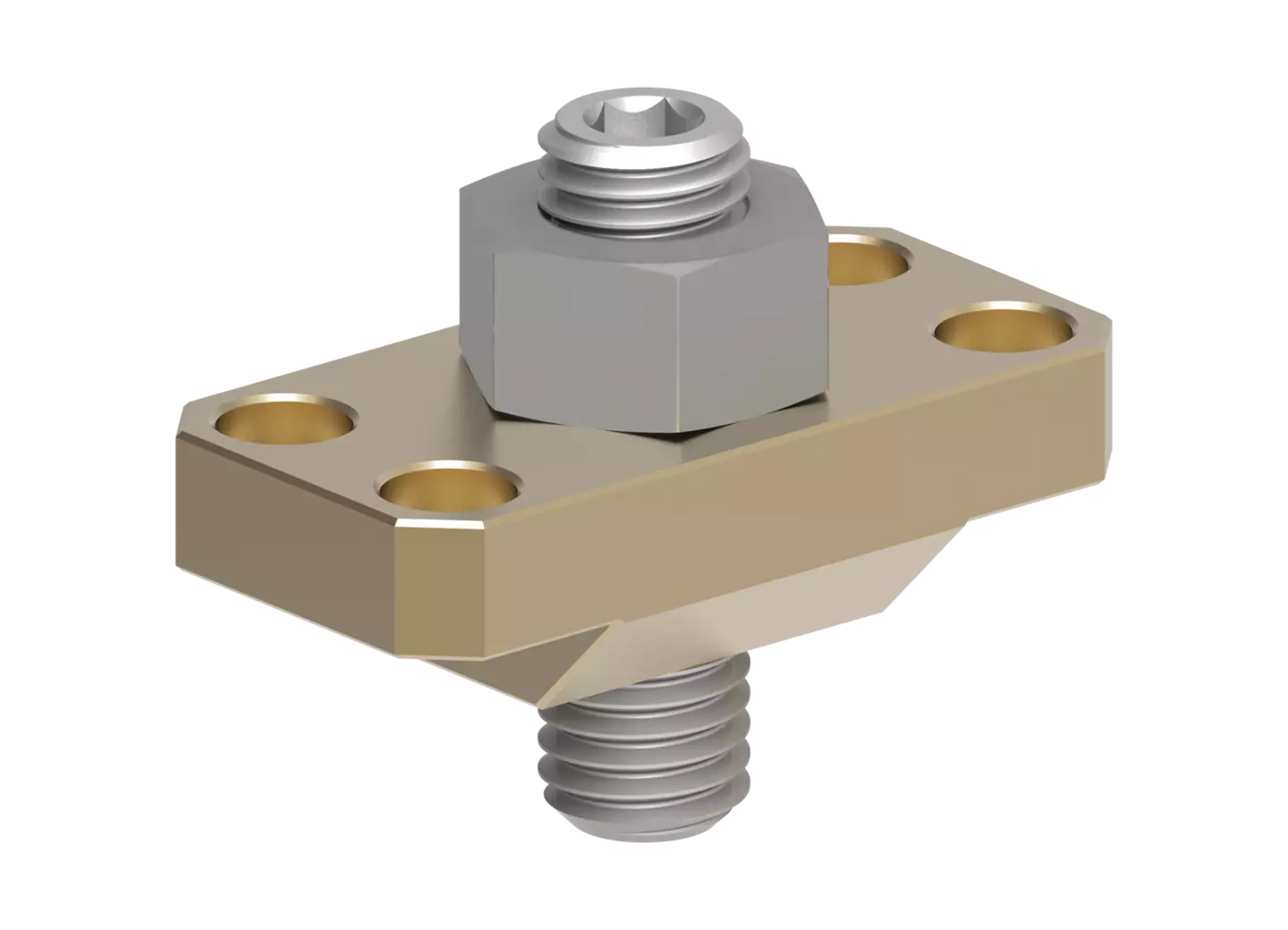

The jaw quick-change system BSWS allows top jaws to be exchanged on the gripper manually and rapidly. One adapter pin (BSWS-A) and a base (BSWS-B) are required for each gripper jaw.

In case of reverse assembly and provided that no additional height is created, one adapter pin (BSWS-AR) and an assembly kit (BSWS-UR) per gripper jaw are required. Another effect of the BSWS-UR is that there are no more disturbing mounting holes in the finger contours.

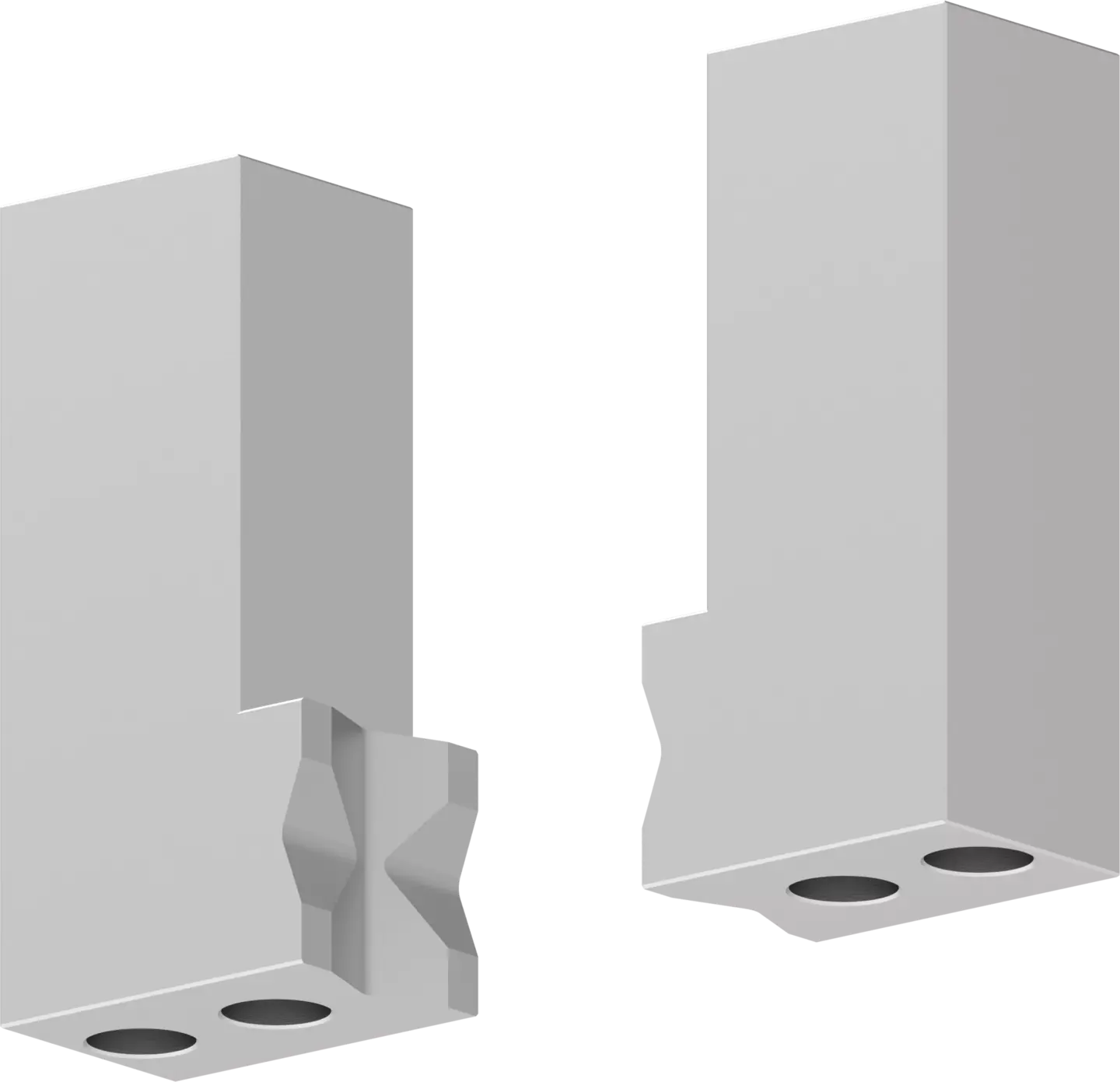

Blanks made of aluminum or steel for rework by the customer

Another effect is that there are no more disturbing fixing bores in the finger contours for jaw blanks with BSWS.

The finger blanks with jaw quick-change system allow fast and manual gripper finger changes. The mechanical interface to the gripper is already integrated. Only the specific workpiece geometry needs to be machined into the finger blank.

Another effect is that there are no more disturbing fixing bores in the finger contours for jaw blanks with BSWS.

Standard fingers for external assembly of rings with the specified cord strength. Six fingers are required. Three form fingers and three rod fingers are required for internal assembly. Their geometry is based on the dimensions of the ring to be mounted. See the downloadable operating manual of the ORG for design rules. SCHUNK offers engineering design and production services on request.

