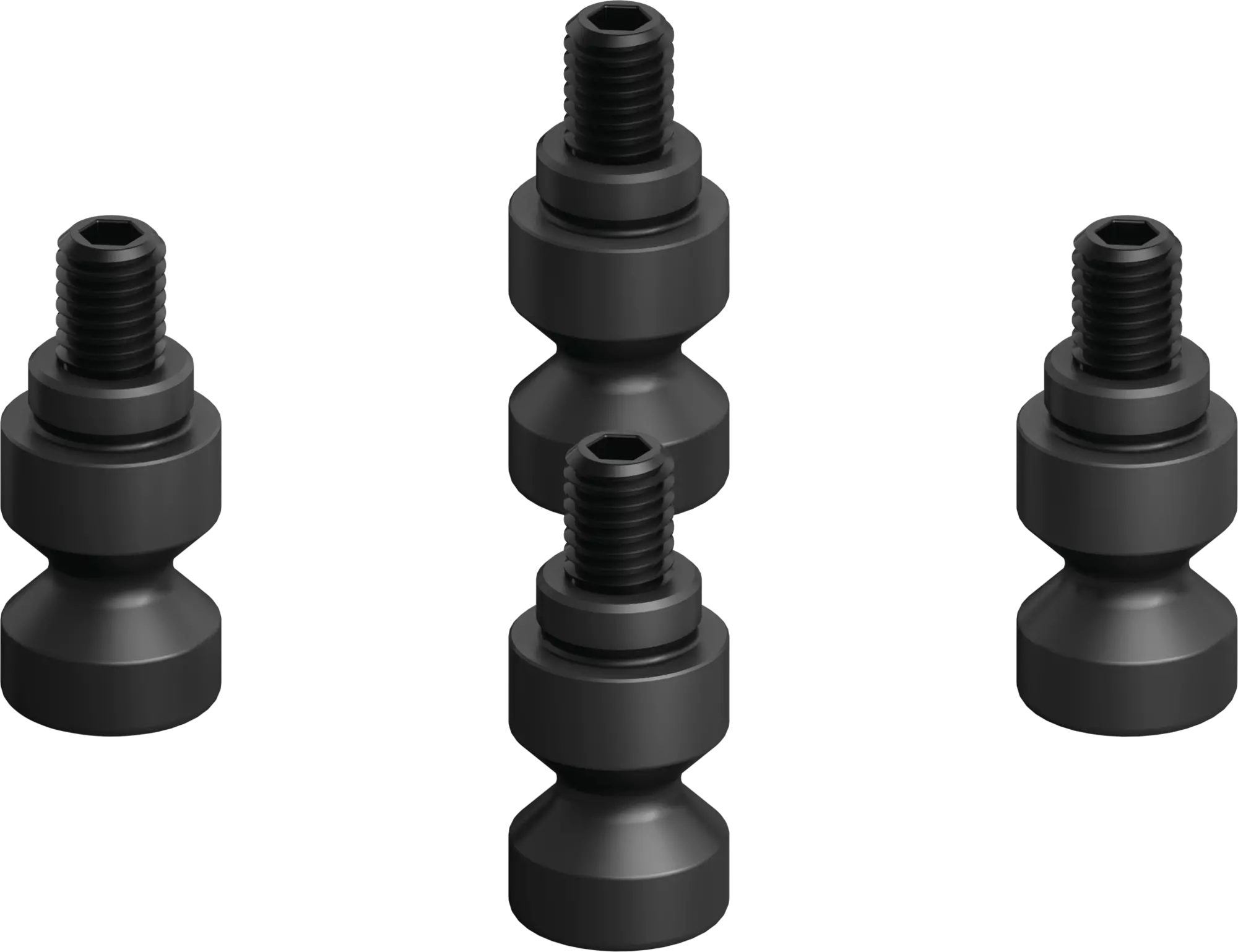

Jaw fastening screws with normal metric or fine threads, according to DIN 912, quality 12.9. Suitable for use with base jaws.

