Available in many designs, customizable to meet requirements of applications with high loads or high speeds. Separable for easier maintenance inspections.

Available in many catalogue or custom designs, especially beneficial for difficult-to-access positions where maintenance or replacement of non-split bearings would cause unreasonably high costs or lengthy machine downtime.

Bearings designed to accommodate heavy axial loads and peak loads and to provide optimal load distribution. Very stiff and require little axial space.

Bearings that have many rollers with small diameters relative to their length, offering a compact solution with high stiffness and load carrying capacity.

Non-locating, self-aligning bearings with high load carrying capacity and axial displacement ability. Made to the SKF Explorer specifications.

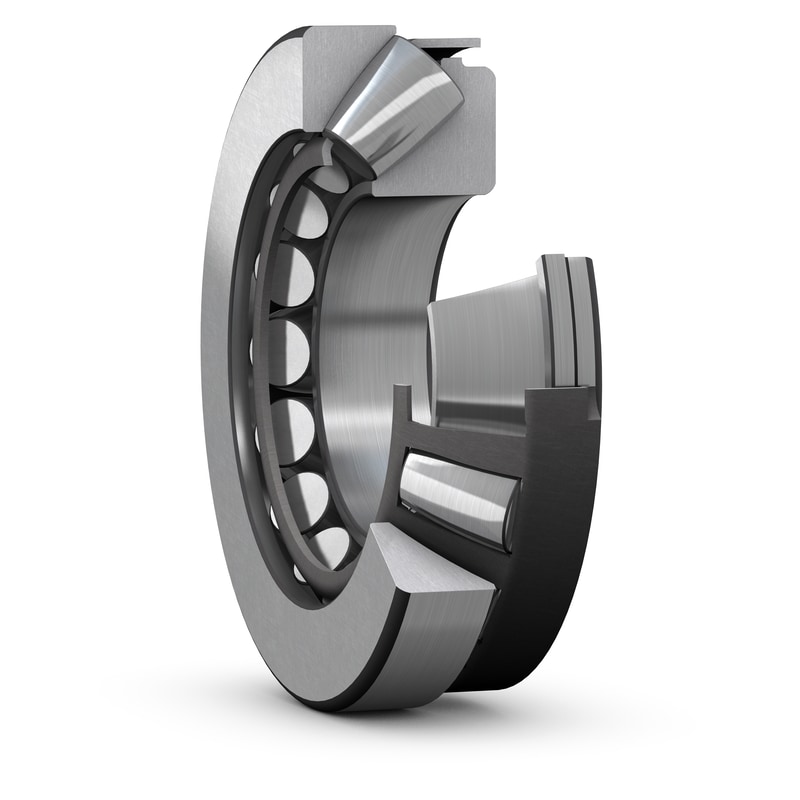

Self-aligning bearings with specially designed raceways and asymmetrical rollers, capable of accommodating axial loads acting in one direction and simultaneously acting radial loads.

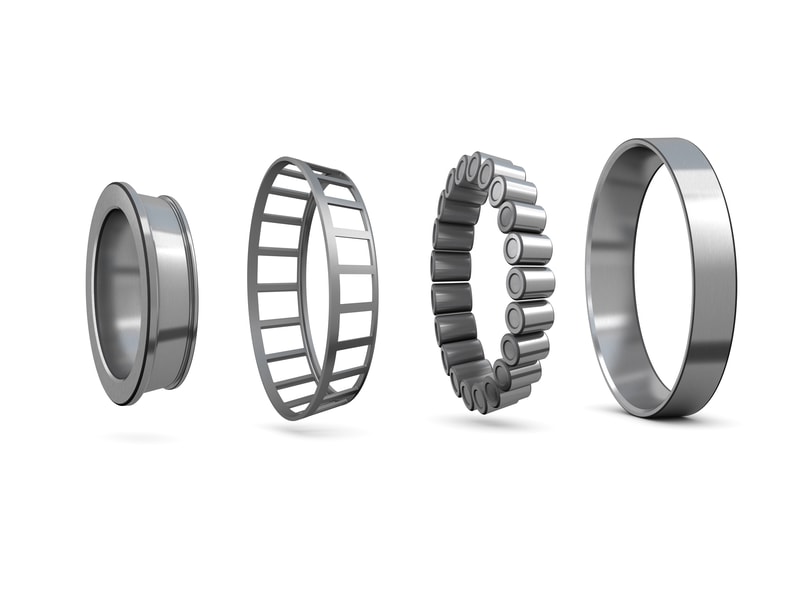

Bearings with tapered inner and outer ring raceways as well as tapered rollers. Designed to take on heavy combined loads. Available in many designs, series, and sizes.

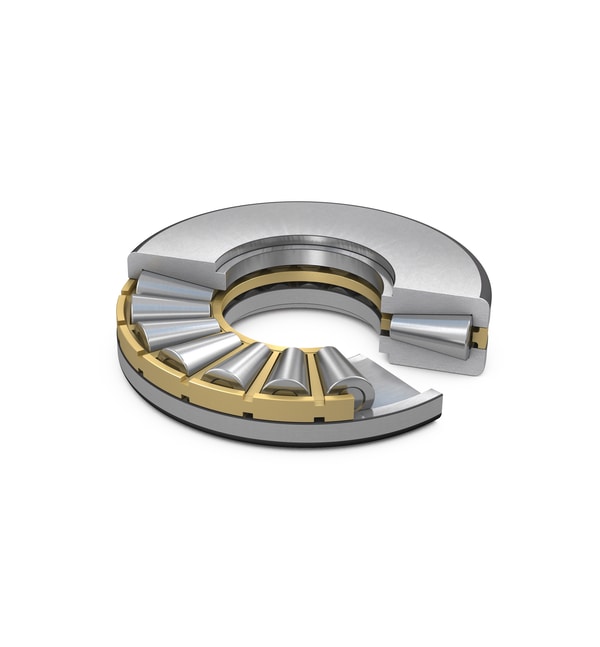

Suitable for arrangements that need to support heavy axial load and no radial load. Very stiff and require little axial space. Components can be mounted separately.

Insensitive to static and dynamic misalignment. These two-row ball bearings generate very little frictional heat even at high speeds – leading to minimal maintenance needs.

Provide a high degree of stiffness within a minimum axial space. A form-stable cage reliably retains and guides a large number of needle rollers. Accommodate heavy axial and peak loads.