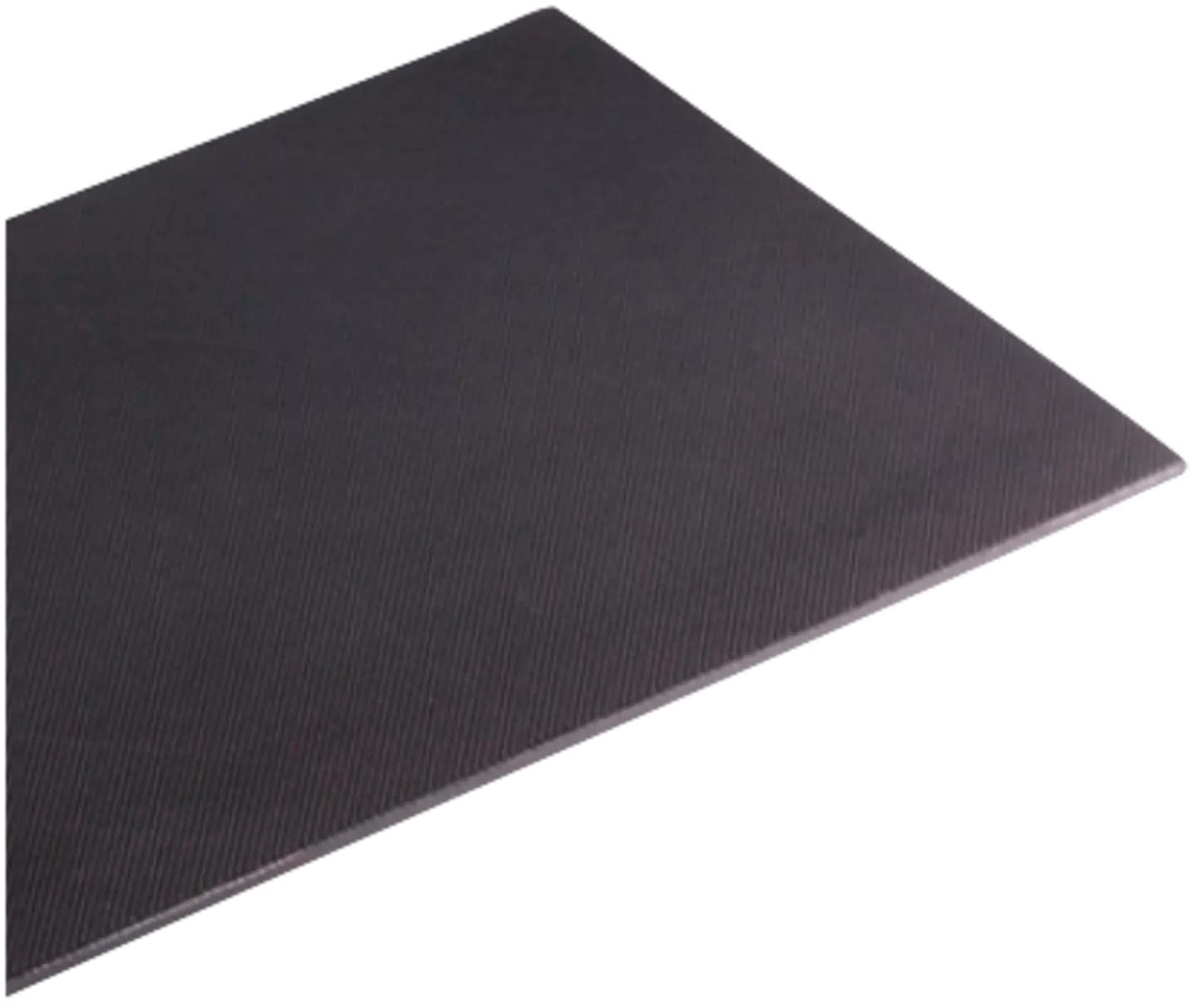

Gripper pads made of soft plastic for surface-friendly gripping of workpieces while increasing the frictional forces

Used for increasing the friction at the contact surface between gripper finger and workpiece.

Used for the gentle clamping of sensitive workpieces and an increase in the static friction.

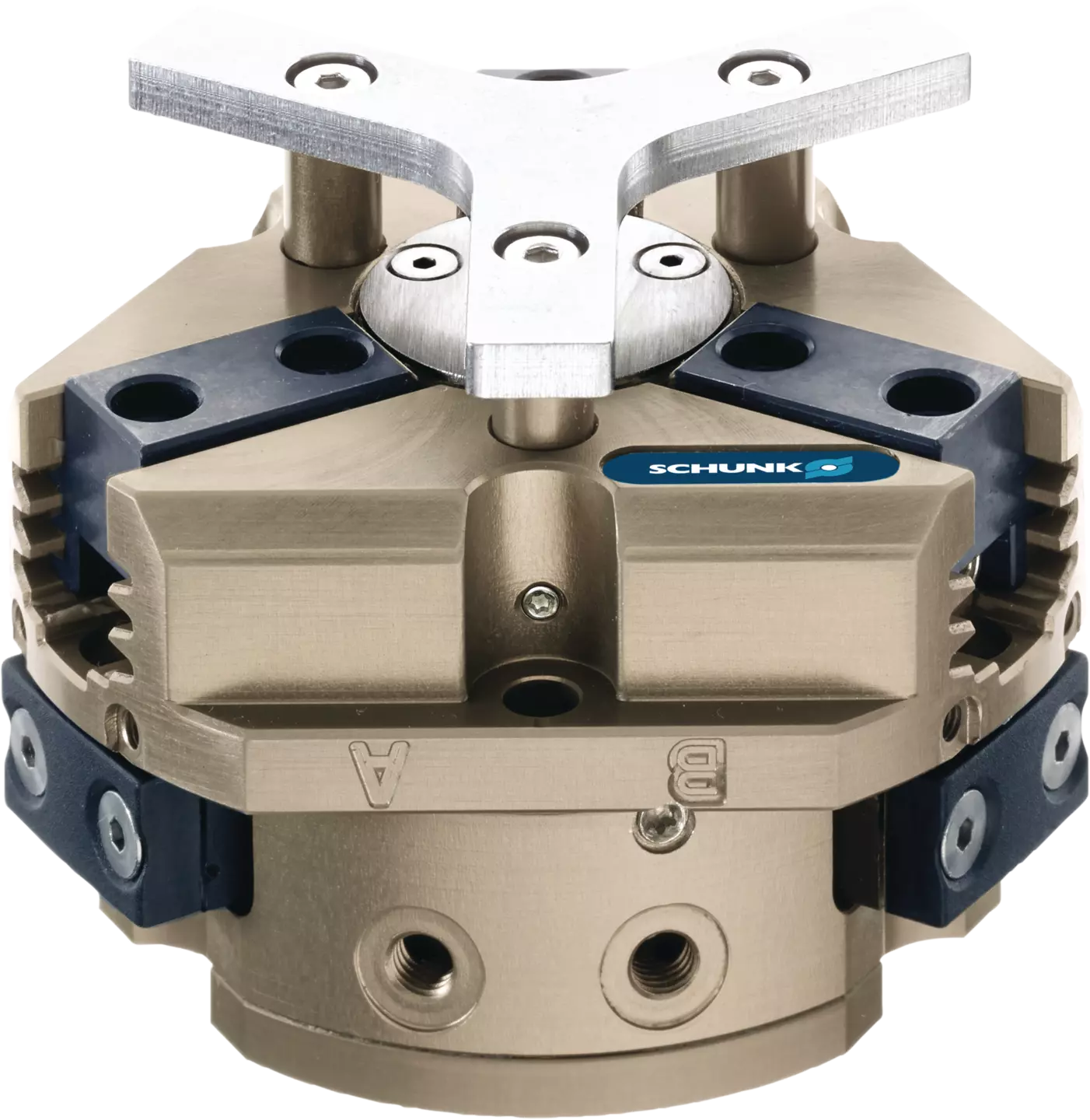

The universal intermediate jaw allows fast tool-free and reliable plugging and shifting of top jaws at the gripper.

Optionally intermediate jaws can be used, enabling direct connection and alignment of top jaws and various standard accessories in Z-direction.

SCHUNK mounting kit expand the functionality of standard products. They provide further monitoring options for futher sensors, too.

The clip allows easy fixing of two straight sensor plug connectors.

Centering sleeves are used for centering between two elements. With SCHUNK grippers, this frequently occurs between the mounting plate and gripper and between the gripper and gripper fingers.

Standardized adapter plates with interfaces for SCHUNK products enable a range of modular automation solutions with no need for machining.