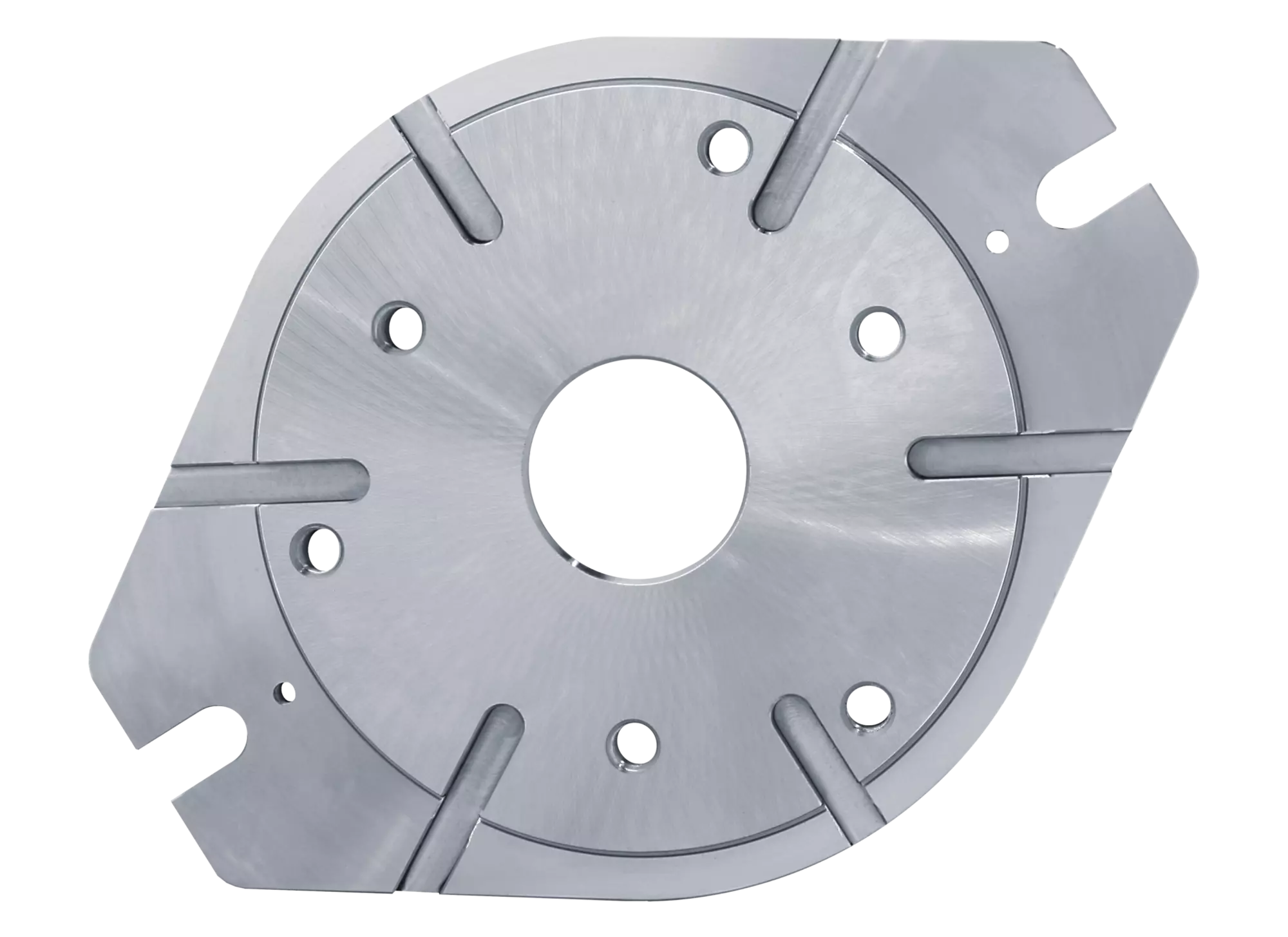

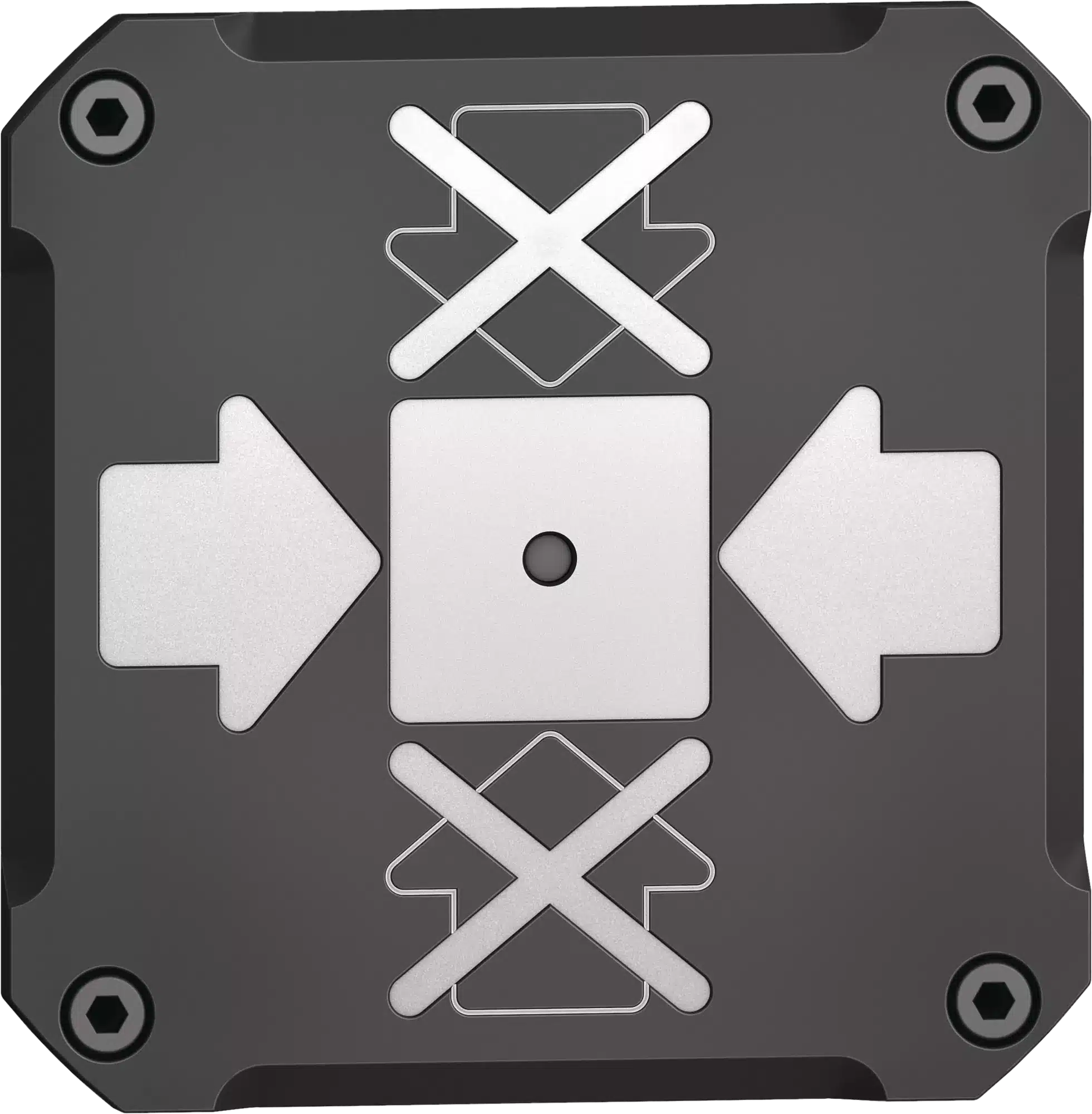

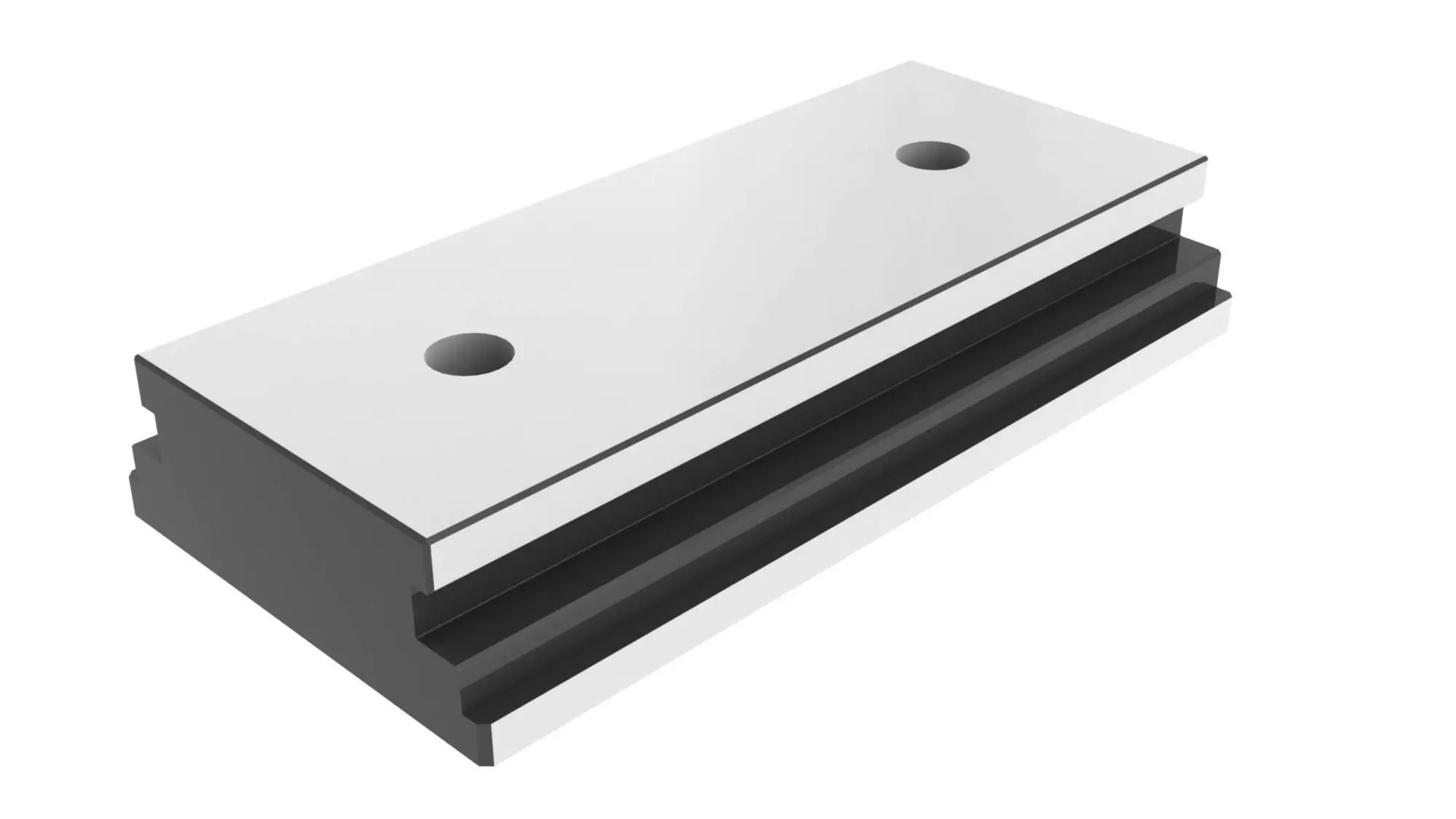

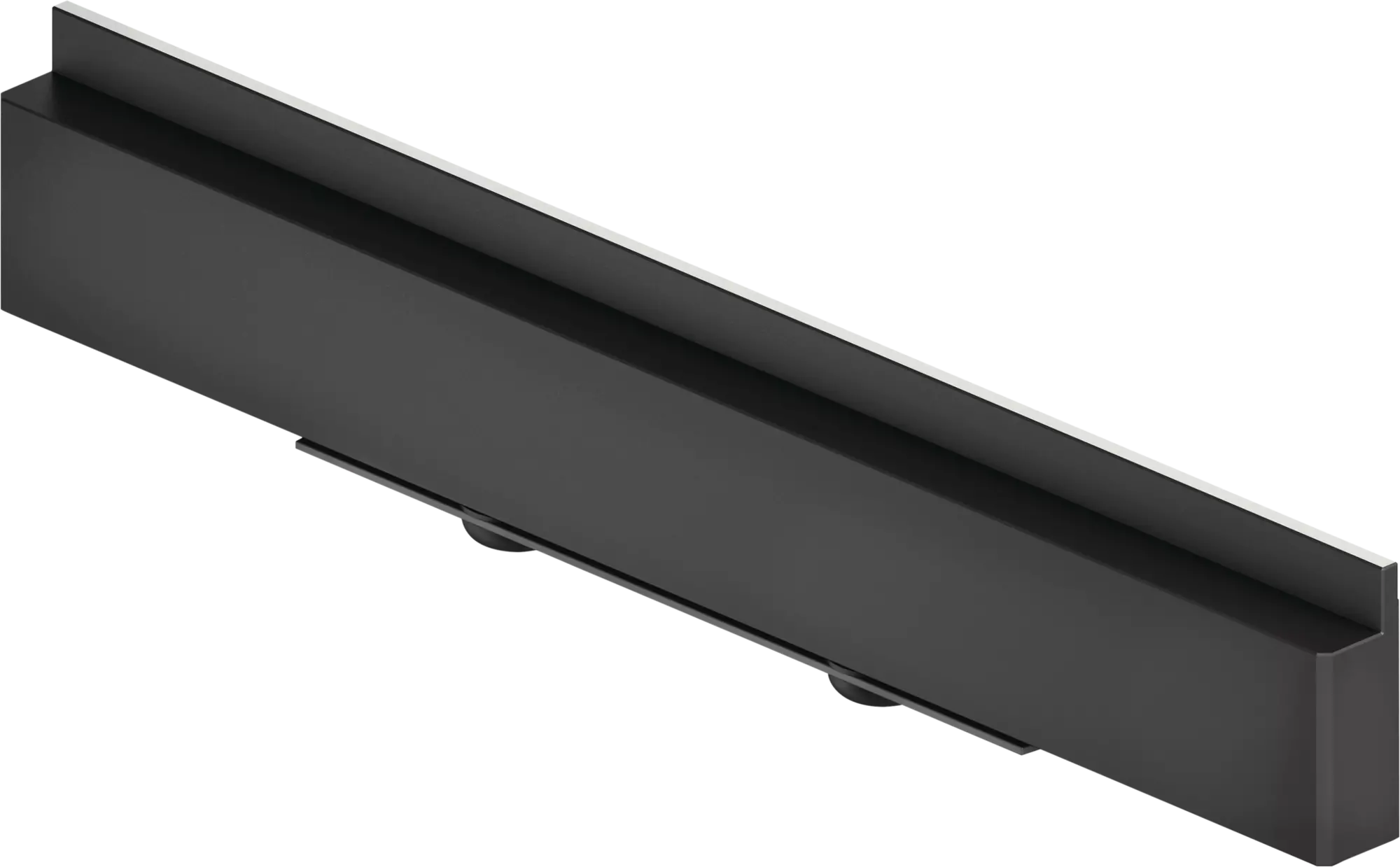

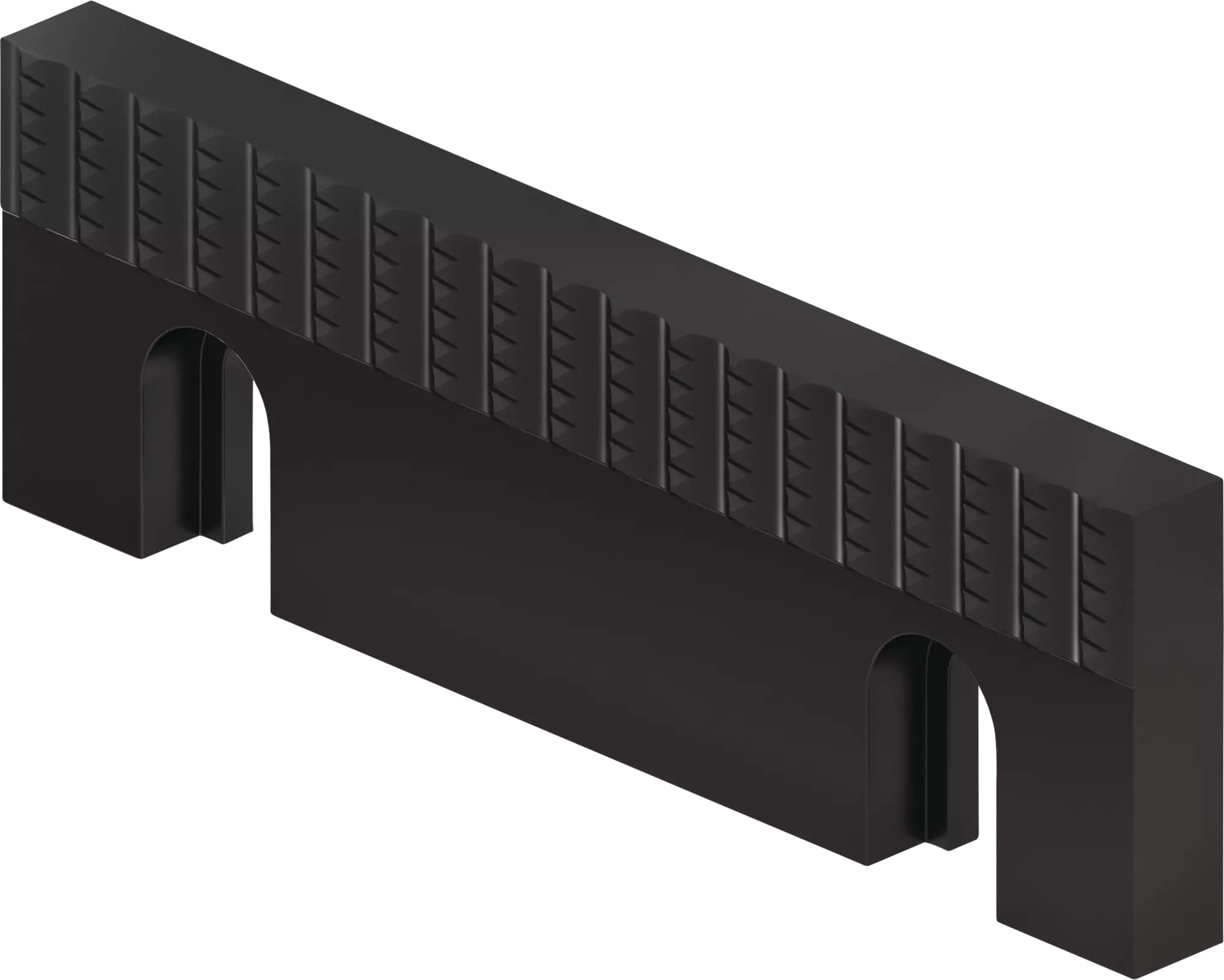

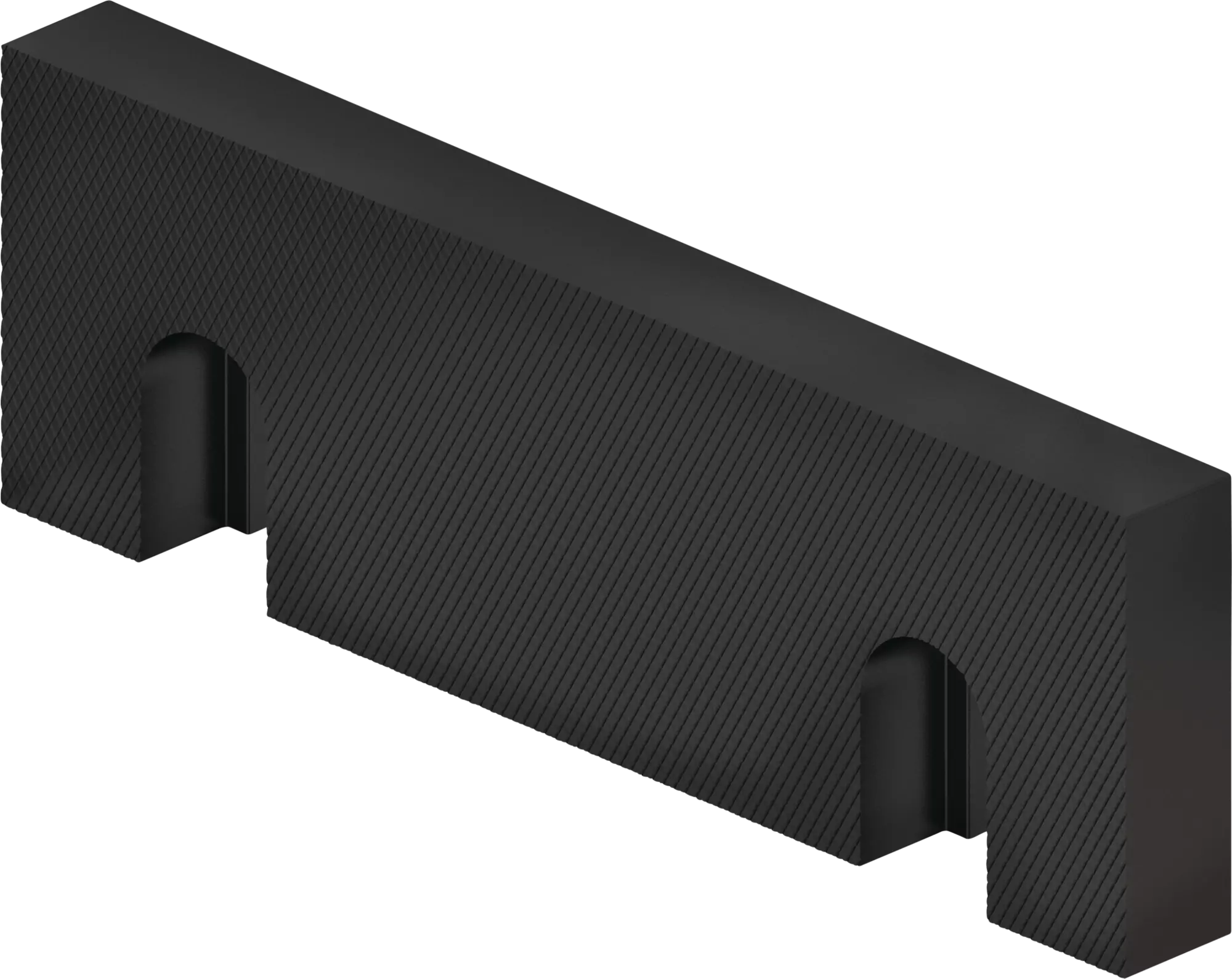

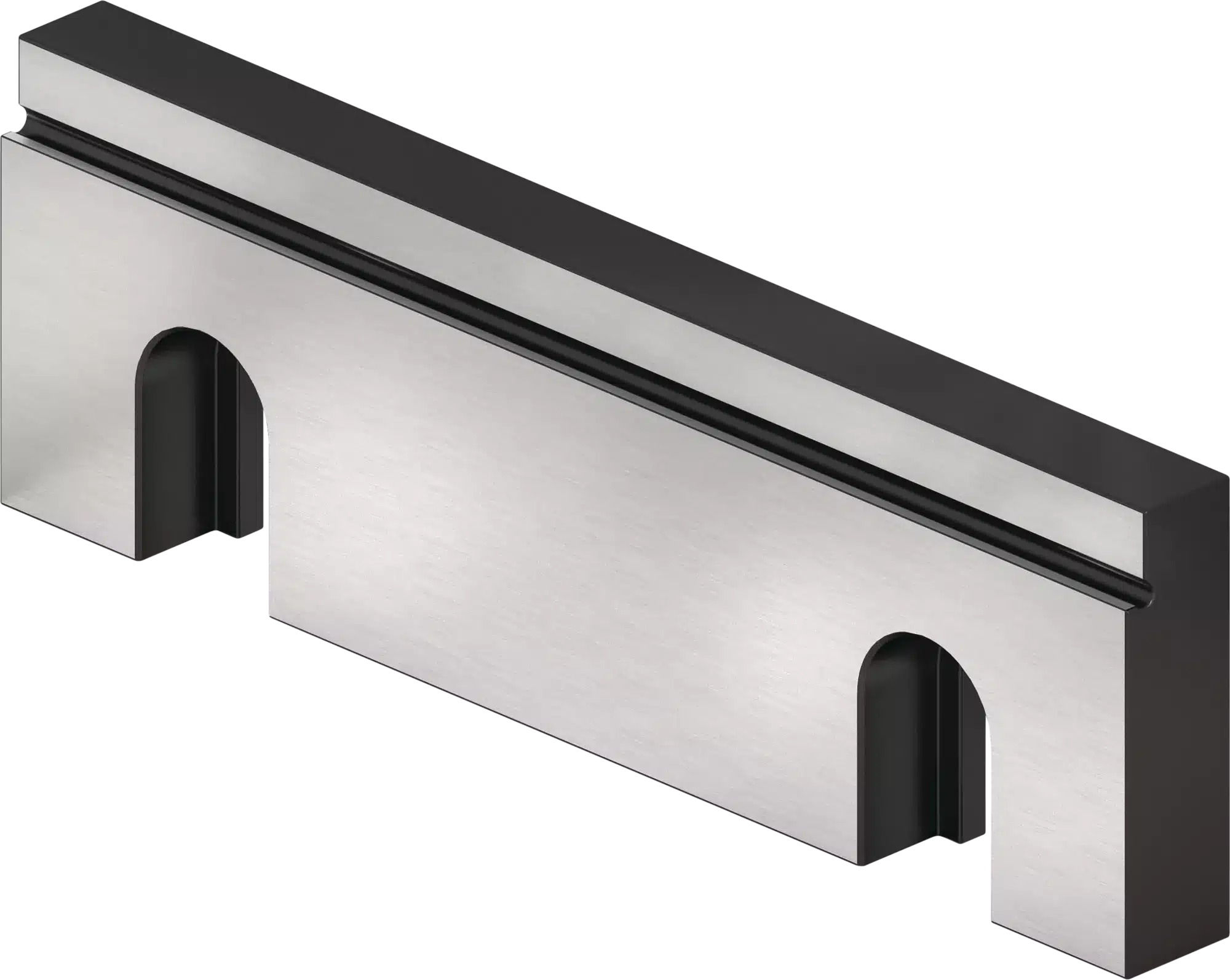

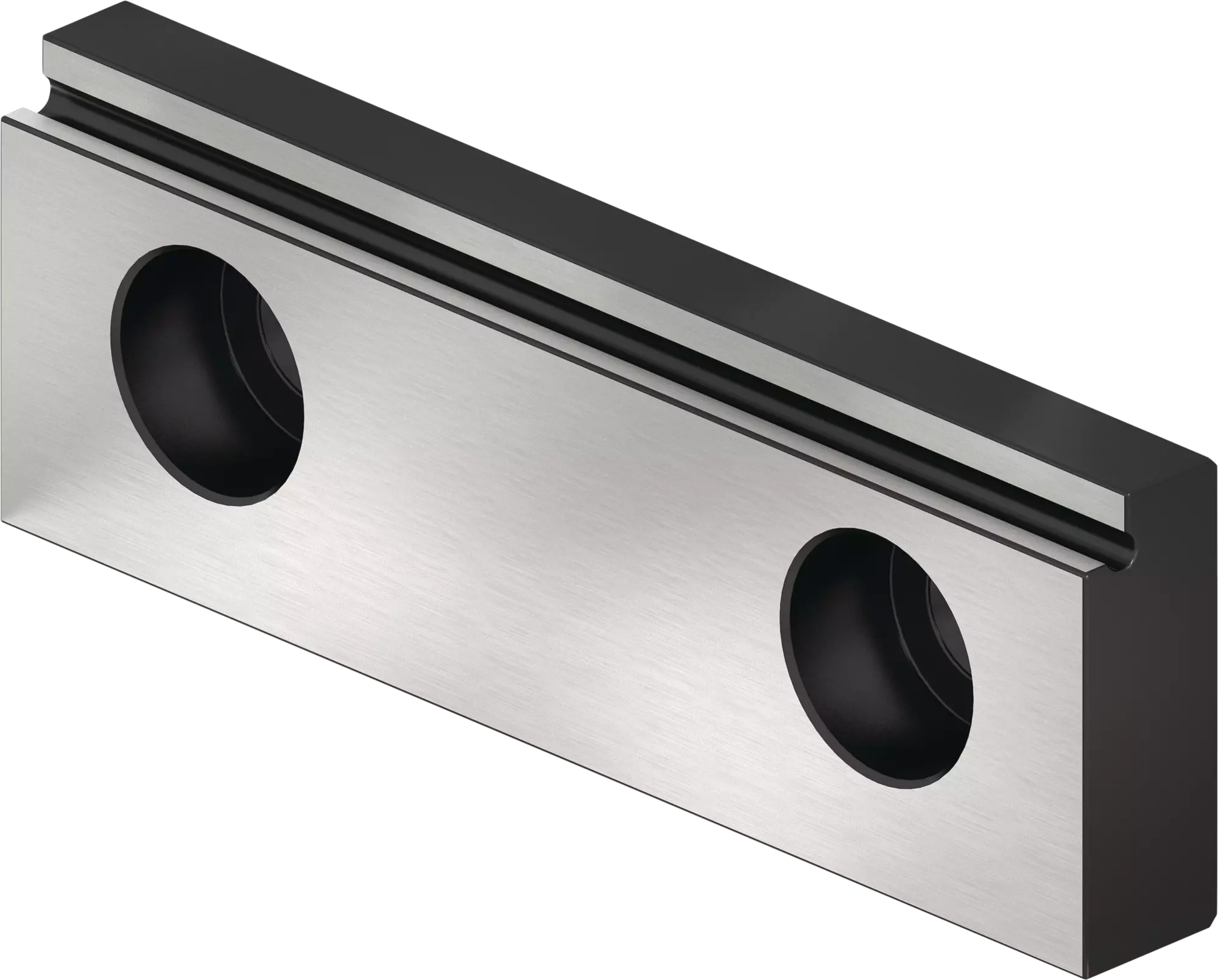

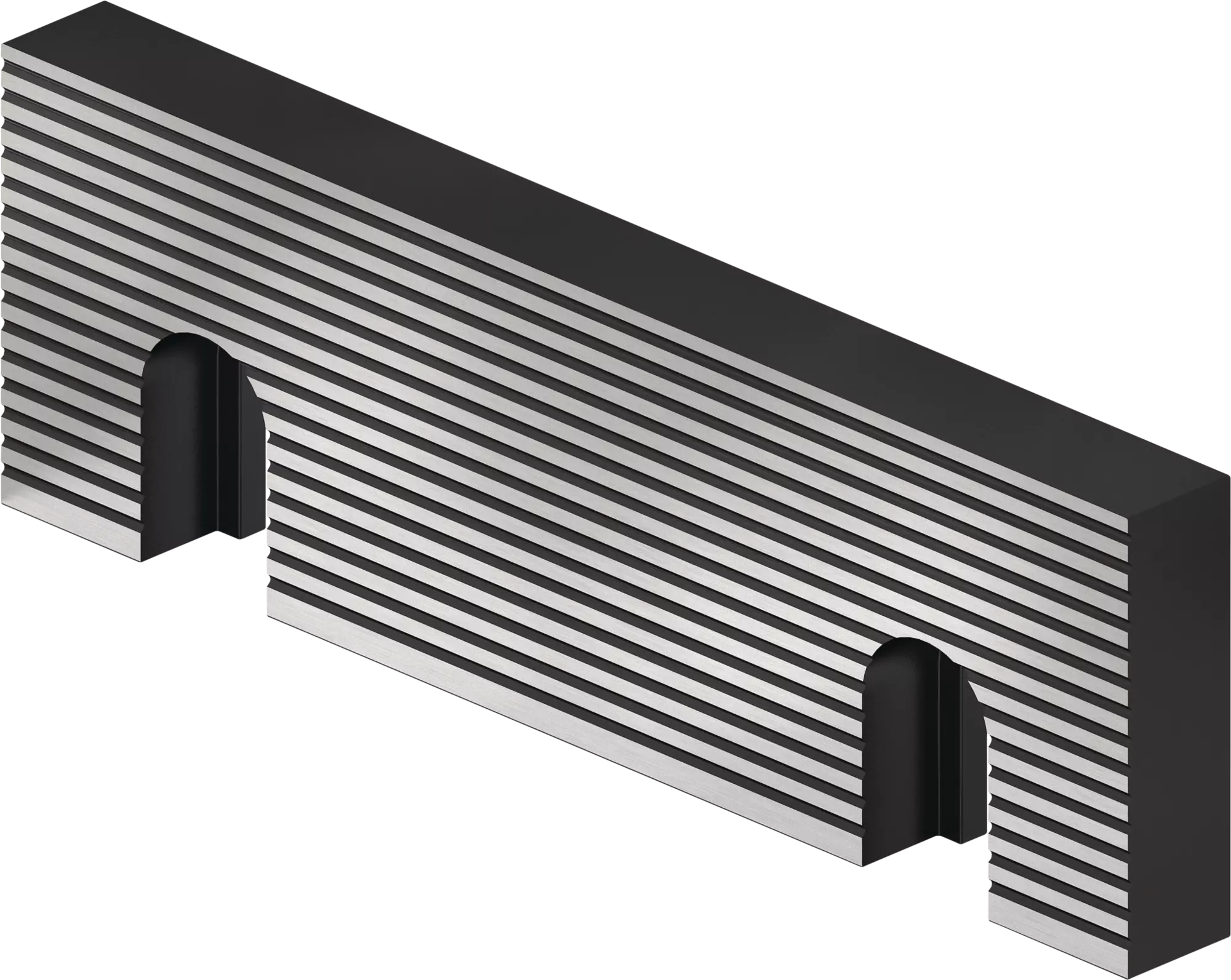

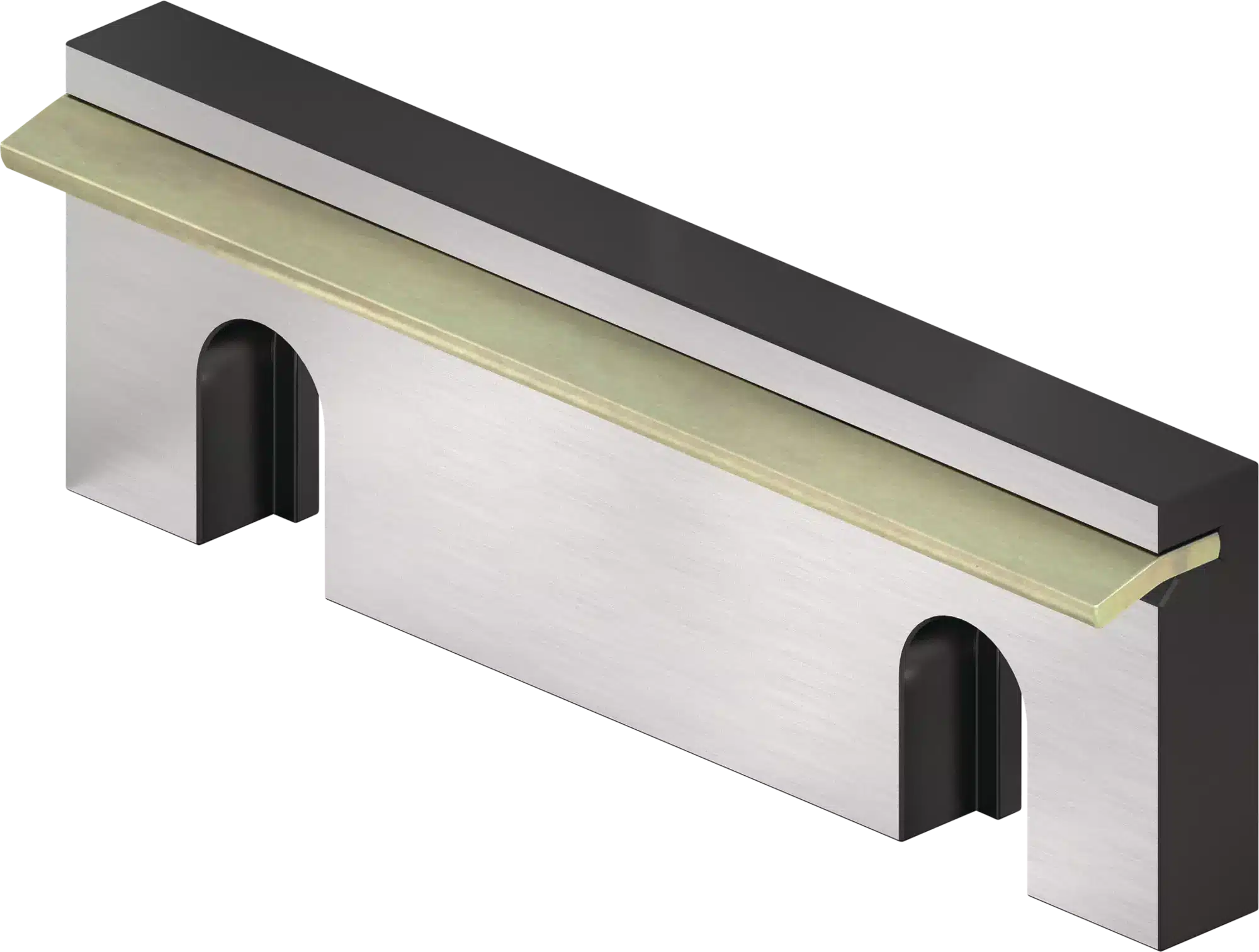

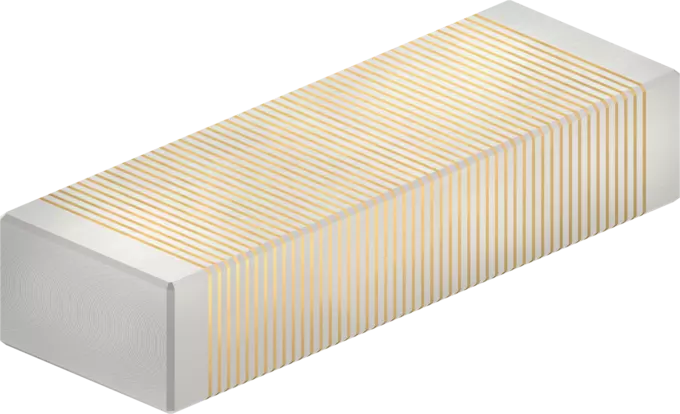

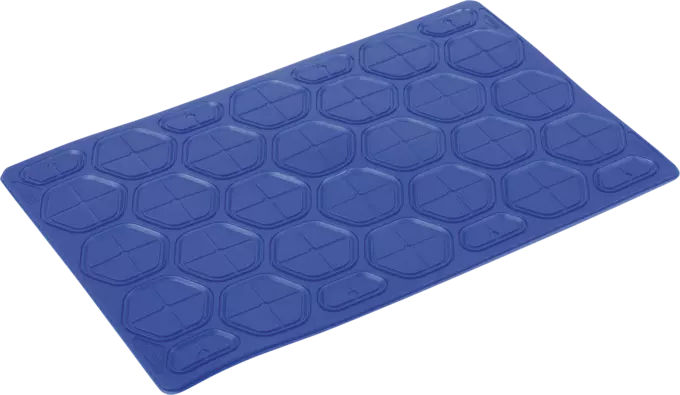

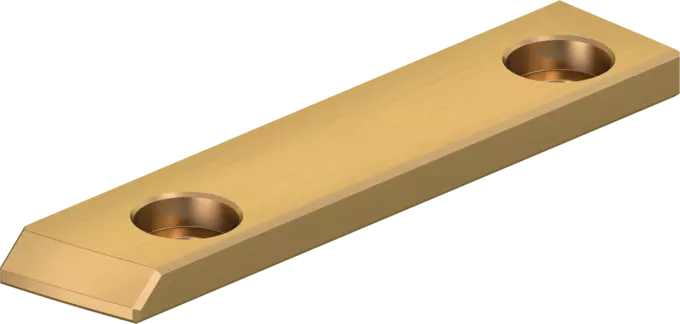

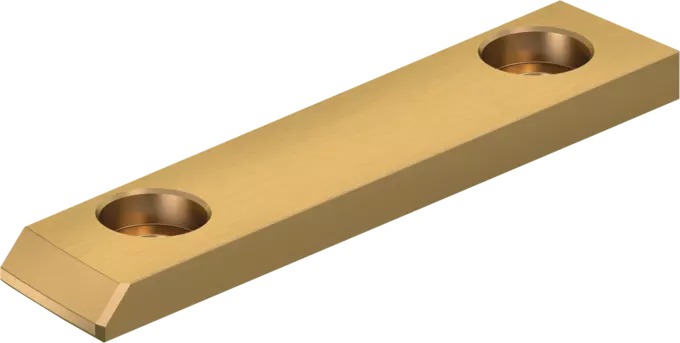

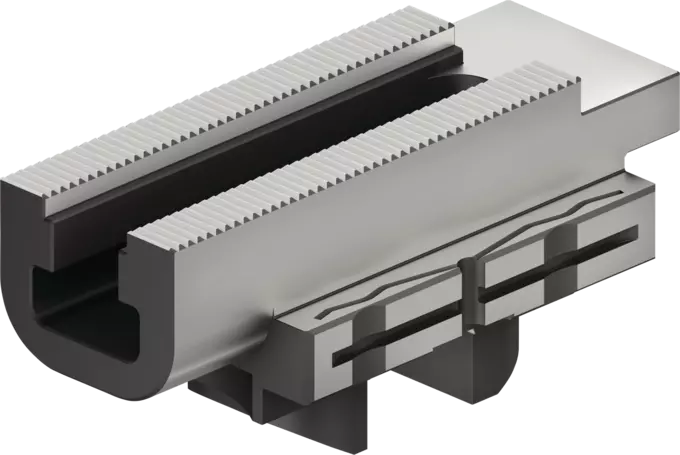

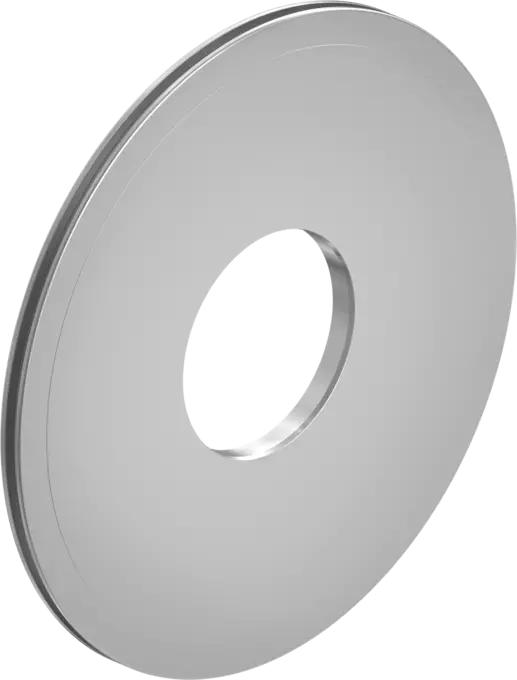

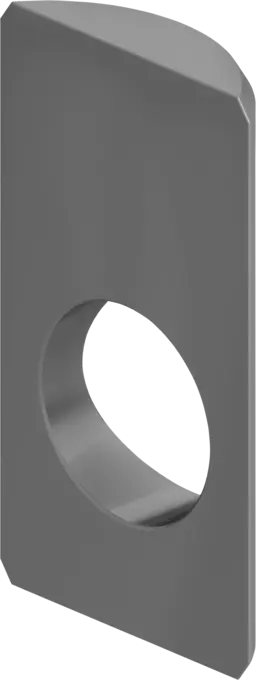

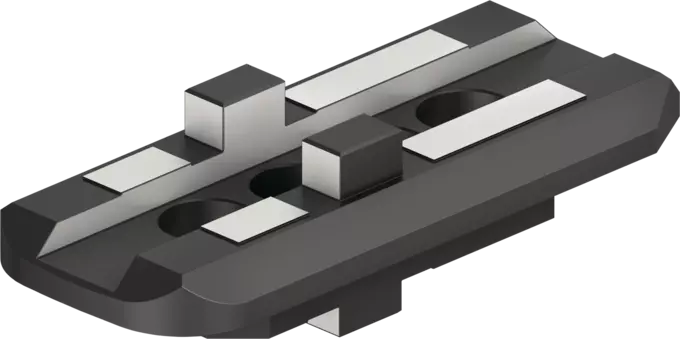

The dress and cleaning plate SRP is suitable for cleaning dirty chuck jaw serrations quickly and safely. The dirt accumulates in the diagonal slot, which also facilitates the cleaning process. It is hardened with precision-ground serration on both sides and adjusted to fit the fine serration of the chuck jaws. Fast deburring and equalizing of damaged points in the serration allows for increased clamping precision and reduces wear. Apply grinding paste (grain size 320), insert chuck jaws on top of it, and evenly move them to both sides.

