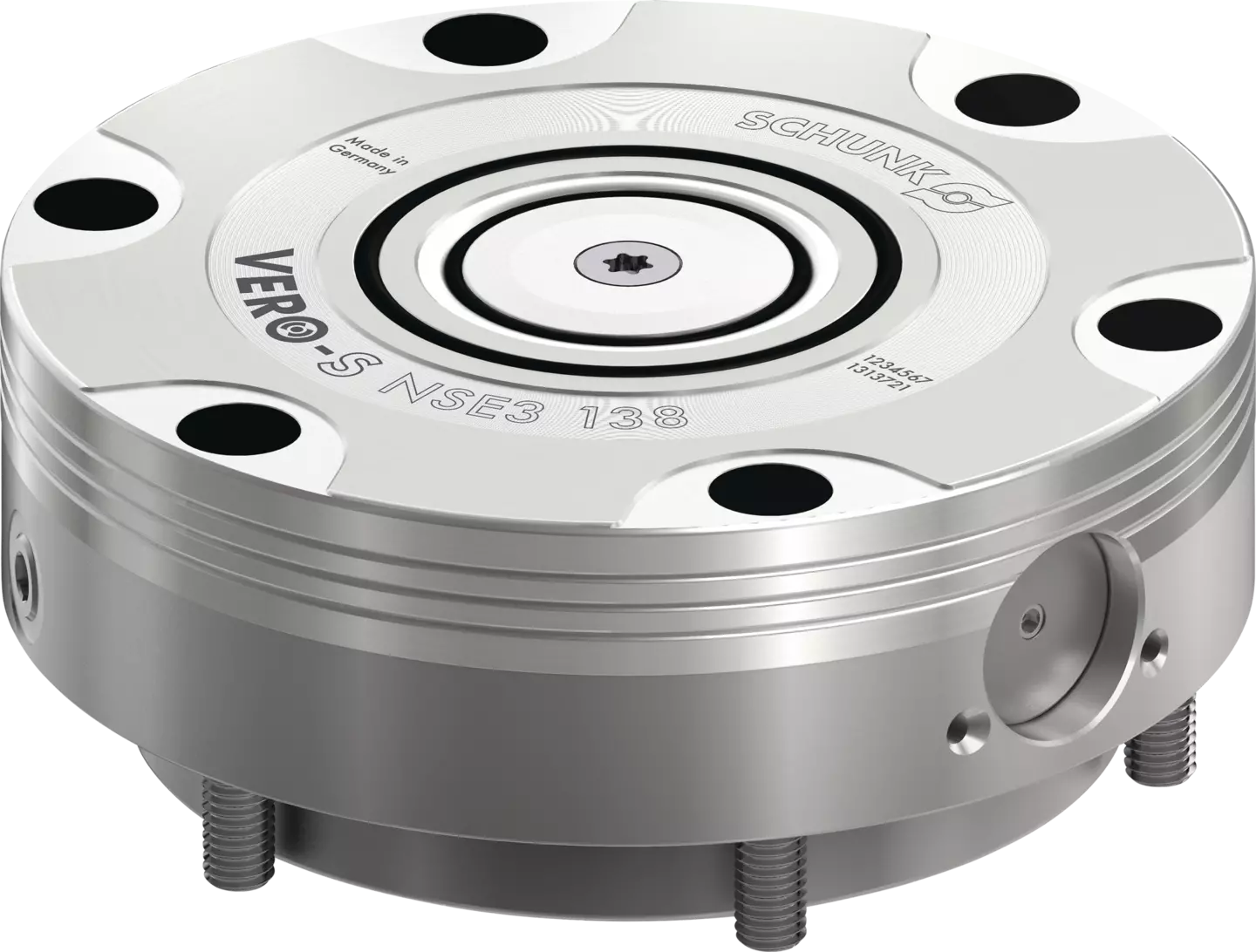

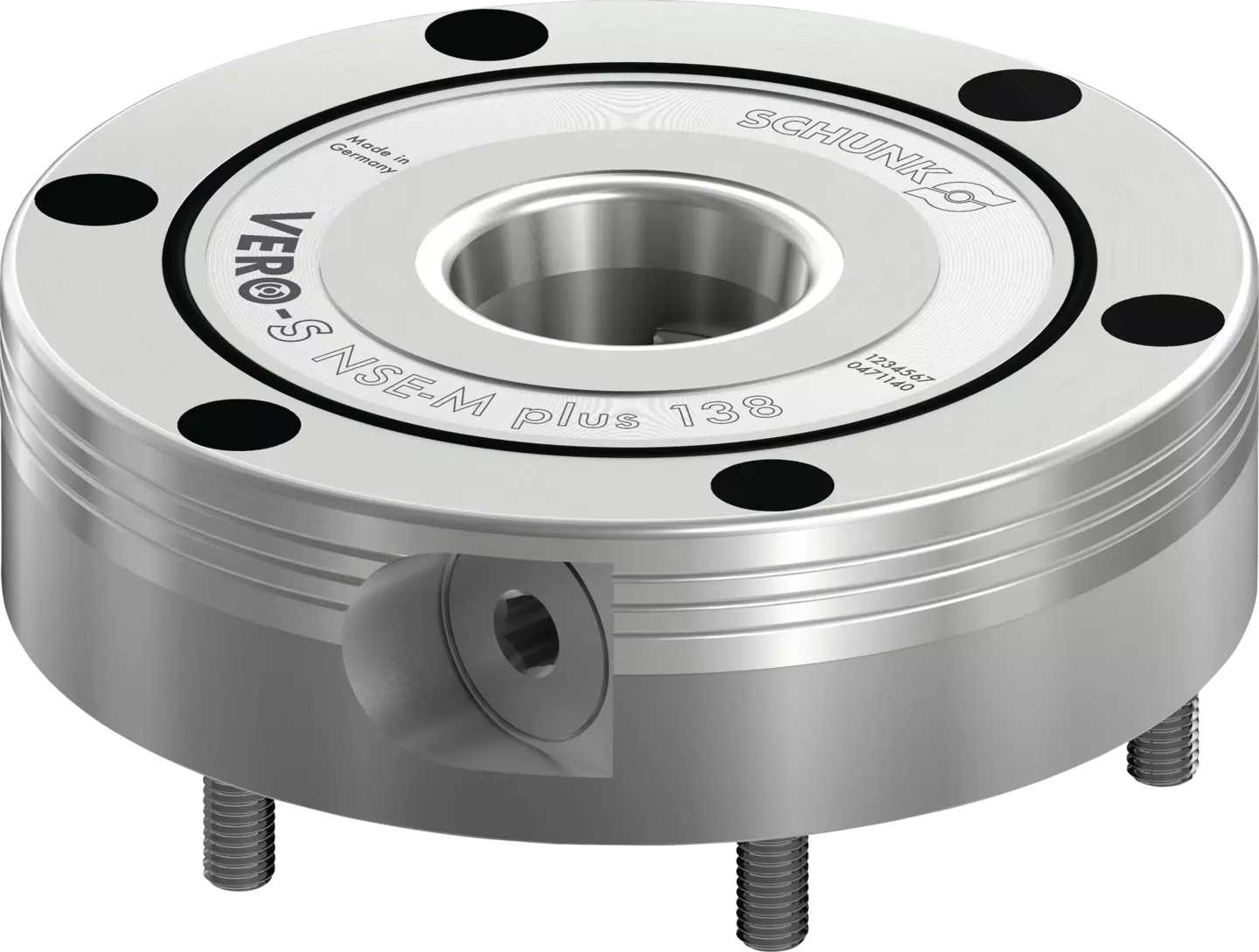

VERO-S NSE3 and NSE plus quick-change pallet modules from SCHUNK are, due to high pull-down forces, the modular quick-change pallet systems for applications with high machining parameters. They reduce set-up times by up to 90% and thus provide optimal utilization of the machine capacity. Clamping takes place in an energy neutral manner via spring force, is self-locking and form-fit.