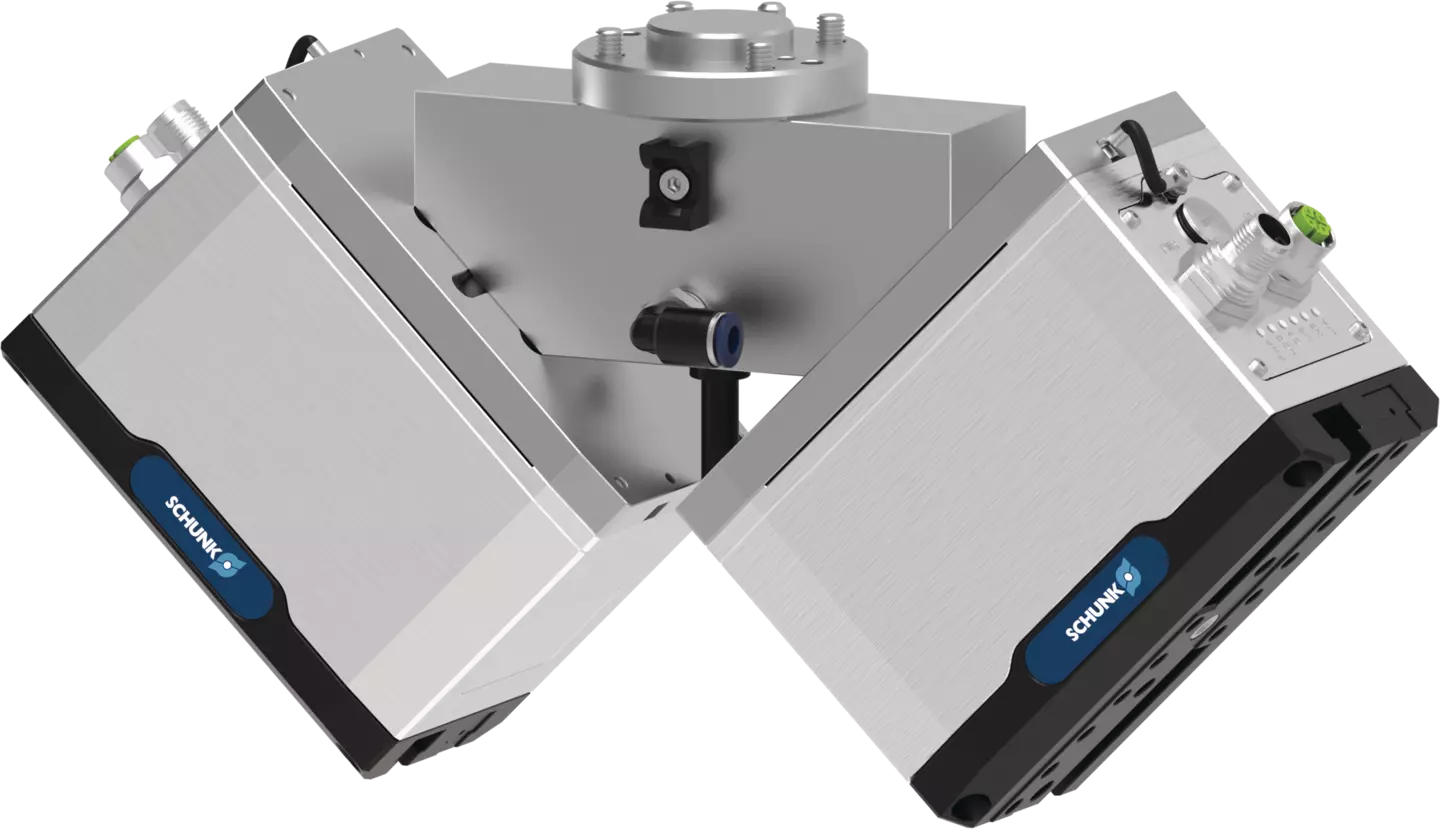

Standardized adapter plates for the mechatronic grippers EGU and EGK. Available for all common ISO flanges and specific robot models. Adaptation kits for single grippers and double grippers are available.

For spring-supported positioning of the workpiece against a stop after the gripper has opened. Especially developed for loading machines.

The "dustproof" option can be subsequently retrofitted to the gripper using the "SAD PGN-plus-P" retrofit kit.

The HUE protective cover fully protects the gripper against external influences. The cover is suitable for applications of up to IP65 if an additional sealing of the cover bottom is provided. For detailed information, please see the HUE series.

The connection diagram shifts by the height of the intermediate jaw.

In case of pressure failure, venting of the module will be prevented by the pressure maintenance valve. Therefore a temporary force or position maintenance can be implemented via different actuators. This is particularly suitable for grippers which cannot be equipped with a mechanical gripping force maintenance.

The SCHUNK add-on valve consists of two 3/2 microvalves (or four 3/2 microvalves for variants with distributor V8 for use as a double gripping unit),

that are screwed directly to the corresponding actuator, as well as an optional electrical distributor box.

The SCHUNK EGM-JB distributor box allows several magnets to be connected to a magnetic controller quickly and easily in a centralized, bundled

fashion.

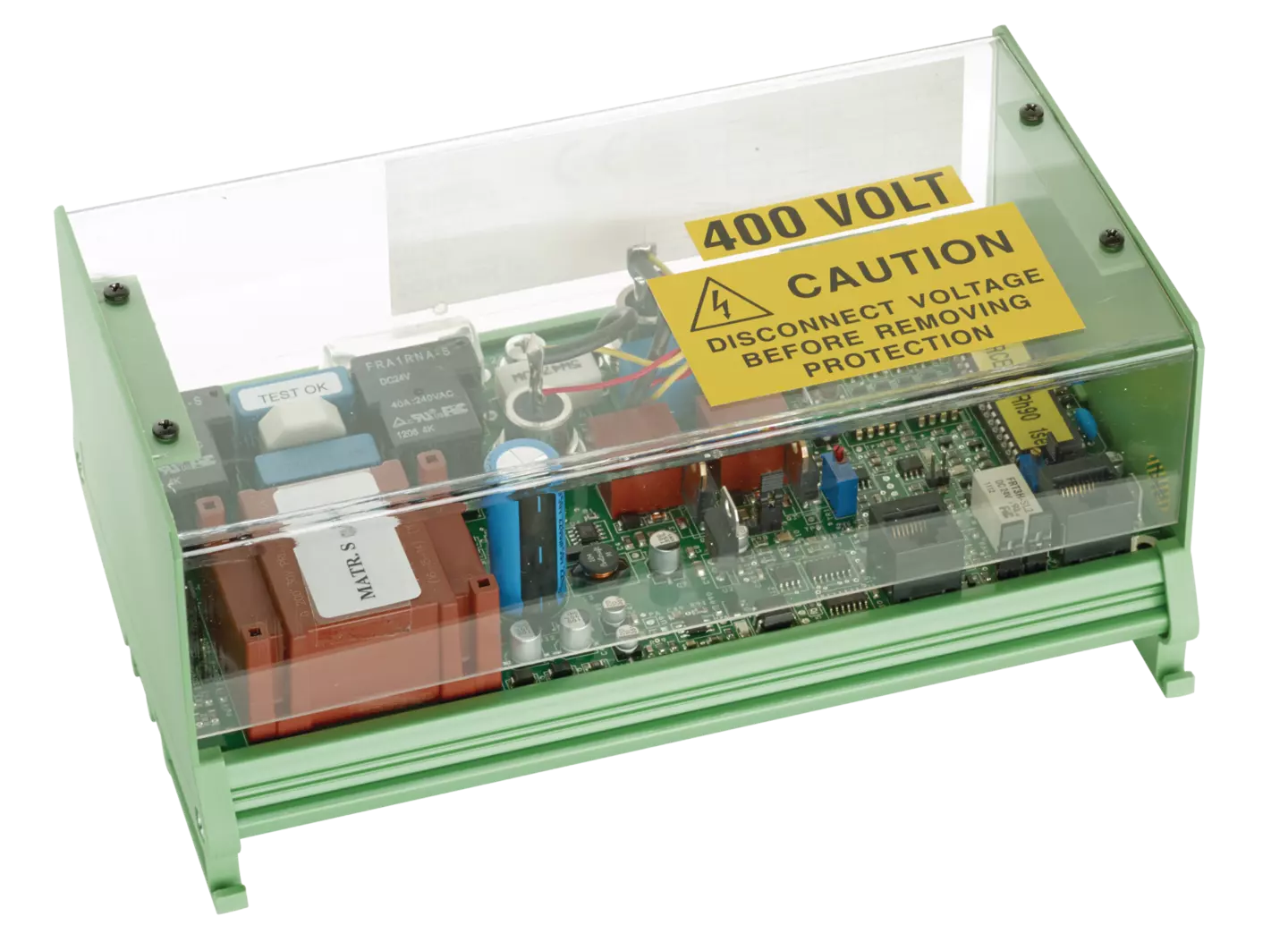

Electrical controllers are used to control/regulate mechatronic modules and systems without integrated electronics. They are offered by SCHUNK for EGN and EZN grippers.

The SCHUNK magnetic controller is used for actuating SCHUNK EGM magnetic grippers.