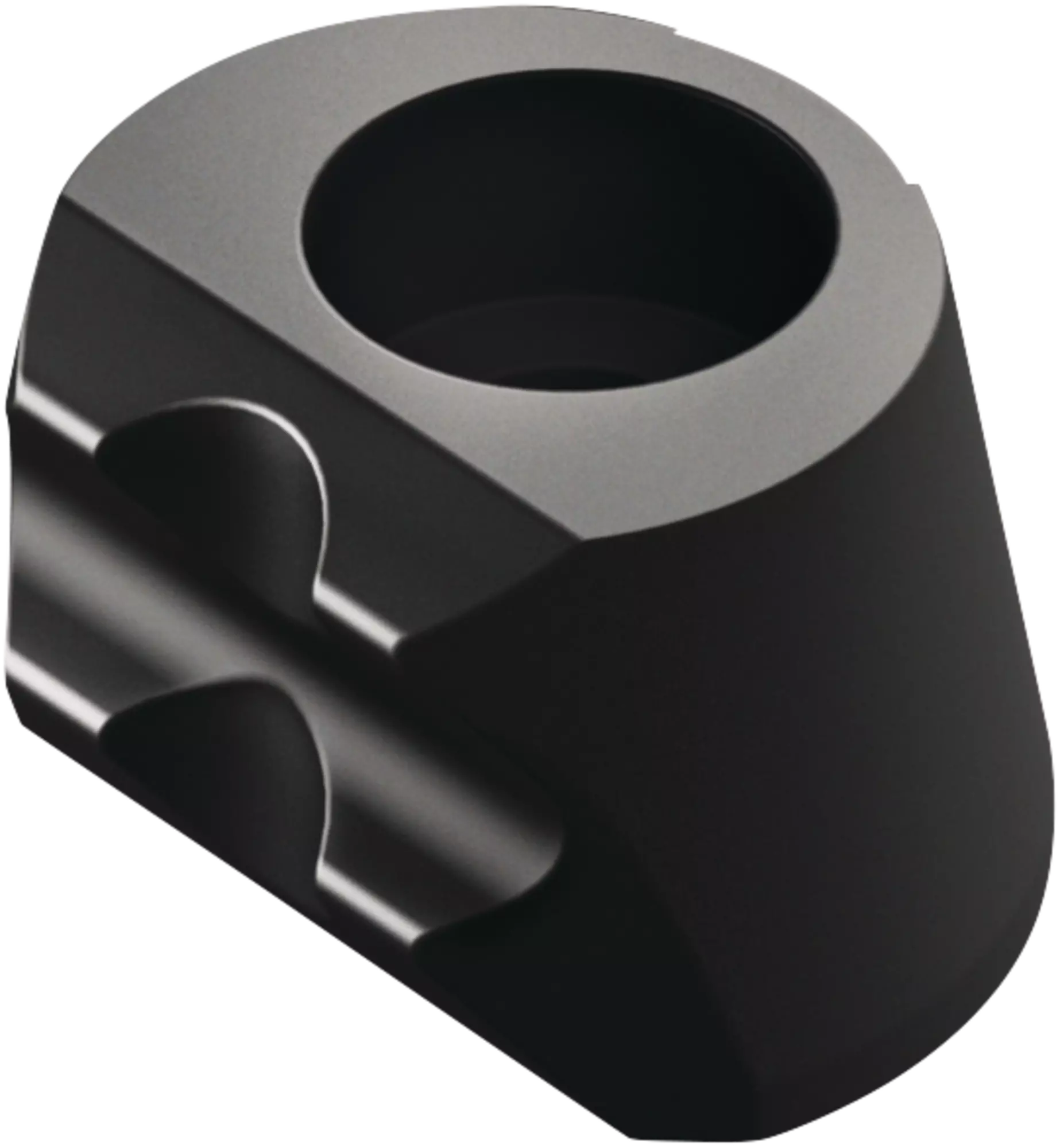

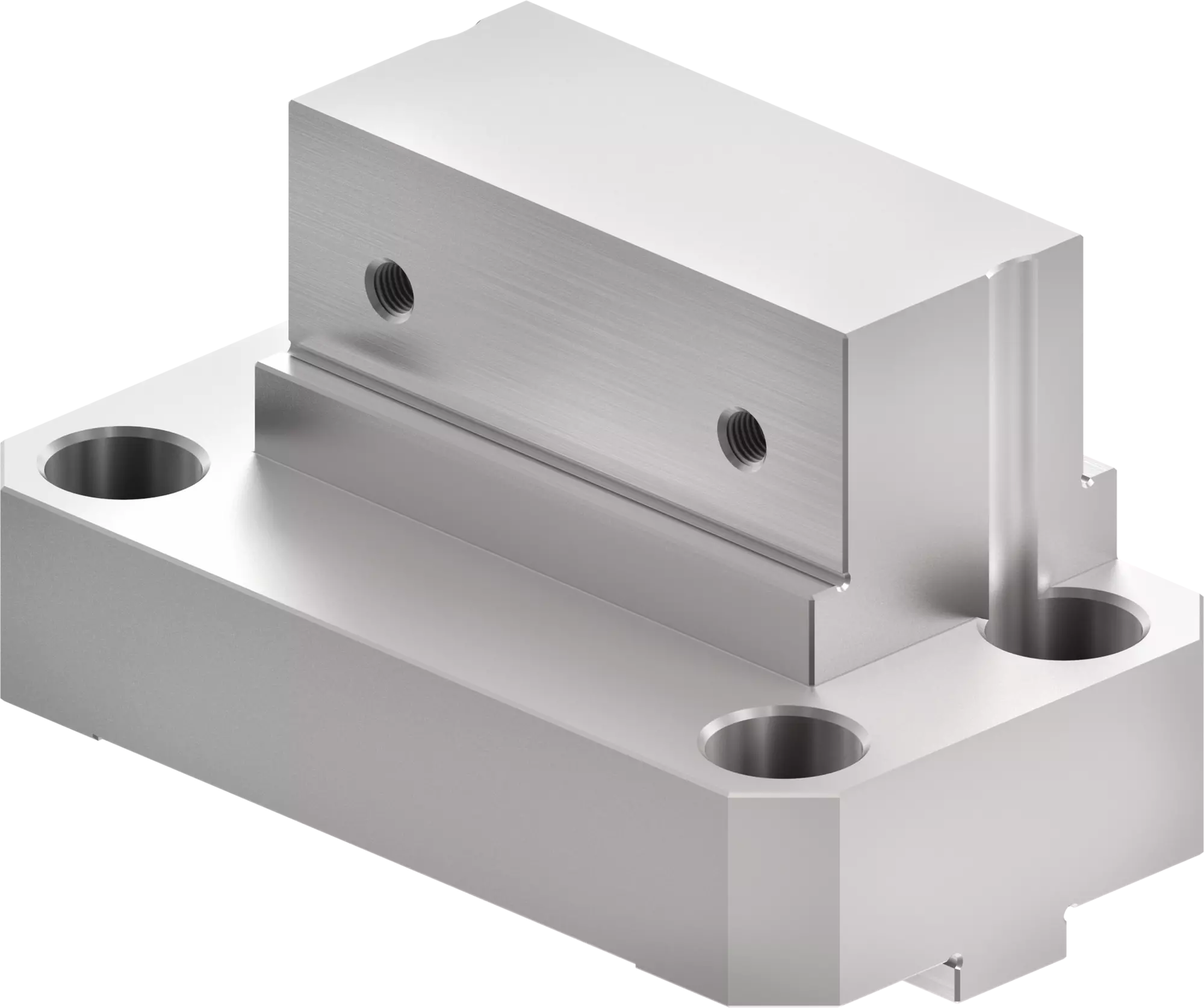

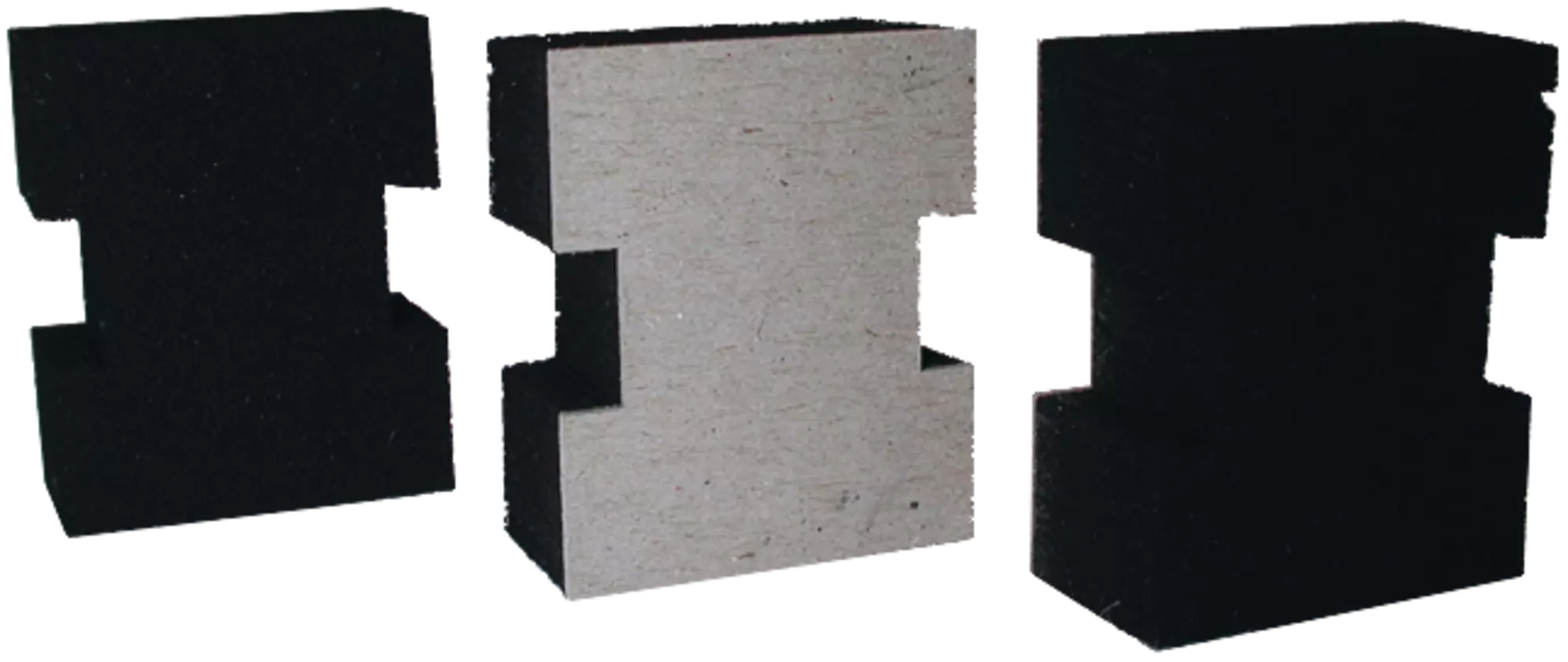

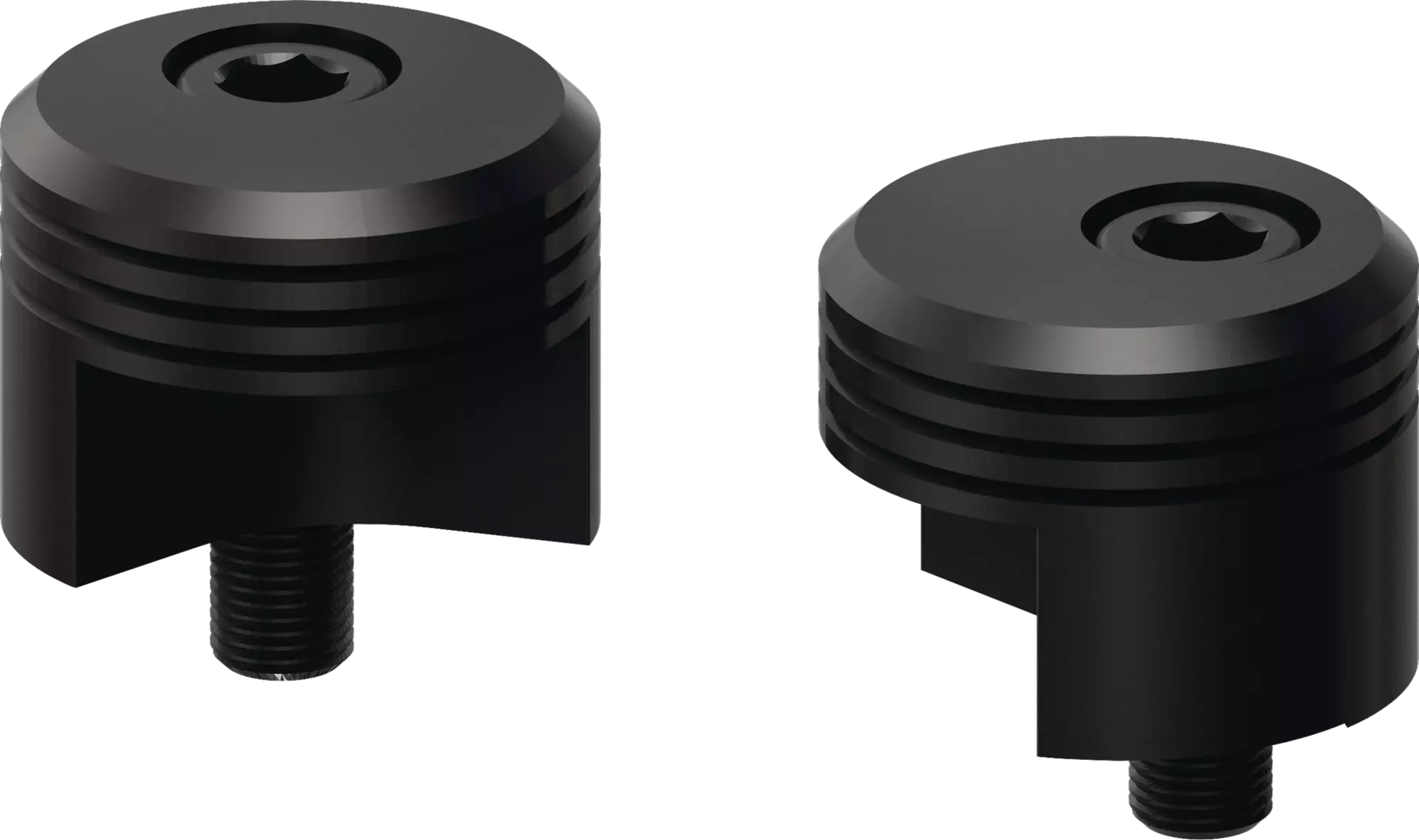

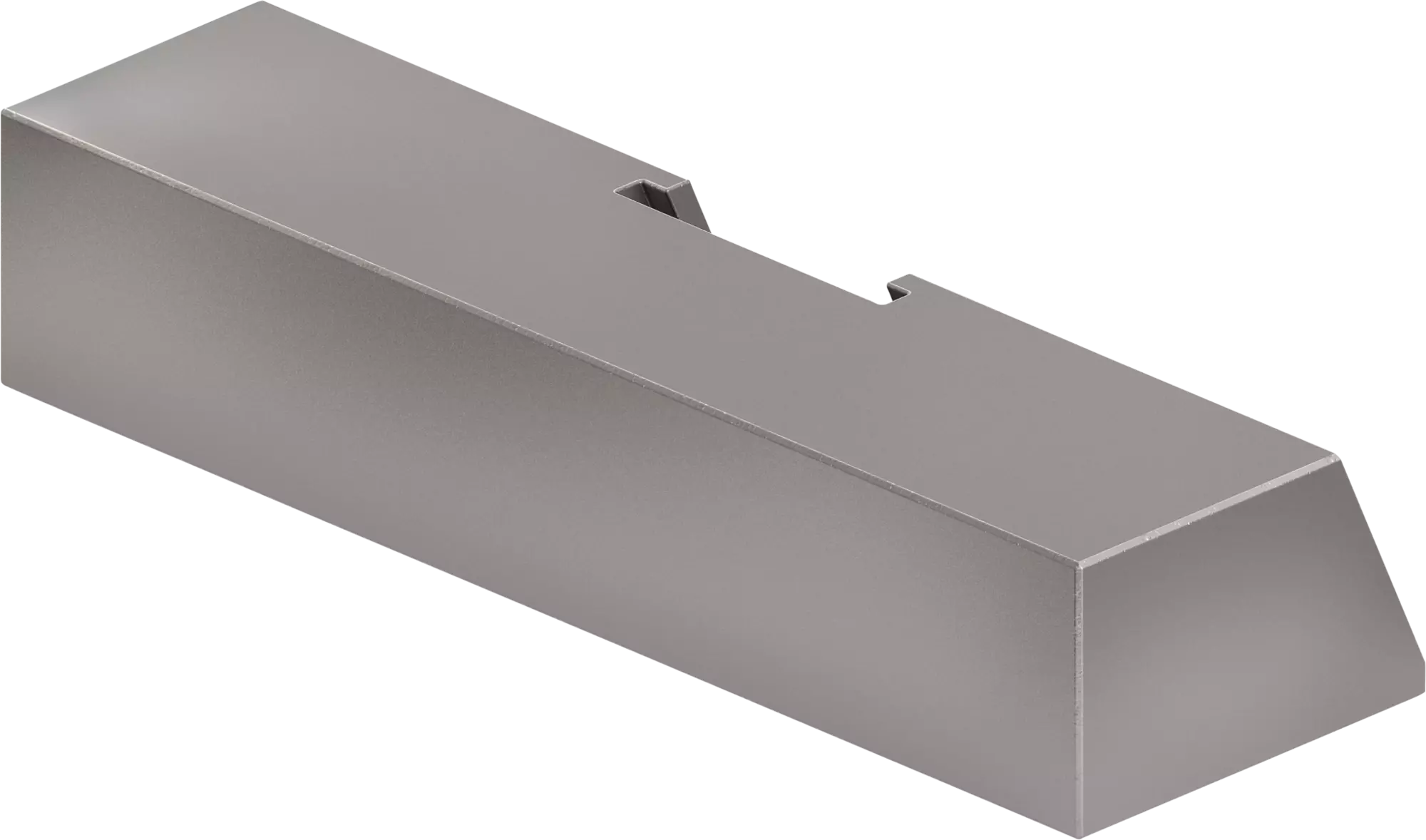

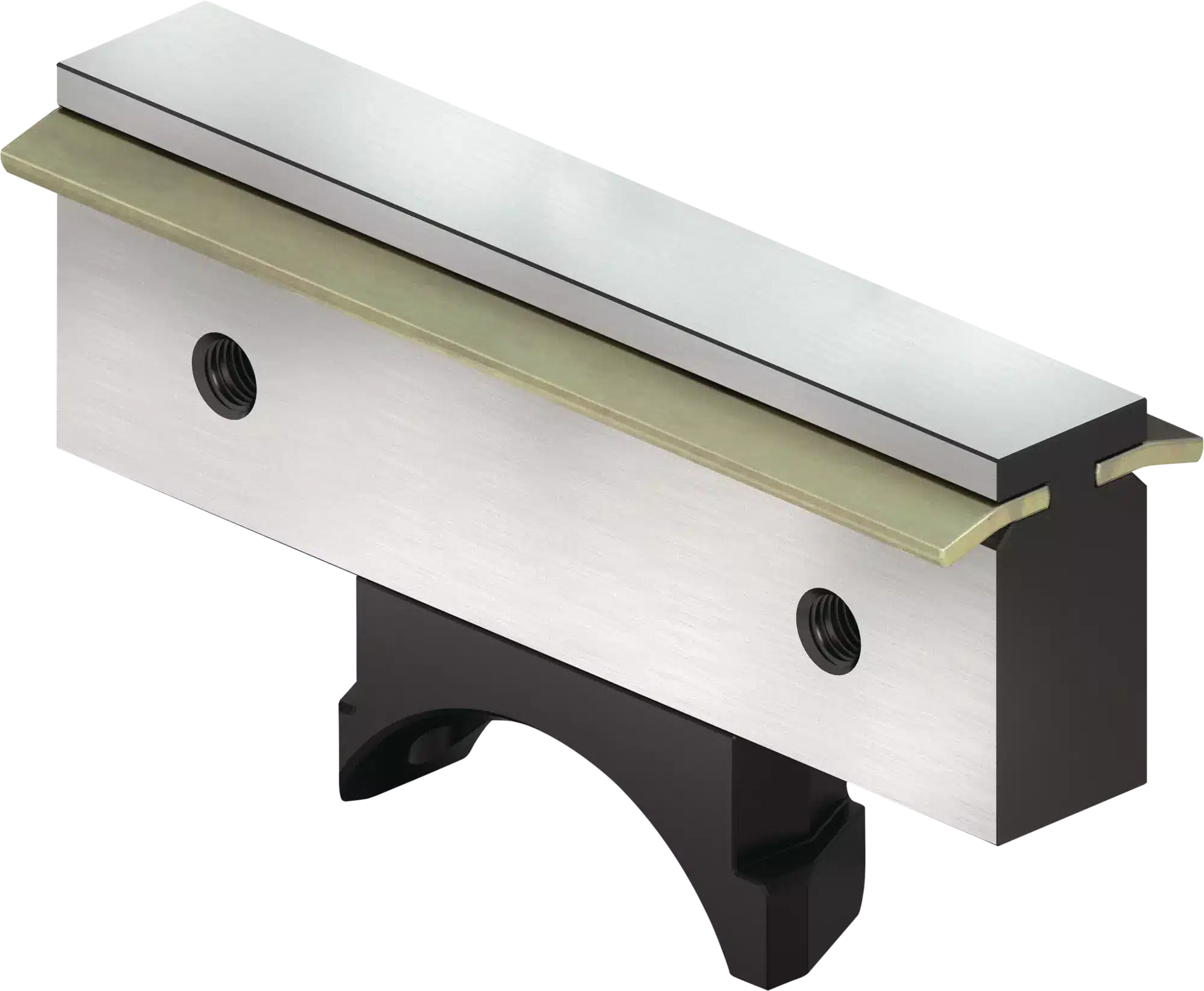

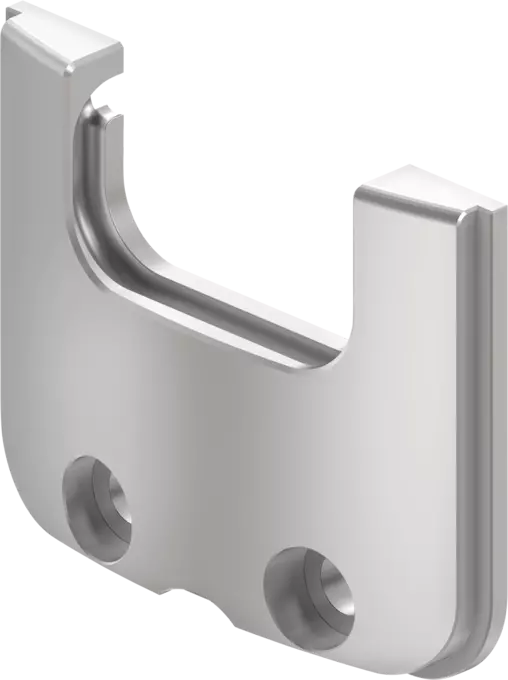

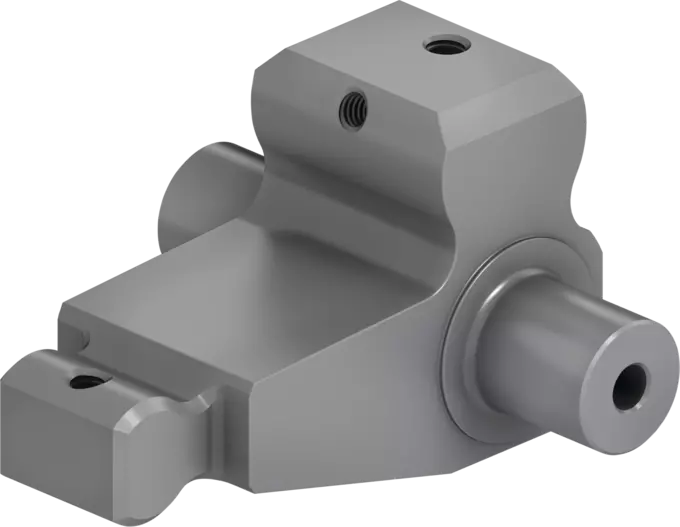

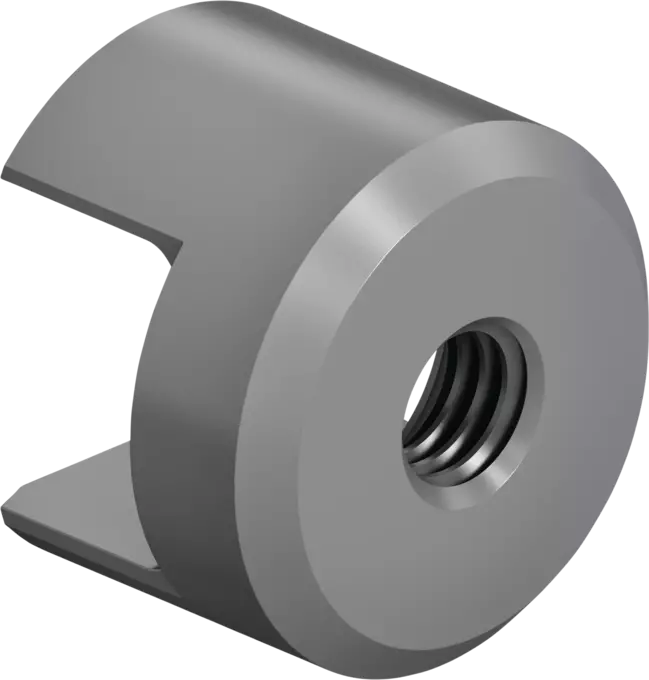

Workpiece stops are used on claw jaws and pendulum jaws to change the clamping depth. As needed, they can be processed to a desired height.

Workpiece stops can also be used for special workpiece-specific special chuck jaws

They are made of C45 steel either as soft or hardened variants.

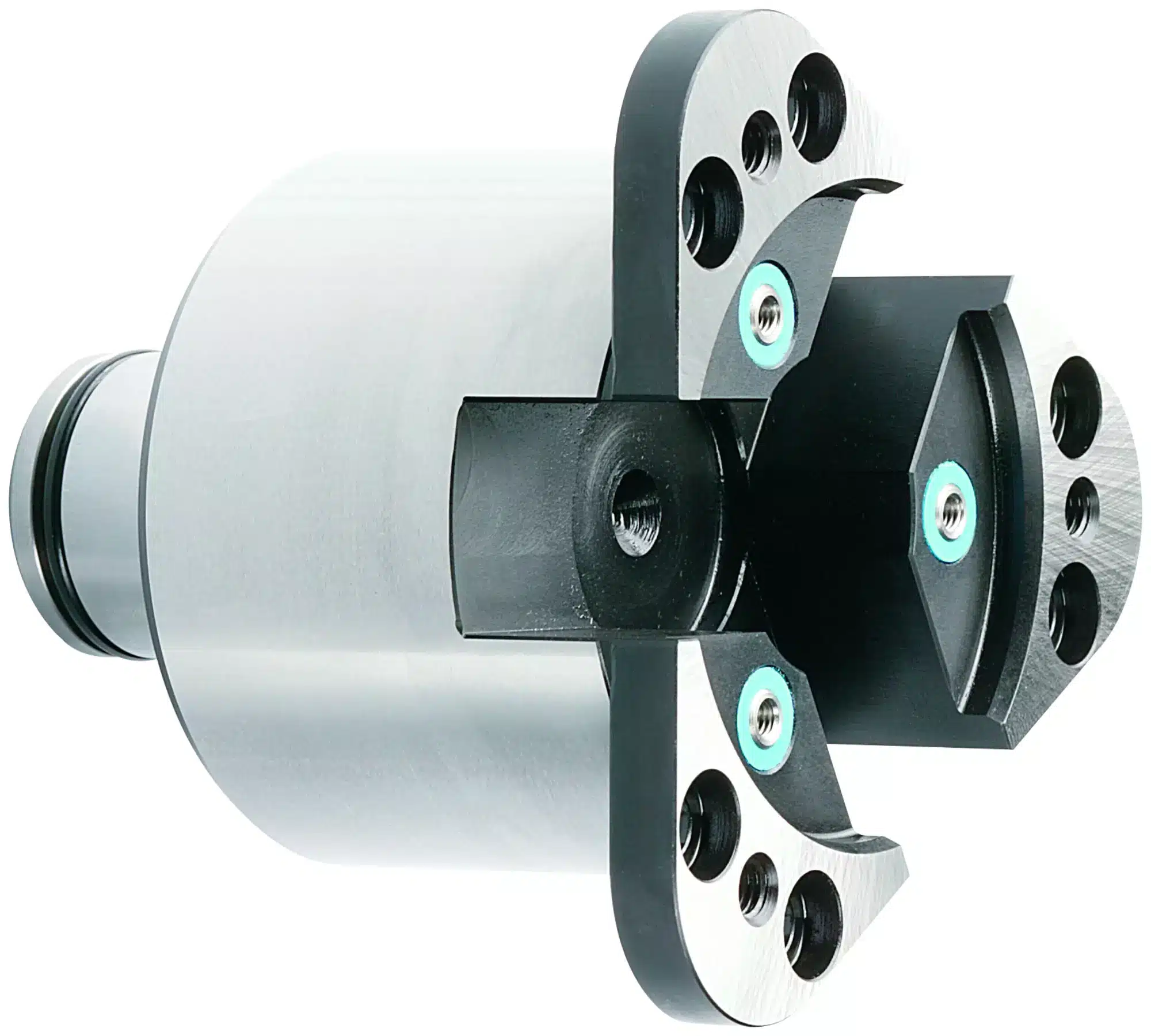

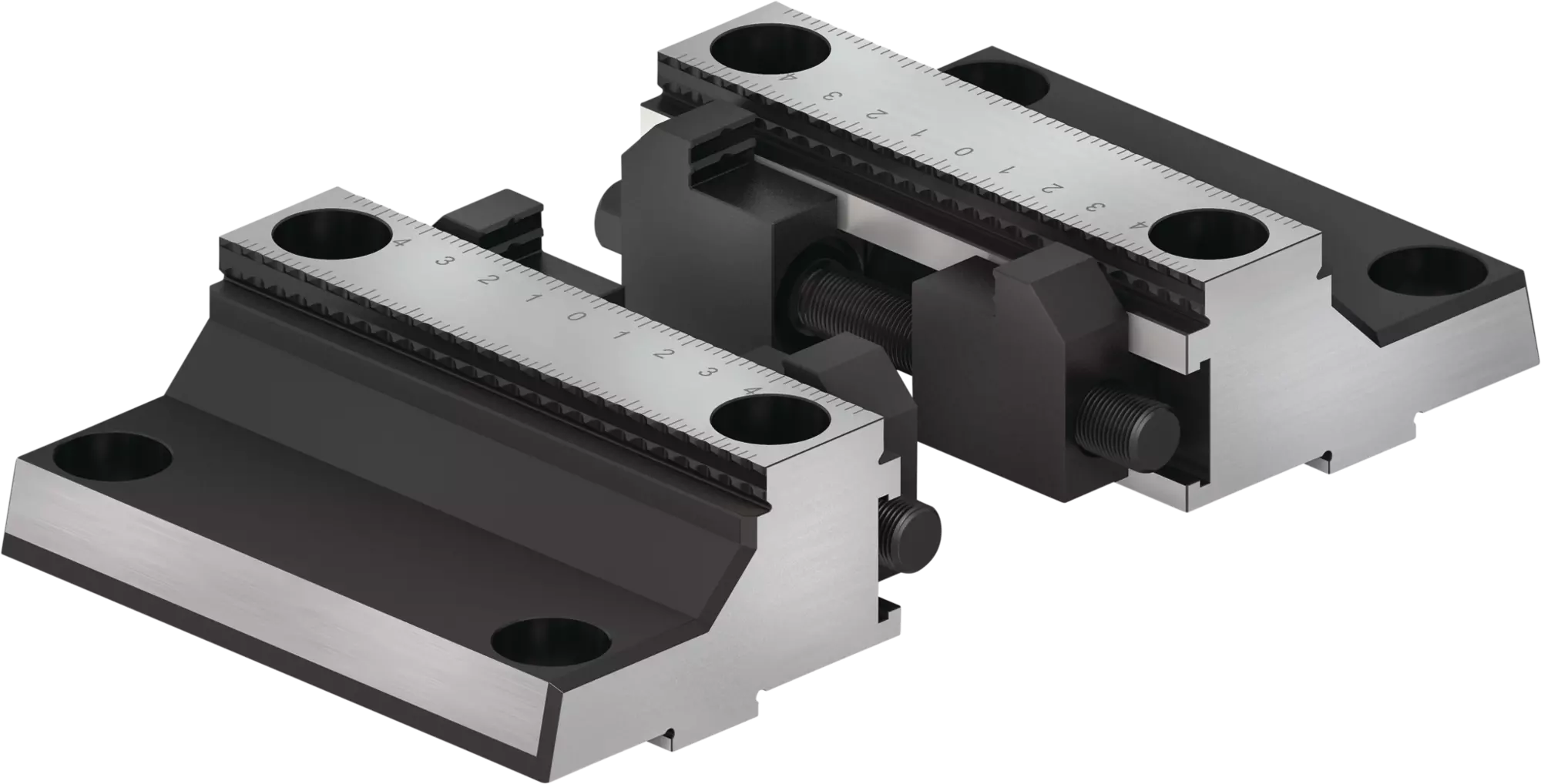

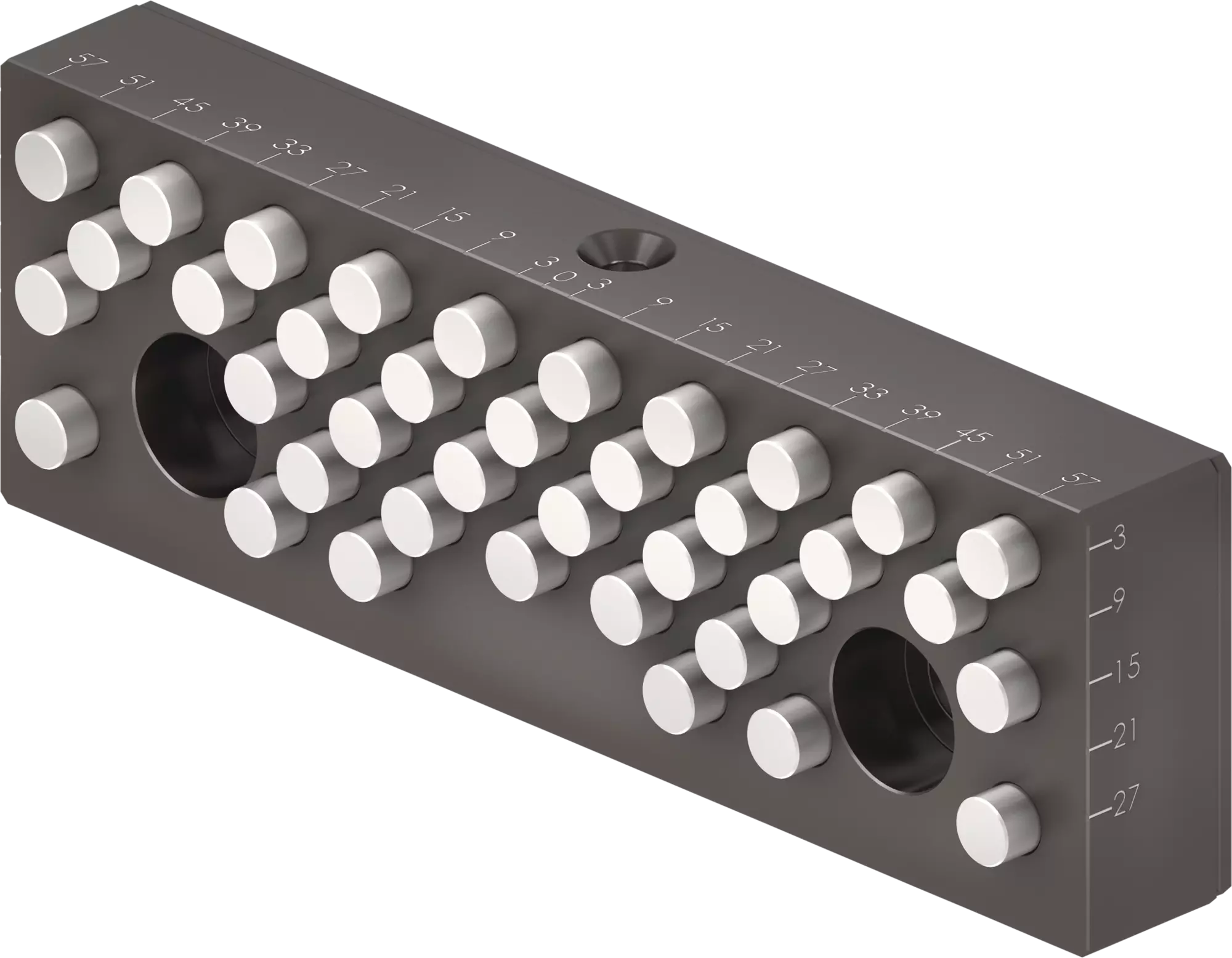

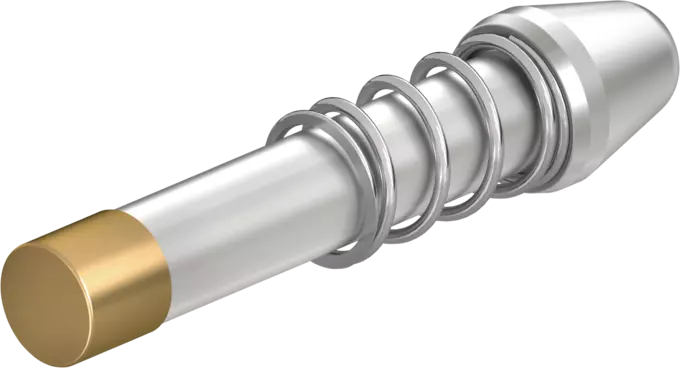

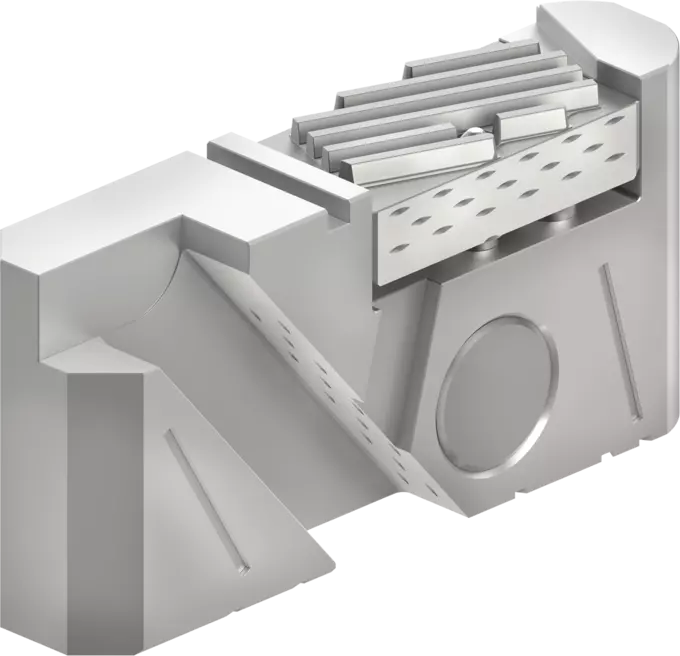

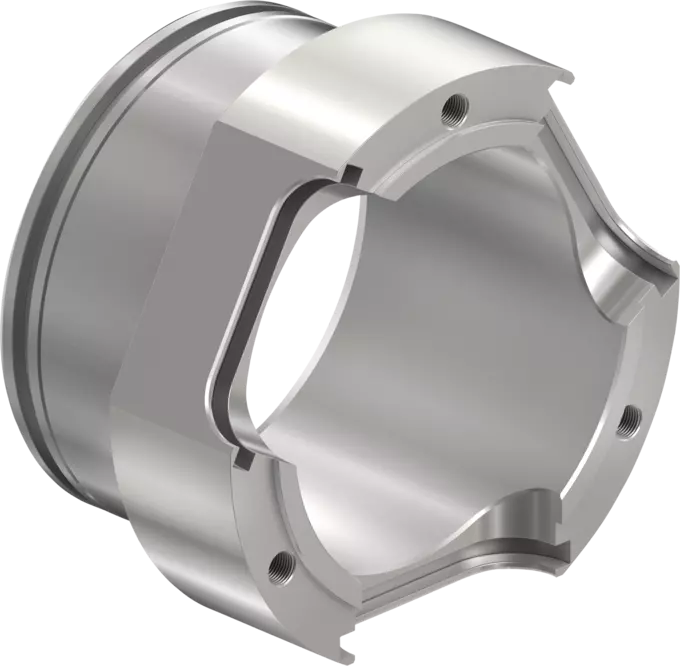

Turning out chuck jaws precisely under clamping pressure and grinding out hard chuck jaws is possible using the SCHUNK RotoRi turning set. The set consists of individual rings in different dimensions, allowing continuous adjustment of the desired clamping diameter. It is used in manual and power chucks, and is suitable for 2, 3, 4 and 6 lathe chucks, for both I.D. and O.D. clamping. Using curve segments with infinite adjustment possibilities, precisely the right amount of material can be removed as required. RotoRi turning sets are available as standard and premium variants: the RotoRi premium variants contain instead of the standard clamping pins, the patented RotoFix clamping pins, which seamlessly offset tolerances of countersunk screws through 2 mm adjustment range. In addition, all versions from RotoRi LX upwards include rings in a reinforced design.