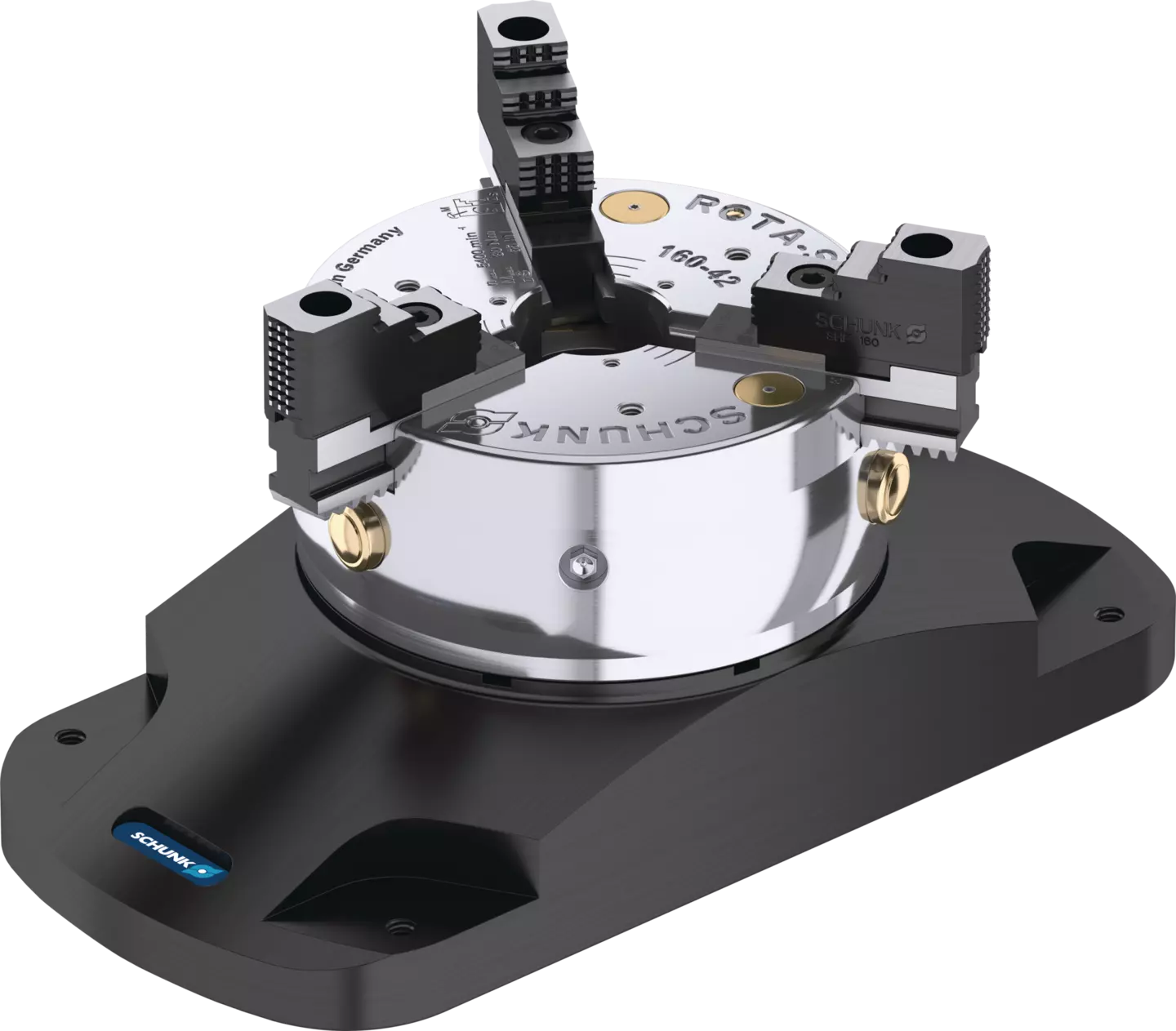

Clamping stations for general milling applications with VERO-S NSE plus modules as a basis for extremely fast set-up processes of clamping devices.

Clamping stations with VERO-S NSE3 modules, particularly developed for mill/turn centers, as a basis for extremely fast set-up processes of clamping devices.

Module height extensions for lifting the clamping device from the machine table and for increasing the accessibility to the machine spindle.

Clamping pins with short taper for form-fit connection of workpieces or devices with the clamping modules.

Empty clamping pallets for placing on the VERO-S clamping stations and VERO-S tombstones, and for customized design with clamping devices.

Already completed clamping pallets with clamping devices for placing on VERO-S clamping stations and VERO-S tombstones.

Clamping device for deformation-free clamping on the entire circumference up to a diameter of 125 mm.

Height extensions to increase the machine running time and accessibility of the machine spindle.

Quick-change pallet system for general milling applications and heavy-duty machining with an even higher rigidity and higher pull-down forces

Automation modules that can be fully integrated into the VERO-S modular system with stepped flat surfaces and integrated cleaning function for automated palletizing.

Quick-change pallet system for general milling applications and heavy duty cutting made of stainless steel.