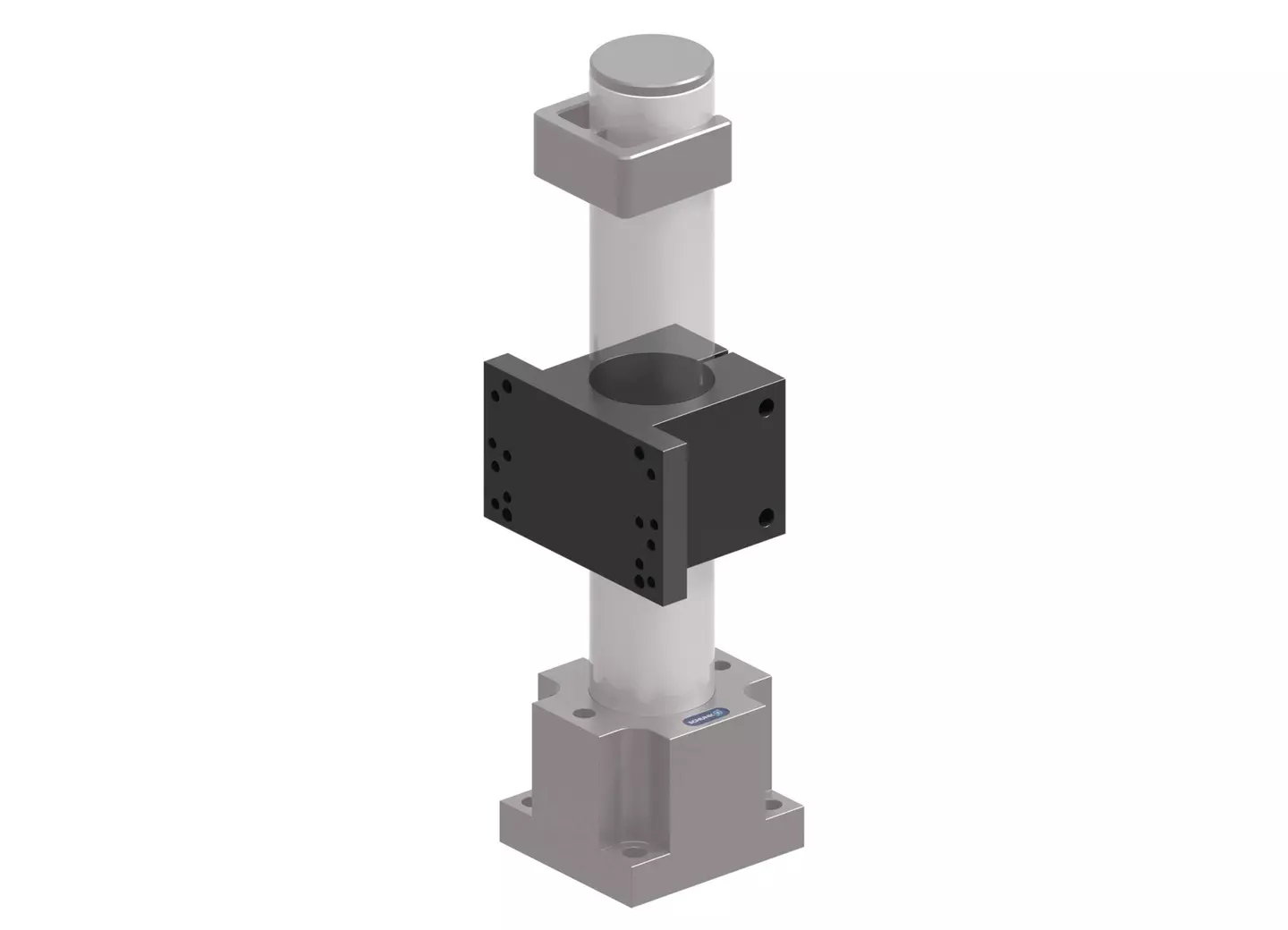

Base for fastening the pillars

Base for fastening the pillars

Mounting plate for vertical connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for vertical connection of various modules or customized assemblies to the pillar assembly system.

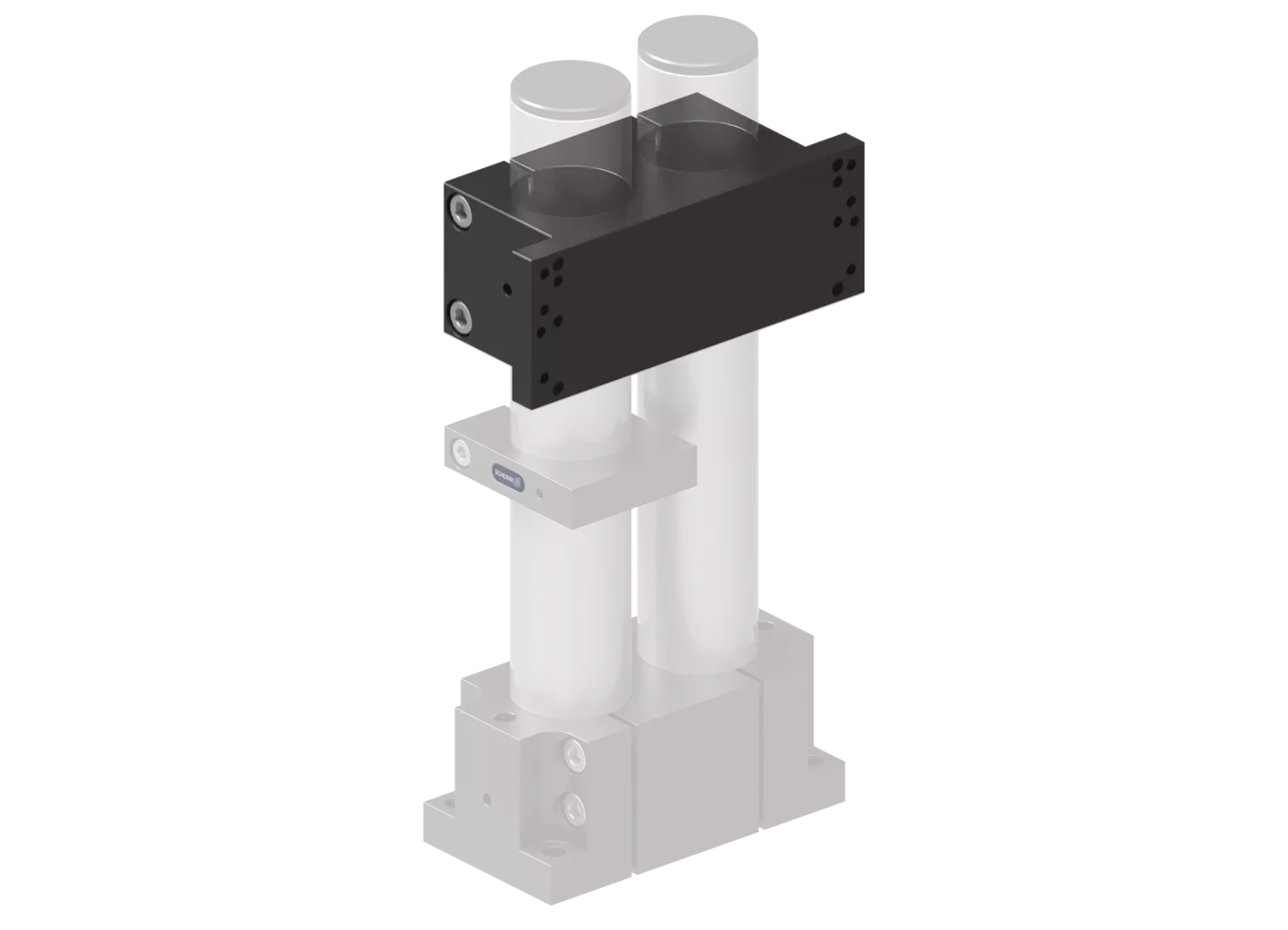

Mounting plate for horizontal connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for vertical connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for horizontal connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for vertical connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for axial connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for horizontal assembly of various SCHUNK standard modules to the pillar assembly system.

Mounting plate for vertical assembly of various SCHUNK standard modules to the pillar assembly system.

Mounting plate for axial connection of various modules or customized assemblies to the pillar assembly system.

Mounting plate for horizontal assembly of various SCHUNK standard modules to the pillar assembly system.

Mounting plate for vertical assembly of various SCHUNK standard modules to the pillar assembly system.

Set collar for exact positioning of structural elements

Set collar for exact positioning of structural elements

Cross connector for implementing perpendicular extended variants

Mounting plate for extending and supporting the pillar assembly system

Pillars, hard-chromium plated, ground

Adjustment unit for easy fine adjustment of the finished handling assembly

Clip for orderly media feeding along pillars

Media routings for feeding through the supply lines through the hollow pillars.

Media routing with direct mounting on SCHUNK standard modules.

Connection cables and connection cable kits for electrical connection to specific robot models and controllers. Depending on the manufacturer, a direct connection to the tool flange is possible or external cabling is required. In combination with mechanical adapters and software modules, this allows commissioning on the robot to be carried out in just a few steps.

The SCHUNK KA connection cable is excellently suitable for supplying SCHUNK components, and for leading signals.

SCHUNK APS-K connection cables are ideal for connecting the SCHUNK APS-M1S sensor to the APS-M1E electronics.

SCHUNK I/O cables reliably transmit digital control or sensor signals from the stationary part of the PPU-E module to the moving cantilever arm.