The compact and light turning ring sets ADR make child's play of precise turning out or grinding out of highly hardened and heat-treated soft chuck jaws. These are easy to handle and versatile in use on 2, 3 and 6 jaw chucks. Instead of a variety of different rings, the boring sets mean you only need a few turning disks to implement clamping diameters for O.D. clamping in 2 mm steps. The individual size required is defined via three pins. These have to be screwed into the thread of the jaw turning rings and then inserted into the lathe chuck. Since no fitting bores are necessary, the turning disks can be used by Plug & Work in no time at all. For more finely graduated intermediate diameters, the pins can be milled. They are available as additional spare parts kits.

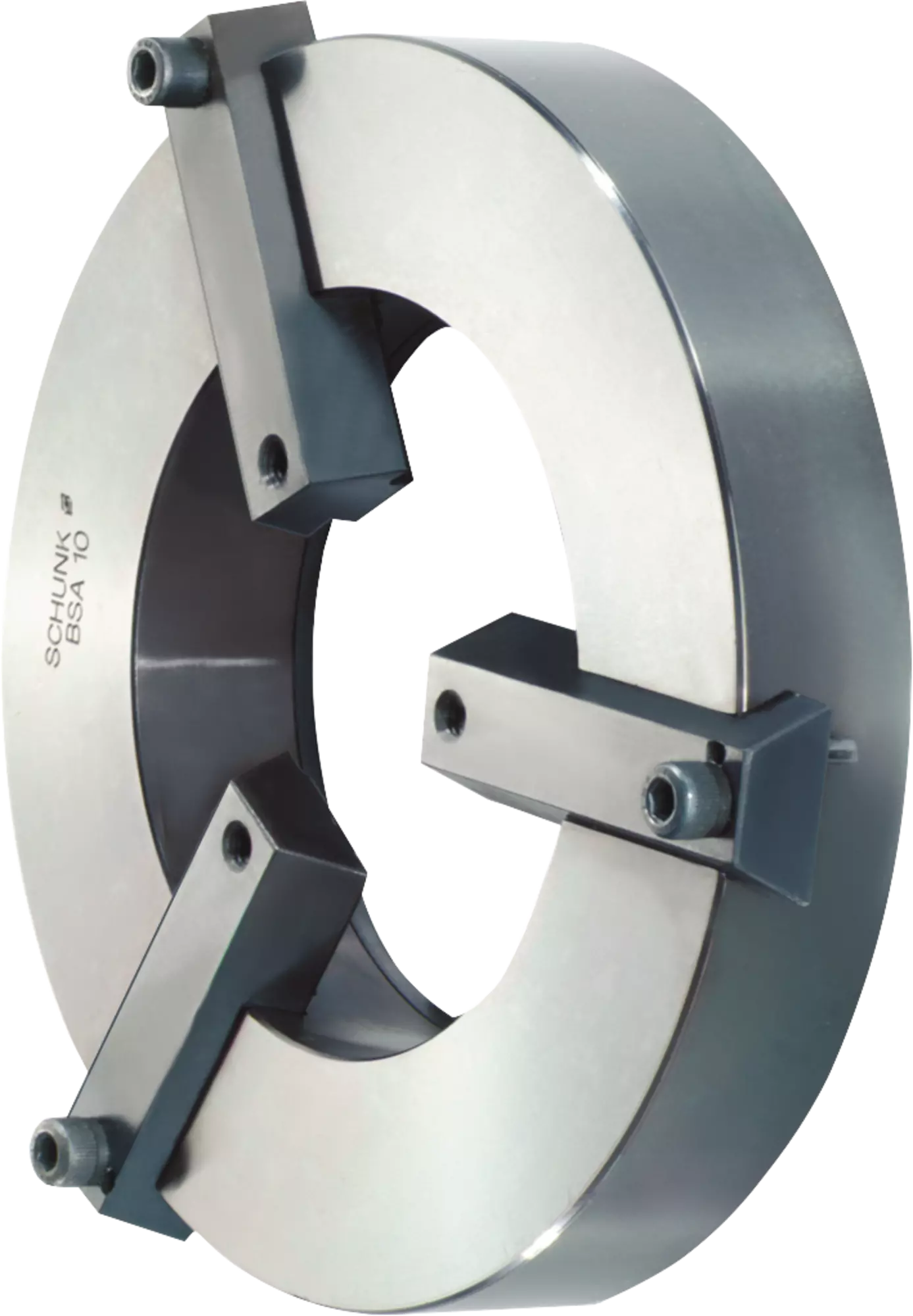

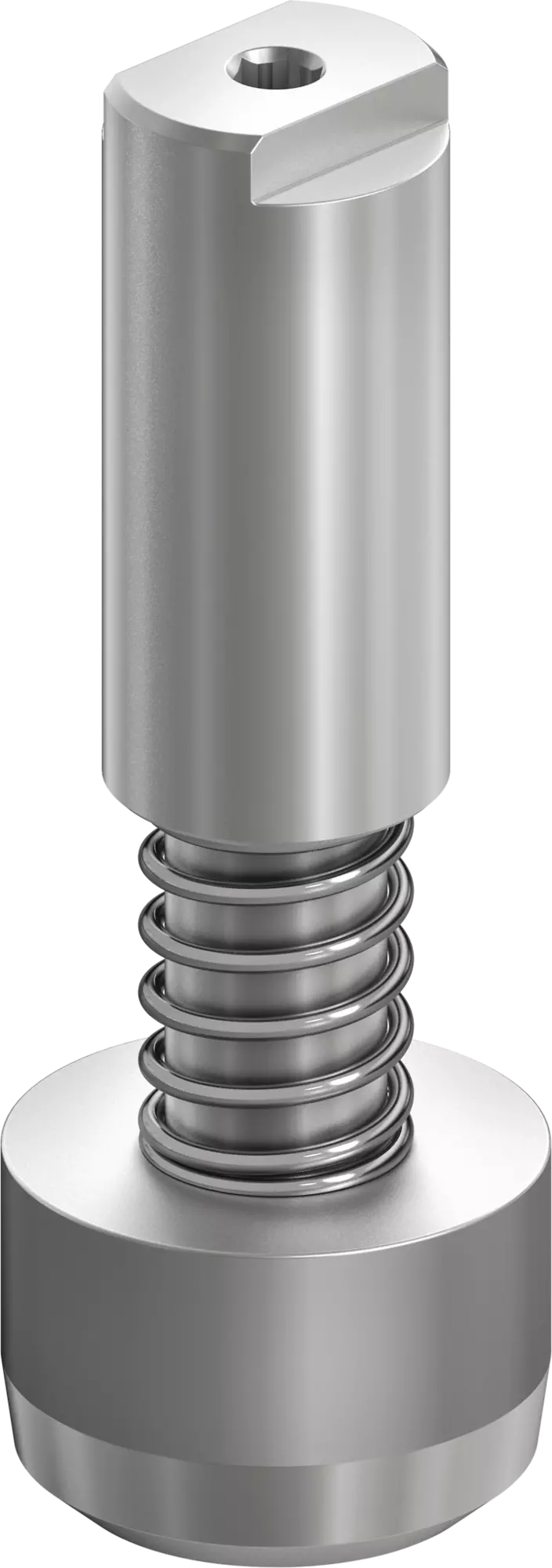

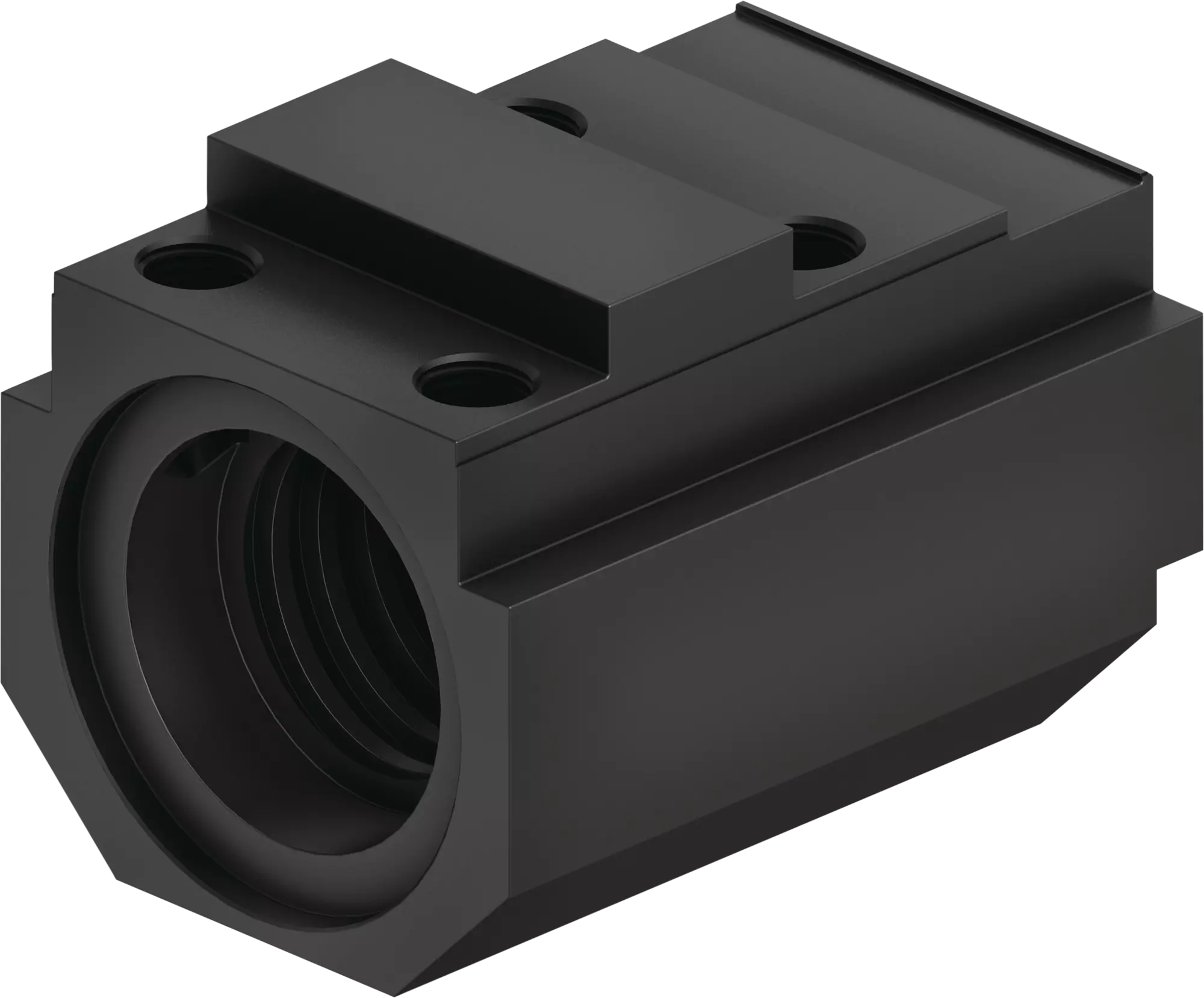

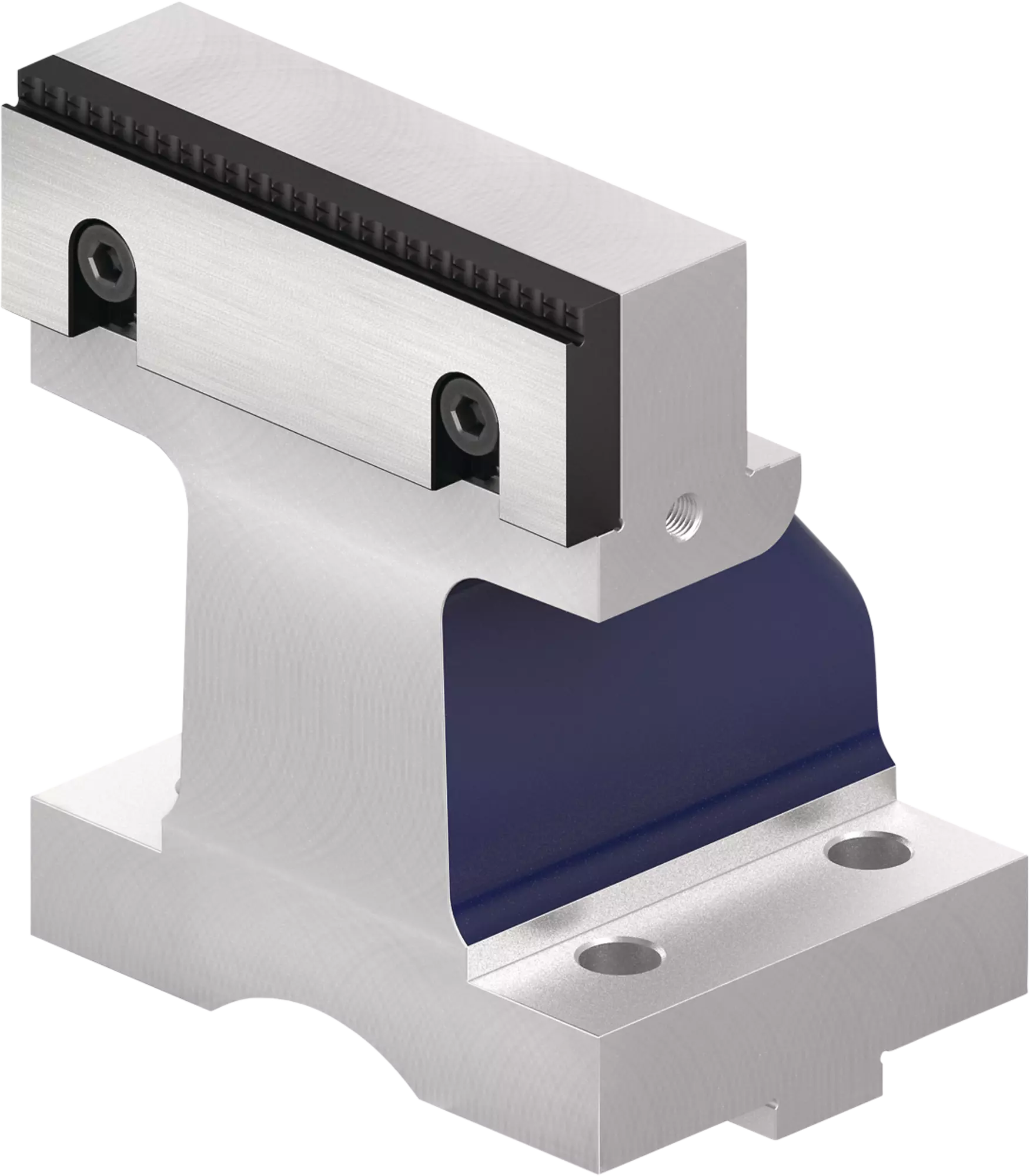

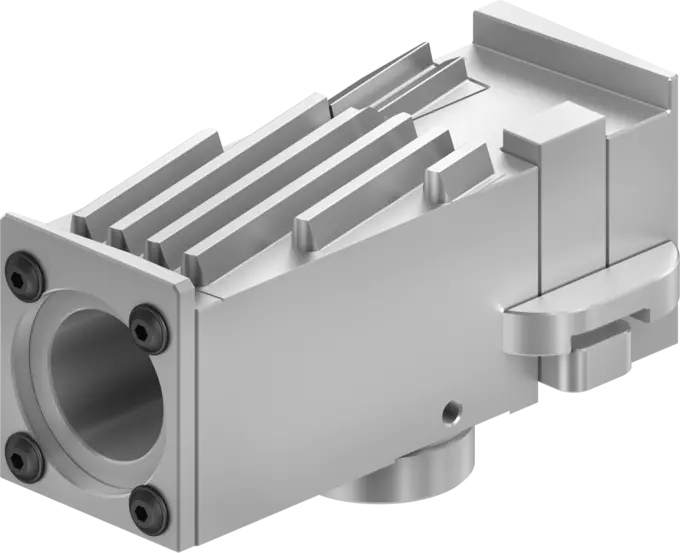

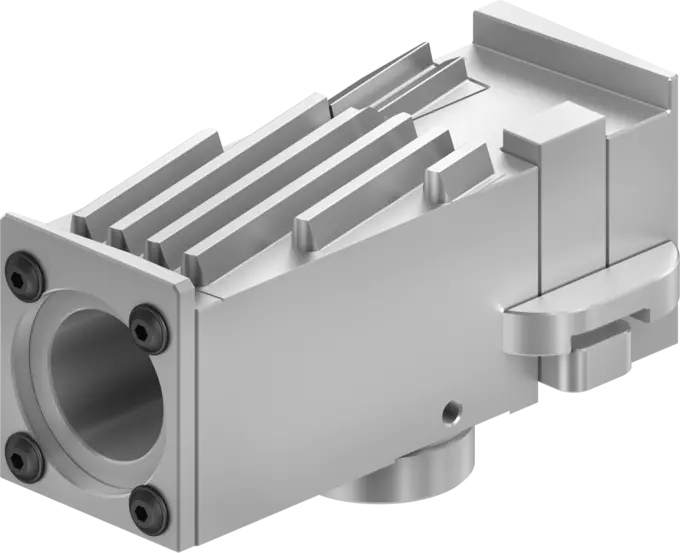

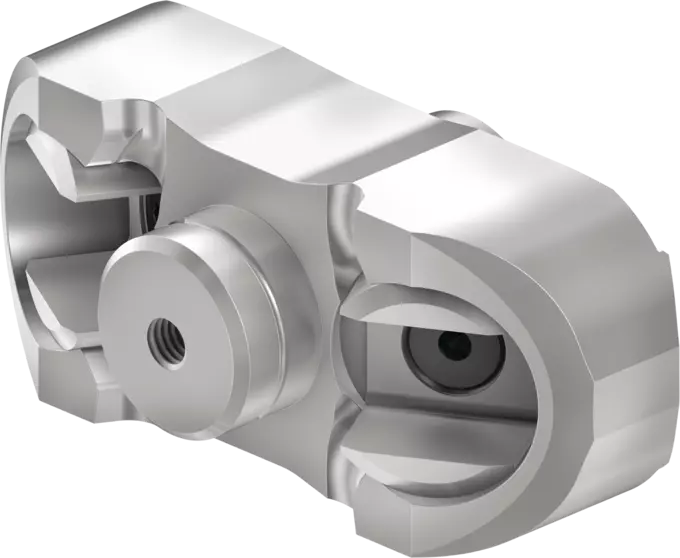

The jaw turning fixture is suitable for turning out all soft or heat-treated chuck jaws on manual and power lathe chucks, and for grinding out hardened chuck jaws on manual and power lathe chucks. The adjusting range can be adjusted by using a scroll. Large clamping ranges can be covered using the chuck jaw turning fixture. The heavy version BSA is mainly used for power lathe chucks, and is suitable for high clamping forces up to 75 kN.

The jaw turning fixture is suitable for turning out all soft or heat-treated chuck jaws on manual and power lathe chucks, and for grinding out hardened chuck jaws on manual and power lathe chucks.

Large clamping ranges can be covered using the chuck jaw turning fixture. The light version BAV is suitable for low clamping forces up to 30 kN

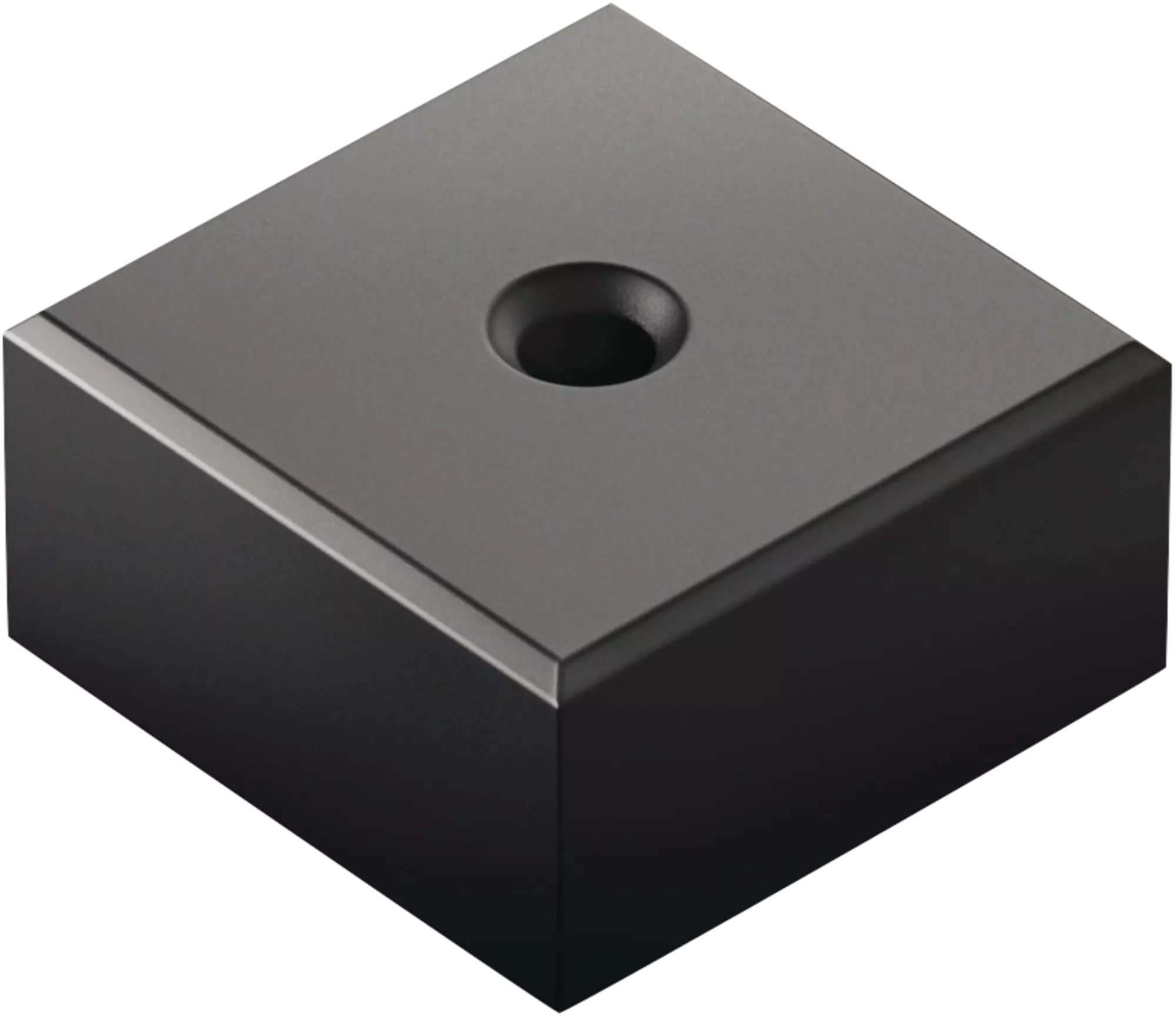

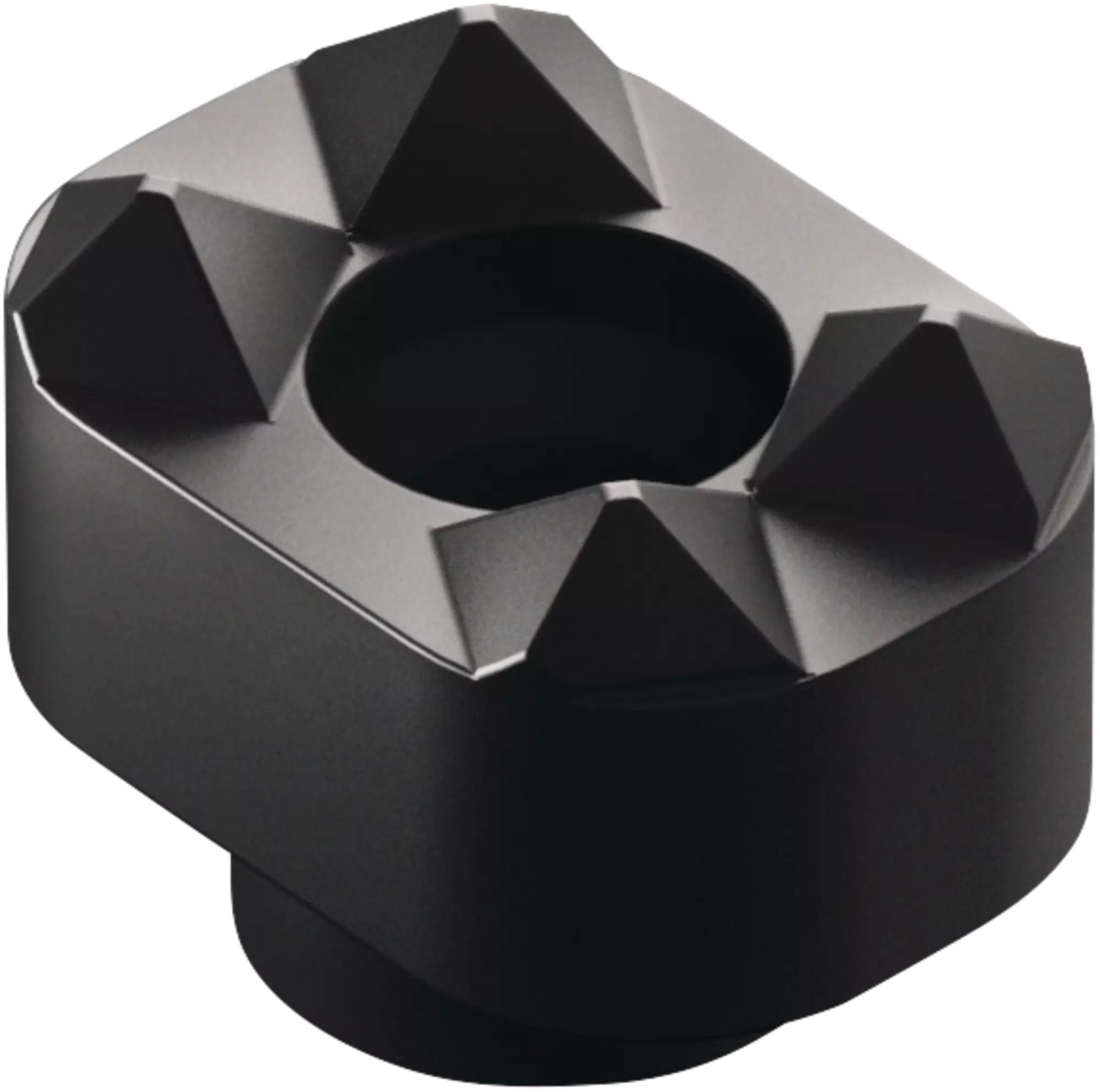

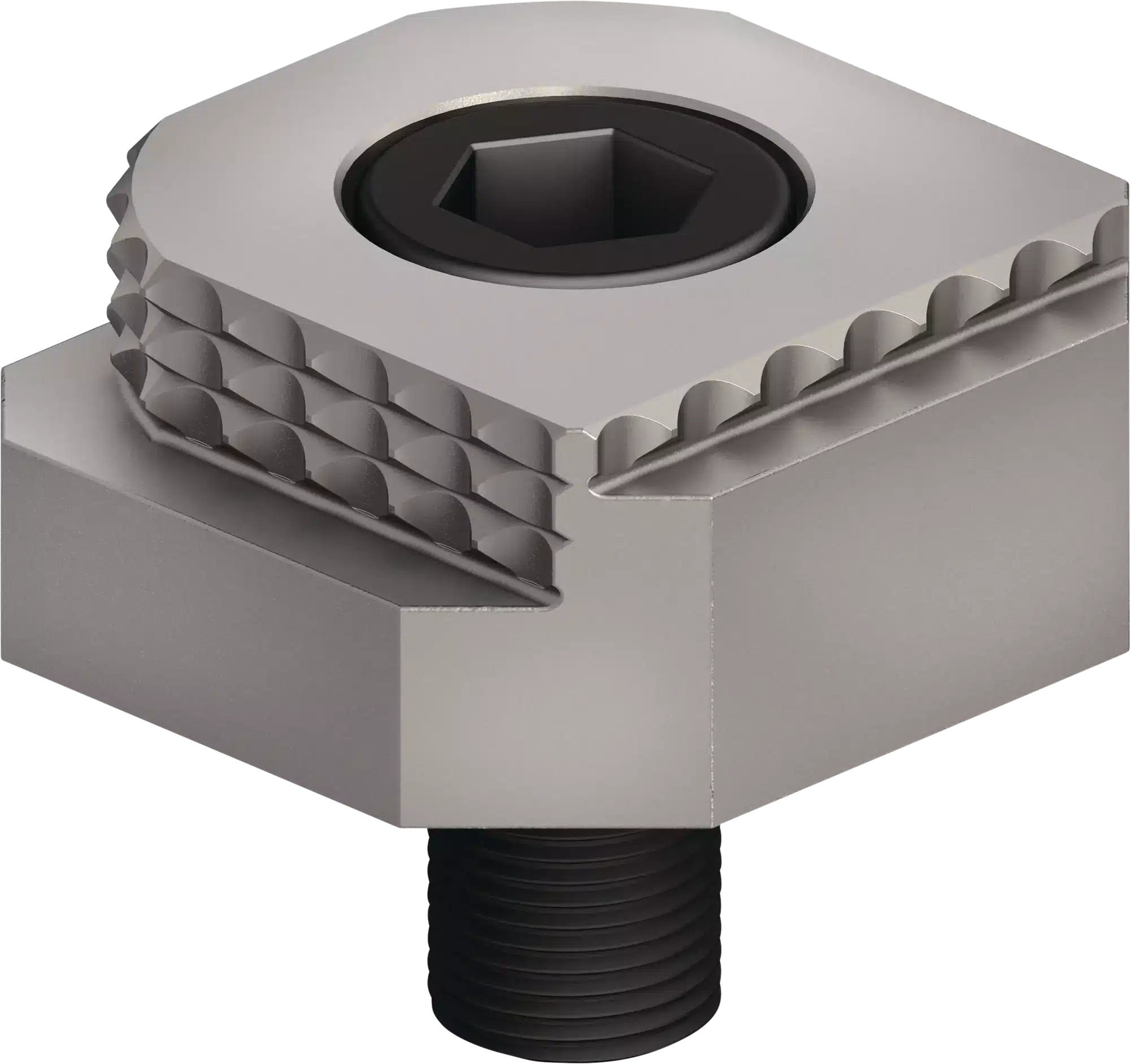

The clamping insert UGE enables the production of claw jaws from jaw blanks, ensuring safe clamping of blanks/forged parts, and workpieces made of high-strength materials. In addition, high torques for heavy cuts can be transferred and costs can be reduced by replacing the worn out inserts. UGE 20 is suitable for O.D. and I.D. clamping. Due to the wedge shape, the workpiece can be additionally pulled down, and in turn ensures a higher clamping reliability. The clamping insert is fastened from above. For installation, the angular milling cutter WSF UGE 20 (ID 010015) is required, which makes the production of a suitable milled recess and thread easier. Hardening of the jaw blanks is not required.