The KST (cable connector) and KBU (cable bushing) are used for preparing lines for sensors and actuators.

The SCHUNK KV cable extensions are excellently suitable for supplying SCHUNK components, and for leading signals.

SCHUNK Ethernet cables reliably transmit bus signals from the higher-level controller to SCHUNK mechatronic components.

The SCHUNK hybrid cable ensures the power supply and the transmission of the CAN signals to the mechatronic SCHUNK components with one cable.

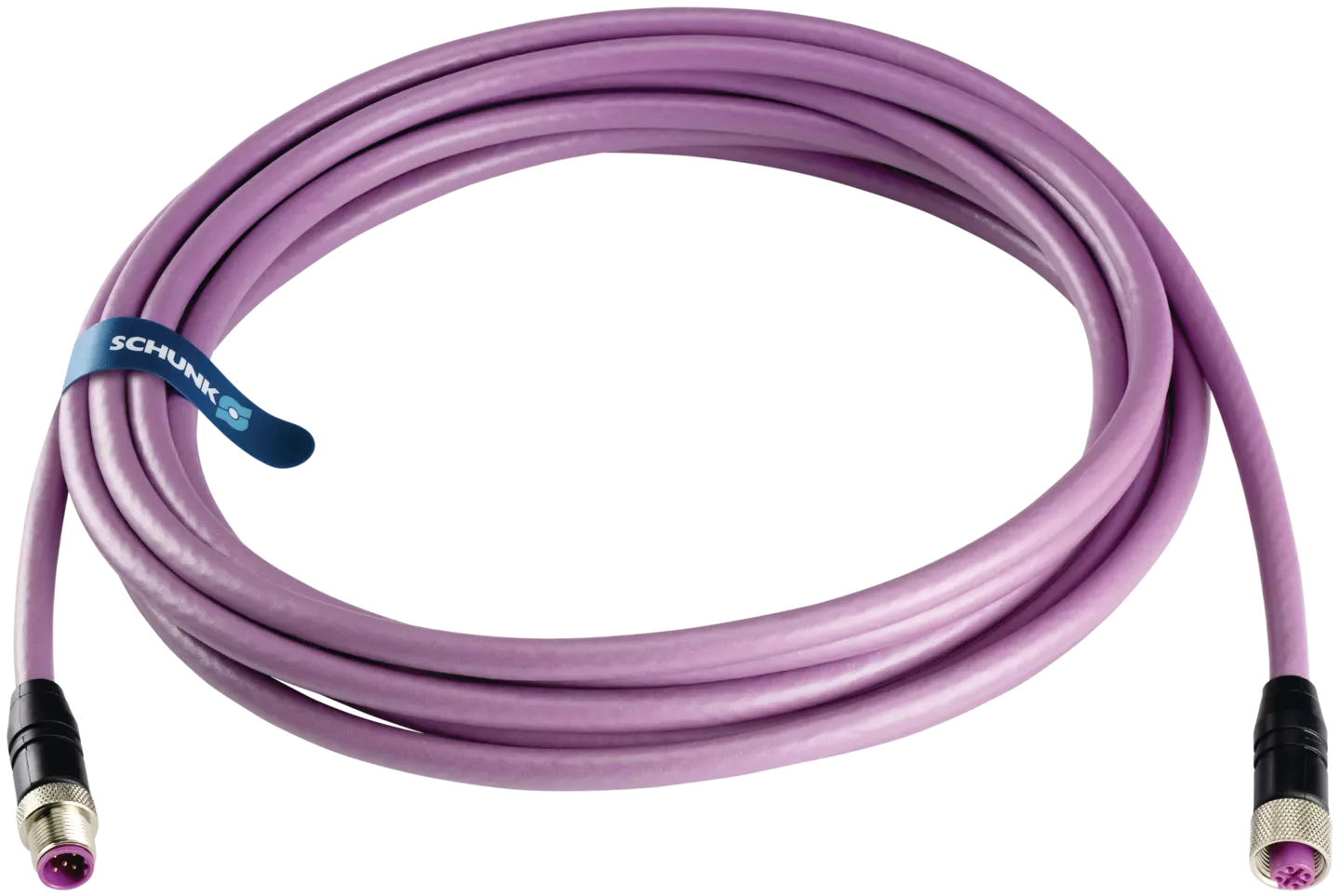

SCHUNK PROFIBUS cables reliably transmit control signals from the higher-level controller to SCHUNK mechatronic components.

The SCHUNK programming cables ensure easy commissioning of SCHUNK mechatronic components via an Ethernet TCP/IP interface.

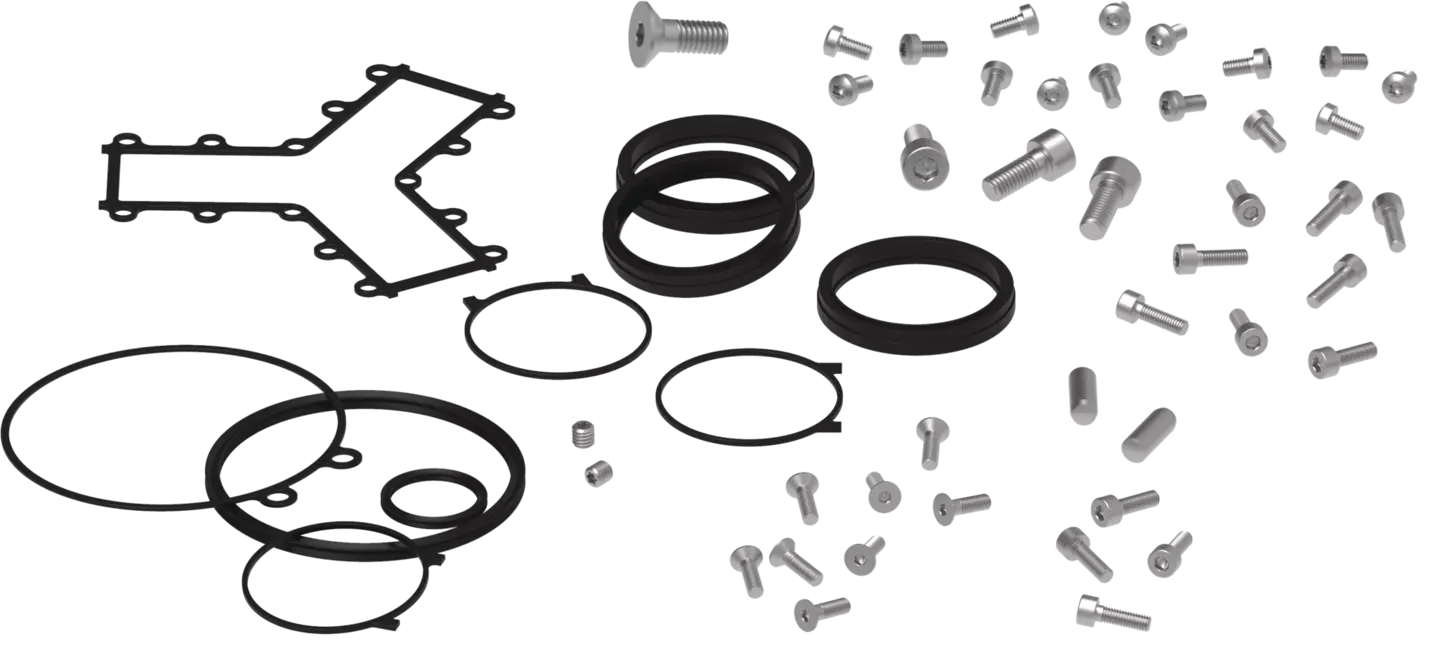

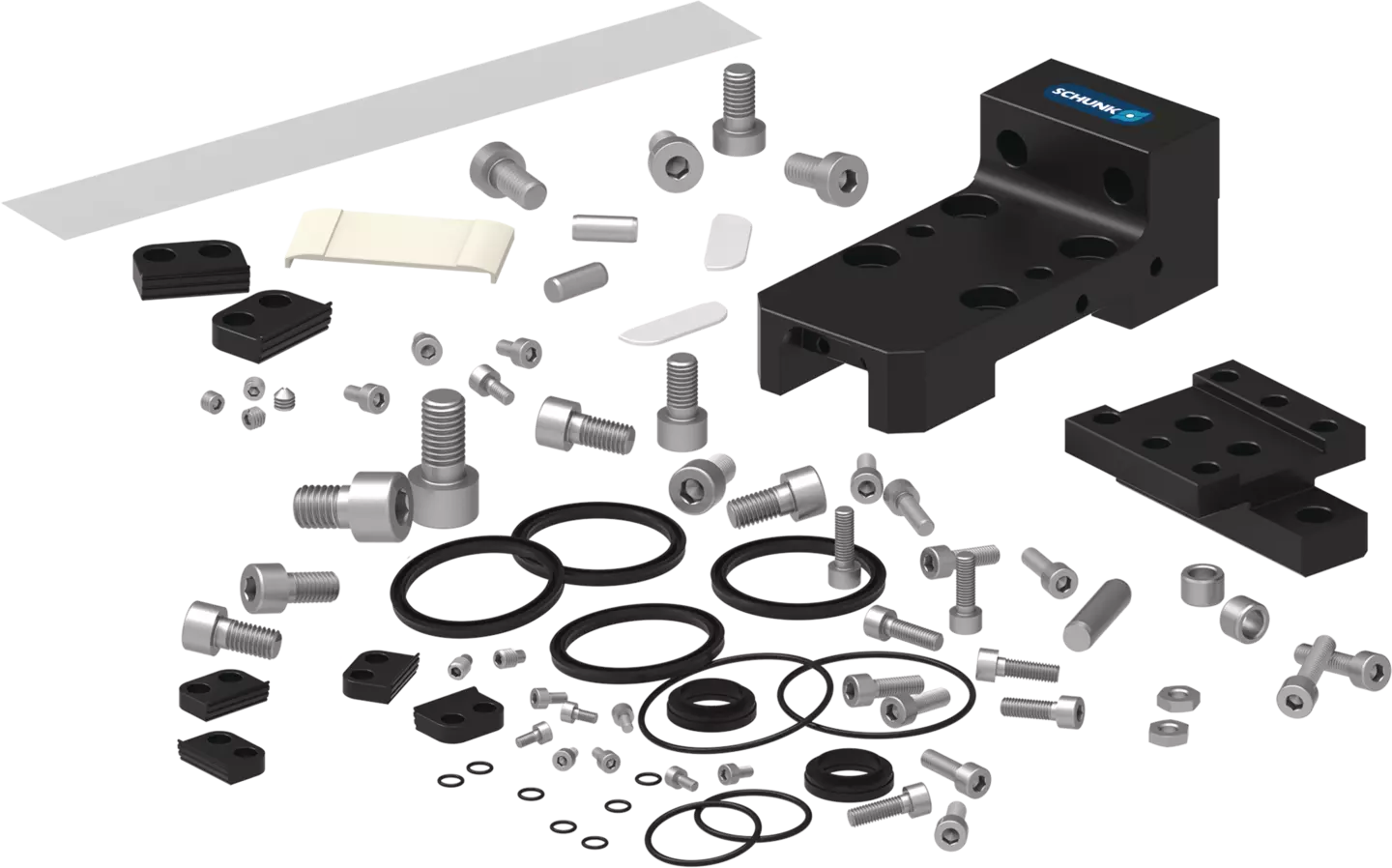

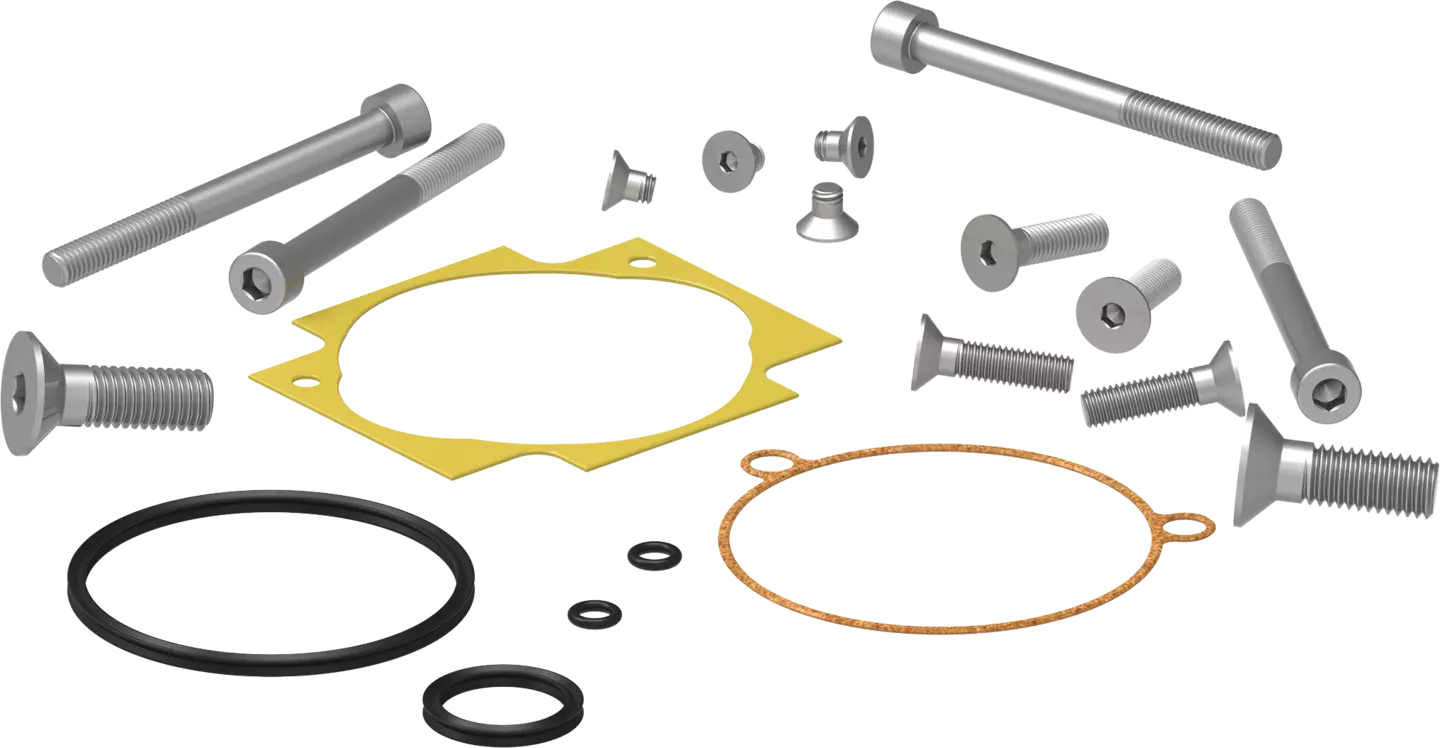