The angular milling cutter makes it easier to create a suitable recess or thread in the chuck jaws for installing the clamping insert UGE 20.

The UGE 30 clamping insert allows soft top jaws and jaw blanks to be converted into full-fledged hard chuck jaws. It is used with turning jaws, vise jaws, and devices for O.D. and I.D. clamping of cubic parts. On request, the clamping insert can also be used in SCHUNK special chuck jaws according to our design or your own. By simply exchanging worn out inserts, a cost reduction can be achieved. The required bore hole and thread are easy to manufacture. Chuck jaw hardening is recommended.

The round version of the HM clamping insert with soldered carbide offers an economic solution combining soft top jaws and blanks to manufacture full-fledged hard chuck jaws. On request, the clamping insert can also be used in SCHUNK special chuck jaws according to our design or your own. By simply exchanging worn out inserts, a cost reduction can be achieved. The clamping insert is suitable for O.D. clamping and is fastened from behind. The seat for the clamping insert can be easily manufactured.

The clamping insert HM in the square version with soldered carbide offers an economic solution combining soft top jaws and blanks to manufacture full-fledged hard chuck jaws. On request, the clamping insert can also be used in SCHUNK special chuck jaws according to our design or your own. By simply exchanging worn out inserts, a cost reduction can be achieved. The clamping insert is suitable for O.D. clamping and is fastened from behind. The seat for the clamping insert can be easily manufactured.

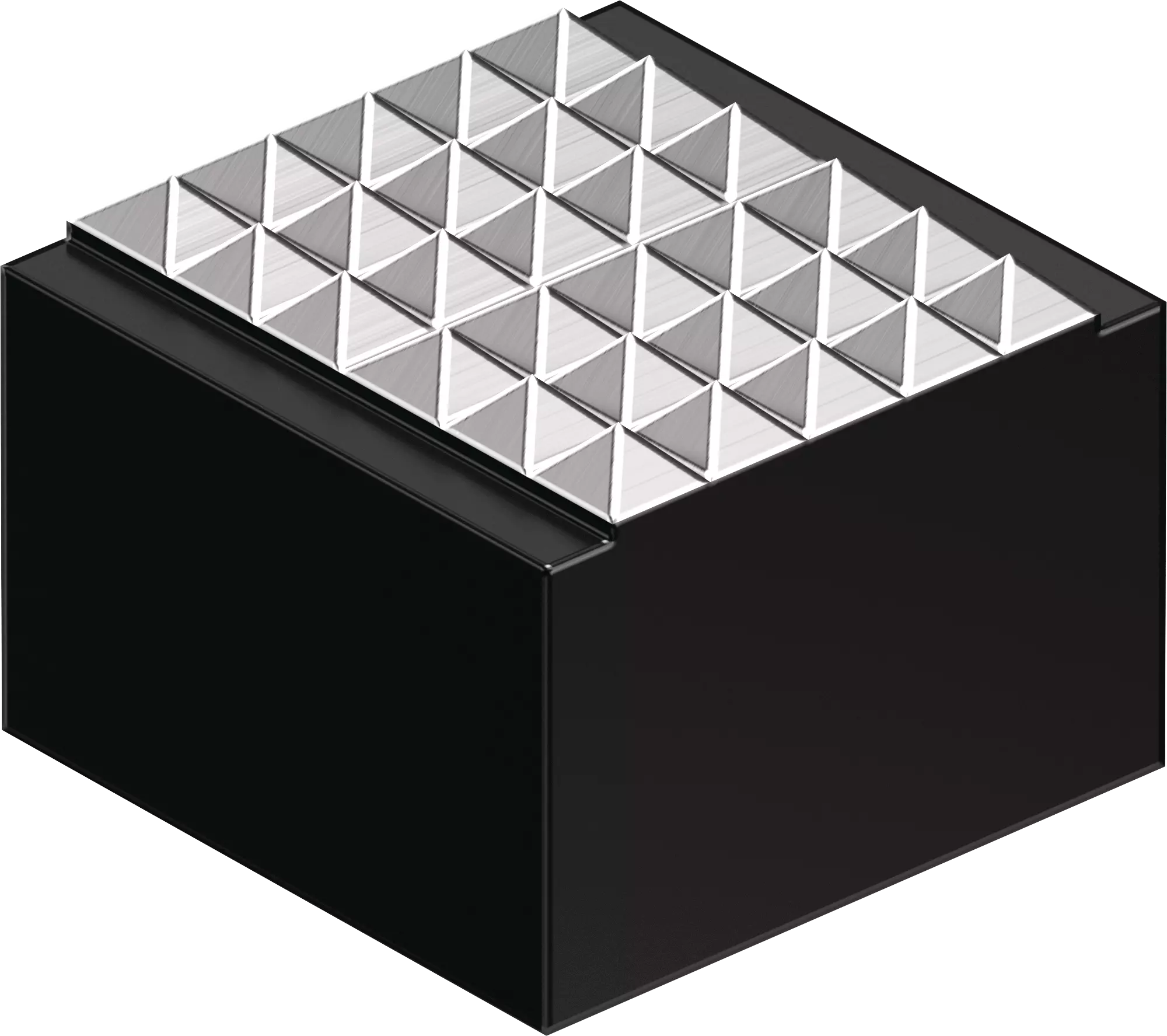

The clamping insert HS offers an economical solution combining soft top jaws and blanks to manufacture full-fledged hard chuck jaws. It is able to better penetrate the hard cast skin in cast workpieces or the compressed surfaces of forged parts, it increases the drive effect and is used to clamp high-strength materials. On request, the clamping insert can also be used in SCHUNK special chuck jaws according to our design or your own. By simply exchanging worn out inserts, a cost reduction can be achieved. The clamping insert is suitable for O.D. and I.D. clamping and is fastened from behind. The seat for the clamping insert can be easily manufactured.

The clamping insert RHS offers an economical solution combining soft top jaws and blanks to manufacture claw jaws. Ideally, the support jaws should be hardened in order to avoid tilting of the clamping inserts. The clamping insert is suitable for moderate level machining and promises optimum workpiece centering via round inserts as well as safe clamping with a low clamping depth. The simple do-it-yourself construction is explained in the installation instructions, which is included in the scope of delivery.

Boring kit for pendulum jaws for turning out pendulum jaws with soft clamping inserts SW. Each set includes three fitting disks and three fixing disks.

The soft clamping insert SW for pendulum jaws for turning out clamping diameters.

Standardized pendulum jaws from SCHUNK enable cost-efficient and safe clamping of thin-walled workpieces that are deformation-prone.

The clamping insert UGE enables the production of claw jaws from jaw blanks, ensuring safe clamping of blanks/forged parts, and workpieces made of high-strength materials. In addition, high torques for heavy cuts can be transferred and costs can be reduced by replacing the worn out inserts. UGE 10 is suitable for flat and round clamping surfaces as well as for O.D. and I.D. clamping. The clamping insert is attached from the front, where it can be placed in a round or a flat groove. The thread is easy to manufacture. Hardening of the chuck jaws is required.

Clamping inserts with six different clamping contours for flexible clamping of a wide range of workpieces. Can be positioned on TANDEM WTG-A jaws via bore hole grid.

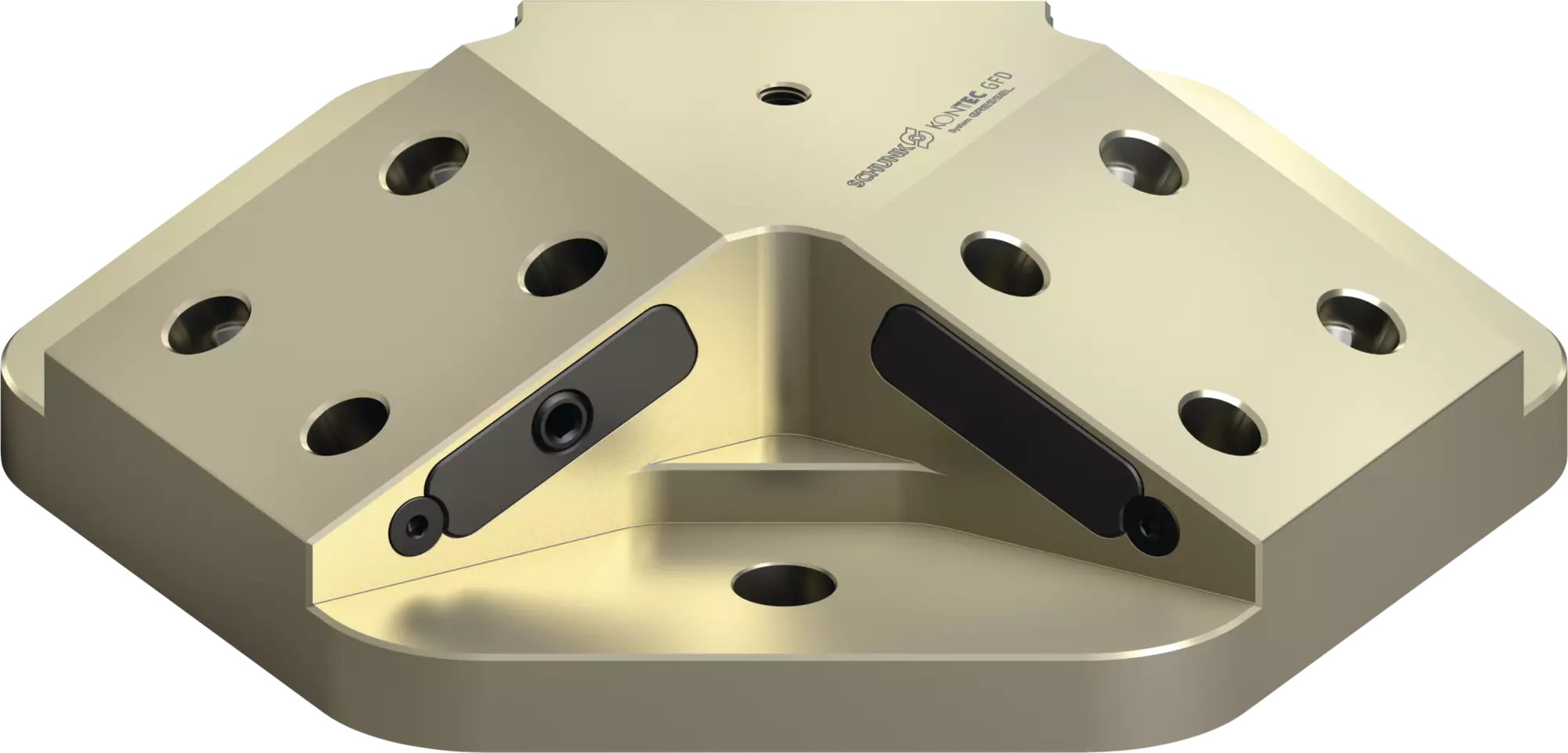

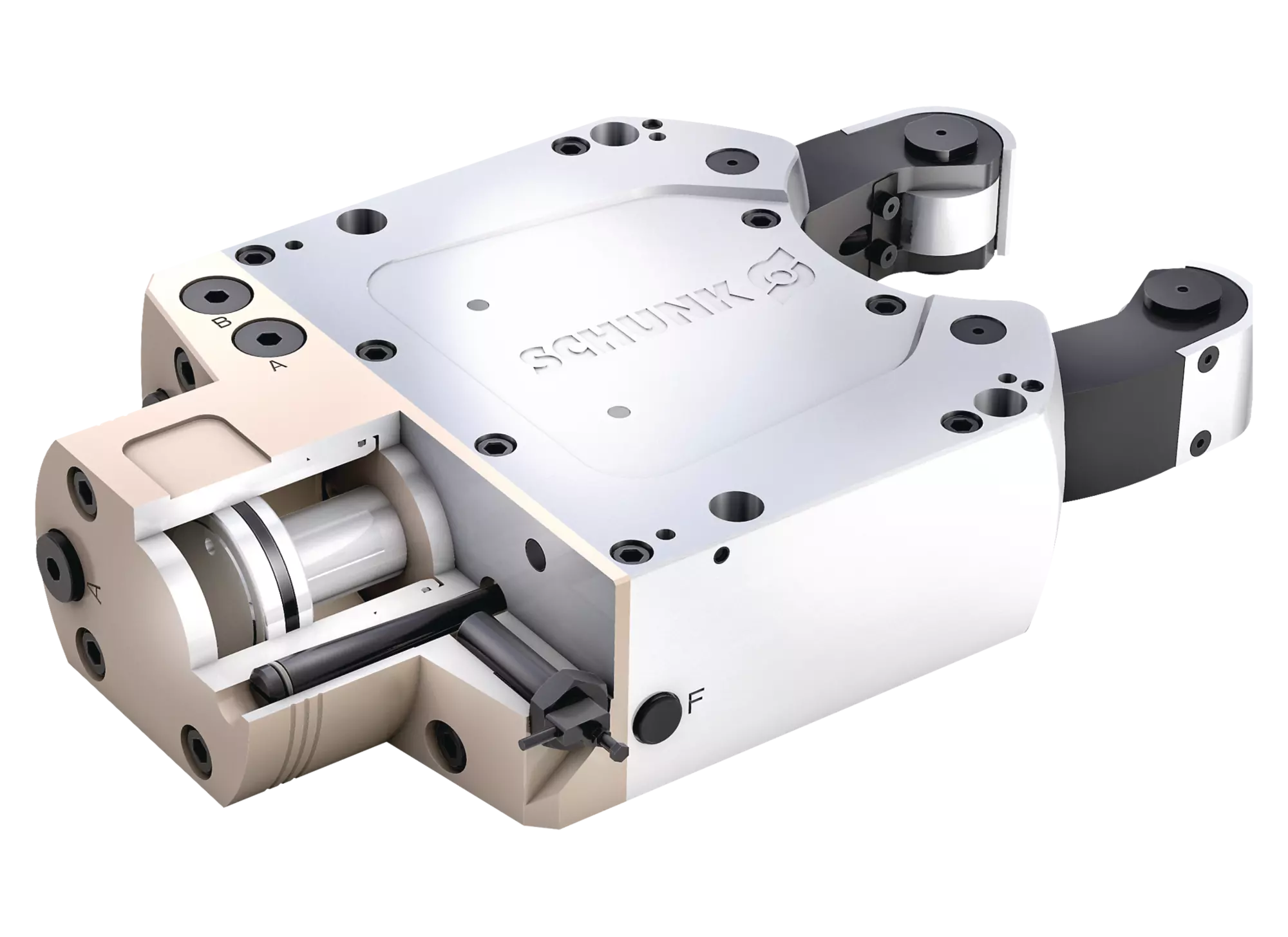

Integrated mechanical quick-change pallet system with 52 x 52 mm gauge on brackets, pyramid brackets and tombstones

For cleaning of clamping devices and automation of machine tools. The cleaning unit can be used in any machine, which provides compressed air or coolant supply via the tool mounting.

The hard clamping insert SP for pendulum jaws.

Standardized pendulum jaws from SCHUNK enable cost-efficient and safe clamping of thin-walled workpieces that are deformation-prone.

Adapter for reducing interfering contours for workpieces as well as compensating different clamping heights.

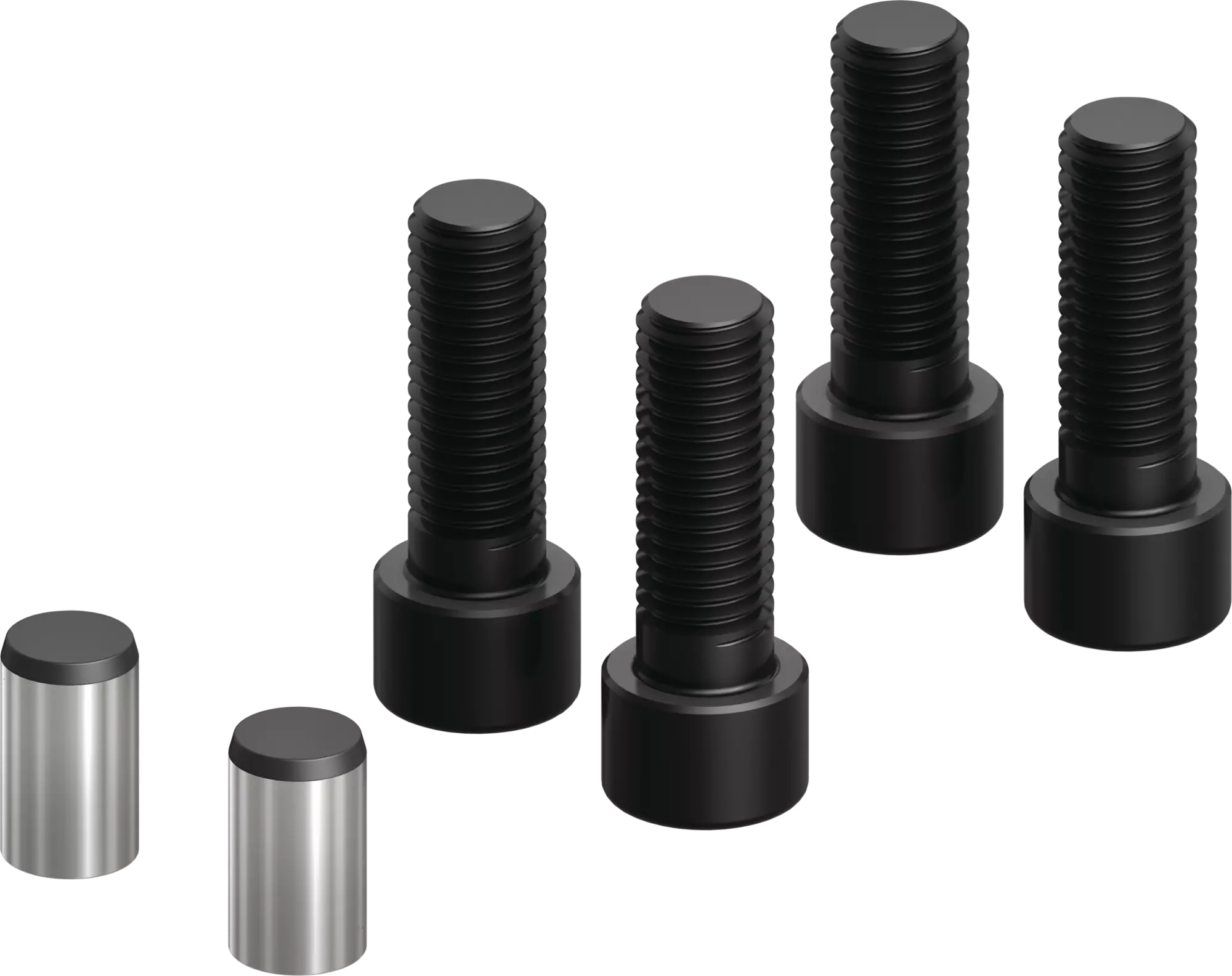

Clamping pins with short taper for form-fit connection of workpieces or devices with the clamping modules.

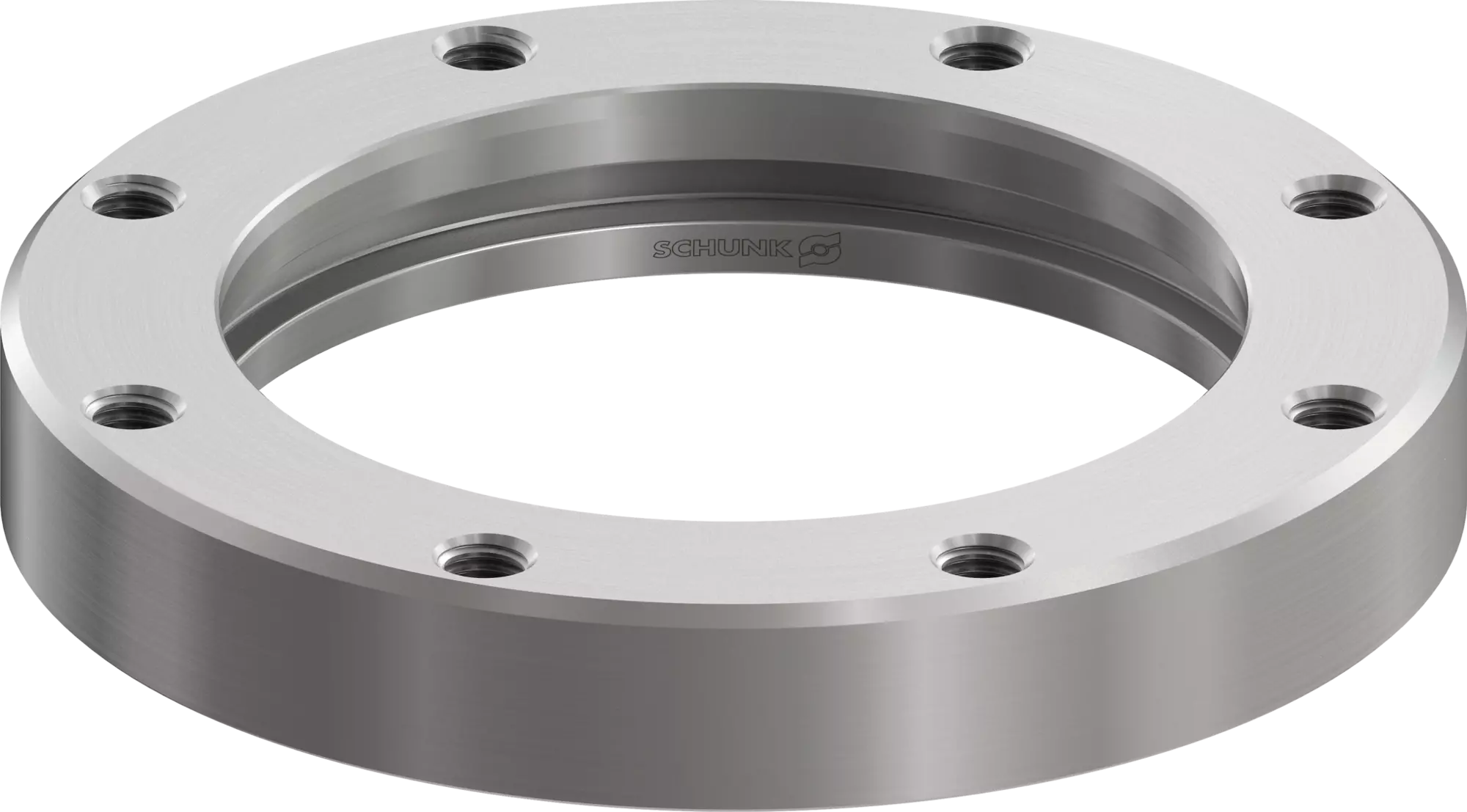

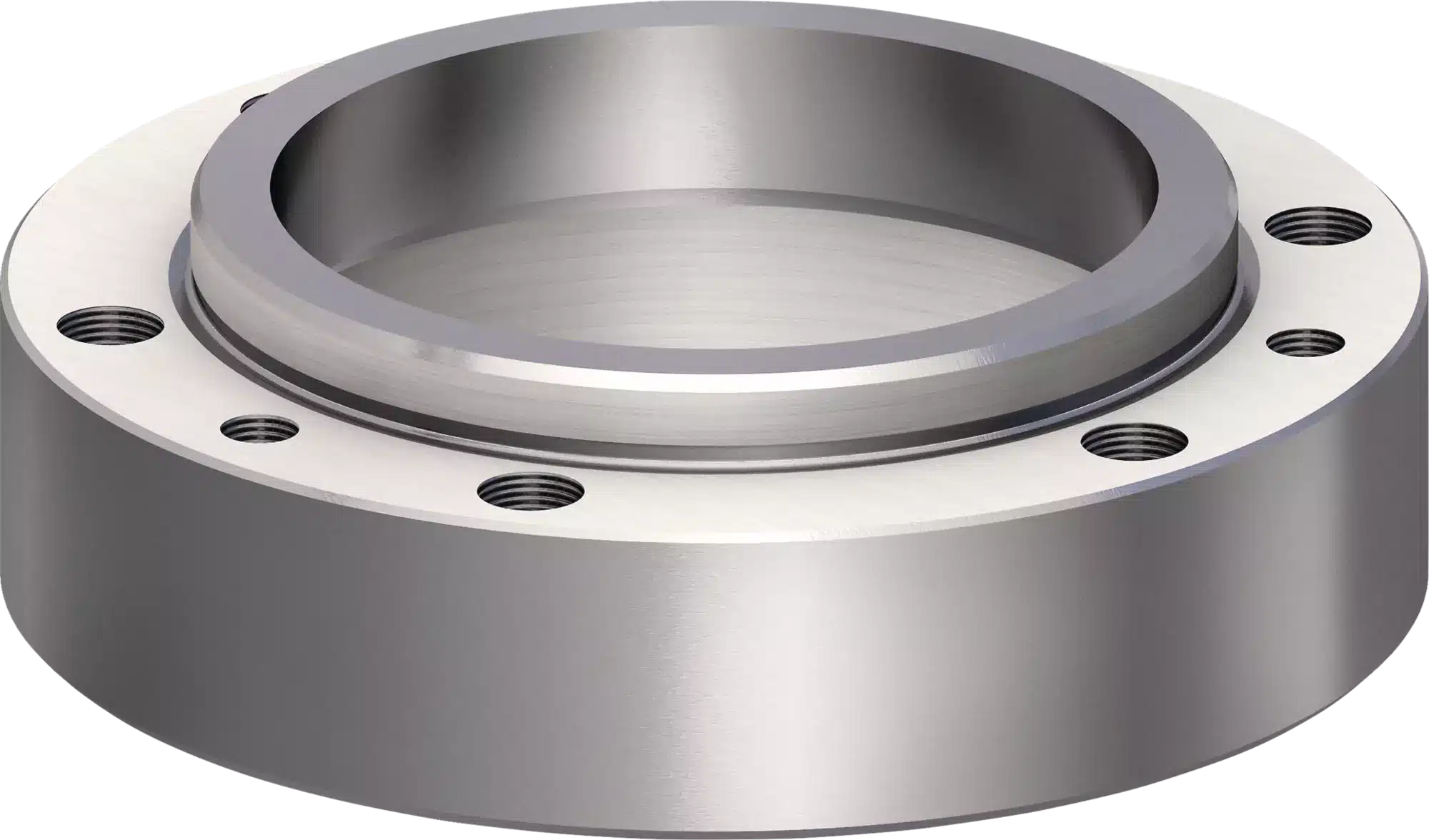

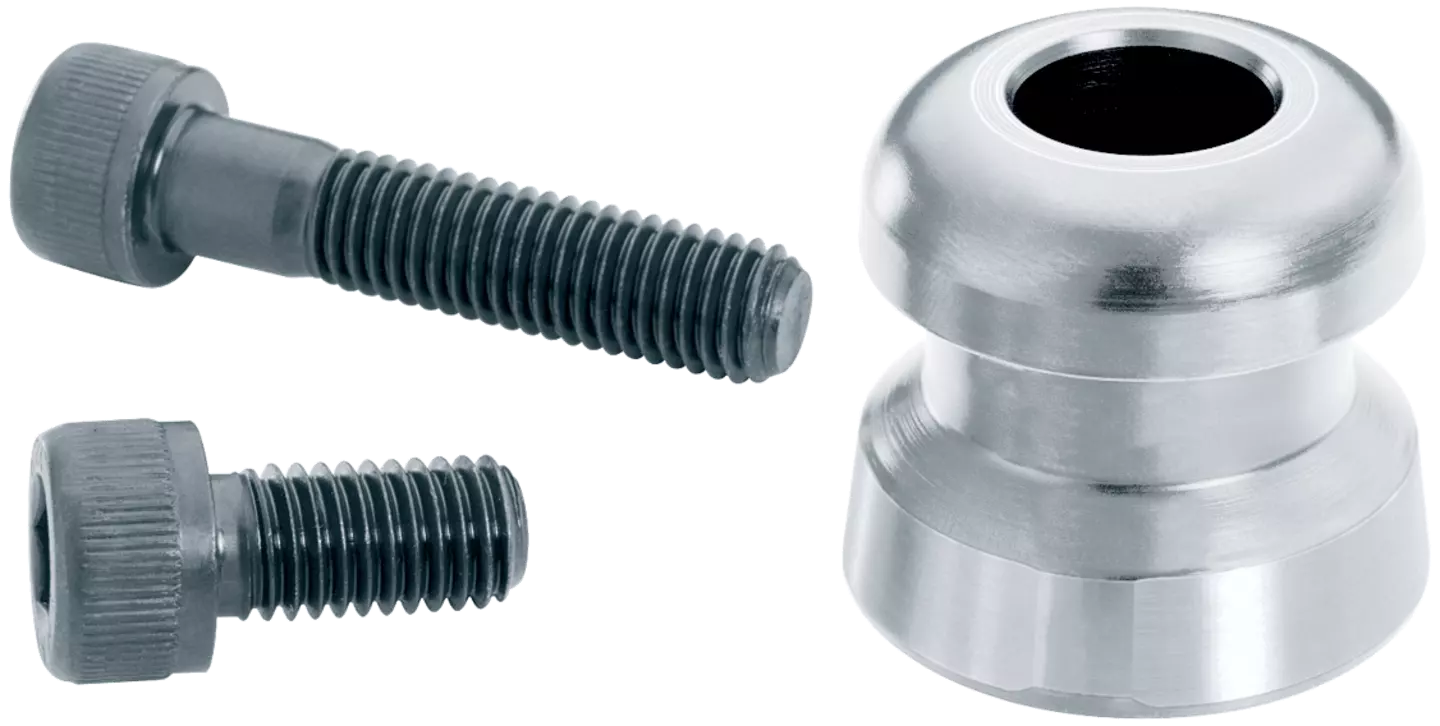

Clamping rings with ground short taper for form-fit connection of clamping pallets or devices with the clamping modules.