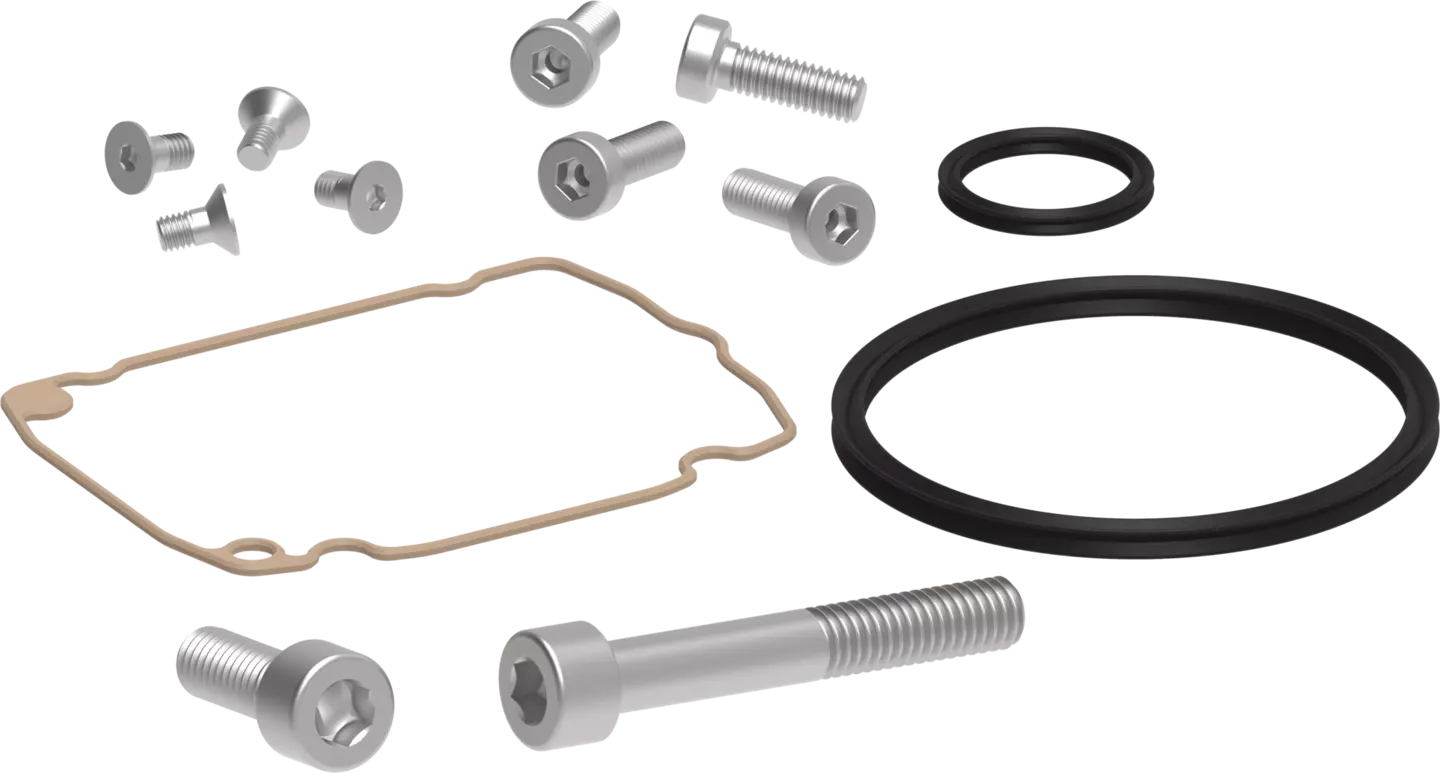

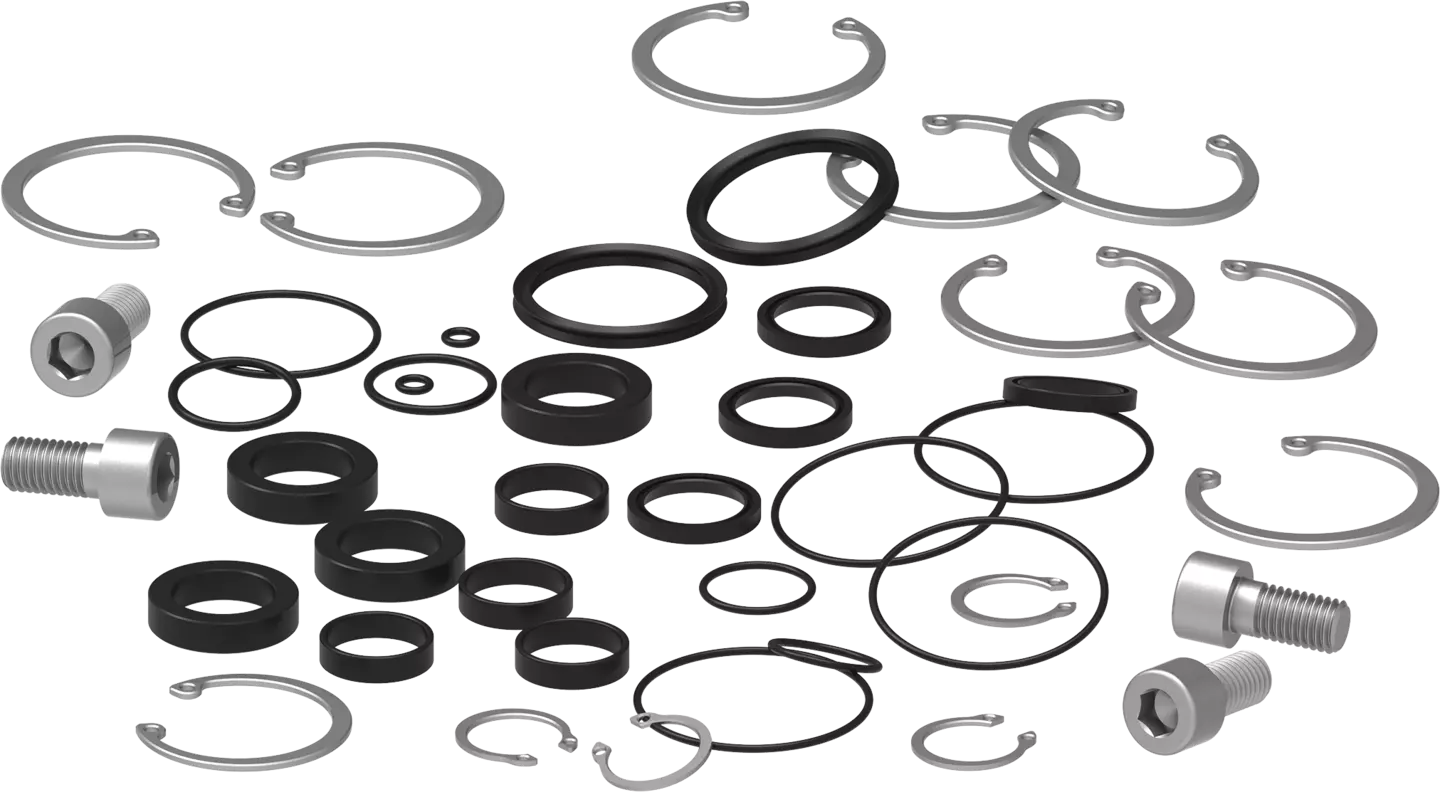

The seal kits contain all seals necessary for maintaining a SCHUNK component.

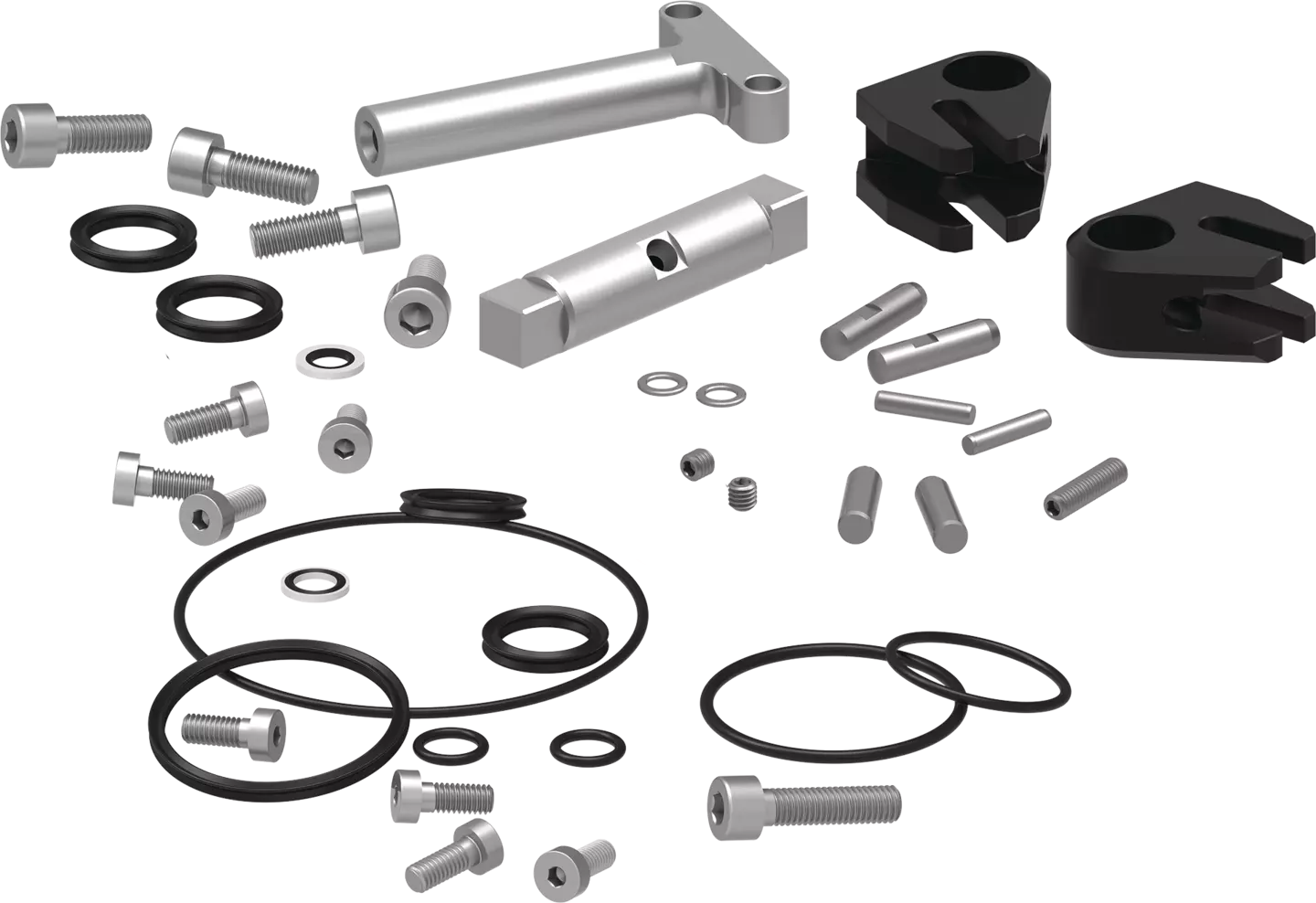

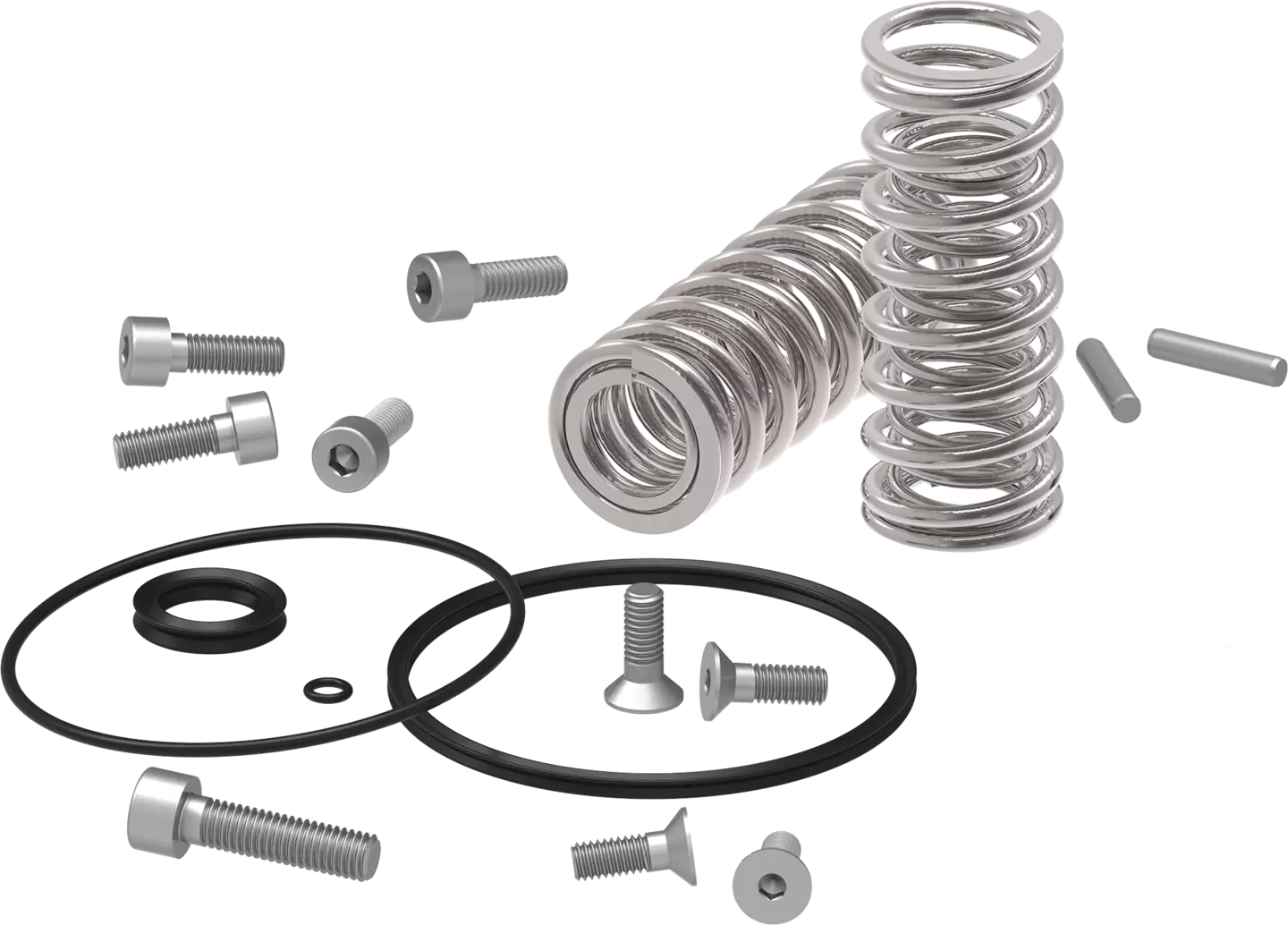

Spare parts packages contain all required parts for repair and maintenance. There are three different spare parts kits for the gripper DPG-plus available: seal kit, lateral cover, and spring.

The spare parts kit contains all seals required for maintenance and the appropriate grease for the gripper DPZ-plus.

Spare parts packages contain all required parts for repair and maintenance. There are three different spare parts kits for the gripper DWG available: seal kit, piston rod, finger, and spring.

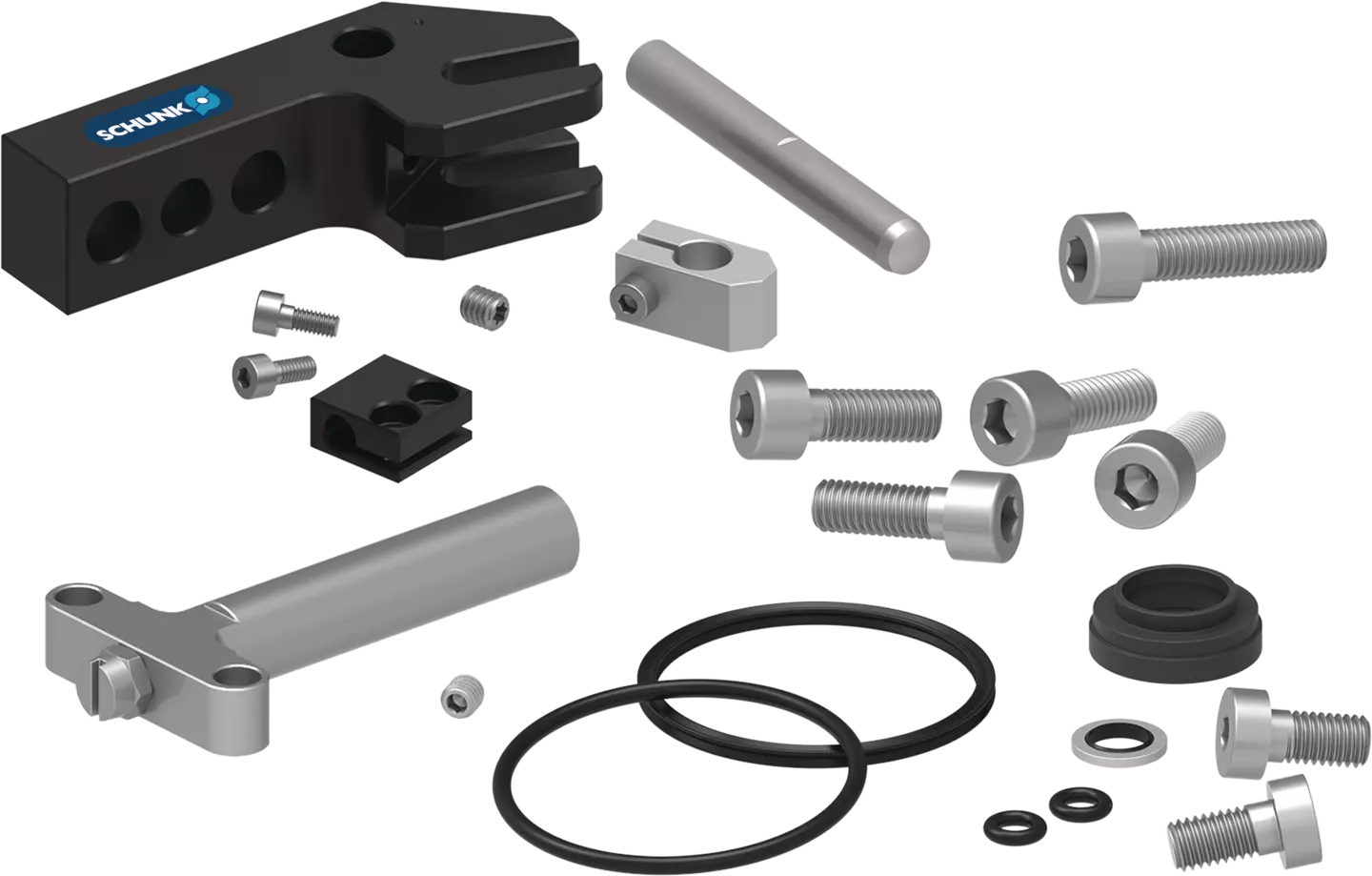

Spare parts kits contain all required parts for repair and maintenance. There are two different spare parts kits for the product EGS available: sensor bracket and swiveling stop.

The spare parts package contains all the spare parts required for changing the gripping module, and the appropriate grease.

Spare parts packages contain all required parts for repair and maintenance. There are four different spare parts kits for the GWB: seal kit, piston rod, finger, and spring.

Spare parts kits contain all required parts for repair and maintenance. The sealing kit is available as a spare parts package for the JGP-P gripper.

Spare parts kits contain all required parts for repair and maintenance. A spare parts kit "protective cover" is available for the MPG-plus gripper.

Spare parts packages contain all required parts for repair and maintenance. There are two different spare parts lots for the gripper PFH available: cover and seal kit.

Spare parts packages contain all required parts for repair and maintenance. There are three different spare parts kits for the gripper PFH-mini available: cover, guide strip, and seal kit.

Spare parts packages contain all required parts for repair and maintenance. For the gripper PGL-plus-P there are the spare parts packages for the sealing kit and the sensor IOL.

Spare parts packages contain all required parts for repair and maintenance. There are three different spare parts kits for the gripper PGN available: spring, switching cam, and seal kit.

Spare parts kits contain all the parts required for repair and maintenance. The spare parts kit dust cover is available for the product PGN-plus-E.

Spare parts kits contain all required parts for repair and maintenance. The sealing kit is available as a spare parts package for the PGN-plus-P gripper

Spare parts packages contain all required parts for repair and maintenance. There are two different spare parts kits for the gripper PSH available: piston rod and seal kit.

Spare parts packages contain all required parts for repair and maintenance. There are five different spare parts kits for the gripper PWG available: spring, jaws, finger, piston rod, and seal kit.