Clamping pins with short taper for form-fit connection of workpieces or devices with the clamping modules.

Clamping pins with short taper for form-fit connection of workpieces or devices with the clamping modules.

Clamping pins with short taper for form-fit connection of clamping pallets, workpieces or devices with the clamping modules.

Cylindrical brush for cleaning clamping diameters from Ø 6 mm to Ø 32 mm.

Cleaning brush TK Cleaner for cleaning the clamping diameter.

The SK/BT/CAT tapered cleaner is used to clean the machine spindle.

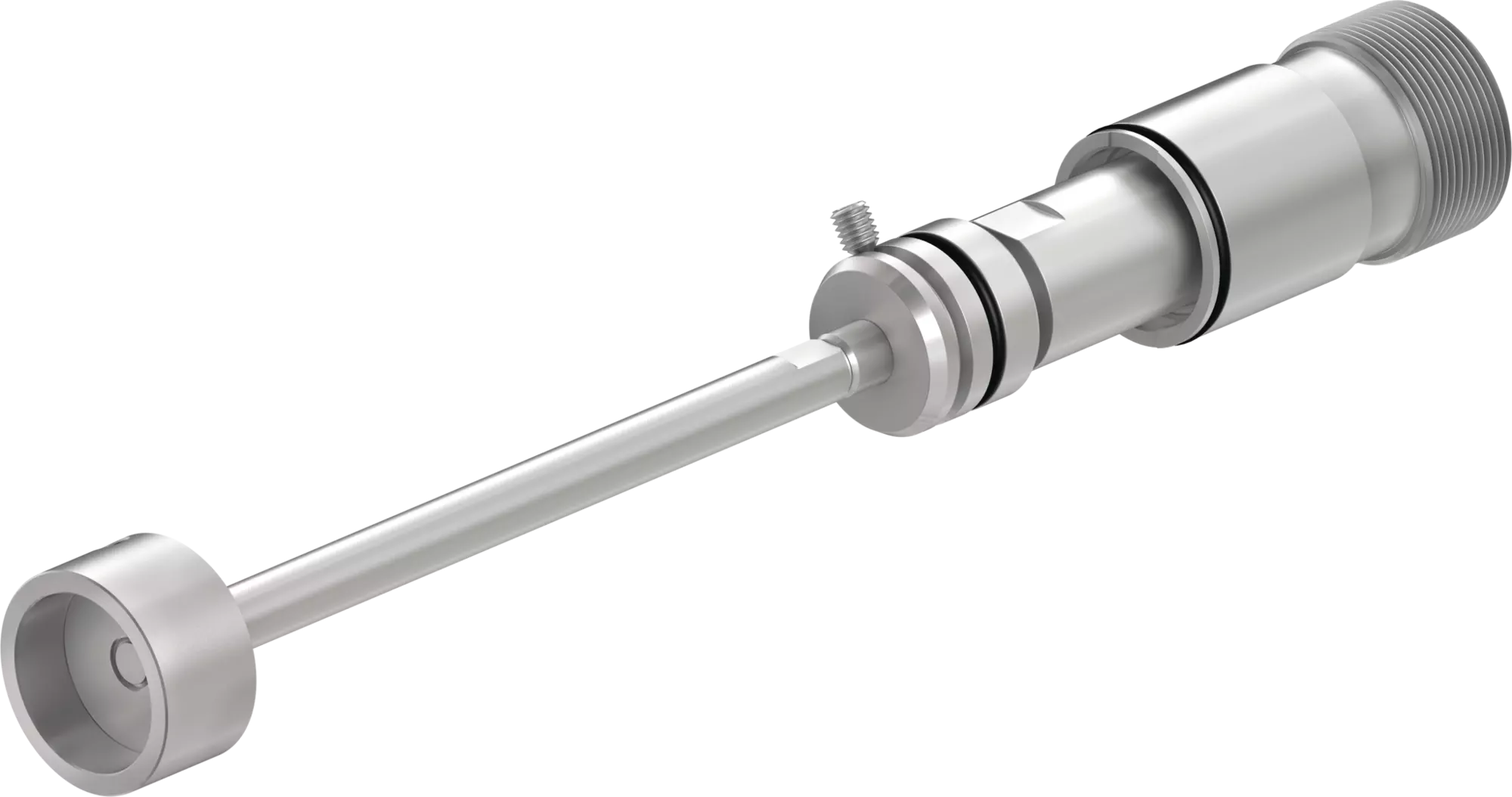

TENDO GZB-S Sleeve Remover for intermediate sleeves GZB-S Ø 12 to GZB-S Ø 32. For safe and easy removal of intermediate sleeves GZB-S from TENDO hydraulic expansion toolholders.

Hexagon socket wrench with cross handle for clamping and unclamping tool shanks in TENDO hydraulic expansion toolholders.

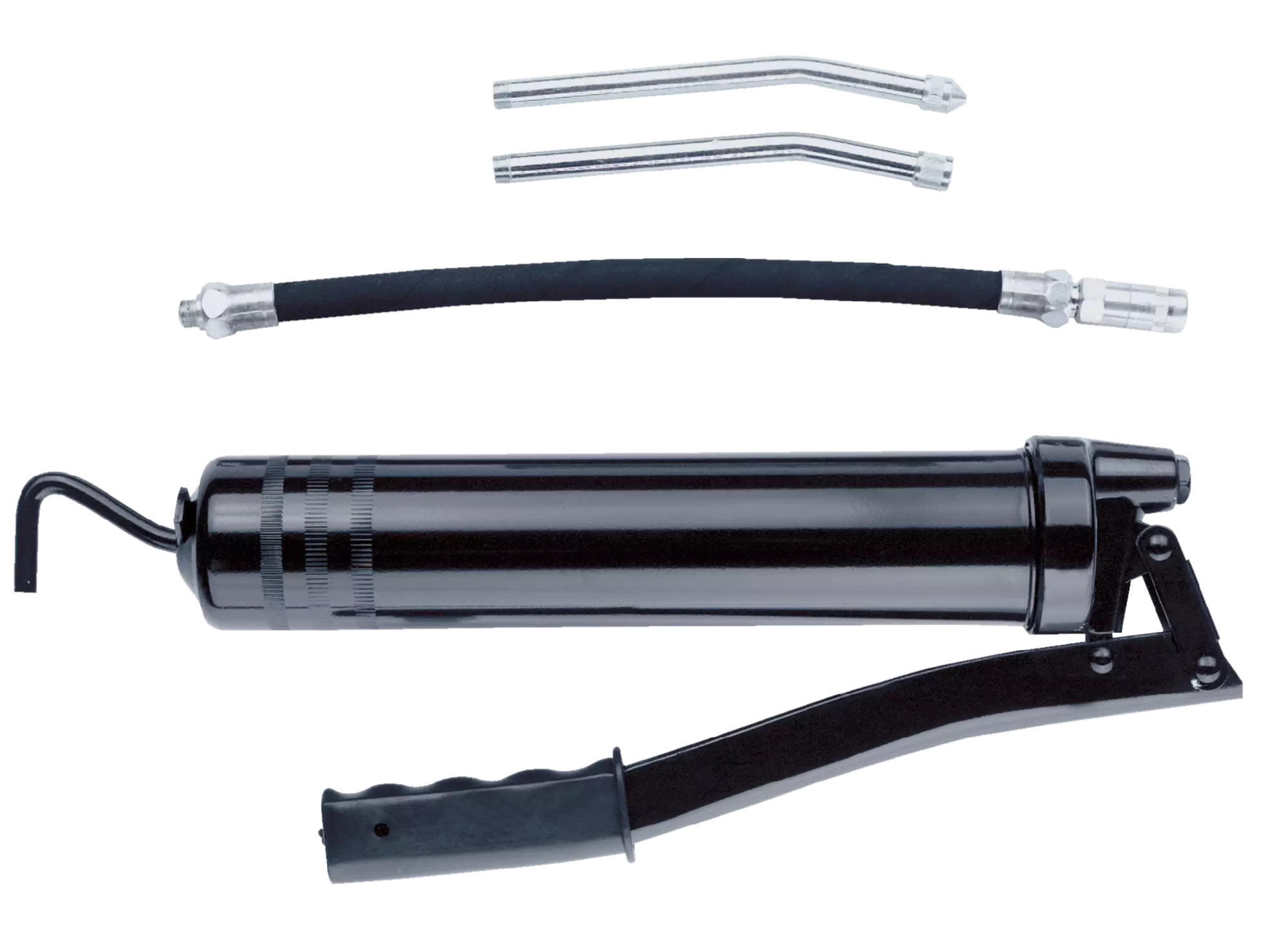

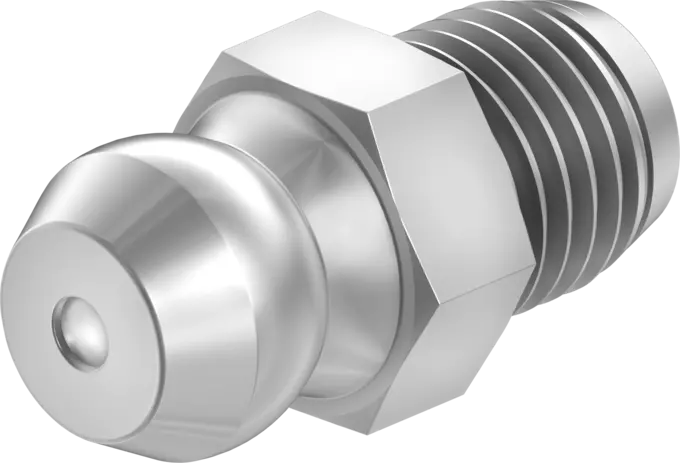

Grease gun for lubrication of all standard manual and power lathe chucks as well as clamping force blocks from SCHUNK.

High-performance grease as standard for regularly lubricating SCHUNK TANDEM clamping force blocks.

High-performance grease as standard for regularly lubricating SCHUNK manual and power lathe chucks and steady rests.

Universally applicable clamping force tester for stationary clamping devices.

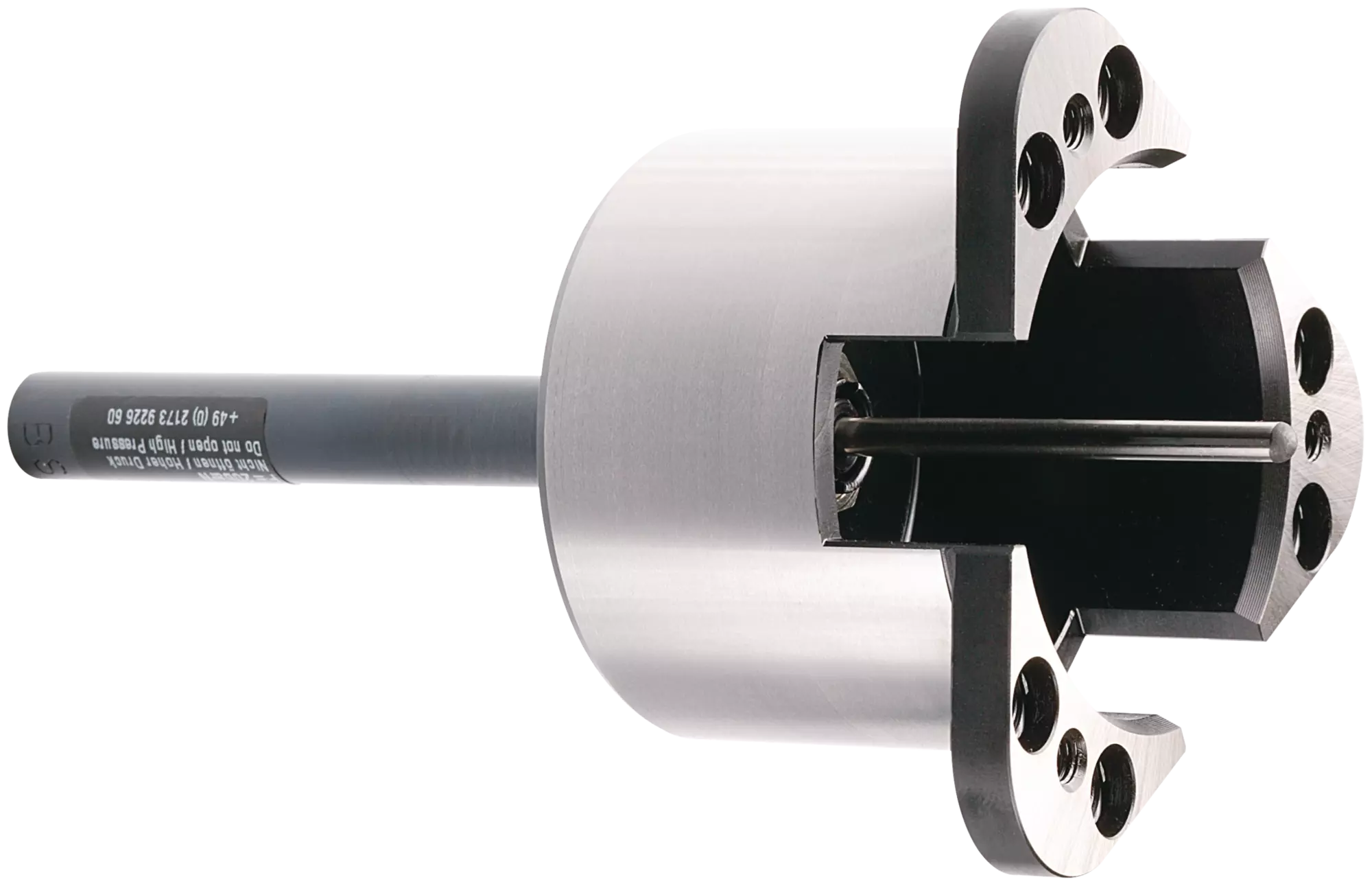

Clamping force tester for measuring the jaw clamping force of 2, 3 and 6-jaw chucks to ensure the greatest possible process reliability in daily use.

A set consists of a grease gun, grease cartridge, chip protection, and a center plug for regular maintenance of SCHUNK manual lathe chucks.

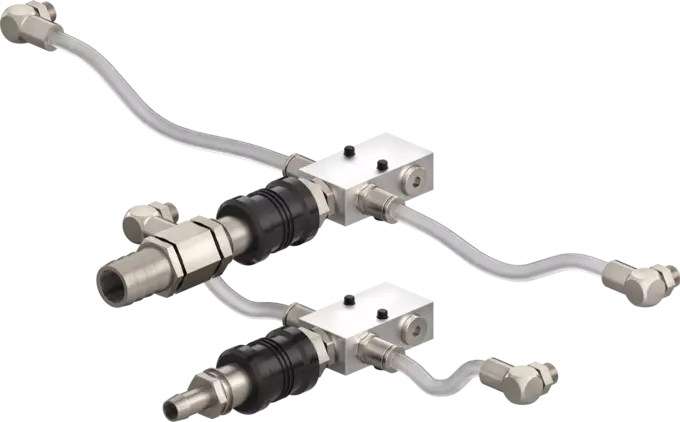

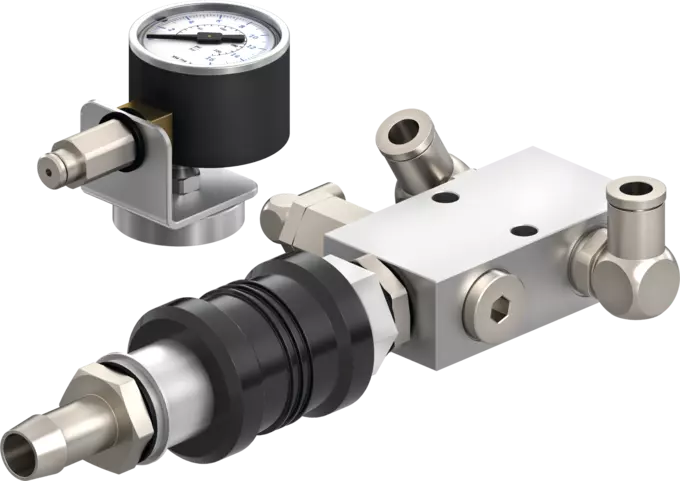

Maintenance unit consisting of pressure regulator, water separator, oiler, and feeder cables for preparing the compressed air for SCHUNK pneumatic power lathe chucks.

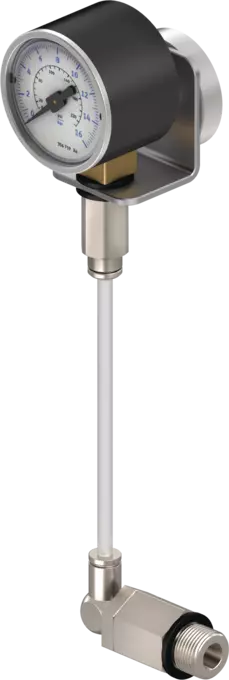

Pressure measurement devices for checking the pressure tightness of SCHUNK pneumatic power lathe chucks.

Torque wrench for actuation of SCHUNK manual lathe chucks.

Ratchet for fast actuation of SCHUNK manual lathe chucks.

Actuating key for manual actuation of the SCHUNK ROTA-S plus and ROTA-G manual chucks.

Spanner wrench for manual actuation of the SCHUNK manual lathe chucks with hexagonal connections.

Actuation key with movable cross handle for actuation of SCHUNK ROTA-S plus and ROTA-G manual chucks. Excellently suitable if there is not much space for actuation.

Spanner wrench adapter as an attachment for torque wrench and wrenches for actuating SCHUNK manual lathe chucks.

Security key for fast change of the jaws for power chucks with jaw quick-change system.

Assembly key for easy assembly of SCHUNK power chucks on the lathe.

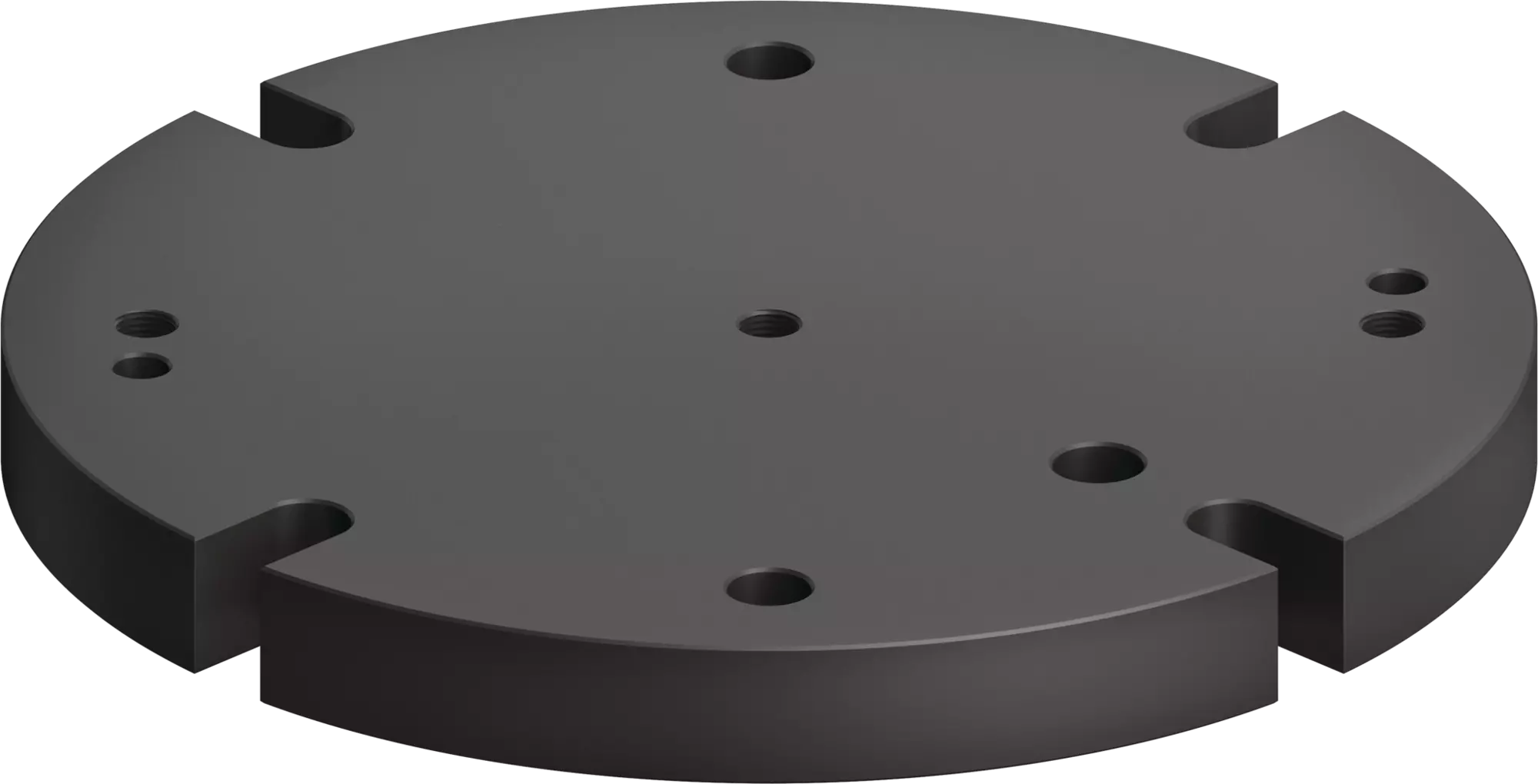

Standardized adapter plates for quick and easy mounting of ROTA-M flex 2+2 manual lathe chucks on VERO-S clamping stations.

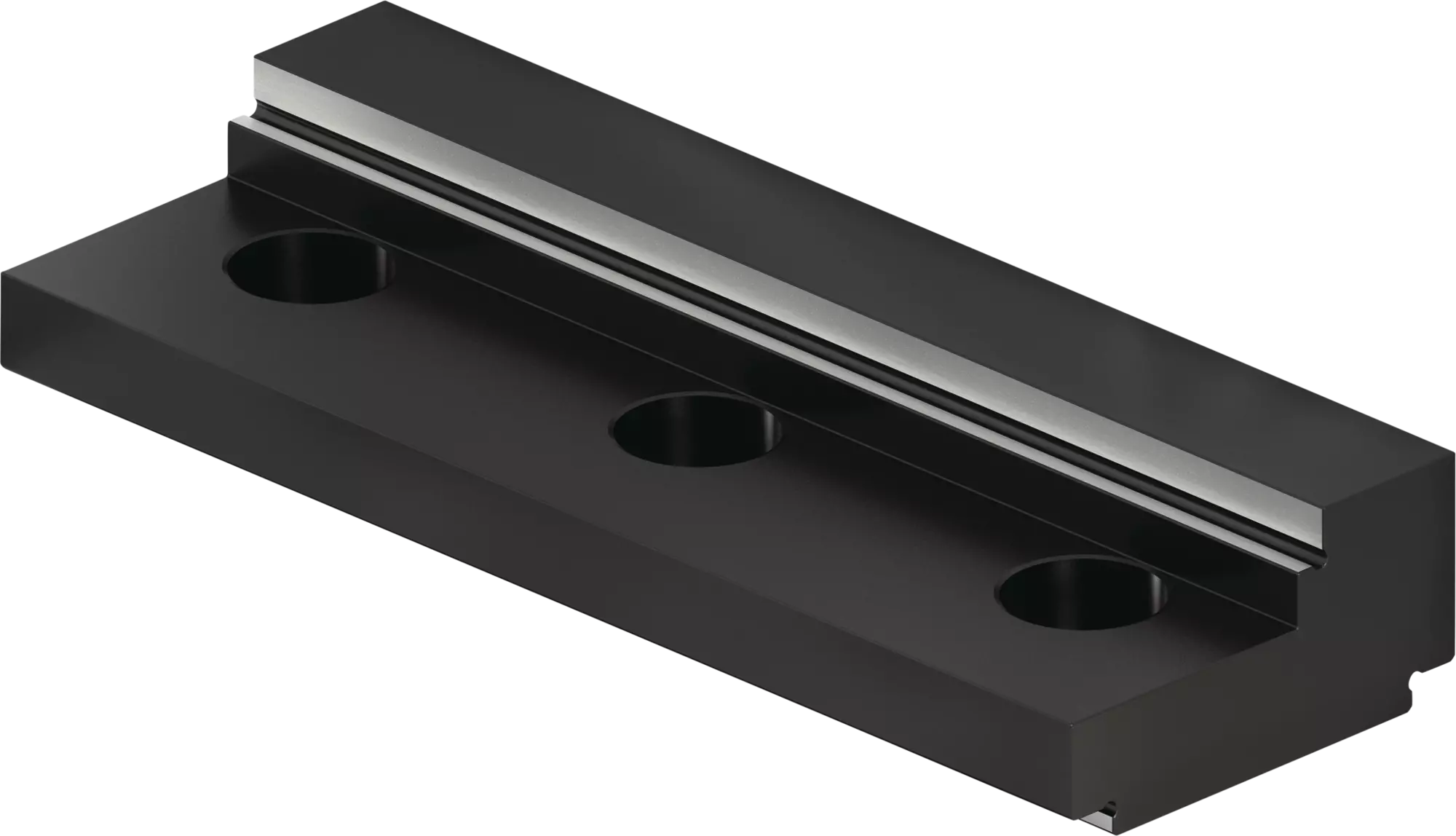

Standardized base plates for fater and simple fastening of SCHUNK manual lathe chucks on mill/turn centers.

Base jaws for the conversion of ROTA-ML flex 2+2 toolholder into a "fixed jaw clamping vise". KONTEC top jaws can be used as top jaws.

For locking of a jaw pair to realize a two jaw clamping.

Chip protection for easily sticking onto the base jaws of SCHUNK manual lathe chucks.

Cover plate for covering fastening screws of the chuck body as well as the guideway extensions for ROTA-S flex manual lathe chucks.

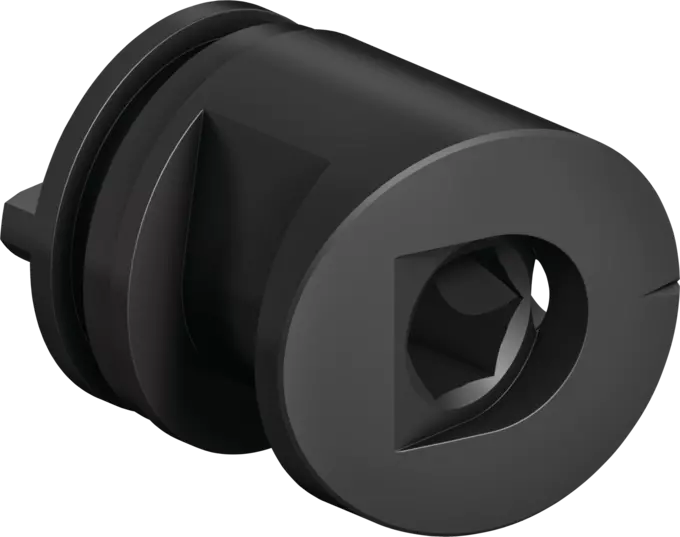

Sealing plug for closing the chuck bore of SCHUNK manual and power lathe chucks.

Centering pins for precise alignment of SCHUNK ROTA-S flex manual lathe chucks on the machine table.

Inductive proximity switches for monitoring the current clamping state of SCHUNK ROTA TB2 power lathe chucks.

Retrofit kit for mechanical pressure monitoring for all ROTA TB2 lathe chucks with continuous rapid and clamping stroke.

Central lubrication, air control, and coolant supply as modifications for fast and easy retrofitting of SCHUNK ROTA NCO power lathe chucks.

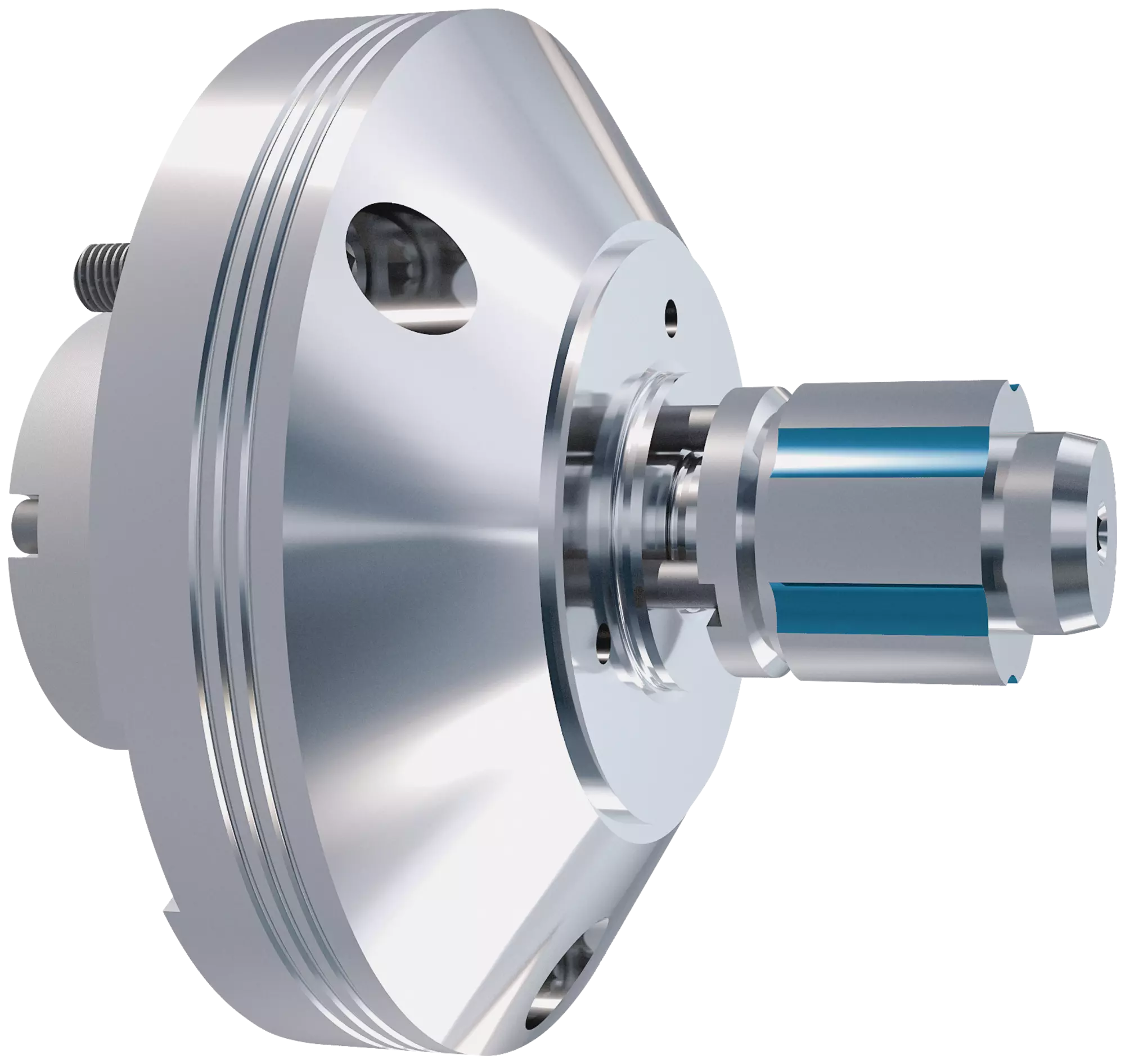

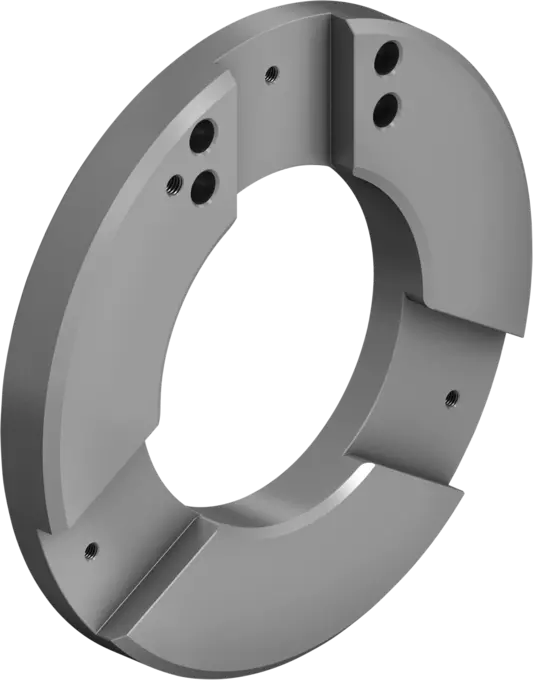

Standardized flanges for adaptation of hydraulically actuated power lathe chucks with Z-mount to the machine spindle with short taper.

Standardized flanges for adaptation of pneumatically actuated power lathe chucks with Z-mount to the machine spindle with short taper.

Standardized flanges for adaptation of pneumatically actuated power lathe chucks with Z-mount to the machine spindle with camlock mount.

Standardized flanges for adaptation of pneumatically actuated power lathe chucks with Z-mount to the machine spindle with bayonet mount.

Standardized flanges for adaptation of hydraulically actuated power lathe chucks with Z-mount to the machine spindle with Z-mount.

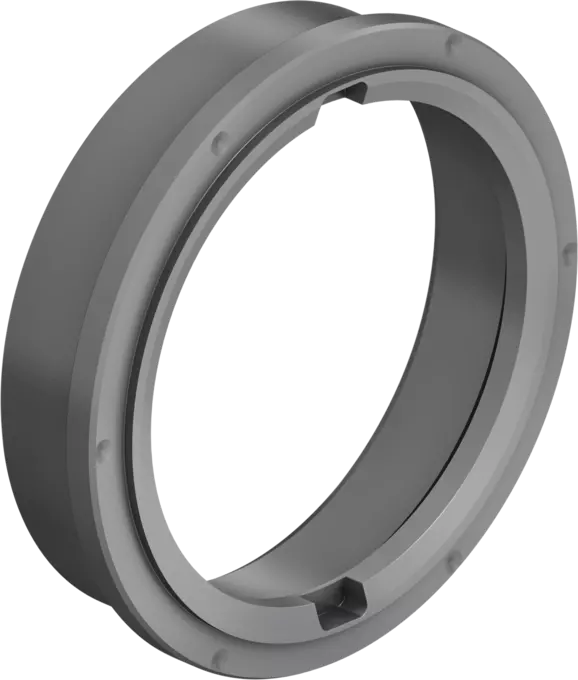

Closed protection sleeves to protect the chuck kinematics against the penetration of chips and coolant.

Closed protection sleeves to protect the chuck kinematics against the penetration of chips and coolant Due to the integrated ejector, workpieces can be automatically ejected from the chuck.

Closed protection sleeve to protect the chuck kinematics against the penetration of chips and coolant By means of an integrated spray nozzle, the coolant can be affixed directly to the workpiece.

Closed protection sleeves to protect the chuck kinematics against the penetration of chips and coolant. Using the integrated stop, workpieces can be positioned with a high repeat accuracy in the chuck.

Segmented arbor or I.D. clamping in combination with 3-jaw manual chuck ROTA-S plus 2.0 in modified design. For use of vario M an additional cone must be ground on the chuck bore; has to be ordered separately.

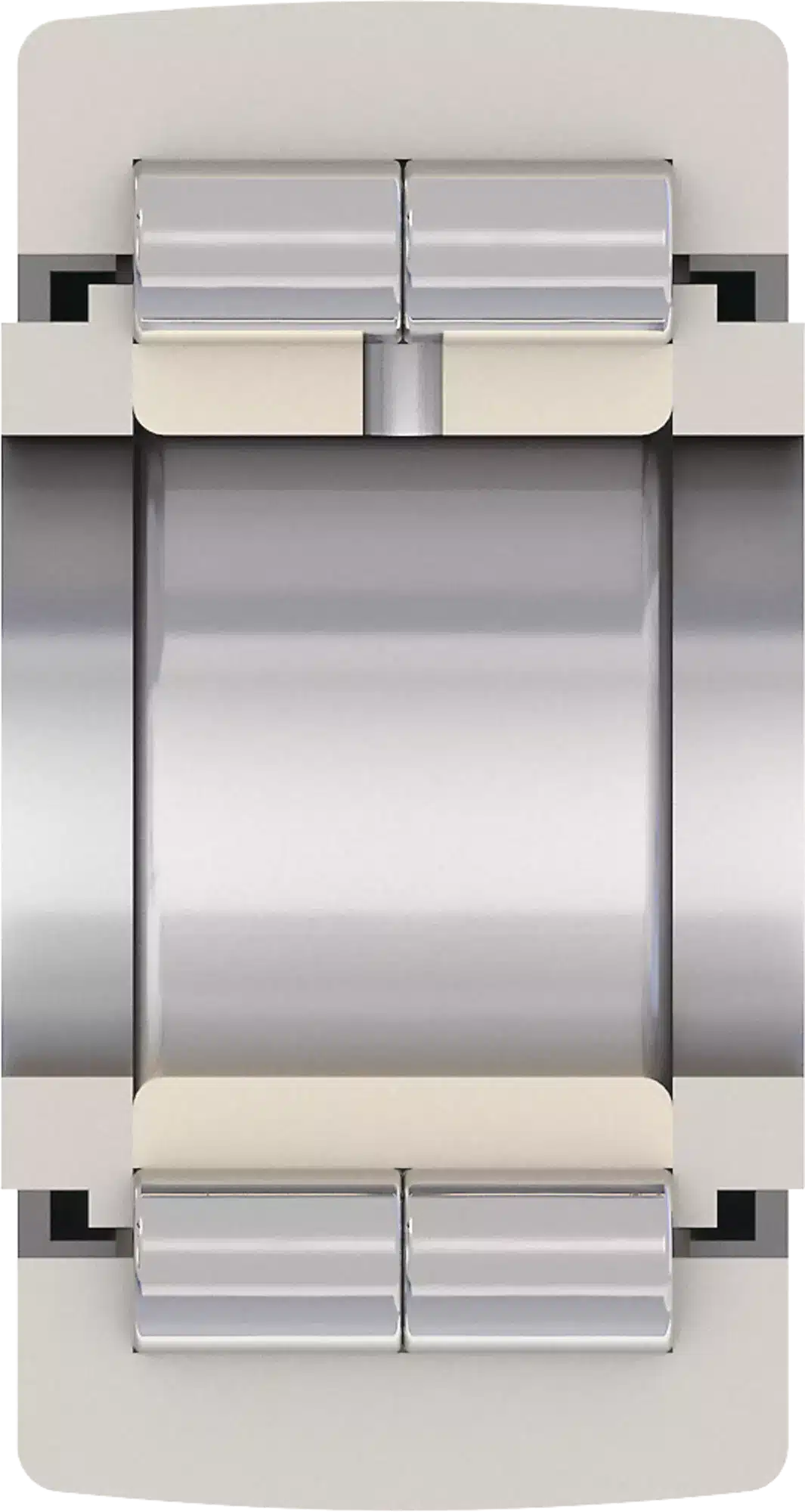

There are 2 different rollers for all steady rests:

cylindrical version for upright steady rest

spherical version for traveling steady rest

Eccentric roller pins on the steady rest arms allow quick fine adjustment of the center.

Enables a continuous position monitoring and a partial opening of the lever arms.

Monitoring units for detecting clamping positions "Opened", "Clamped" and also to some extent "Clamped without pin".

Indexing pins for position orientation of clamping pallets and clamping devices on VERO-S clamping devices.

Fitting screws for clamping pin mounting if these do not have any centering collar.

Compensation screw for minimum compensation of thread coax errors on workpieces.

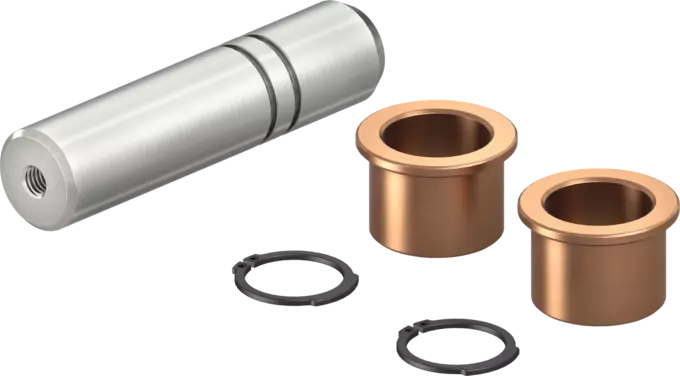

Centering taper for retrofitting NSL3 turn or NSL turn clamping stations for highly precise centering of clamping pallets and for increasing the run-out accuracy.

Centering sleeve for retrofitting clamping pallets for highly precise centering on NSL3 turn or NSL turn clamping stations and increase in run-out accuracy.

Cone seal for quick and easy retrofitting of existing NSE3 modules without cone seal to protect the change interface.

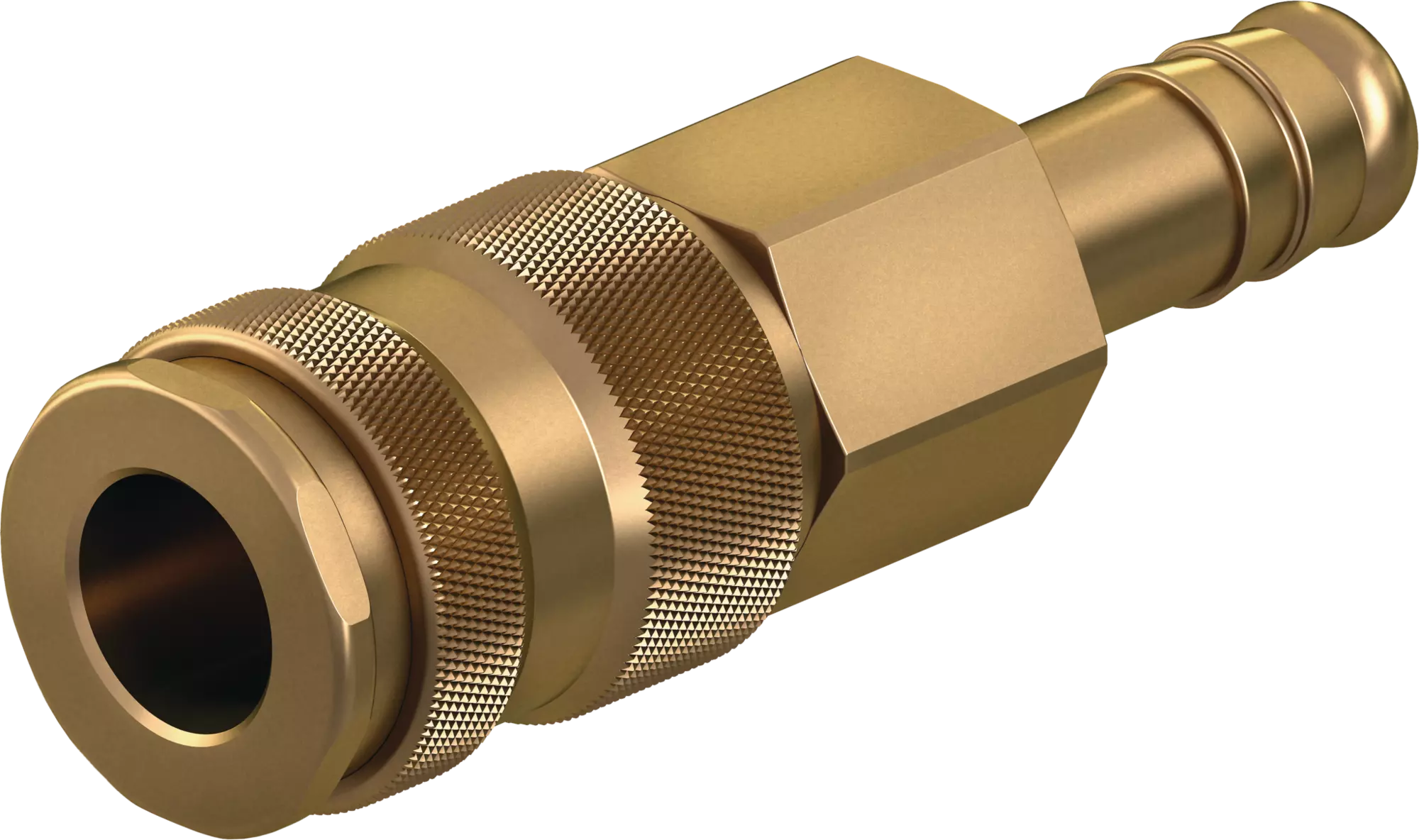

Quick-change coupling for easy actuation of VERO-S clamping stations or module height extensions.

1- way strip for convenient actuation of VERO-S clamping stations.

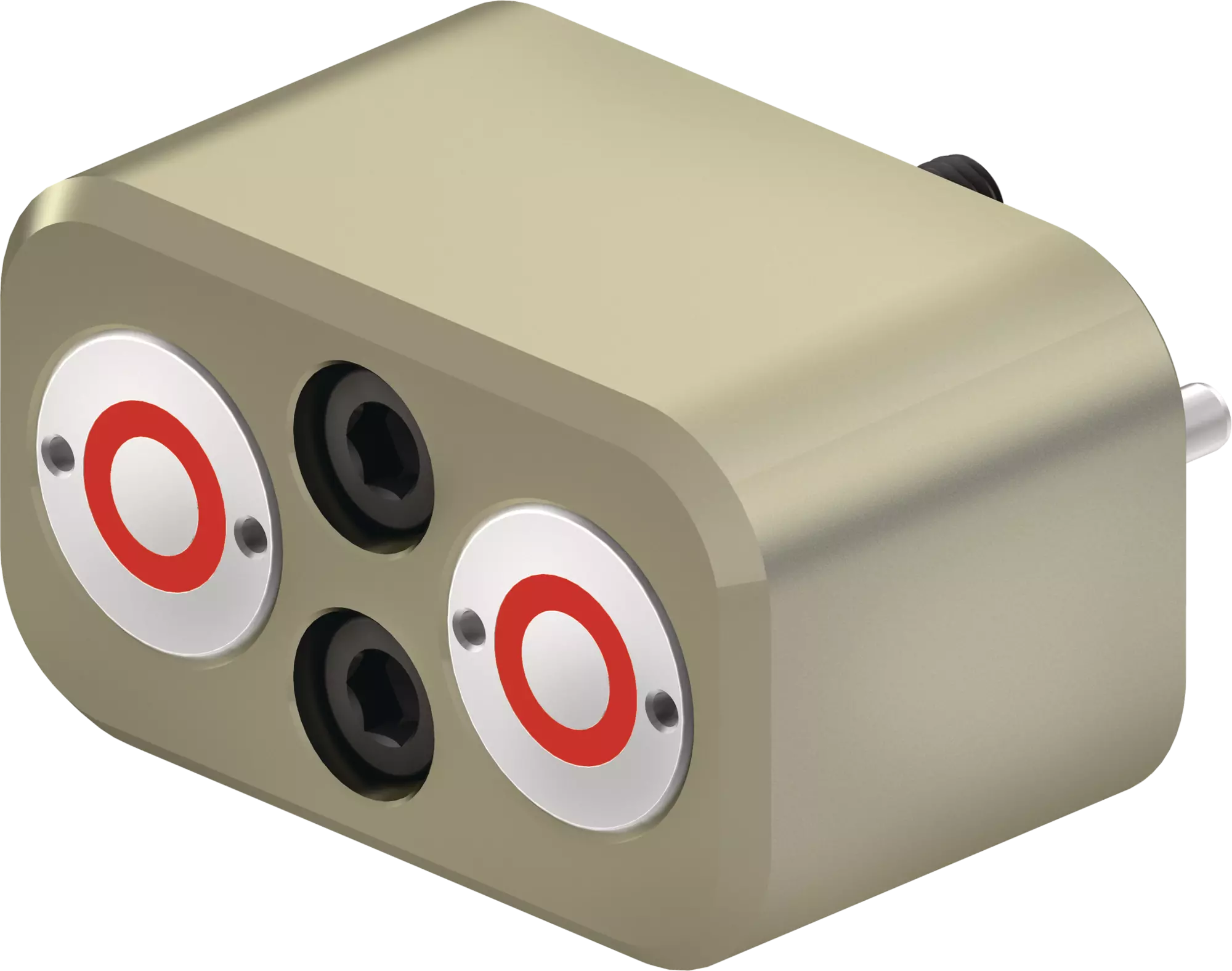

Universally applicable Plug & Work media transfer unit as standard for all current VERO-S clamping stations.

Coupling strips for clamping stations and clamping pallets for transmitting the compressed air from the robot module to the clamping device.

Coupling nipple with media transfer unit for actuating clamping stations and clamping devices via the appropriate coupling strip.

Used as a counter piece in clamping pallets or devices for the transfer of compressed air or hydraulics.

Coupling set for connecting two NSL mini 100-2 clamping stations.

Cylindrical clamp blanks for customer rework, for individual fastening of VERO-S clamping stations on all common slot spacings of the machine tables.

Protective covers for sealing the changing interface and for covering the flat surfaces of VERO-S clamping modules.

Bracket for protection covers

Cover caps serve to cover the fastening screws and avoid the accumulation of chips.

Alignment element for basic module

Positioning arbor for exact positioning of base modules on the machine table using the machine spindle.

Height extension for basic module as a stable underframe for set-up of WDM-5X basic modules on T-slide table.

Serves as insert for WDB 99-60 or WDR 99-60 base modules for positioning on grid plates.

Clamping pin mountings for storing clamping devices as inserts in the inlay sheets of the VERO-S setup cart

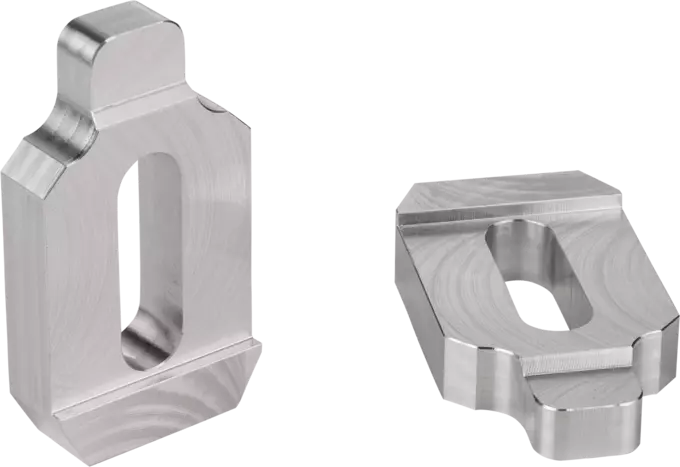

Reversible supporting jaws with fine serration for mounting standard top jaws from SCHUNK.

Reversible 3-axis jaw with grip step on both sides as well as ground step.

Reversible 5-axis jaw with grip step on both sides as well as ground step.

Hardenable top jaw blanks with jaw quick-change interface BWA for reworking by the customer. These can be customized according to requirements.

Top jaw with mounting threads to accommodate clamping inserts or clamping bars with jaw quick-change interface BWA.

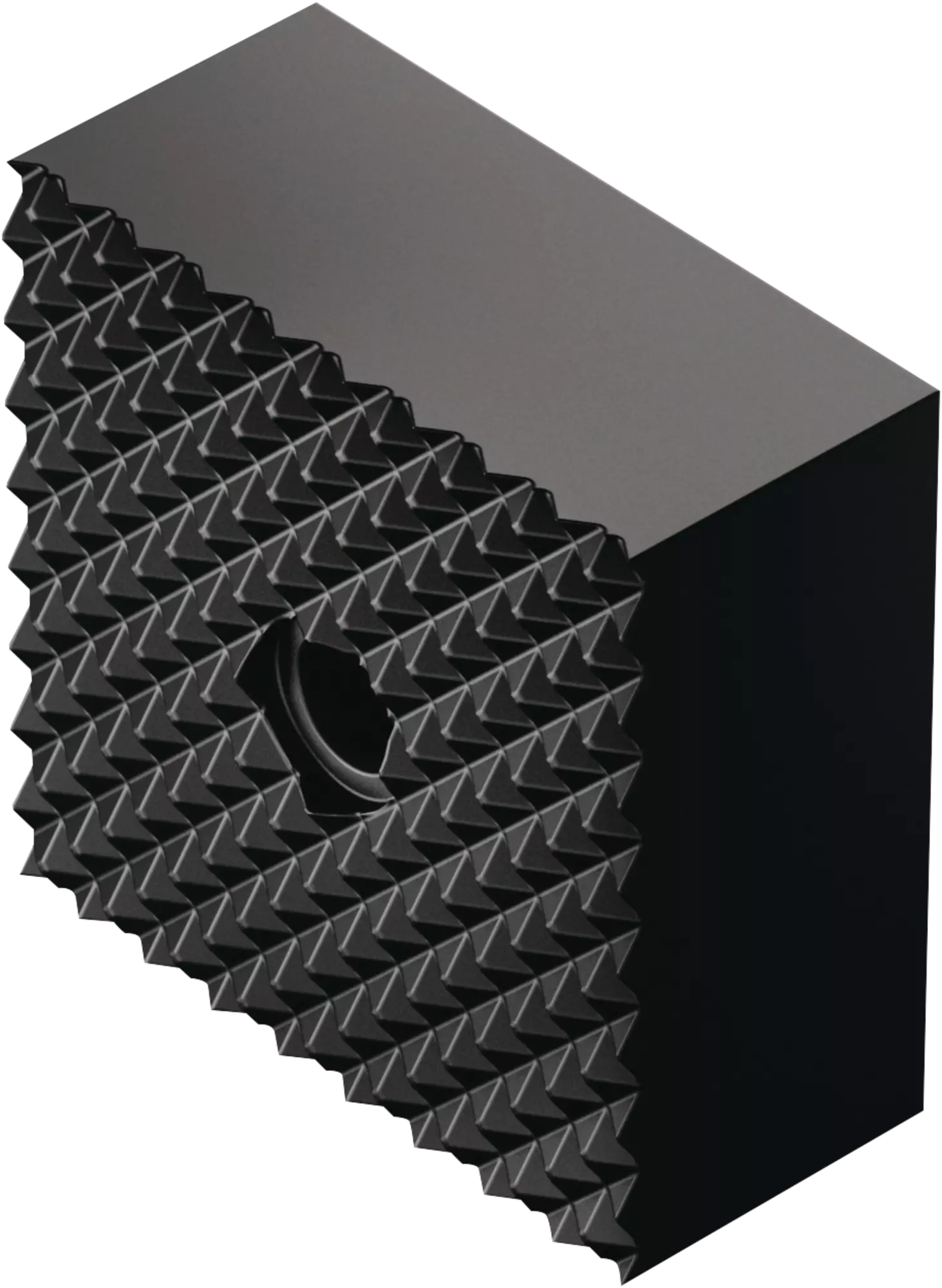

Claw jaws with fine serration for embossed clamping of cylindrical workpieces on 3-jaw clamping force blocks.

Top jaw blanks with tongue and groove and preassembled mounting holes for customer rework.

Top jaw blanks serve for customer rework and can be adjusted depending on the requirement.

Top jaw blanks with fine serration and preassembled mounting groove for customer rework.

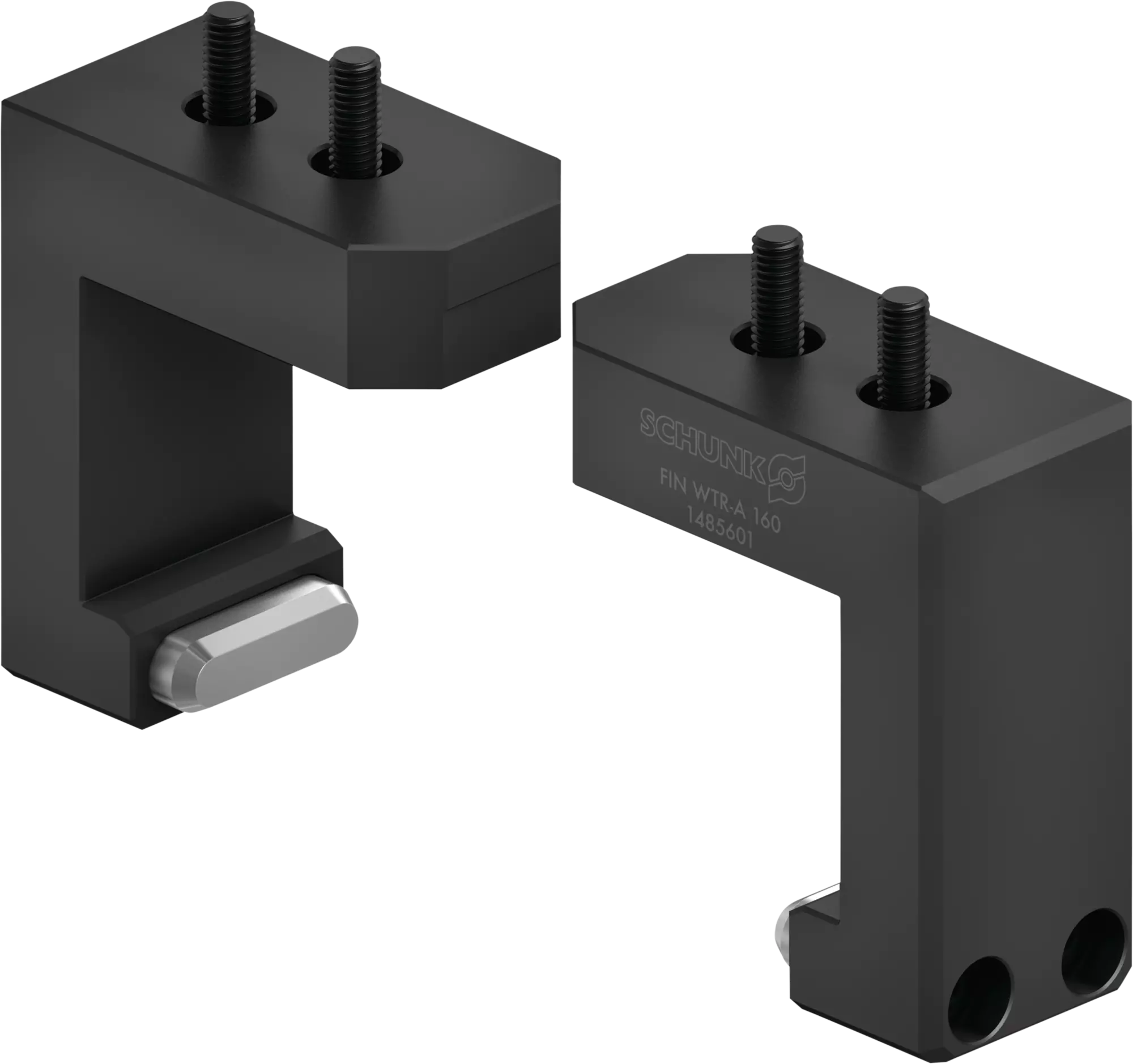

Gripper fingers specifically designed to clamp the WTR-A and WTG-A quick-change jaws.

Base plate for pneumatic TANDEM clamping force blocks with VERO-S interface

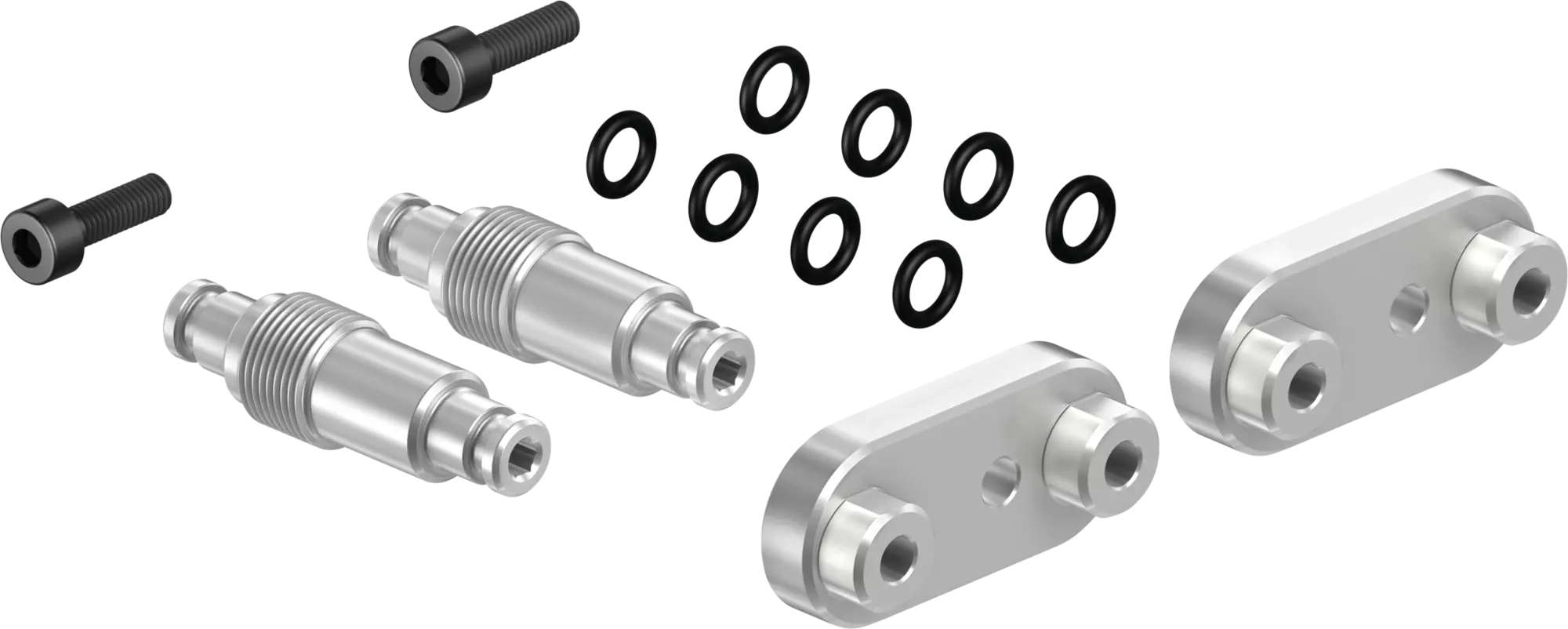

Retrofit kit for SCHUNK clamping devices for quick use on VERO-S quick-change pallet systems

For accurate positioning and mounting of manual clamping vises on the machine table.

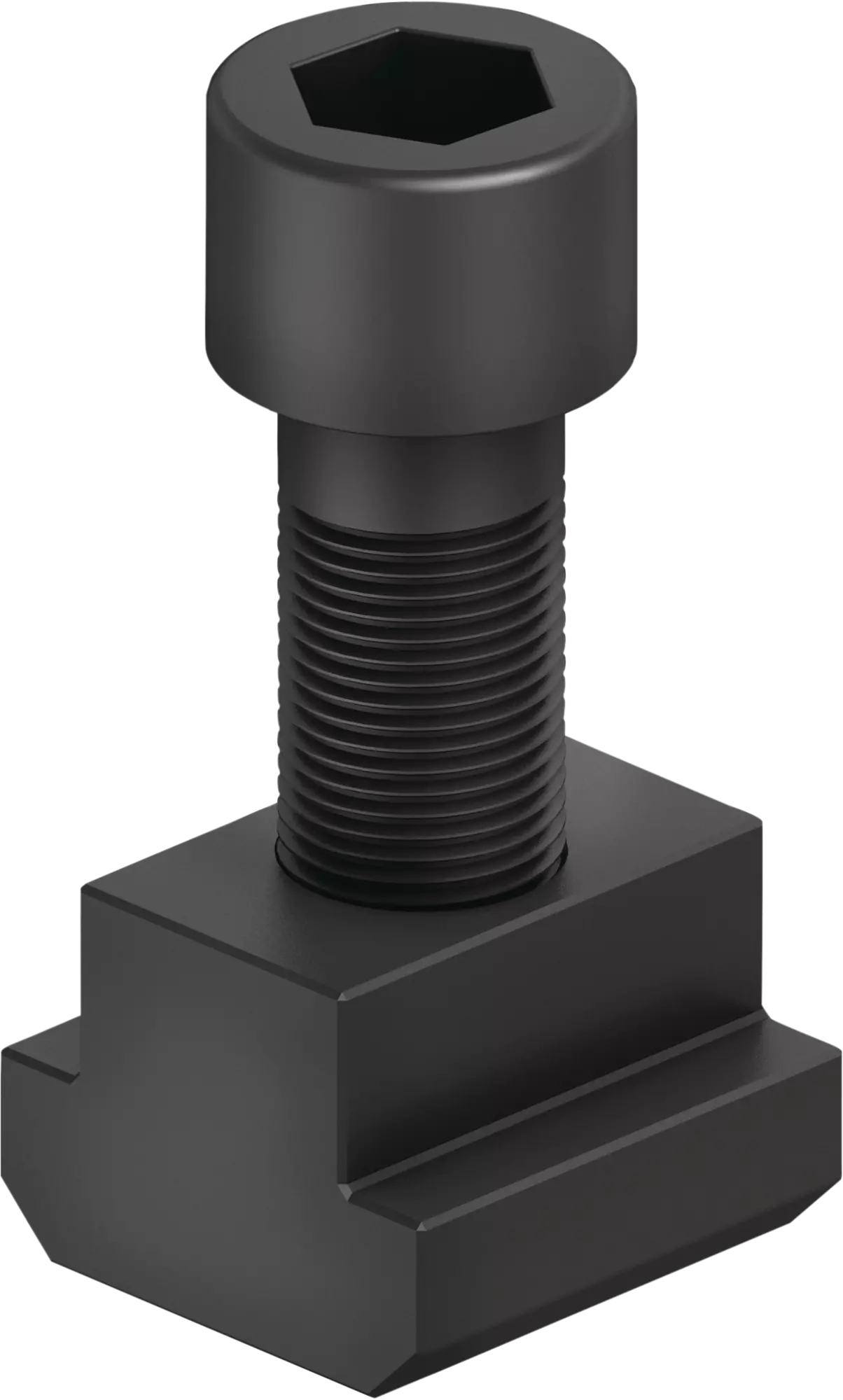

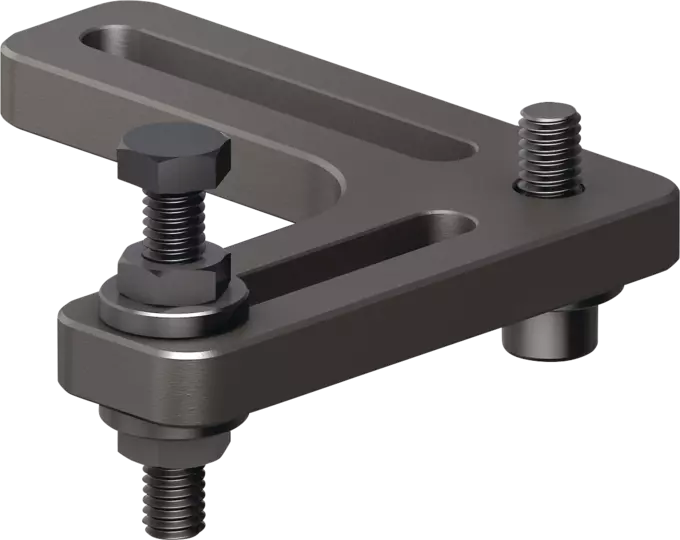

Clamping screws for indirect fastening of SCHUNK clamping devices via clamping claws or directly through the base body.

Clamping claws for quick and easy mounting of SCHUNK clamping devices on the machine table.

For precise position orientation and mounting of manual clamping vises on the machine table.

Clamping and alignment sets for alignment and fastening of the clamping system on the machine table.

Console for lifting SCHUNK clamping devices from the machine table and for improving the accessibility of the machine spindle to the workpiece.

Assembly sets for simple and quick assembly of SCHUNK clamping devices on clamping pallets or consoles.

Cylinder pin set for quick and easy positioning of SCHUNK clamping devices on clamping pallets.

Clamping lever and clamping lever with joint for operating SCHUNK clamping devices.

Torque wrench for actuating manual clamping systems from SCHUNK.

For fast jaw and clamping range adjustment

For fast jaw and clamping range adjustment

Hexagonal inserts with hexagon socket or hexagon pin insert for the actuation of manual vises with the help of torque wrenches or clamping levers.

Set of clamping pins for positive locking of centric clamping vises for small components to the consoles with gauge dimensions 52 x 52 mm.

Hexagonal adapter for increasing the wrench size from A/F 12 to A/F 27.

For extension of the base body and therefore the extension of the clamping range for the KONTEC KSX 5-axis clamping vise.

Drawbar extensions for extending the clamping range of SCHUNK clamping devices.

For connecting two or more SCHUNK clamping rails

Spindle assembly group fast and easy exchange of already existing spindles.

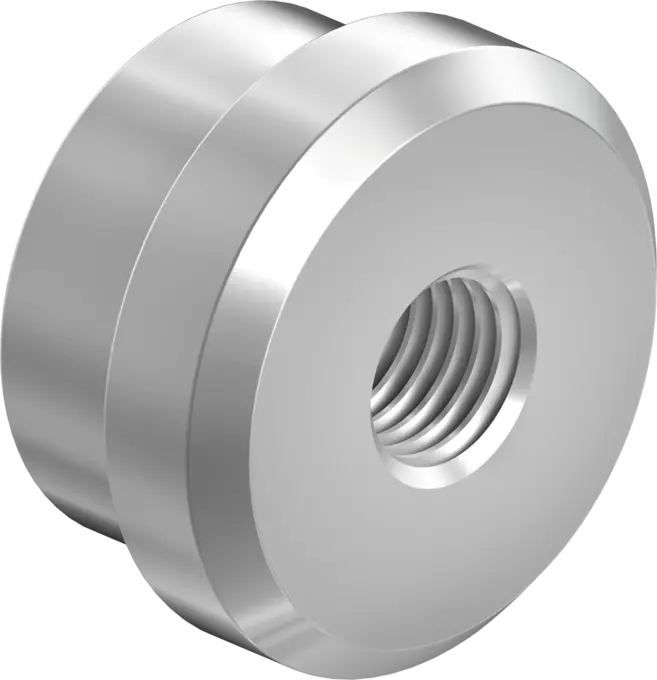

Spindle nut for the movable jaw for fast and easy exchange of already existing spindle nuts.

Mechanical force box for quick and easy replacement of force boxes that are already present.

Handles for easier handling of SCHUNK clamping devices.

Cover plates to prevent accumulation of chips within the clamping device.

Workpiece stops for quick positioning of workpieces on SCHUNK clamping devices.

Hardened and ground workpiece supports for placing workpieces. Workpiece supports can be quickly and easily fastened on SCHUNK clamping devices.

Hardened and ground workpiece supports for placing workpieces. Workpiece supports can be quickly and easily fastened on SCHUNK clamping devices.

Due to the different clamping areas, the vises can be quickly and easily adjusted with reversible jaws to the customized clamping tasks.

Due to the different clamping areas, the vises can be quickly and easily adjusted with reversible jaws to the customized clamping tasks. The additional grip stages is used for better hold of the workpiece during machining.

The quick-change jaws can be replaced in a very short time. This means that the clamping device can be adapted to the customized clamping task in a matter of seconds.

Adapter pates serve, combined with pendulum plates for clamping bulky workpieces.

Adapter plates serve, combined with pendulum plates for clamping bulky workpieces.

Aluminum jaws serve for customer rework and can be adjusted depending on the requirement

Steel jaws serve for customer rework and can be adjusted depending on the requirement.

Combi jaws are used due to the two different clamping areas for fast and easy adjustment to the customized clamping tasks.

6x jaw system for clamping the workpiece from six sides and thereby significantly increased holding force.

5-axis jaws for improved accessibility of the machine spindle or the tool to the workpiece.

Central jaws, combined with the movable jaws, are used for double clamping vises as fixed jaws in the middle.

Prism jaws are used for clamping round or bulky workpieces.

Precision jaws for a higher squareness of the workpieces.

Wedge clamping elements are used to clamp a number of small workpieces in confined spaces.

Adjustable jaws are used on KSM2 clamping rails for mounting clamping inserts and at the same time are used as fixed jaws for the next workpiece.

VS jaws with enlarged clamping range and increased accessibility of the machine spindle or the tool to the workpiece.

The intermediate jaw is used to retrofit KSG vises in order to increase the number of workpieces.

Spring leaf available as an accessory for the spring leaf of the pull-down jaw for raw part clamping with pull-down function.

Reversal jaw with six different clamping contours for flexible clamping of a great variety of workpieces.

For fastening of MFRS magnetic chucks on the machine table.

Clamping claws for quick and easy fastening of magnetic chucks on the machine table

Flexible pole extensions in a square design, which are applied to the workpiece.

Flexible pole extensions in a square design, which are applied to the workpiece.

Fixed pole extensions in square design

Patented pole extension quick change for increased flexibility in production through fast and tool-free positioning of the pole extensions.

Fixed pole extensions in round design

Fixed pole extensions in square design

MAGNOS pole blocks are used for ensuring that the customer can mill the contours and special shapes (workpiece negatives) by himself.

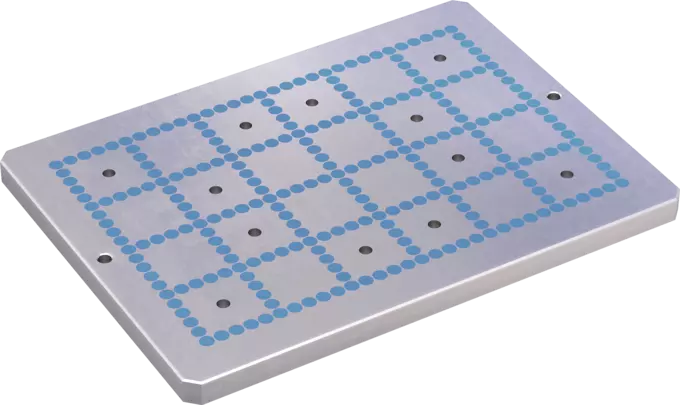

MAGNOS pole plates are used for ensuring that the customer can mill the contours and special shapes (workpiece negatives).

MAGNOS pole blocks are used for ensuring that the customer can mill the contours and special shapes (workpiece negatives) by himself.

MAGNOS pole plates are used for ensuring that the customer can mill the contours and special shapes (workpiece negatives).

Connection cable for installation between control unit KEH plus and magnetic chuck

To install between control unit KEH and magnetic chuck

PLC cable for connection between control unit KEH plus and PLC box

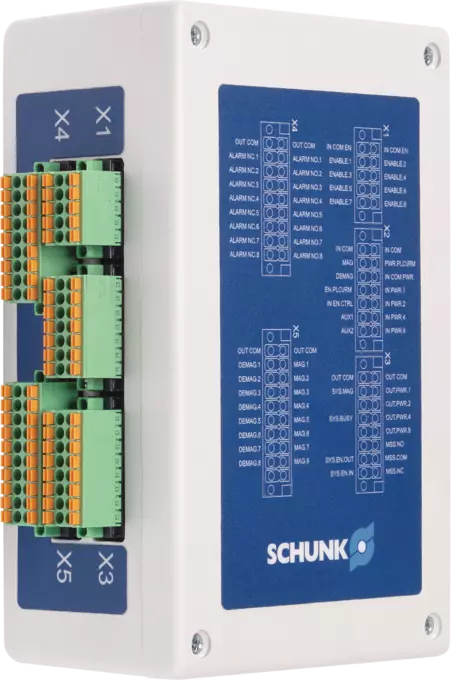

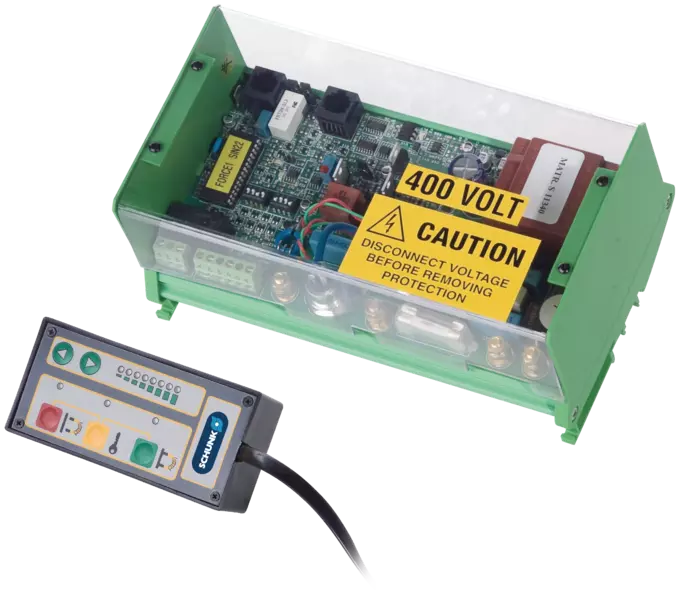

PLC box for installation between KEH plus control unit and PLC machine for automation

The hand remote controls HABE KEH plus are used to control magnetic chucks.

The control units KEH P are used to control MSC magnetic chucks

The MAGNOS control units activate and deactivate the magnetic chucks. A specially sealed quick-release connector connects the unit and the magnetic chuck. The control units are fitted with a manual controller as standard, and an industrial remote control is available on request.

Workpiece stop for MAGNOS magnetic chucks MFR and MFRS

Manual gaussmeter for quickly checking residual magnetism in workpieces after machining by magnetic chucks

Docking station for the connection cable between the control unit and magnetic chuck. With additional safety device via an inductive sensor that checks whether the connector is in the docking station.

Cover for MFRS magnetic chucks for additional mechanical protection against chips.

Clamping claws for quick and easy mounting of SCHUNK matrix plates on the machine table.

Support plates used as intermediate plates for machining workpieces with suction cups or new FlexMat.

Suction cups for 5-sided workpiece machining and production of cut-outs.

Elastomer mat specially developed for production of recesses and complex parts.

Connection set with manual slide valve for optimal vacuum supply.

Connecting link between matrix plates and connection kits.

Replacement valve for the vacuum connection sets.

Pressure gauge for continuous vacuum monitoring on the workpiece

Vacuum connection set for monitoring and distributing compressed air as well as for easy activation of the vacuum and ventilation of the clamping system.

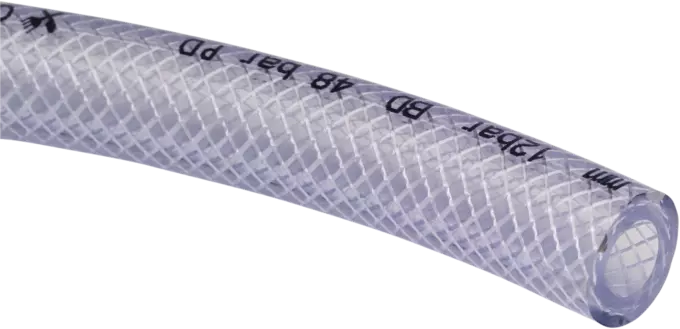

Connecting hoses as connecting elements between matrix plates and aggregate, connection kits and matrix plates and matrix plates to pressure gauges.

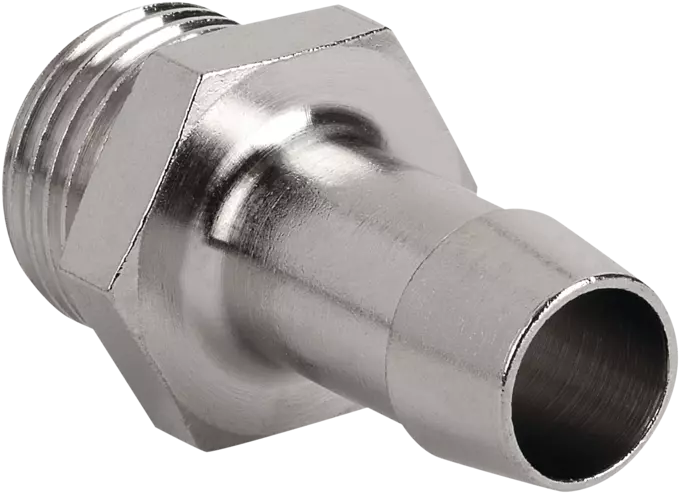

Connection piece between connection set and vacuum hose.

Hose clamps for safely mounting the vacuum hose to the hose clip.

Stop with set-screw and knurled nut.

Friction island to increase shear force absorption by up to 30%.

Magnetic hose holders for safe guidance of hoses.

Blind plug for screw connection or dummy cover of unused plug-in connection on the vacuum connection kit.

Locking screws for screw connection or dummy cover for unused plug connections on the vacuum connection kit.

Closing magnets for closing unused connection bore holes on the support plates in combination with suction cups.

Caulking strips for sealing the clamping surface by pushing caulking strip into the corresponding matrix plate grid.

Replacement seals for the corresponding suction cups regardless of height.

Sealing ring for SCMB-HD vacuum block.

Spare parts kit for workpiece stops.

Cover on base jaws to effectively prevent the leakage of grease.

Wiper bar for sealing the base jaw on the chuck face.

Wiper bar for sealing the base jaw on the chuck face.

Indicator pin for indicating the clamping status on ROTA-S plus 2.0 and ROTA-S plus manual lathe chucks.

Release bolt for initiating the rotary movement of the jaw quick-change key for jaw change on ROTA THW plus power lathe chucks with jaw quick-change.

Internal sealing disk for sealing the piston chamber to the chuck kinematics in pneumatic power lathe chucks.

Pressure bolt for actuating the jaw release mechanism on ROTA-S plus 2.0 manual chucks.

Eccentric bolt for transferring the rotary movement of the jaw-change bolt to the jaw release on ROTA THW plus power lathe chucks with quick jaw-change.

Filling plug as a spare part for the pressure maintenance valve on pneumatic power lathe chucks.

Base jaws for power chucks either with tongue and groove, imperial or metric fine serration.

Retainer ring for mounting the center sleeve.

Cover for ROTA NCR-A chuck.

Lever for transferring the axial force of the chuck piston into a radial jaw movement of the base jaws on ROTA NCR and ROTA NCR-A compensation chucks.

Sleeves or inlays to further increase the tightness and rigidity of the chuck in the area of the mounting screws.

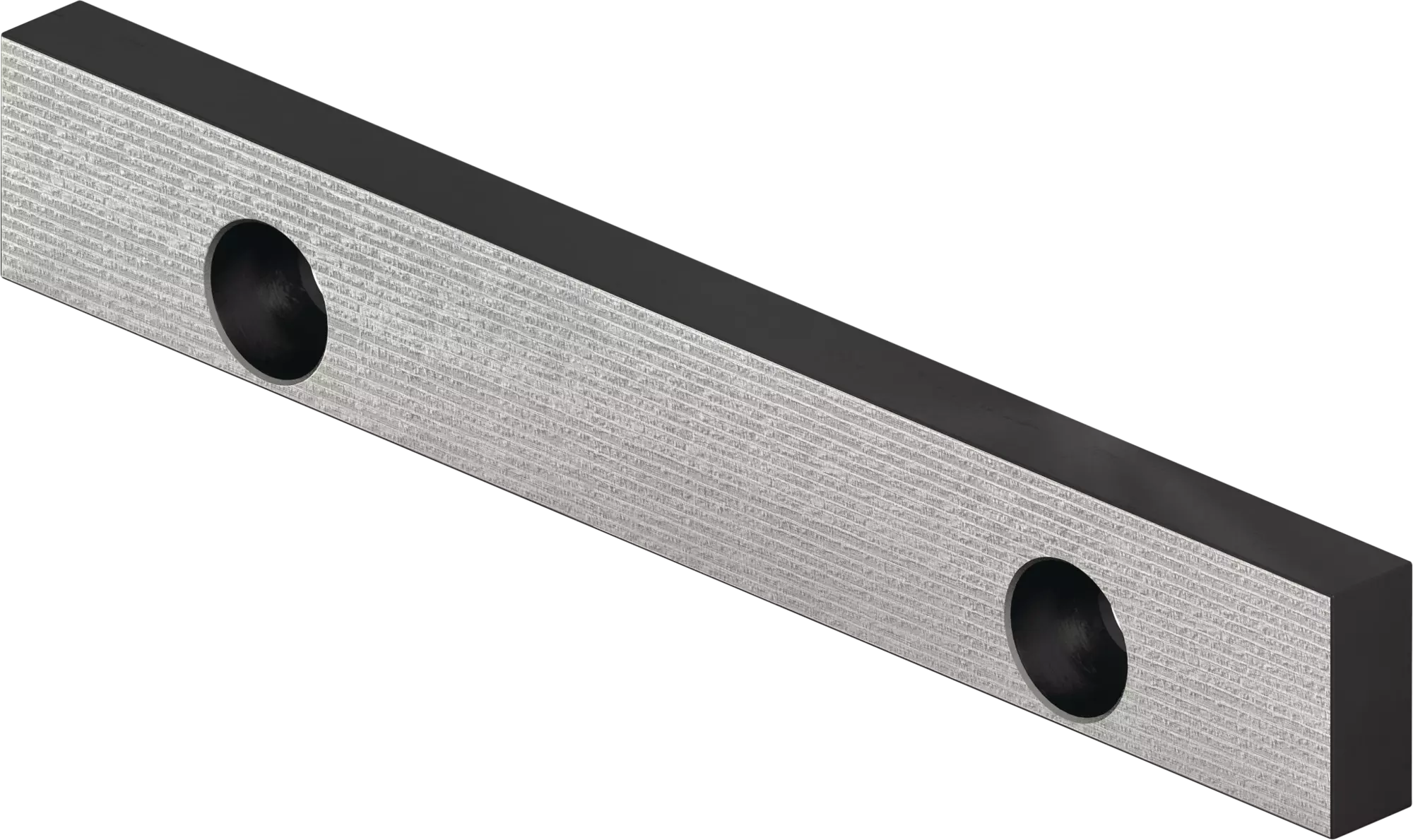

Wedge bars without thread for transmitting the torque of the drive ring on ROTA-S plus 2.0 and ROTA-S plus manual lathe chucks to the base jaws.

Wedge bar with thread for transmitting the torque of the actuation spindle on ROTA-S plus 2.0 and ROTA-S plus manual lathe chucks to the drive ring and the base jaw.

Complete wedge bars for 1:1 replacement on ROTA-S plus manual lathe chucks or ROTA THW plus power lathe chucks.

Piston cover for the integrated pneumatic cylinders on pneumatic power lathe chucks.

Chuck piston for transmitting the axial force from the hydraulic cylinder to the base jaws, thereby generating a radial jaw movement.

Connecting member serving as connecting piece between pendulum body and angle lever on ROTA NCR compensation chucks.

Seat of bearing for supporting the angle lever on ROTA NCR and ROTA NCR-A compensation chucks.

Seats of bearing for supporting the drive spindle on ROTA-S plus manual lathe chucks.

Complete cartridge for actuating the jaw release mechanism on ROTA-S plus 2.0 manual lathe chucks.

Pendulum lock for locking the balancing mechanism on 6-jaw power chucks.

Pendulum bodies for mechanical connection of the base jaw pairs on ROTA NCR and ROTA NCR-A power lathe chucks.

Plunger pin for pre-positioning the base jaws on ROTA-S plus and ROTA THW plus chucks with jaw quick-change.

Check valve for maintaining pressure on pneumatic power lathe chucks during machining.

Lubrication nipple for quick and easy lubrication of SCHUNK lathe chucks.

Lubrication nipple for quick and easy lubrication of SCHUNK lathe chucks

Center sleeves for protecting the chuck kinematics against the penetration of chips and coolant.

Distributor rings for transmitting compressed air into pneumatic power chucks when at a standstill.

Safety bolt for checking the presence of the base jaws on ROTA-S plus manual chucks, without which actuation is not possible.

Thread spindles for operating ROTA-S plus 2.0 and ROTA S plus manual lathe chucks.

Drive ring for transmitting the applied force of the thread spindle to the base jaws on manual lathe chucks.

Cover plate to protect the underlying chuck and pendulum kinematics on ROTA NCR and ROTA NCR-A pendulum compensation chucks.

Wearing parts kit with all the typical wearing parts for performing the prescribed maintenance.

Locking screws for closing different bore holes on power lathe chucks.

Blank draw nuts for rework by the customer to be used for connecting power lathe chuck and drawbar/draw tube.

Base jaw intermediate stop for power chucks with a complete hood over the chuck face as a cover.

Clamping pin extensions to increase the clamping height of the workpiece and reduce the interfering contour.

Clamping pins with short taper for form-fit connection of pallet coupling and robot module.